Cree Announces Next-Generation XP LED Delivering 200 Lumens Per Watt

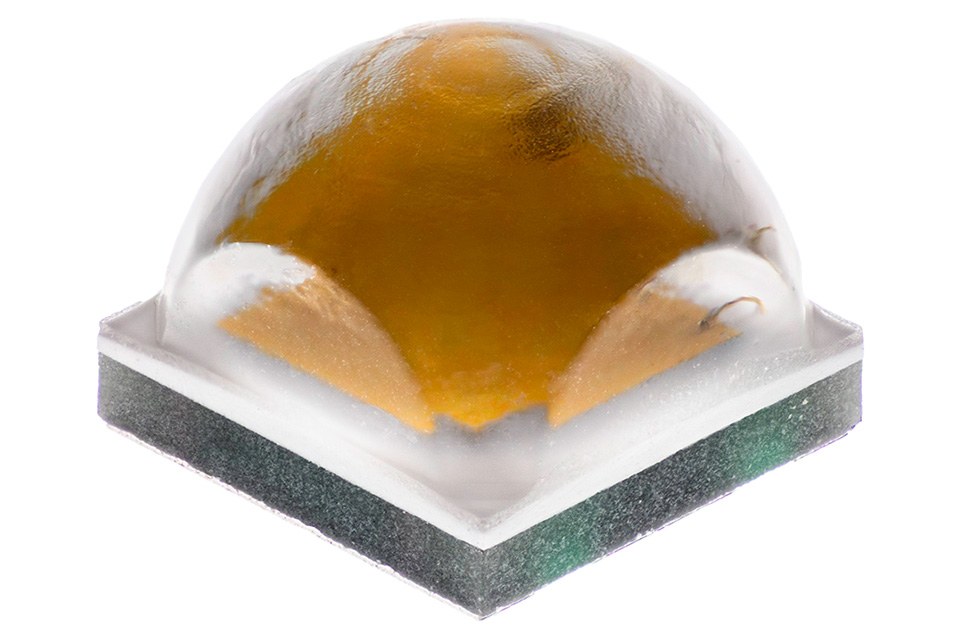

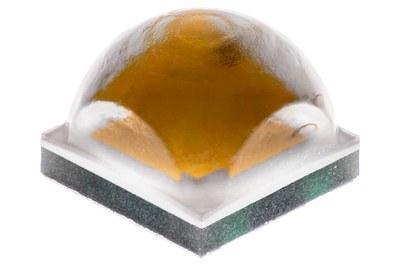

Cree, Inc. introduces the XLamp® XP-L LED, the first commercially available single-die LED to achieve breakthrough efficacy of up to 200 lumens per watt (LPW) at 350 mA. Delivering up to 1226 lumens in a 3.45 mm x 3.45 mm package, the game-changing Cree® XLamp XP-L LED enables an immediate performance increase of 50 percent or more as a drop-in upgrade for lighting designs based on Cree’s market-leading XLamp XP-G LEDs.

“We’re excited about the new XLamp® XP-L LED because its next-level performance enables us to create the next generation of light output and efficacy for our directional lighting products,” said Mike Joye, president, Auroralight. “Since XP-L uses the existing XP footprint, we can expand our product lineup quickly and without the burden of increased development time and cost that would be expected for such a significant performance enhancement.”

As the brightest member of the industry’s only family of high-density class discrete LEDs, the new XP-L LED also touts the industry’s highest optical control factor (OCF), a measurement of the impact that LED size and performance have on directional lighting applications. With its high OCF, the XP-L will enable lighting manufacturers to improve the performance of existing lighting designs in the XP footprint, reduce the size and cost of new designs and create innovative new solutions to address applications ranging from lamps to stadium lighting.

“We evaluated many high power LEDs before deciding on Cree’s new high-density discrete LEDs,” said Jason Gerard, group GM, engineering, Gerard Lighting Group. “Cree’s high-density LEDs enable us to develop a core design that was not possible with previous LEDs for our given design targets. We’re excited that we can use the newest of Cree’s innovations to make our products stand apart from everyone else’s.”

Characterized and binned at 1050 mA, 85°C, the XP-L LED is available in up to 90 CRI and color temperatures ranging from 2700 K to 8300 K. As a “successor” product to the XLamp XM-L2, lighting manufacturers seeking ENERGY STAR® qualification can use just 3,000 hours of LM-80 data, potentially saving up to four months in the approval process.

Product samples are available now and production quantities are available with standard lead times. Please visit www.cree.com/ocf to learn more.

About Cree:

Cree is leading the LED lighting revolution and making energy-wasting traditional lighting technologies obsolete through the use of energy-efficient, mercury-free LED lighting. Cree is a market-leading innovator of lighting-class LEDs, LED lighting, and semiconductor products for power and radio frequency (RF) applications.

Cree’s product families include LED fixtures and bulbs, blue and green LED chips, high-brightness LEDs, lighting-class power LEDs, power-switching devices and RF devices. Cree® products are driving improvements in applications such as general illumination, backlighting, electronic signs and signals, power suppliers and solar inverters.

Please refer to www.cree.com for additional product and company information.