Developing Phosphor-Free White Light from Nanopyramid LEDs

Researchers in China have used nitride semiconductor nanopyramid structures to create light-emitting diodes (LEDs) with spectra that are similar to those provided by ‘white light’ LEDs with yellow phosphors [Kui Wu et al, J. Appl. Phys., vol115, p123101, 2014]. The researchers are at the Chinese Academy of Sciences’s institutes of Semiconductors and Mechanics, and Tsinghua University. A similar CAS/Tsinghua team previously reported such devices, using a polystyrene nanosphere mask to make holes for selective-area growth of nanopyramids.

The light-emitting structures are grown on the semipolar facets of the nanopyramid. Growth in semipolar directions of the crystal structure should avoid electric field polarization and strain-dependent effects that make the growth of high-indium-content indium gallium nitride (InGaN) difficult. High-quality high-indium InGaN is needed to achieve longer-wavelength light emission for ‘white light’.

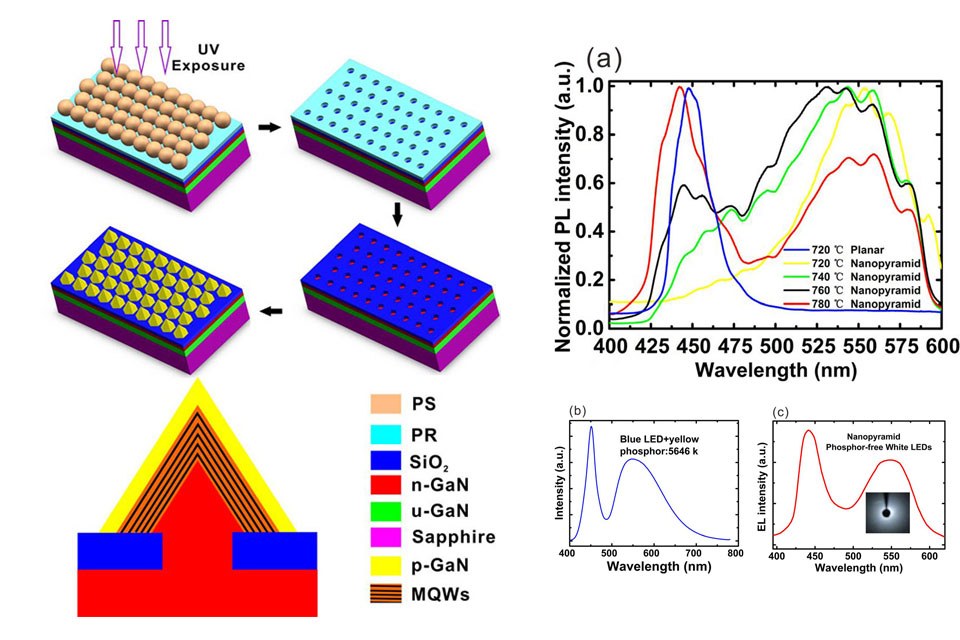

The n-GaN template consisted of a 2μm n-type layer on 2μm undoped GaN buffer on sapphire substrate. A mask layer of silicon dioxide was deposited and patterned using a hexagonal array of polystyrene nanospheres (Figure 1). The photoresist patterning created 400nm-diameter holes in a 900nm periodic array. The pattern was transferred to the silicon dioxide by inductively coupled plasma (ICP) etch.

Metal-organic chemical vapor deposition (MOCVD) then proceeded to grow the nitride semiconductor material on the exposed n-GaN template. The initial growth was 1050°C n-GaN for 4 minutes to form nanopyramids with {10-11} facets. Next, a five-period InGaN/GaN multiple quantum well (MQW) was grown (720-780°C), followed by a 13 minute 950°C p-GaN layer. The resulting nanopyramids were about 600nm high.

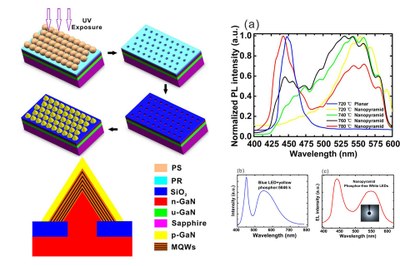

The photoluminescence spectra (Figure 2) of the nanopyramids gave two peaks around 445nm (blue) and 550nm (yellow). The balance of the peaks depended on the MQW growth temperature. In particular, the higher-temperature growth increases the blue relative to the yellow peak. The researchers attribute this to the decomposition of the yellow-emitting regions, which have a higher indium content.

The researchers comment: “Interestingly, when grown at 780°C, the nanopyramid LEDs exhibit a spectrum which is similar to white LEDs from blue LEDs combined with yellow phosphors.”

Microscopic inspection of electroluminescence showed that the blue radiation comes from the apex of the pyramids, while the yellow radiation comes from the base region. The researchers attribute the yellow emission to the base region having higher indium content and wider, less quantum-confined wells, leading to a smaller energy gap.

The researchers admit that the nanopyramid radiation is still weak: “We believe that the brightness can be improved by optimizing the growth parameters, including the size, aspect ratio, and the structure of MQWs.”

Also, conventional LED fabrication processes need to be developed to cope with the rough surface of the nanopyramid structures. The researchers are working on device structures and chip processes that will enable detailed electroluminescence characterization of nanopyramid LED structures.

On the basis of finite-difference time domain (FDTD) simulations, the researchers believe that the nanopyramid arrays have a light extraction efficiency about four times higher than for conventional planar MQWs that suffer from a small escape cone at the air-GaN interface due to differences in the index of refraction. The simulations give an escape cone as high as 85°, compared with less than 40° for planar structures.