Dow Corning Launched Four New Products at Light+Building

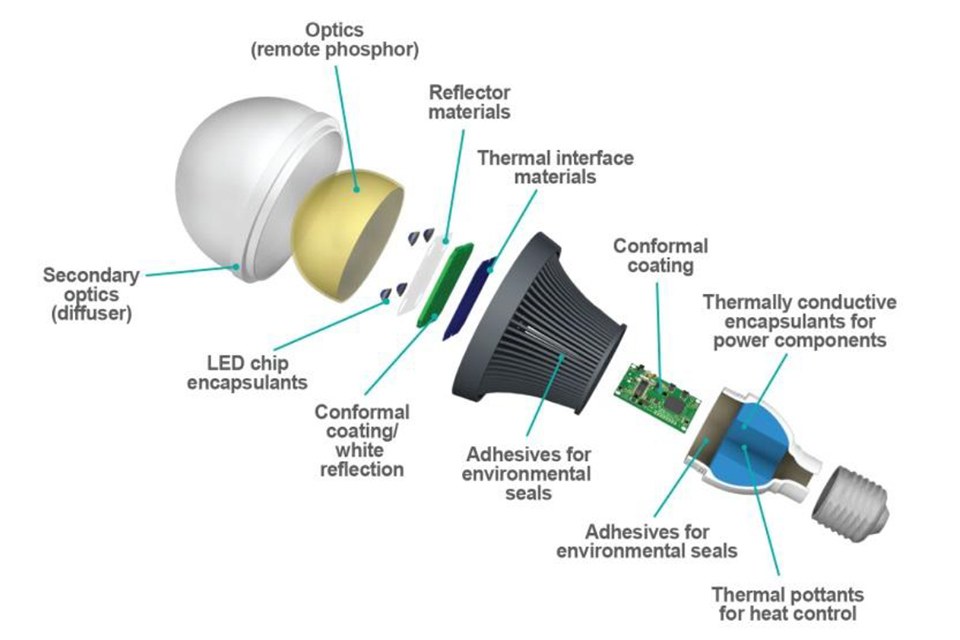

Dow Corning, a global leader in silicones, silicon-based technology and innovation, showcased at Light+Building its fast-growing portfolio of optical silicones, which are helping LED lighting manufacturers worldwide to expand possibilities for LED lamp and luminaire designs. In addition to four new high-performance materials at the show, the company spotlighted the unique design flexibilities, proven reliability and simpler processability enabled by Dow Corning® Moldable Silicones technology as well as its portfolio of proven assembly solutions for LED lamps and luminaries.

The industry-leading Dow Corning Moldable Silicone product family will be on display at the company’s booth, including the two newest additions to the line:

• Dow Corning® MS-1001 Moldable Silicone offers the product line’s highest hardness after cure to expand design flexibilities for thinner optical parts, and enable excellent reproduction of surface features possible only with silicone technology

• Dow Corning® MS-3003 Moldable Silicone delivers the higher thermal stability necessary to develop optical parts with remote phosphors, helping to speed processing and provide reliable optical, thermal and mechanical stability for advanced LED lighting designs

Dow Corning will further expand its customer design portfolio during Light+Building with the launch of two additional technologies:

• Dow Corning® CI-2001 White Reflective Coating sprays on reflectors easily with standard equipment to help boost total internal reflectivity, light diffusion and, ultimately, increased efficiency and value for LED lamps and luminaires

• Dow Corning® EA-2900 Sealant is a white silicone adhesive that is chemically compatible with the company’s other optical materials, and bonds rapidly and firmly in as little as 10 minutes to allow accelerated cycle times for handling and processing LED lighting assemblies

“The global LED lighting market is poised for tremendous growth as LEDs replace conventional light sources,” said Kaz Maruyama, global strategic marketing director, Lighting Solutions at Dow Corning. “But in order to make that leap, LED lighting will need advanced new materials technologies to unlock the potential for the design of more efficient, reliable and cost-effective LED lamps and luminaires. As a dedicated global collaboration and innovation partner to the LED lighting industry, Dow Corning is helping to develop the cutting-edge silicone solutions that will help designers meet these challenges and usher in an era of LED lighting that offers more appeal to consumer needs and designs.”

Dow Corning’s innovative expertise, industry collaboration and optical silicone technology is changing the game for LED design, and the company will show exactly how at Light+Building. Many of the cutting-edge designs it has enabled will be on display at the Dow Corning booth as real-world applications, such as secondary lenses, reflectors, light pipes, light guides and other high-performing optical components.

A market leader in materials, expertise and collaborative innovation for LED lighting concepts, Dow Corning offers solutions that span the entire LED value chain, adding reliability and efficiency for sealing, protecting, adhering, cooling, and shaping light across all lighting applications.

About Dow Corning:

Dow Corning (dowcorning.com) provides performance-enhancing solutions to serve the diverse needs of more than 25,000 customers worldwide. A global leader in silicones, silicon-based technology and innovation, Dow Corning offers more than 7,000 products and services via the company’s Dow Corning® and XIAMETER® brands. Dow Corning is equally owned by The Dow Chemical Company and Corning, Incorporated. More than half of Dow Corning’s annual sales are outside the United States. Dow Corning’s global operations adhere to the American Chemistry Council’s Responsible Care® initiative, a stringent set of standards designed to advance the safe and secure management of chemical products and processes.