Tech-Talks BREGENZ - Daniel Doxsee, Nichia Europe, Deputy Managing Director

Nichia is arguably the company with the longest history of manufacturing white LEDs. Recently, however, new competitors especially from China, have started challenging Nichia’s market share. Nichia’s role in strategic and technical solid-state lighting issues and its past, present and future were discussed with Daniel Doxsee, Nichia Chemical Europe’s Deputy Managing Director.

LED professional: Could you give us an overview of the Nichia Corporation?

Daniel Doxsee: Nichia is a privately held, family owned company, very focused on technology. It is located on the Shikoku Island in Japan. Mr. Nobuo Ogawa started the company in 1956 and the current chairman is Mr. Eiji Ogawa. Historically we were called Nichia Chemical. We basically started as a chemical company focusing on calcium materials and our first business was making high purity calcium compounds for the medical industry. In the 1960s, GE discovered a material for fluorescent lamps called calcium halo phosphate, which they patented but could not produce in production scale quantities so they partnered with Nichia. GE gave the rights to Nichia who then learned how to make this material in very high quality, in production scale. Then they sold it to GE and other companies and still do. Currently, our main products are optical semiconductors, LEDs, laser diodes. We have also been the world’s largest phosphor manufacturer for several decades. Recently we started making the cathode materials that go into Li-ion batteries. We see that as a very important market in the coming years not only with mobile devices but also with electric vehicles. Next year is the 60th anniversary of the company and the 20th anniversary of the introduction of the world’s first white light LED by Nichia.

LED professional: Could you tell us about the scale of the business and how Nichia maintains its high quality?

Daniel Doxsee: We are not only known as a very innovative company and the inventor of the technology but an extremely high quality manufacturer which we feel is extremely important especially for the lighting industry. Our failure rate is less than 1 ppm and has been for many years. We test virtually 100% of our LED production. In addition, we do accelerated life testing on samples from every lot of LEDs and only ship after the testing is completed and the lot is certified. If people have a bad experience from a quality perspective, this is not only bad for that particular luminaire or lamp manufacturer, it is bad for the industry as a whole.

Figure 1: Daniel Doxsee and Amrita Prasad talking in front of the floating stage with Turandot’s “Chinese Wall”

LED professional: What is the business structure and philosophy of the company?

Daniel Doxsee: Nichia has three different main businesses. Besides our historical business as a phosphor manufacturer for fluorescent lamps and other applications, Nichia is the leading maker of materials for Li-ion batteries, and we are the world’s largest LED manufacturer. Nichia was also the first to develop a warm white LED and the first to bring a high CRI LED to the market. Right now more than 80% of our revenue comes from optical semiconductors. We focus very much on innovation and technology, and we want to bring technologies that benefit the world and not just concentrate on good business for us. All three of these businesses have environmentally friendly benefits and that is very important to the management of our company. We see a huge benefit to society as a whole from an energy savings point of view from converting conventional lighting to solid state. The overall philosophy is to make a contribution to society.

LED professional: How has the company evolved since the invention of the blue and white light LEDs?

Daniel Doxsee: The company evolved in four stages. From a high purity chemical company for the medical industry to manufacturing phosphors for fluorescent lamps, followed by phosphors for CRTs. In 1993, the fourth stage began with the commercialization of the world’s first high brightness blue LED and this was quickly followed by the green LED. Then in 1996 the first white LED was introduced.

The first big wave for Nichia was the mobile phone market in the early 2000s when the first mobile phones started using full color screens. This was driven by Nichia developing the world’s first side- view white LED, which simplified the white LED coupling with a light-guide as a backlight for LCD panels. As the technology evolved and the lumen per watt and package power became higher, the amount of usable light became interesting from a lighting perspective and this saw a ramp up in the penetration for use in the general lighting market for many players including Nichia but it was much longer and slower.

LED professional: Has the proportion of LCD backlighting diminished compared to general or automotive lighting?

