Development of Anti-fuse Element for Controlling Open Defects in LEDs

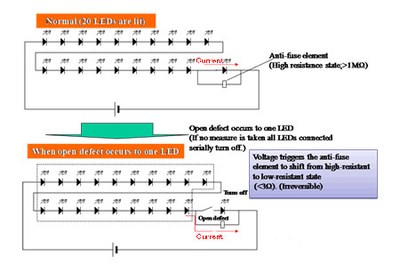

Murata Manufacturing Co., Ltd. has developed “anti-fuse element” for controlling open defects in LEDs. This device allows LEDs serially connected to an LED having open defect* to stay lit, reducing open defect-related maintenance cost for LED lighting fixture. This product may be used for all lighting fixtures using LEDs, and especially suitable for large outdoor type lighting fixtures.

Compared with other conventional measures for controlling open defects, this product allows for simpler and more economical circuit design, reduces unevenness in color, and prevents lowering of power supply voltage typically observed in Zener diodes, resulting in higher energy efficiency.

Recently LED lighting fixtures are replacing other types due to their advantage in low power consumption and small size.

However, when LEDs are connected serially in a circuit, an open defect in one LED causes all other LEDs to turn off.

Serial-parallel circuit design currently used to control the problem with open defect causes fluctuation in current with the occurrence of open defect, resulting in uneven coloring in the light emitted. When an open defect occurs in a circuit with Zener diodes placed for preventing static damage, voltage drop causes other LEDs connected serially to darken.

Our newly developed anti-fuse element parallel-connected to a serial LED circuit can solve all the problems above providing a simple measure against open defects.

Advantage:

• Brightness of the lighting fixture as a whole is maintained even when an open defect occurs.

• Anti-fuse elements are smaller (1.0x0.5x0.5mm) than Zener diodes making them more inconspicuous.

• Since its resistance is smaller than a Zener diode upon activation, large current can flow through the anti-fuse element stably.

• Simpler anti-fuse element-based circuit construction contributes to reducing cost compared with more complex serial-parallel circuit design, and reduces color unevenness.

• Open defects can be controlled without lowering power supply voltage.

• Ideal for large outdoor lighting fixtures where maintenance cost is higher

Electric characteristic:

• Allowable current: 350mA

• Nominal voltage: 4V

• Trigger voltage: 20V

• Insulating resistance (before activation): 1MΩ

• Resistance after activation: Less than 3Ω