Veeco Launches Lowest Cost of Ownership GaN MOCVD System

Veeco Instruments Inc. (Nasdaq: VECO) announced today the introduction of the TurboDisc® K465i™ gallium nitride (GaN) Metal Organic Chemical Vapor Deposition (MOCVD) System for the production of high-brightness lightemitting diodes (HB LEDs).

Veeco’s industry-leading beta site customers rapidly qualified the K465i for volume production, and the Company has received orders for the system from multiple LED customers throughout the Asia Pacific region.

Based on Veeco’s production-proven K-Series platform, the new TurboDisc K465i combines the industry’s highest productivity with the capability to drive best-in-class LED yields approaching 90 percent in a 5nm bin. Fully automated with only a short recovery period required after maintenance, the TurboDisc K465i enables higher productivity and reduced cost of ownership compared to competitive tools.

According to Bill Miller, Ph.D., Senior Vice President, General Manager of Veeco’s MOCVD business, “With superior wavelength uniformity and excellent run-to-run repeatability, the K465i extends Veeco’s lead in capital efficiency – the number of good wafers per day for each capital dollar – for high volume LED manufacturers. We are extremely pleased that our beta site customers achieved world-class results in a very short period of time. Industry interest in the K465i is strong.”

John R. Peeler, Veeco’s Chief Executive Officer, added, “The K-Series is a robust, reliable, multi-generational MOCVD platform that is in production at more than 80% of the world’s key LED manufacturers. Veeco is committed to advancing its leadership position by increasing R&D investment, introducing innovative new technologies, ramping MOCVD production capacity, and partnering with customers to maximize their LED manufacturing. The K465i MOCVD System is the latest example of Veeco driving down the cost of LEDs to enable applications such as display backlighting and general illumination.”

Demand for HB LEDs is high and expected to increase in the coming years. In an August 2009 report, “High-Brightness LED Market Review and Forecast 2009,” research firm Strategies Unlimited forecast the HB LED market to grow from $5.1 billion in 2008 to $14.9 billion in 2013, representing a compound annual growth rate of 24%.

“Our research indicates the fundamental drivers for the HB LED market have become even stronger in recent years as new applications for LEDs in lighting and backlights continue to emerge,” said Robert V. Steele, Director, LED practice at Strategies Unlimited. “To meet the overwhelming demand that we expect this will create over the next few years, LED makers will need to quickly ramp up their manufacturing capabilities, including the addition of substantial MOCVD capacity.”

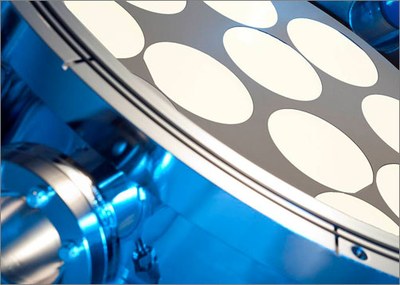

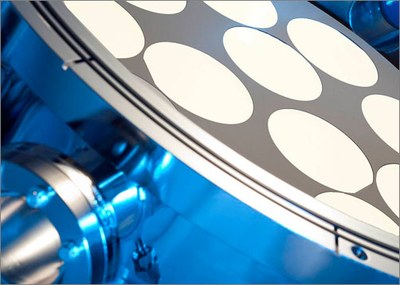

TurboDisc K465i: Uniformity and Repeatability by Design

At the heart of the TurboDisc K465i GaN MOCVD System is Veeco’s patent pending Uniform FlowFlange® technology. Designed to create a uniform alkyl and hydride flow pattern across all wafers, the K465i delivers superior uniformity and repeatability with the industry’s lowest particle generation. The FlowFlange’s simplified design provides ease-of-tuning for fast process optimization on wafer sizes up to 8 inches and fast tool recovery time after maintenance for the LED industry’s highest productivity.

To listen to a podcast series about high-volume LED manufacturing and for further information about the K465i, please visit www.veeco.com/mocvd

About Veeco:

Veeco Instruments Inc. manufactures enabling solutions for customers in the HB-LED, solar, data storage, semiconductor, scientific research and industrial markets. We have leading technology positions in our three businesses: LED & Solar Process Equipment, Data Storage Process Equipment, and Metrology Instruments. Veeco’s manufacturing and engineering facilities are located in New York, New Jersey, California, Colorado, Arizona, Massachusetts and Minnesota. Global sales and service offices are located throughout the U.S., Europe, Japan and APAC. For more information about the Company, please visit www.veeco.com.