Edison Opto Improves Uniformity of White Light with MAPLE Coating Technique

Mixing luminescence phosphor with silicone and dispensing it on a blue light emitting chip is a common LED package method in producing white light.

The quality of white light depends heavily on the uniformity of phosphor on the blue die. Often times, when coupling secondary lens on white LED, it will reveal yellow circling. Such yellowing greatly shadows the quality of white light.

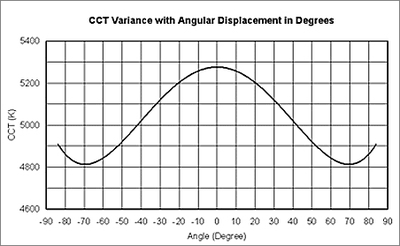

To improve the CCT uniformity of white LED, Edison Opto incorporates the principle of ceramic injection forming, combined with unique, patent-pending coating technique: Multi-Axial Phosphor Layer Envelope (MAPLE) process, to effectively form a thin layer of phosphor around the emitting faces of a LED. The spatial uniformity can be controlled within 3-steps McAdam ellipse and CCT variance within ±300K (Refer to Figure). Moreover, through fine tuning of the recipe, the CCT can fully satisfy various ANSI binning that are widely adapted among SSLS manufacturers.

Different from traditional phosphor gel dispensing technique, the proprietary MAPLE process can maximize the value proposition by delivering highly uniform white light. Edison Opto is going to fully implement its MAPLE technology into its range of high power LED products for lighting applications.

About Edison Opto:

Edison Opto is a leading high power LED manufacturer and a solution provider experienced in optical design and thermal management for the emerging SSL market. With R&D headquarter in Taiwan, as well as distribution network over twenty-six countries, Edison Opto offers a diverse range of high power LED products to worldwide commercial, industrial, retail, and residential markets. For more information, visit www.edison-opto.com.tw .