Lumileds Implements Lumiramic Phosphor Technology as Part of its Roadmap - Reduction of Warm White LUXEON Rebel Bins at First

The general lighting industry can look forward to dramatic improvements in the manufacture and supportability of color-consistent, white power LEDs under a new technology roadmap for Lumiramic phosphor technology.

As a kickoff to the new technology, an immediate reduction in the number of white color bins for the company’s warm white LUXEON Rebel has been implemented.

“For all the acknowledged benefits of power LEDs, such as efficiency, sustainability, and durability, we believe that providing a supportable, high color-quality supply of white LEDs is the single biggest challenge facing the power LED industry and today Philips Lumileds is addressing this headon with a superior technical solution for our LUXEON LEDs,” said Michael Holt, CEO of Philips Lumileds.

The binning of white LEDs is a “work-around” to manage the variation in white color and tint that are the result of today’s manufacturing processes. The inefficiencies of binning create structural vulnerability in the supply chain for the market. To date, there have been no solutions that decrease or eliminate this risk. The only way most manufacturers can consistently produce sufficiently large quantities of the desired bins for general lighting has been to increase the volume of white LEDs manufactured and discard those that don’t fit in the desired color spaces. However, this does little to address the supply chain risk and produces tremendous waste, the cost of which must be absorbed by the market.

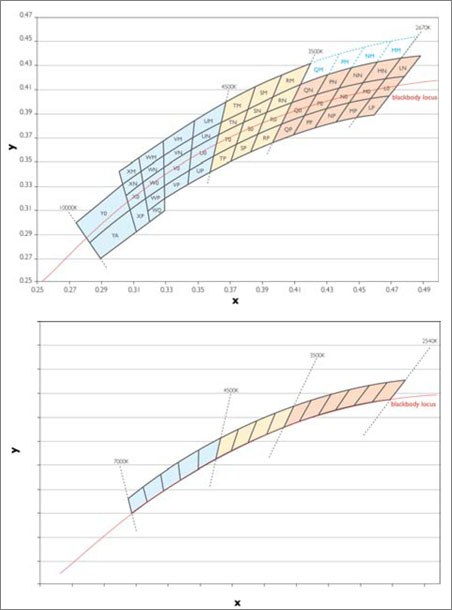

Over the last 18 months, flux improvements have resulted in power LEDs delivering upwards of 80 lm/W. Light output and efficiency has been a primary obstacle to adoption. Now that solidstate lighting systems can outperform fluorescent, the industry must continue to improve the quality, consistency and availability of white LEDs. Philips Lumileds patented Lumiramic phosphor technology enables specific targeting for correlated color temperature which for the first time puts the manufacturer in control of the color temperature and tint and allows for production variance to be minimized. The new technology and production innovation from Philips Lumileds will result in a single row of white bins along the black body locus. Each bin will be sized to represent a total space no more than 3 MacAdam ellipses. Controlling the production process for white LEDs enables Philips Lumileds to accelerate growth of the general lighting market.

With a reduction in bin spaces for warm white already in place, Philips Lumileds will turn its attention to a similar reduction for neutral and cool white LUXEON Rebel products. When complete, the process to remove additional bins and shrink remaining bins on the black body locus will commence.

About Lumiramic Phosphor Technology:

Philips expertise in phosphors and Lumileds power LED technologies uniquely combined to create the powerful phosphor conversion process that will bring supply-chain stability to the solidstate lighting market. Lumiramic phosphor technology utilizes a ceramic phosphor plate and Philips Lumileds’ Thin Film Flip Chip (TFFC) technology. The process matches royal-blue (pump) TFFC die that have been characterized and sorted by wavelength to pre-measured ceramic phosphor plates (Lumiramic). By matching Lumiramic plates of the appropriate thickness with the correct wavelength of TFFC die in advance of final manufacturing, a specific correlated color temperature can be targeted. While the concept is well understood, years of invention were required to identify phosphors and create the ceramic plates that would be stable in the intended environments. The solution also required that an LED die with an unobstructed surface be created to which the ceramic plate could be bonded. This optical alignment in which there is no anode or cathode in the light path is unique to Philips Lumileds TFFC die.

About Philips Lumileds:

Philips Lumileds is the world's leading provider of power LEDs for everyday lighting applications. The company's recent records for light output, efficacy and thermal management are direct results of the ongoing commitment to advancing solid-state lighting technology and enabling lighting solutions that are more environmentally friendly, help reduce CO2 emissions and reduce the need for power plant expansion. Philips Lumileds' LUXEON LEDs are enabling never before possible applications in the general lighting, automotive, digital imaging, display, and signage markets. More information about the company's LUXEON® LED products and solid-state lighting technologies can be found at www.philipslumileds.com .

About Royal Philips Electronics:

Royal Philips Electronics of the Netherlands (NYSE: PHG, AEX: PHI) is a global leader in healthcare, lighting and consumer lifestyle, delivering people-centric, innovative products, services and solutions through the brand promise of “sense and simplicity”. Headquartered in the Netherlands, Philips employs approximately 134,200 employees in more than 60 countries worldwide. With sales of USD 42 billion (E26 billion) in 2007, the company is a market leader in medical diagnostic imaging and patient monitoring systems, energy efficient lighting solutions, as well as lifestyle solutions for personal wellbeing. News from Philips is located at www.philips.com/newscenter .