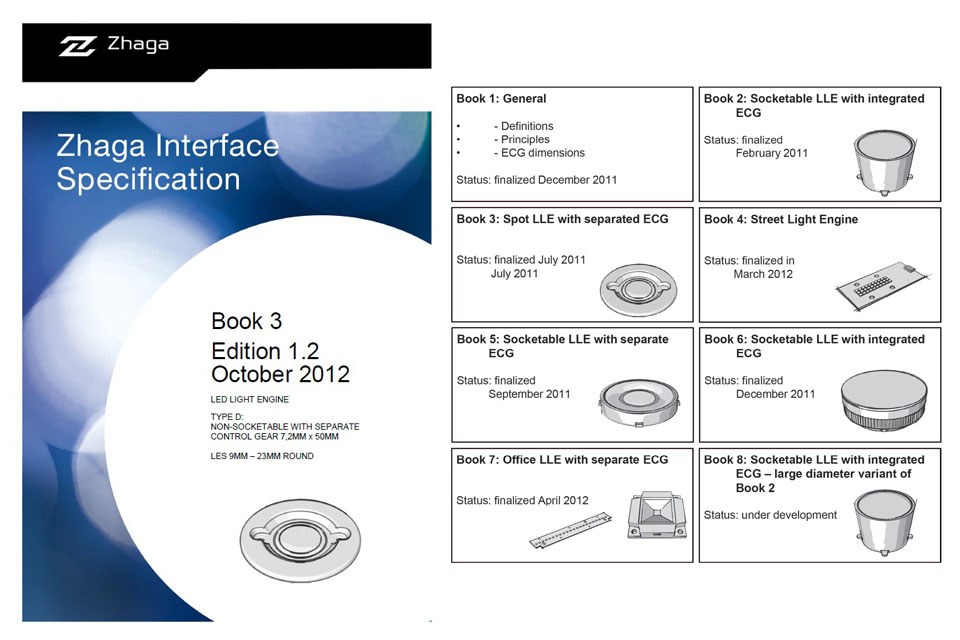

The Zhaga Consortium Makes Book 3 Public, the First of Seven Interface Specifications for LED Light Engines

Zhaga has made the interface specification ‘Book 3’ publicly available as free download from its website. Book 3 defines the interface for a small, round, LED light engine suitable for spot lighting and other applications that need a point light source.

Zhaga specifications start their life as confidential documents, available only to the more than 270 members of the Zhaga consortium. Zhaga makes a specification publicly available when the first products that implement that specification have entered the market. As of today, 32 LED light engines and 2 luminaires have been certified to be compliant with Book 3. By publishing Book 3, Zhaga is making it possible for everyone in the lighting industry to use the specifications. The right to display the Zhaga logo on products will remain available only to companies that are members of the consortium.

“LED innovation is swift,” points out Menno Treffers, Zhaga’s Secretary General. “An LED that’s state-of-the-art today will be outperformed by new LEDs within six months. As a result, luminaire manufacturers must continually upgrade the LEDs in their products. Until now, this has often required product modifications. By conforming to Zhaga interface specifications, manufacturers reduce the business risks of developing and selling LED lighting systems because the supply of components is more reliable, component stock levels can be lowered, and the risk of obsolescence and write-offs is reduced.”

Fostering interchangeability, preserving design creativity

Zhaga specifications foster interchangeability by defining an LLE’s size, fixation method, thermal performance, light-emitting surface, photometric properties, and electrical characteristics, as well as the test procedures to certify compliance. Book 3 does this for the interface of an LED light engine consisting of a disk-shaped LED modules designed to be screwed to the heat-sink base of a luminaire and controlled by a separately housed LED driver (an optional screwless, locking-ring mounting is also specified). The modules have a diameter of 50mm and a maximum height of 7.2mm, offering the optimum balance between compactness and thermal management.

Their light output is essentially Lambertian, giving luminaire manufacturers a defined input from which to adjust light distribution to the needs of their individual products.

It’s important to note that interchangeable doesn’t mean identical. Zhaga specifications only establish a stable interface between a luminaire and an LLE, leaving luminaire and LLE manufacturers with ample freedom to pursue aesthetic and technical innovations.

Together with Book 3, Zhaga has also released the specification ‘Book 1’, which defines Zhaga terminology and describes aspects that are common to all Zhaga interfaces.

You can find more information on Zhaga at http://www.zhagastandard.org, http://twitter.com/zhaga_led and http://www.youtube.com/zhagaled.