Lumitronix Has Designed New Flexible LED Strips for L+B

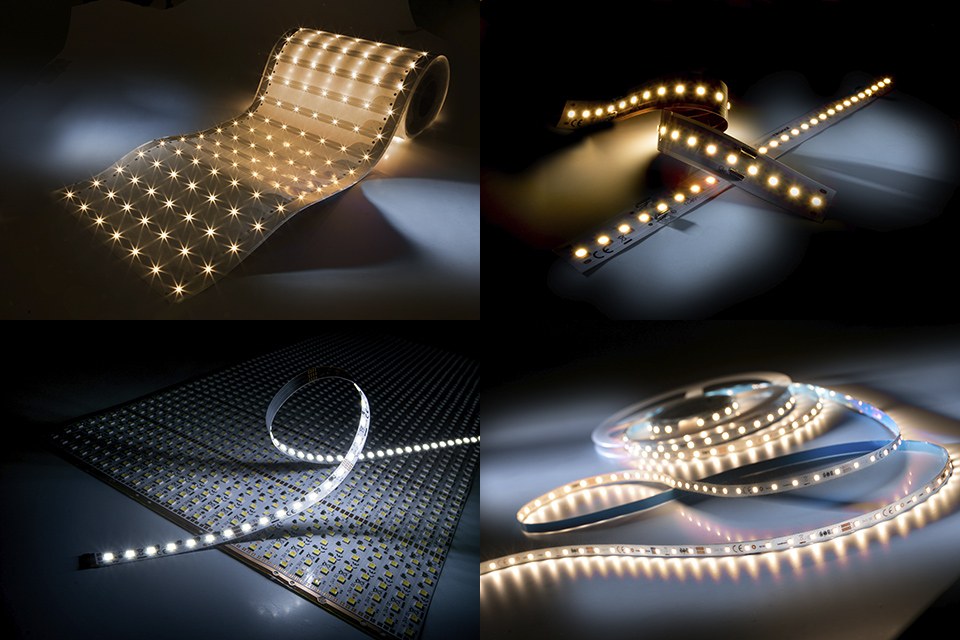

Lumitronix has prepared several product innovations for the postponed Light + Building. Amongst these products are flexible LED strips for different applications. Z-Flex 280x20 based on the widespread Zhaga standard of modules with a length of one foot and therefore compatible with many linear luminaire types. LumiFlex560 Professional TW has been assembled in the reel-to-reel process on the new in-house production line which allows an individual assembly of the desired dimensions. LumiFlex350 Professional and offers luminaire manufacturers new possibilities, primarily due to its processing and is equipped with an integrated linear control. As a highlight – first samples were already presented at LpS 2019 - Paper-Flex uses paper as base material and is manufactured by a proprietary plasma metallization technology.

Paper-Flex – Flexible LED modules using paper as a base material on rolls of up to 50 meters

Paper-Flex, a flexible LED module made of paper, can be assembled on the new in-house production line in a reel-to-reel process. The state-of-the-art production line is capable of processing flexible substrates of any kind in almost endless lengths - including paper.

The standard version of Paper-Flex has a length of 24.85 meters and a width of 35 centimeters. It consists of a total of 497 LED strands, each five centimeters wide. Each LED strand has seven LEDs, which together produce a luminous flux of 55 lumens. In total, the complete roll of Paper-Flex provides a luminous flux of 27335 lumens. As the Paper-Flex modules are divided into separate strands, they can be individually assembled in different lengths according to customer requirements. Currently, rolls of up to 50 meters are possible.

The LEDs installed on the Paper-Flex module have a color temperature of 2700 K and a CRI of over 80. In addition, individual configurations of Paper-Flex with regard to the LED types in terms of colour temperature, CRI and efficiency are available on request.

Advantages of Paper Flex compared to conventional base materials

"Compared to rigid boards, which form the basis of many LED module types, one of the advantages of Paper-Flex is the simplification of processing. The paper modules to be adhered can be installed in a time-saving manner and are also touch-proof due to the low voltage of 24 V," Christian Hoffmann, CEO of Lumitronix, reports.

In addition, the extremely low weight - one strand weighs about 2 grams - and the roll shape ensure that storage and transport costs are significantly minimized. Moreover, the paper substrate is ultra-flat (approx. 0.8 mm after assembly) and thus more than suitable for large-area applications where a low installation height is required. The diffusion openness of Paper-Flex is a decisive factor in ensuring that the paper modules can be used as wallpaper. Due to the breathability of the paper there is no danger of moisture accumulation.