Daniel Doxsee: Automotive and lighting are growing very fast. LED forward lighting has driven the automotive sector growth. LCD backlighting is still important for Nichia and that is also driving innovation. The backlighting market for LED manufacturers is still growing, just not at the rate of lighting and automotive, as it was not limited to mobile phones, tablets, and laptops. There is proliferation of devices into LED TVs and many applications that didn’t seem obvious like putting LCD screens into white goods. The market went to very hybrid and brand new applications enabled by LED technology.

LED professional: What is Nichia’s product portfolio and main product lines?

Daniel Doxsee: In terms of our LED business we are strictly a component manufacturer and we deliberately don’t sell just the chip, phosphor or finished products. We think that the best way to get the value out of our chip and phosphor technology is to package that into an efficient LED ourselves and we also don’t want to compete with our customers. In terms of just the LED package as our finished product, there are three main components; there is the chip technology, phosphor technology and actual packaging technology. We do all our own chip and phosphor manufacturing. We also make our own equipment for MOCVD. In the early 90s you couldn’t buy MOCVD tools for the type of GaN technology that we were developing so we built our own. We make 100% of the tools at key process for making an LED.

LED professional: Could you tell us about your laser diode technology?

Daniel Doxsee: Laser diode technology is closely related to LED technology on the chip level. Nichia was the first to introduce blue laser diodes that are widely used in consumer electronics like in Blu-ray and projector technologies. Projectors were using vacuum tube sources with life and heat issues and the laser diode is particularly applicable in that area because of the very high luminance that you can obtain. Our experience in the last 10 years in the consumer projection market using blue laser diodes is now being translated into the automotive forward lighting market. You’ve seen certain automotive OEMs announce the use of laser diodes for very long beam technology with up to 1 km in throw. The more innovative OEMs, especially here in Europe, are very actively and vigorously pursuing that technology. So, blue and white laser diodes are becoming a much more important market for us. The spot luminance levels that you can attain are much higher with laser technology than with LEDs. With that being said, we are also pursuing higher luminance LED technology.

LED professional: Could you tell us about how the lighting market has evolved and what is the state-of-the-art?

Daniel Doxsee: Basically, we see the lighting market delineating in a few different ways. On the indoor side it is cost effective luminaires and lamps while for outdoors it is more performance luminaires for street lighting, etc. The indoor market is not so much about precision optics or extreme conditions of operation like street lighting or automotive markets. Often it is in a controlled environment that you are trying to deliver light as efficiently and cost effectively as possible. When the indoor market for SSL was still emerging a decade ago they were mainly using high power style LEDs and we always heard that LED technology is great but the payback is too long. For the indoor market, Nichia found that the cost per lumen dropped significantly by moving to smaller chip or multiple smaller chips in a single package because the yields at the wafer level went up. The lumen per dollar factor really drove us to innovating in the mid-power area. These are used very extensively in indoor markets, especially commercial and consumer markets. Even the industrial markets that still require a higher lumen level are moving towards a cost effective mid-power range using many LEDs.

The use of mid power LEDs also makes sense aesthetically in some applications. In a linear application where you are trying to replace a fluorescent troffer, early designs used high power LEDs and very often the light was non-uniform with a lot of glare. With mid power LEDs you now have this very beautiful, uniform looking light with low glare and high efficacy. In an environment where workers have to look up, using very high power LEDs with lot of glare creates a difficult working environment. Mid power LEDs spread the light over a larger area reducing the glare, reducing the cost and increasing efficacy. Thermal management is also better because you spread the heat over a larger area.

LED professional: What about the outdoor market?

