FlexRad Delivers Cutting Edge Innovation

It seems impossible at first glance - the most innovative supplier of custom light engines in the market is also the most reliable in quality and in delivery. MetroSpec Technology® LLC has well over 3,000 miles of installed base to prove these points. FlexRad®, a novel, high performing, cut-to-size, LED light circuit technology, has been in volume production for 14 years and is installed in hundreds of thousands of locations. FlexRad was a decade ahead of other LED products, with reels of circuits over 200 feet trimmable to the inch. Well proven and perfected, FlexRad carries a seven-year warranty that actually means something.

"We have always supported and championed the North American fixture manufacturer".

That was never enough for the MetroSpec founding team; however. "We have always supported and championed the North American fixture manufacturer" said Vic Holec, founder of MetroSpec and the FlexRad brand. "From the first adaptation of LED to replace tubes and bulbs, to the newest innovations that greatly reduce size, weight, and assembly labor, we have been there as partners to our customers - to help them win business in the most competitive markets".

It is generally understood that nothing has remained static in the Lighting Industry since LED was introduced, and Mr. Holec and his team understand this very well. In 2007, with the invention of FlexRad, they focused on enabling the efficiency and the flexibility of LED lighting. Efficiency meant thermal transfer and control in the most reliable form. Flexibility meant the ability to be able to use the same product, the same inventory in as many fixtures as possible - cutting to size and fit with no fasteners required, and supporting the customer with any color temperature and any color combination required.

As the LED market grew in size, cost cutting was relentless. "Quality LEDs are no longer the most expensive part of an LED light fixture. Today it is the power supply, the glass and metal, and of course the labor to build it", said Todd Crandell, CEO at MetroSpec. "We have transitioned our business to get the waste out of the process, helping our customers be highly competitive".

From the beginning, FlexRad has been very compact, and highly efficient in materials and space. In its continuous form there is little or no circuit waste for the customer. The most telling aspect shown at the Mendota Heights, Minnesota factory is the final product that is shipped to customers in boxes just larger than 2x the size of the emitter reels they started from. On the customer end, FlexRad eliminates screws, fasteners, solder pads, cables, wires and connectors - allowing the electronic "guts" of a light fixture to be simply a one-to-one connection of a light source to a power supply. Lots of savings there.

Contact MetroSpec Technology about FlexRad technologies:

sales@flexrad.com

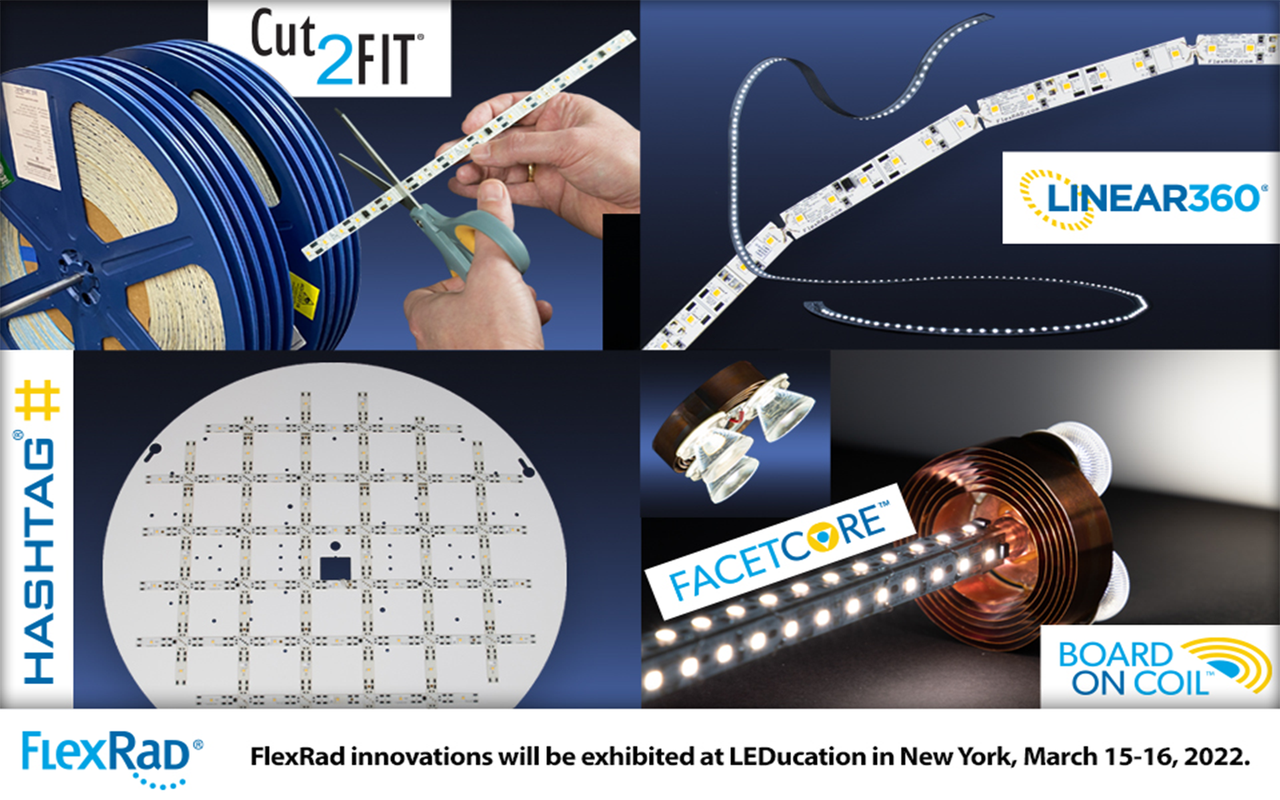

What came next was two- and three-dimensional reductions in size, cost, and complexity. Mr. Holec explained several of these inventions. "Hashtag® is our two dimensional version of FlexRad, where almost any shape can be supplied from a pre-connected mesh of LED strips. Linear360® is inherently linear, two-dimensional and three-dimensional all at the same time. In a single continuous installation you can spiral and bend in and out of plane. It is perfect for rings, raceways, and inside and outside curves. FacetCore™ is a rollable light source, perfect for radial lighting in cylinders, globes and a wide variety of sconces and pendant fixtures. And to this, we have added the brand new BOC (Board On Coil™), which is a powerful, low profile, directional light source. One look at BOC and a feel of its surprising lightness and compactness, and it is easy to understand this is a revolutionary approach to downlight - better than bulky COB solutions.”

What is really surprising is how simple all of these are for customer implementation in their fixtures. MetroSpec has used what they call a 2/2/2 program for customized development since the beginning. The customer starts out with technology samples that demonstrate how these ideas work, and then customizes to meet their needs - the best solution for a wide range of fixtures. The first "2" in 2/2/2 stands for two weeks to a pilot run of a fully customized solution. Absolutely amazing turn around. "From time-to-time customers come to us because their existing vendors have fallen down", said Mr. Crandell. "In two weeks they have something in hand that exceeds anything they have purchased in the past, and the volume they need is available in less than 2 months".

For more information about FlexRad® technologies:

www.flexrad.com

Company Description

MetroSpec Technology is an LED light source design and manufacturing company specializing in custom flexible, high quality, high intensity lighting solutions tailored for light fixture manufacturers producing high-end commercial, architectural, and hybrid lighting systems. MetroSpec offers quick development for all of their patented FlexRad LED light engines made exactly to custom specifications. FlexRad designs are innovative, field proven and customizable to any shape and size.

___

© 2022 LED professional / Luger Research e.U./FP01032022PD