"Paper-Flex is a future-oriented product that uses paper as a sustainable and environmentally friendly basis. This makes the paper module a novelty in the industry, enabling it to be used in a wide range of applications," Hoffmann continues.

Possible applications and areas of use for the Paper-Flex LED modules include: wallpapers, very large advertising surfaces, decorations and backlighting of furniture, trade fair construction, luminaire manufacture and basically all large-area applications with radii and curved shapes.

Simplification in processing and cost reduction with Z-Flex 280x20

Christian Hoffmann, CEO of Lumitronix, is aware of the advantages of the Z-Flex 280x20: "Unlike rigid modules, which have to be fixed in large numbers with screws depending on the nature of the luminaire, the Z-Flex LED strips can be glued into the body in one piece. Another advantage over modules based on rigid boards is the wiring. The Z-Flex modules can be operated up to a maximum length of 1.4 metres with one feed."

The 280 x 20 mm Z-Flex modules are produced by Lumitronix on the new Flex production line in lengths of 5.6 and 56 m using the reel-to-reel process. "This results in considerable savings for companies in the lighting industry, especially with regard to such costs as warehousing and transport. The roll form also proves to be helpful in terms of reducing the time required to install the Flex modules, as rigid modules are usually individually wrapped in ESD foil and are therefore very time-consuming to install." Hoffmann continues.

Available in SELV and non-SELV versions

The flexible modules are available in SELV and Non SELV versions. The SELV version offers the decisive advantage that the modules can be mechanically separated without the risk of flashovers due to the low operating voltage, thus making them safe to touch. The Non SELV modules are not electrically plated through over their entire length due to the higher voltage, thus ensuring a sufficient safety distance to the conductor tracks even after disconnection.

LumiFlex560 Professional TW – flexible LED strips with innovative 2-in-1 tunable white LEDs

The LumiFlex560 Professional TW is a flexible LED strip that has been assembled in the reel-to-reel process on the new in-house production line, which is capable of processing flexible substrates of any kind in almost endless lengths. Subsequently, an individual assembly of the desired dimensions is possible. The standard version of the LumiFlex560 Professional TW has 560 LEDs over a length of 5 meters.

The special feature of the new flex strips lies in the LEDs installed. "We rely on the groundbreaking NF2W757G-MT 2-in-1 Tunable White LEDs from Nichia." says Lumitronix CEO Christian Hoffmann. These are the world's first LEDs to combine a color temperature range of 2700 to 6500 K under one phosphor layer. "This results in a much more homogeneous light image and finer color matching and mixing, since all color temperatures are under one emitting surface. In addition, a higher color rendering index (CRI 90) is possible." Hoffmann continues. Furthermore, the 2-in-1 form creates more options regarding optics and greater scope and creativity when designing new luminaire designs.

LumiFlex350 Professional - produced in a reel-to-reel process

"The new LumiFlex350 Professional LED strips are the first flexible LED strips from Lumitronix that have been produced in a reel-to-reel process on the company's own new Flex production line." emphasizes CEO Christian Hoffmann. Equipped with 350 LEDs, the LED flex strips have a standard length of 5 metres, are available in colour temperatures of 2700 K, 3000 K, 4000 K and 6500 K and have a long service life and high efficiency. An integrated linear control also ensures that the brightness remains constant throughout. The strips can easily be cut every 100 mm with scissors, thus increasing flexibility in terms of applicability.

Hoffmann continues: "The Lumitronix production line allows processing beyond the standard length of 5000 mm up to 50 meters in one piece. Individual assembly following placement is also possible."

For additional information on Lumitronix's product innovations, please visit b2b.lumitronix.com/en/ or email to b2b@leds.de

About Lumitronix:

Lumitronix has been one of the leading specialists for LEDs and LED products for many years. As a competent partner for the industry, Lumitronix possesses broad application knowledge from numerous sectors. The Swabian company, based in Hechingen, Germany, has ISO 9001 certification and is also the official distributor of market-leading manufacturers of LED technology. Lumitronix is not only involved in the distribution of LED products, but also develops and manufactures in-house according to customer-specific requirements. Two ultra-modern production lines with the latest machine technology allow the assembly of both rigid and flexible PCBs. A special feature of the flex production is the reel-to-reel processing, with which almost endless lengths can be realized. The production site in Hechingen furthermore provides the benefit of being able to respond quickly and reliably to individual customer wishes and requirements. Quality Made in Germany. - b2b.lumitronix.com/en/