High Volume Laser Diode and VCSEL Testing

Hitherto established measurement technologies for laser diodes – such as dispersive scanning spectrometry and Fourier-transform infrared spectroscopy (FTIR) – can react sensitively to a production environment. High-resolution array spectroradiometers are effective alternatives that offer multiple advantages, also in continuous production. Laser diodes, and in particular vertical-cavity surface-emitting lasers (VCSELs), have experienced rapid market growth due to new applications and new technological approaches. Examples of this are infrared VCSELs integrated into consumer electronics and direct diode lasers based on VCSEL arrays, replacing conventional laser systems.

A high volume production requires fast and also accurate production testing. Particularly VCSELs – in contrast to edge-emitting lasers (EEL) – allow early material testing at wafer level due to the already monolithically integrated laser cavity in the epitaxial structure. At this testing level the key measurement parameters are the peak wavelength and power of the devices. Hitherto established measurement technologies for laser diodes such as dispersive scanning spectrometry and Fourier-transform infrared spectroscopy (FTIR) enable high-resolution measurements, while the spectral range under investigation remains high flexible. These properties result from a rotating mirror (scanning spectrometer) or a moving mirror (FTIR) that makes these measurement systems very effective for product development or product specification in a laboratory environment.

For applications within production lines, however, these moving parts are a disadvantage:

• Measurement systems are very sensitive to production-caused vibrations that may compromise the stability and repeatability of measurement results

• Optical measurement times are limited due to the movement of the grating/mirror

• Optical measurement requires constant optical output of the laser diode during the measurement in order to avoid a distortion of the spectrum

In contrast, array spectroradiometers, which are much-proven for LED production on wafer and package level, have ideally-suited properties for laser diode production:

• The fixed configuration of optical components ensures high mechanical stability and repeatability.

• The spectrum is captured in one shot and integration times are reduced to the one-digit millisecond range. This permits a very high throughput (units per hour)

• For absolute calibrated spectroradiometers, the power is an immediate result of the measurement, i.e. no additional photodiode is necessary

• Spectral information can be measured for laser diodes with very short pulsed operation

• If necessary, a supplementary photodiode can be integrated into the measurement probe, e.g. an integrating sphere. This can be useful for temporary measurements, e.g. pulse shape evaluation

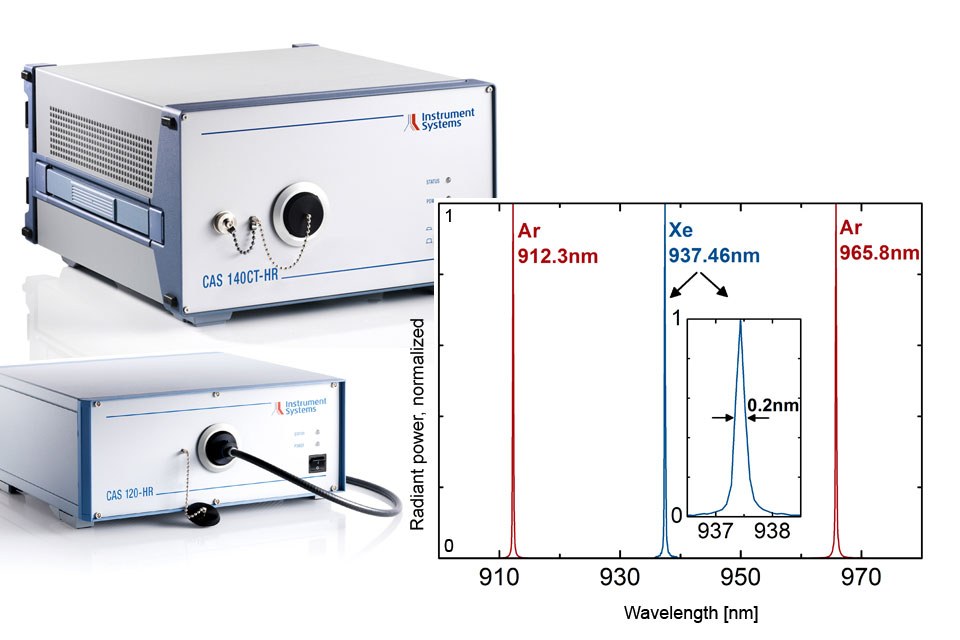

Based on the successful and well-proven spectroradiometers of the CAS series, Instrument Systems has developed special devices particularly designed for narrow band emitters, e.g. laser diodes. The high resolution CAS 140CT HR spectroradiometer combine the demands of high spectral resolution and short testing times for sophisticated measurement tasks in production and laboratory environments. It achieves very high spectral resolutions down to 0.2 nm for a spectral measuring range of 80 nm (see figure 1). Measuring ranges of 120 and 160 nm result in spectral resolutions of 0.3 and 0.4 nm, respectively. The spectrograph architecture with its CCD array allows to capture the spectrum of the emitter in a single exposure of the detector and thus renders possible integration times down to 10 ms. The cost-effective alternative CAS120-HR – mainly developed to use in continuous production – even renders integration times down to 4 ms. The latter are especially important for the measurement of emitters with a pulsed operating mode in the order of milliseconds.

Therefore, with the array spectroradiometers of the CAS-HR series Instrument Systems provides very stable and reliable measurement solutions for high volume testing of laser diodes and particularly VCSELs.

For additional information, please visit www.instrumentsystems.com or send an email to sales@instrumentsystems.com

About Instrument Systems GmbH:

Instrument Systems GmbH develops and manufactures turnkey solutions for light measurement. Its main products are array spectrometers, imaging photometers and colorimeters. Key applications are LED/SSL and display measurement, as well as spectroradiometry and photometry. Products of the Optronik Line for the automotive industry and traffic technology are developed and marketed at the Berlin facility. Since 2012 Instrument Systems has been a wholly owned subsidiary of the Konica Minolta Group.