Newly Launched Products for Coating LED Assembled PCBs

To a growing extent, PCBs are assembled with LEDs and are thus partially visible when used in illuminants. In choosing your solder resist or conformal coating, you will therefore have to consider optical requirements, too.

For optimising the radiation characteristics of LEDs, white solder resists are particularly well-suited, such as the temperature-stable solder resist ELPEMER® SD 2491 SM-TSW-R2. This product stands for the new generation of purely white, opaque photoimageable solder resists which have maintained the high remission values as well as the outstanding thermal stability of their predecessor ELPEMER® SD 2491 SM-TSW-R1 and which, on top of this, can be processed more securely within immersion tin (Sn) and immersion gold (ENIG) methods.

An optical adaptation to aluminium reflectors can been implemented by coating with the silver-grey 2-pack screen printing lacquer FP 2410-1020. This product with the typical aluminium look is recommended for LED assembled boards in illuminants provided with aluminium reflectors. The thermal-curing solder bath resistant screen printing lacquer FP 2410-1020 can be used on top of either white or green photoimageable solder resists.

A maximum light yield plus a reliable protection is ensured when selective-coating with white-opaque conformal coatings such as ELPEGUARD SL 1397: All LEDs are spared during coating while dark components are covered, thus increasing the light yield (remission) distinctively. The ELPEGUARD SL 1397 is characterised by extremely high remission values along with a high light and heat stability.

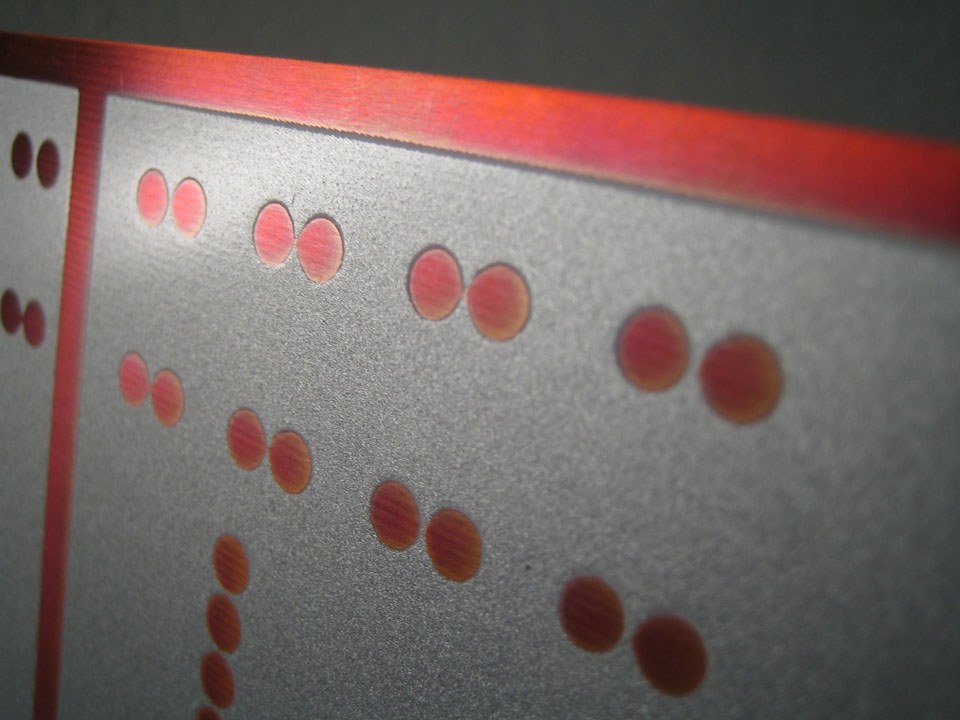

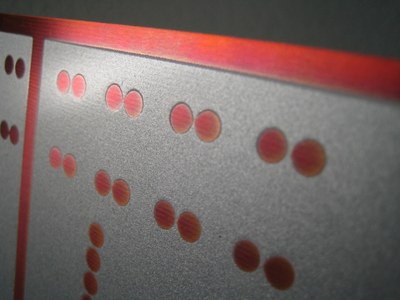

A striking contrast with the base material plus a reliable protection can be achieved by the black-opaque, mat conformal coating ELPEGUARD SL 1347. With this product, is possible to selective-coat in black your assembled PCBs which are usually coated with green solder resist, in a way that a striking contrast of the LEDs with the non-reflecting base material is produced. This is of particular advantage in display applications such as panels, signalling lights etc.

Contact address:

Lackwerke Peters GmbH + Co KG, P.O. Box 10 05 20, 47882 Kempen, Germany

Phone +49 (0) 21 52 20 09 - 0, Fax +49 (0) 21 52 20 09 - 70

E-mail: peters@peters.de, www.peters.de