Zhaga: Standardizing Interfaces, Enabling Interoperability

Lighting must become both connected and serviceable to unlock IoT related business opportunities, enable the circular economy, and meet regulatory expectations. But doing so requires standardized interfaces that support interoperable components – which is where Zhaga comes in.

“Zhaga, the global lighting industry organization, puts the spotlight on interoperability,” says Dee Denteneer, Secretary General of the Zhaga Consortium. “Our mission is to specify the electrical, mechanical, optical, thermal, and communication interfaces for the interoperable components used in LED luminaires.”

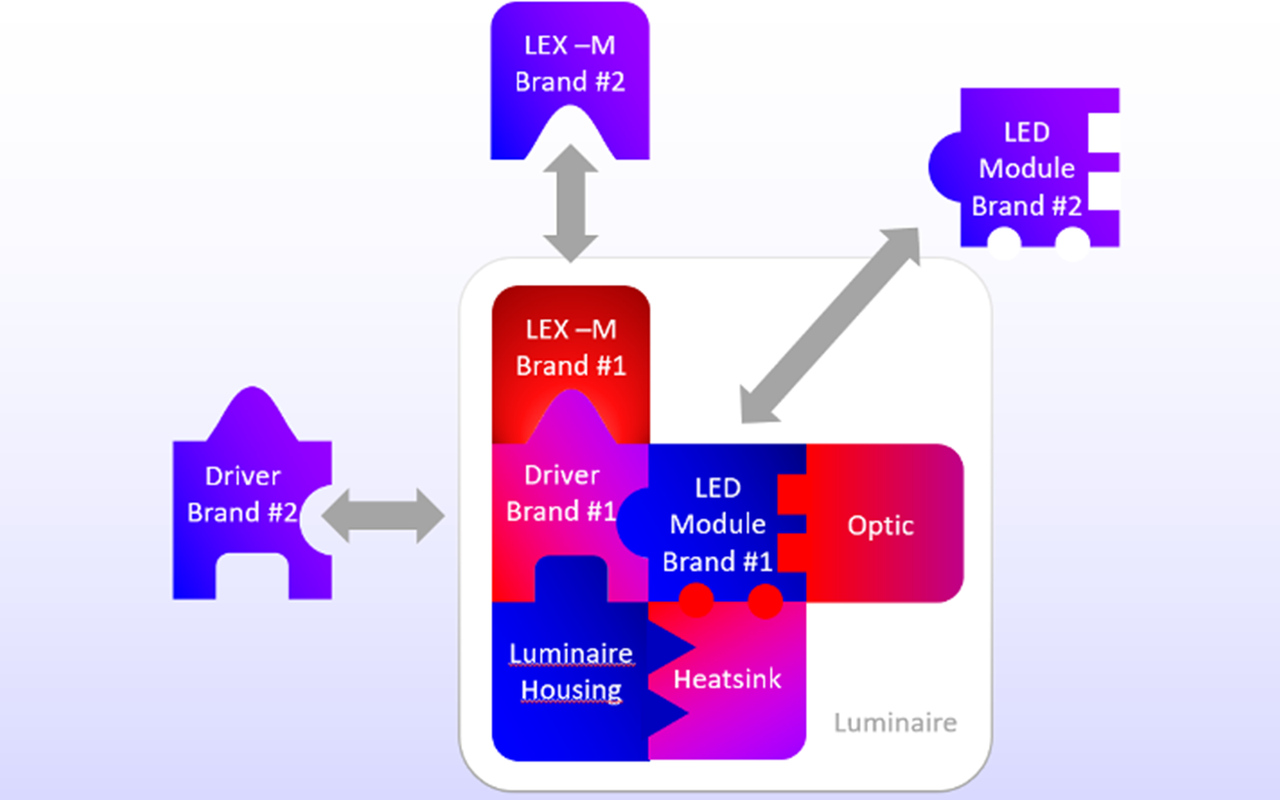

According to Zhaga, a luminaire component is interoperable when it can be combined with (an)other interoperable component(s) and function as specified in the component datasheet. “Interoperability requires that components match on all aspects of each relevant component interface,” adds Denteneer.

