VCSEL Testing in Production Lines

Quality control of VCSELs and EELs in production lines requires the full optical characterization of a device-under-test (DUT) within milliseconds. For this, the combination of an integrating sphere (ISP series) and a high-resolution array spectroradiometer of our CAS series is the ideal system for fast and reliable tests of semiconductor laser diodes, determining key characteristics like the centroid wavelength and the radiant power.

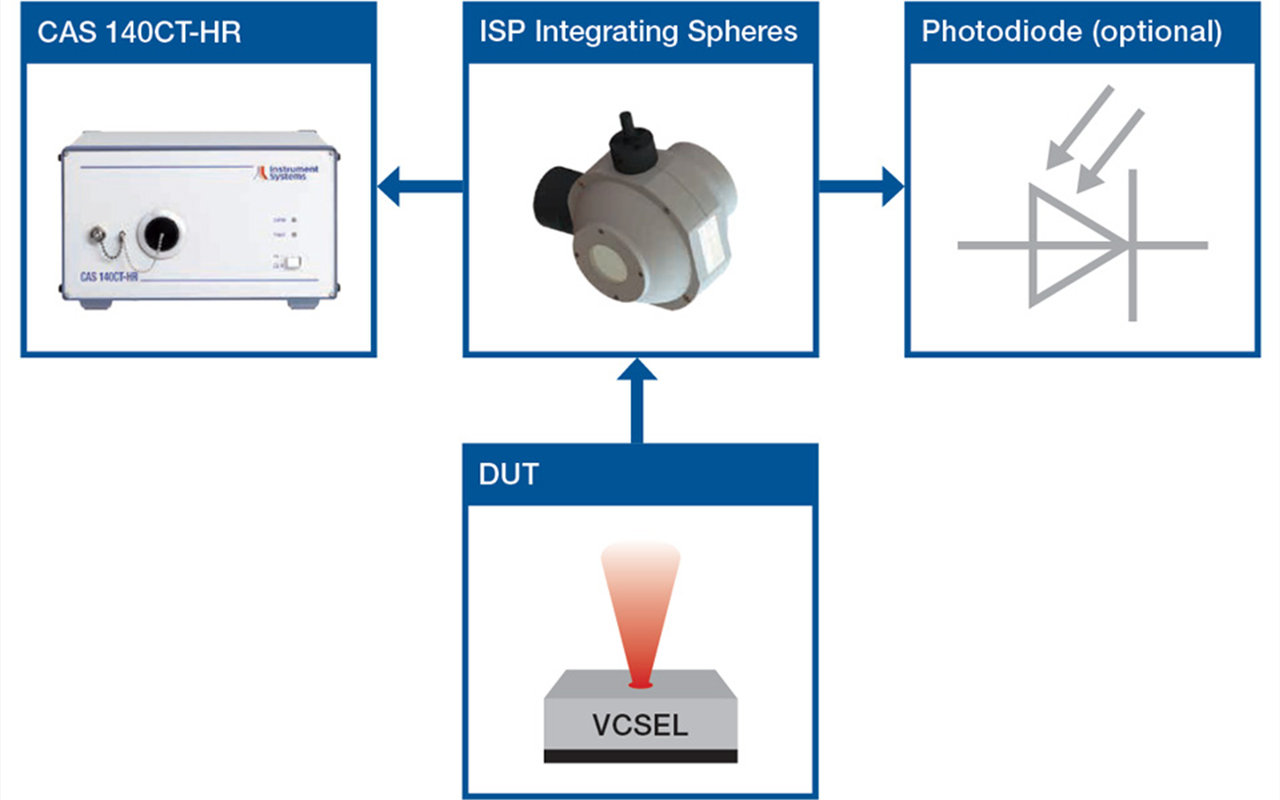

Figure: High-resolution array spectroradiometers with integrating spheres allow for the fast and reliable spectral characterization of VCSELs. Optional photodiode sensors can further increase the precision of the radiant power measurement.

The high measurement speed requires that such spectral measurements are usually carried out with only a single, millisecond long optical pulse in the integration time window of the spectroradiometer.

In such systems, the integrating sphere homogenizes the light field and the array spectroradiometer has to record the laser spectrum with the necessary accuracy and measurement speed. For light sources with a very narrow spectrum, the precision of the radiant power measurement can be further increased with an additional photodiode sensor attached to and calibrated with the ISP. This is recommended for high precision measurements to correct deviations due to the wavelength-dependent reflectivity of the DUT and its surroundings with the self-absorption correction method. For this, it is necessary to choose an appropriate auxiliary light source with a suitable spectral power density distribution. The narrow spectral bandwidth of VCSELs – typically in the range of a nanometer – requires spectroradiometers with sub-nanometer spectral resolution. Instrument Systems offers with the CAS 140CT-HR, the CAS 120-HR and the CAS 100-HR three high-resolution spectrometer platforms and additionally integrating spheres and suitable auxiliary light sources for semiconductor laser diode testing in production lines. A new fast InGaAs photodiode specially designed for nanosecond pulsed VCSEL measurements (as used in LiDAR or Time-of-Flight 3D sensing applications) completes the portfolio.

Key features:

- High spectral resolution down to 0.12 nm

- PTB traceable measurements

- High sensitivity for high throughout (UPH)

- Short integration times down to 9 ms with CAS 140CT-HR &

4 ms with CAS 120-HR / CAS 100-HR - Optional: ISP with photodiode sensor

- Optional: auxiliary light source for DUT specific self-absorption correction

- Optional: 1.4 GHz InGaAs photodiode for ns pulse testing

Key results:

- Optical spectrum

- FWHM

- Peak wavelength

- Radiant power

GLOBAL LIGHTING DIRECTORY (GLD)

INSTRUMENT SYSTEMS

Munich, 81677

Germany

+49 89454943-0

sales@instrumentsystems.com

www.instrumentsystems.comInstrument Systems GmbH, founded in Munich in 1986, develops, manufactures and markets all-in-one solutions for light measurement technology. Our key products are array spectroradiometers, luminance cameras and imaging colorimeters. The main areas of application are LED/SSL and display colorimetry, spectral radiometry and photometry as well as laser/VCSEL characterization. Today Instrument Systems is one of the world’s leading manufacturers in the industry. Products of the Optronik Line for the automotive industry and traffic technology are developed and marketed at its Berlin location. Since 2012 Instrument Systems has been a wholly-owned subsidiary of the Konica-MinoIta Group.

- PRODUCTS

Light Modules|LEDs/OLEDs|Optics|Testing Equipment - SERVICES

Testing

© 2022 Luger Research e.U. – Institute for Innovation & Technology