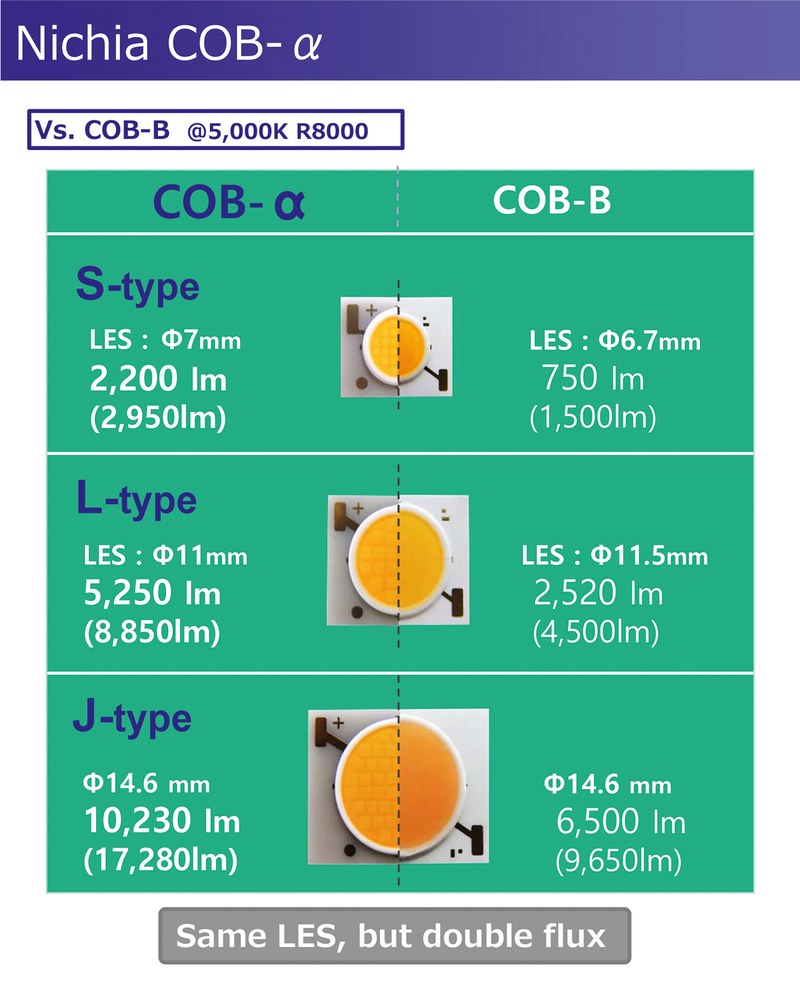

Daniel Doxsee: The outdoor market has traditionally used high power LEDs and we see this delineate into 2 types; street lighting is a market for large, single chip high power LEDs where you need to optically control the light in a precise way for pattern and uniformity. For more general illumination like pathways or outdoor public spaces where the optical spread of the light is not such a challenge, the market is moving towards multiple low power LEDs for both cost and glare reasons. Even in street lighting some manufacturers are moving towards mid power. One other area is the COB LED and we see some specific markets where this is ideal, like directional lamps and recessed lighting. COB gives a nice uniform look, such as one core solution. It is still to be seen what other markets COB can expand into. The typical benchmark for state-of- the-art efficacy is somewhere in the cool white, 5000 K and we are in excess of 200 lumen/watt.

Figure 2: COB lineup and comparison of the new COB-α with COB-B

LED professional: Very high efficacy LEDs are usually interesting for outdoor lighting where you don’t need high CRI. What about the CRI considerations for different applications?

Daniel Doxsee: We are also seeing some outdoor applications where they want high CRI but yes, usually a CRI of 80 is enough and they tend to be cooler white around 4000-5000 K. Indoor tends to be much warmer and high CRI is much more common. We are actually seeing applications where the customers want emphasis on certain parts of the spectrum. We can make phosphor blends for different types of lighting. High CRI for retail, enhanced red for meat retail and some primary color phosphor blends for produce lighting.

LED professional: Could you comment on Nichia’s competency and approaches towards packaging technologies?

Daniel Doxsee: Nichia is doing a lot in actual package material technology. Some manufacturers claim that mid power LEDs are not as reliable as high power LEDs and while there is some truth to that, the reason is mainly the package.

There are a few different styles in packages; mid power, high power and COB. High power LEDs tend to be ceramic, which is optically stable but not very reflective. Mid power are very often resins, which are cheaper and highly reflective so the initial lumen/watt can look attractive

Figure 3: Daniel Doxsee uses the flip chart to explain different phosphor coating approaches

but many resins absorb blue light and the top monolayer decomposes. There is discoloration, color shift and lumen depreciation. The degradation and color shift happens faster under high temperatures. Consumer level bulbs are not sold with a meaningful warranty and bulb manufacturers are strictly looking at efficacy and cost. If you are selling a commercial luminaire it is almost always sold with a meaningful warranty. That is where the reliability and color stability are very important especially for mid power because these are all indoor applications.