To illustrate, Denteneer points to replacing an LED module with a more efficient LED module. “The new LED module is considered interoperable if it fits into the luminaire and can function according to its datasheet,” he explains.

However, such interoperability is only possible when the proper interface specifications are in place. “At the most basic level, a specification supports interoperability when all the compliant components of a first type are interoperable with all the compliant components of a second type,” says Reinhard Lecheler, Chair of the Zhaga Steering Committee. “In more advanced cases, the specification defines several profiles, with the interoperability of compliant components limited to the defined profiles.”

In all cases, the specification never interferes with safety and other regulatory requirements. Zhaga develops interface specifications, known as Books, that define the necessary conditions for interoperability and serve as the standard for the lighting industry. For example, Book 18 specifies the smart interface for outdoor luminaires, while the smart interface for indoor luminaires specified in Book 20 allows luminaires to be interoperable with sensing and communication modules in indoor applications.

“These interface standards create ecosystems of interoperable components, and the certification of these components gives confidence in their interoperability and capability of becoming a part of an existing ecosystem,” notes Lecheler.

Benefiting the Lighting Value Chain

Having components available that comply with and are certified in accordance to such standards benefits luminaire OEMs, component manufacturers, specifiers, and end-users alike. For example, an OEM’s design of a new luminaire is facilitated by the availability of many components of different types, all of which are based on standardized interfaces. Having certified components of different types readily available alleviates the need to check whether they will function together.

By defining what is required for components to work together, interface specifications benefit component manufactures too. Products manufactured in accordance with such an interface specification require less, or even no, co-development. It also eliminates the hassle of having to deal with companies providing complementary components.

“No longer concerned about whether their products are interoperable, these companies can now focus on innovation and differentiating features,” explains Denteneer. “These products then become part of a richer ecosystem of complementary products, which ultimately benefits the end customer.”

Having interoperable components based on standardized interfaces also means LED luminaires can be upgraded and serviced – particularly if the interface supports plug-and-play interoperability. “This advantage is especially appealing to end-users and specifiers,” adds Denteneer.

The ability to upgrade and service an LED luminaire plays an important role in the various stages of a luminaire’s life cycle. For example, replacing a component in-the-field not only fixes the broken part, it could also serve as an opportunity to adjust, upgrade, or even extend a luminaire. More so, it allows end-users to separate certain decisions (e.g., they can first decide on the luminaires and later about adding sensors for smart applications), thus easing both project planning and execution.

Finally, during the end-of-life treatment of a luminaire, plug-and-play interoperability allows components to be ‘unplugged’ – a feature that supports the circular economy and facilitates sustainable recycling.

Addressing Challenges Head On

Despite these advancements in interface specifications, challenges remain. For example, interoperable luminaire components require a technical alignment of all interface aspects, including electromagnetic compatibility. There’s also the issue of how the module driver interface makes it difficult to match a module to a driver (e.g., when exchanging modules in the field). The specification of the thermal interface between LED modules and luminaires is another challenge that needs to be addressed.

“We must also provide specifications that ensure the minimum level of functionality necessary for interoperability whilst leaving room for performance differentiation,” explains Lecheler. “This means ensuring that different suppliers provide products with different performance characteristics on top of the specified, minimum functionality.”

Finally, there’s the challenge of legacy management. “Legacy management must be considered so that a new generation of components is still interoperable with all the other components in the luminaire,” adds Lecheler.

Zhaga is addressing all these challenges head on. For example, it is developing standards that evolve with market and/or technology changes and is working to demonstrate the technical feasibility of using reference luminaires for the EMC testing of LED modules and drivers. The consortium is also taking concrete steps to future proof LED luminaires.

“Zhaga is developing the standardized interfaces needed to support the interoperable components that make lighting both connected and serviceable,” concludes Denteneer. “This work will ultimately benefit companies and end users along the entire lighting value chain.”

The White Paper on Interoperability can be downloaded here.

Zhaga invites all companies to join and participate in this important task. To learn more, visit www.zhagastandard.org or contact Zhaga at +1-732-562-5404 or info@zhagastandard.org.

___

© 2021 LED professional / Luger Research e.U.