Fraunhofer FEP Presented Transparent Color Tunable OLED

The project LOIGB (LED and OLED integration into glass and plastic composites for the use in lighting systems for railway and further applications) has been successfully completed. The results were presented at LOPEC 2015 (March 4th – 5th, 2015, Munich, hall B0, booth 230).

The objective of the joint project was the development and integration of large-area color variable OLED modules, whereby the light colors red, green and blue (RGB), which are required for the achievement of white mixed light, can be controlled separately. Thus it is possible to generate any desired color, including white, with one and the same OLED module. The realization of large-area 3-color-variable OLED modules could be demonstrated in the project.

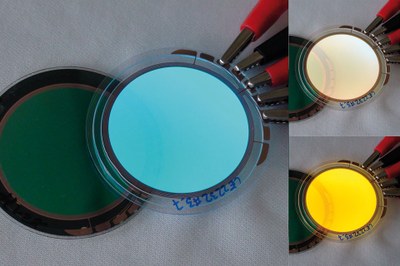

The OLED modules have a diameter of 55 mm with an active light area of 42 mm. They were encapsulated with a full thin film, which enables the lamination of OLED modules in glass composites.

For the first time worldwide a transparent 2-color variable OLED, which can show a color gradient from blue to white to yellow, was demonstrated. This exhibit was presented to the visitors of LOPEC 2015 at the Fraunhofer FEP booth. A possible field of application could be its use as the light source in a laminated glass sheet which serves as baggage compartment in trains. The company SBF Spezialleuchten GmbH, the coordinator of the project, is working on such solutions.

“The possibilities for application of the results, which are achieved within the project, are extraordinarily versatile”, says project manager Jan Hesse. “In addition to the use in general lighting, e.g. in windows, wall elements or wallpapers, the color variable OLEDs are as well suitable for the interior vehicle lighting – especially for the ambient or accent lighting – in the automotive and rail vehicle industry.”

Besides, the aviation industry shows great interest in using this technology for ambient lighting within an aircraft cabin.

The results which were achieved in the project LOIGB provide a basis for further activities at Fraunhofer FEP. Currently, the scientists are working on the process development in order to achieve higher yield and reduce manufacturing costs as well as to realize the process transfer to a roll-to-roll system for flexible OLED. Moreover, the intuitive control of such lighting elements will become a priority. Compared to conventional light sources (on / off), the complex functionality (dimmability, color variation and dynamization through segments) requires new intuitive control possibilities. A simple control is absolutely necessary in order to achieve market acceptance for that innovative lighting technology.

The project was funded by the European Union and the Free State of Saxony (Funding reference: 100133280).

About Fraunhofer FEP:

We are one of 67 institutes of the Fraunhofer-Gesellschaft, Europe's largest applied research organization. The Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP is located in Dresden and focuses on developing technologies and processes for surface modification.

Our core technologies are sputtering technology, plasma-activated high-rate deposition, high-rate PECVD, and electron beam technology, which we use to develop surface technology solutions for various industrial tasks.

The deposition of individual layers and multilayer systems and the processing of surfaces are of huge practical importance for many industries. Regardless of whether for machine building, the utilization of solar energy, the packaging industry, biomedical engineering, optics, sensor technology, or electronics: We develop suitable processes and technologies and the associated technological key components.

Feasibility studies, to evaluate surface coating and processing, and pilot production, to facilitate the introduction of new customer products to the marketplace, are also included in our range of services.

The scaling up of technologies to industrial quantities and integration into suitable plant technology and into existing production processes are key services of the Fraunhofer FEP. The cost efficiency of a technology for industrial production is always taken into account.

Our comprehensive know-how allows us to support the research and development work of our customers from the concept phase right through to industrial realization.