Ceramics are excellent from a lifetime perspective because they are usually optically and chemically inert so for an industrial environment where you might have halogen or sulfur gases, ceramics won’t be affected. The highly reflective

resins usually will be very affected, but Nichia has developed a special composite material, a thermoset material that has the resin optical reflective characteristics without the degradation. As the only manufacturer, we already provide this technology for mid power LEDs. The color and lumen stability at maximum drive current elevated temperature and chemical (sulfurization) tests show a positive difference between using a pure resin vs. this high quality composite.

LED professional: Could you tell us more about the package-less flip-chip technology that has been announced by Nichia with 1/9th of the size of standard LEDs, which will be launched in October 2015?

Daniel Doxsee: There is a tremendous amount of price erosion and price pressure due to great penetration in the lighting market. This drives us to be innovative in how to deliver reliable SSL in a cost effective way. We are developing “wafer level package” LEDs which is the next evolution of package-less technology for Nichia. This is a freestanding chip that has the electrodes built directly on the back. We can conformably coat phosphor on the top of the chip and that’s it! No ceramic carrier, no resin package to put the chips and phosphor into. It is the simplest bill of materials for an LED. However, there are two handling challenges. There are no Zener diodes, so protecting from ESD during pick-and-place and also protecting at the board level for ESD is a challenge. We are researching ways to make chips that are strong against ESD without any additional components. The second challenge is direct reflow, because the pad sizes and the gap are very small so precision in pick and place is very important. It is structurally the simplest LED and since there is no dome or secondary optics built into the LED, if you are using a secondary optic in your product, you can get the lens very close to the LED. That improves the optical extraction through the lens. We plan to launch these types of products this year.

LED professional: What is the light distribution for the wafer level package LED?

Daniel Doxsee: When the phosphor layer is just on the top, it has a Lambertian distribution. We are also doing a high luminance style LED for certain applications. In a third version, we can coat the sides of the chip with phosphor and give a very wide directivity. There are some options in terms of the optical characteristics of a wafer level package that can be designed.

LED professional: Could you comment on some main trends for Nichia with wafer level packages and SSL in general?

Daniel Doxsee: We’d love to talk more about “sexy” applications like solid-state lighting of the Ponte Vecchio in Italy that we did recently and are proud of. But there has been a very intense drive towards not only high efficacy but also cost effectiveness and user experience for large level penetration. The first white LEDs we introduced in the 90s could have been 100 dollars/lumen, now it is at a point where the cost of light is on par or even lower than the incumbent technology. The replacement model was used a lot by the lighting industry in the past. With SSL, it is our hope and goal that people will put a lot more effort into intelligent design and quality of light. The efficacy is far ahead of any older technology. I’d rather have a higher CRI with perfect color temperature and a very tightly controlled LED-to-LED color control than just a cheaper one.

There are also some types of non-obvious technologies that Nichia is bringing to the market based on our phosphor technology. We’ve developed blends that are of specific interests for example, in meat lighting. In the supermarket business, produce and meat generate more revenue. People associate dark red meat with good taste. With phosphor technology you can enhance the red and we have customers who have successfully implemented this. Furthermore in retail when you have produce with a rich variety of colors you would want to enhance the primary colors. Tri-band fluorescence is often used in the produce sector. The third one is to make a very “pure” white and that can be of interest especially in clothing retail. We have developed special blends where we achieve this by suppressing the green. We are implementing that in COB arrays and also in mid-power LEDs.

LED professional: Does Nichia have a team to support clients with education about product design?

Daniel Doxsee: We certainly put a lot of effort into getting the details of the characteristics of the LEDs and making sure the customer understands that. We have a lot of knowledgeable and technical people worldwide and we get a lot of support from headquarters. We actively try to ensure that the people setting the standards and guidelines get the information about LED technology and we want to be an education resource for the market in general as well as government and standard setting bodies to help them make coherent guidelines.

LED professional: Thank you very much.