World Premiere: Osram Presents 10° Binning for White LEDs - Soleriq S 13 Gen 3 at First

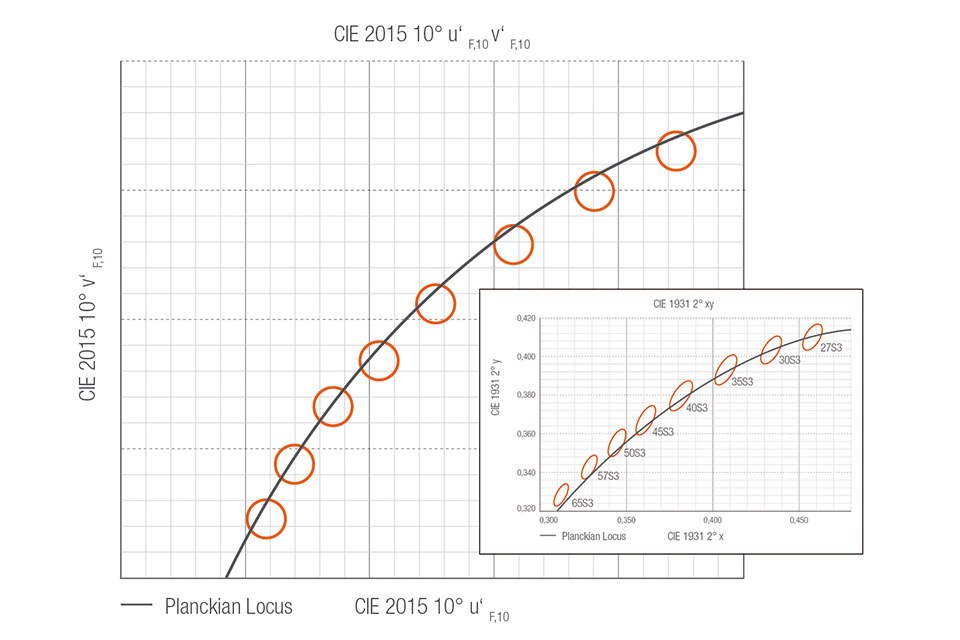

New “TEN°” binning from Osram Opto Semiconductors provides the basis for unprecedented color consistency for white LEDs which are used for example as single-LED light sources in spotlights and downlights. To achieve this the current standard CIE 1931 2° xy color space has been supplemented with CIE 2015 10° u‘v‘, recently developed by the International Commission on Illumination and implemented by Osram Opto Semiconductors as 10° binning. In the third generation of the Soleriq S 13, “TEN°“ will be available on the market as an additional feature from March 2016.

“TEN°“ is the name of the new white binning from Osram Opto Semiconductors. In contrast to the established CIE 1931 2° color space, the recently developed CIE 2015 10° corresponds much better to the physiological perception of color – hence 10° binning. This subject is of particular interest for achieving uniform illumination from spotlights and downlights in which individual white CoB LEDs are primarily used. This new binning will be used for the first time in the new generation of the Soleriq S 13 and will provide optimum color consistency in applications. “Obviously these Soleriq LEDs comply with current industry standards and continue to be completely compatible with existing white groupings. “TEN°“ binning is simply an additional property – and an extremely useful one”, said Alexander Wilm, Key Expert for General Lighting at Osram Opto Semiconductors.

If Soleriq LEDs that have been binned on the basis of these latest findings are installed for example in spotlights it will be much easier to avoid differences in light colors compared with products grouped according to the old CIE 1931 2° standard. This in turn means fewer process stages for luminaire manufacturers which would otherwise be necessary because of different white color impressions in the ultimate application.

The starting point for development activities at Osram Opto Semiconductors was that two LEDs with the exact same color coordinates in the CIE 1931 2° color space could still exhibit noticeably different white tones. One reason is that the small rods that are responsible for color perception in our eyes are not evenly distributed. This leads to different color perceptions even with LEDs in 1 SDCM binning with conventional metrics. This problem has been known and researched by scientists for many decades. However the results of their research have never been applied to general lighting. Osram Opto Semiconductors has now changed all that.

Further information on the new white binning system and the Soleriq S 13 is available on our website www.osram-os.com/tenbinning

About Osram:

Osram, based in Munich, is a globally leading lighting manufacturer with a history dating back more than 100 years. The portfolio ranges from high-tech applications based on semiconductor technology, such as infrared or laser lighting, to smart and connected lighting solutions in buildings and cities. Osram had around 33,000 employees worldwide at the end of fiscal 2015 (September 30) and generated revenue of almost €5.6 billion in that fiscal year. The company is listed on the stock exchanges in Frankfurt and Munich (ISIN: DE000LED4000; WKN: LED 400; trading symbol: OSR). Additional information can be found at www.osram.com