MD-SIG Launches LEDset Specifications for Interoperable LED Drivers and Modules

The Module-Driver Interface Special Interest Group (MD-SIG), a lighting-industry consortium, has published its LEDset specifications. LEDset provides the lighting market with a standardized, multi-vendor, electrical interface for LED systems, which simplifies the process of matching LED modules with suitable drivers.

MD-SIG is an open, global consortium consisting of leading lighting and LED driver manufacturers: BAG electronics, BJB, Helvar, Osram, Panasonic/Vossloh-Schwabe, Philips Lighting, TCI and Zumtobel/Tridonic.

Today, there are many different options on the market for communication and power transmission between an LED control gear (driver) and one or more LED modules. This leads to increased complexity, availability issues and risk of incompatibility for fixture OEMs.

MD-SIG was formed with the aim of introducing a standardized electrical interface between LED control gear and LED modules. This “missing link” is an essential feature of a mature components business for solid-state lighting.

The LEDset interface created by MD-SIG meets the growing demand in the market for harmonization, and makes it much easier to match LED modules with configurable LED drivers.

Specification Details:

MD-SIG has published two specification documents – the “LEDset Power Interface Specification” and the “LEDset1 Information Interface Specification” – which can also be downloaded from the MD-SIG website (ledset-standard.org/specifications).

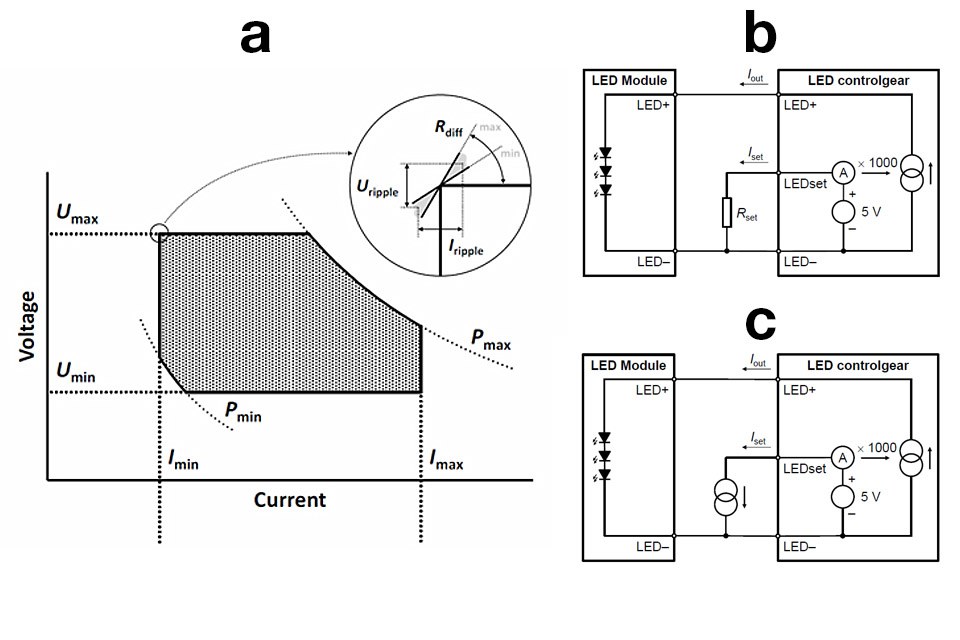

The LEDset Power Interface Specification describes the data-sheet information that should be provided for LED modules and LED drivers, in terms of the output current, voltage and power ranges.

With this standardized approach, luminaire makers can identify interoperable components without the risk of inaccurate matching due to poorly-defined specification parameters (e.g. temperature drift, forward-voltage tolerances and current-modulation effects). The specification also describes the testing conditions and measurement methods that should be used to verify the provided information.

The LEDset1 Information Interface Specification describes a setting method that uses a resistor to configure the output current of a window driver. The resistor is attached to the driver in the production line of the luminaire manufacturer. The LEDset1 interface can alternatively be used to automatically adapt the output current of a window driver according to an integrated coding resistor on the LED module(s). It also supports thermal de-rating of LED modules with integrated temperature sensors. Digital configuration methods are under consideration for future specifications.

The MD-SIG specifications are complementary to those developed by the Zhaga Consortium, another lighting-industry organization that is independent from MD-SIG. Zhaga defines various interfaces between LED components and LED luminaires, but it does not address the electrical interface between LED modules and drivers. Instead, several Zhaga Books already contain references to the new MD-SIG specifications.

About MD-SIG:

The Module-Driver Interface Special Interest Group (MD-SIG) is a global lighting industry consortium open for all interested parties, aiming to introduce a standardized multi-vendor electrical interface. The smart electrical interface LEDset between LED control gear and modules is the missing link essential to the maturity of SSL components business. The LEDset interface created by the consortium allows communication and power transmission between an LED control gear and one or more LED modules. Today, many different options are available on the market, leading to increased complexity and shortened availability for fixture OEMs. MD-SIG meets the growing demand in the market for harmonization by introducing a standardized multi-vendor electrical interface for LED systems. Thus matching LED modules with LED window drivers becomes much easier.