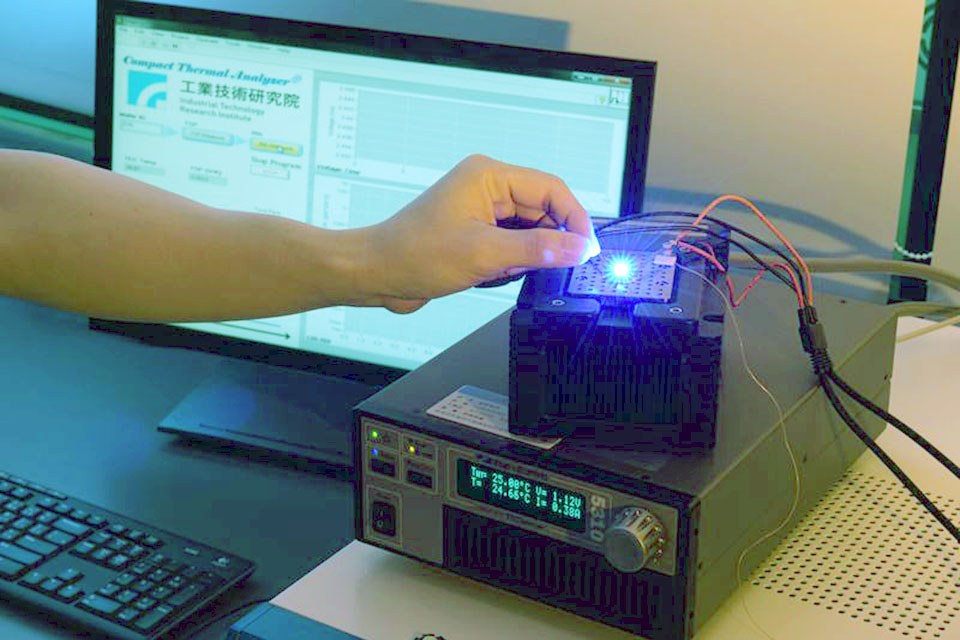

ITRI Introduces ICTA Reducing LED Thermal Testing Time by More Than 90%

Industrial Technology Research Institute (ITRI), Taiwan's largest and one of the world's leading high-tech research and development institutions, is pleased to introduce In-Line Compact Thermal Analyzer (ICTA) Technology. The world's leading automatic thermal analyzer, ICTA offers a measurement speed of 12,000 LEDs per hour, reducing each LED's component thermal resistance testing time to 0.3 seconds. This is 2,000 times faster than the traditional lab method where only six components can be measured per hour. ITRI will receive a 2014 R&D 100 Award in November for this breakthrough technology in the "Imaging" category.

Thermal performance has always been the primary factor impacting the life and light quality of LEDs. ICTA Technology is the most powerful, cost efficient and high performance thermal analyzer when compared to other LED thermal testers available today -- greatly reducing the defect ratio of LED illumination products. While decreasing LED testing time, ICTA improves production yield, performance and lifespan of LED devices such as LED bulbs, mobile phones, TV, laptop display backlight, etc. This innovative technology has a high-speed temperature sensitive parameter (TSP) measurement technique that could reduce LED testing time by more than 90 percent, thereby improving the efficiency of thermal structure analysis. These attributes lead to more reliable LED devices for end-users. In power semiconductor devices, ICTA can be used to solve thermal-induced stress, enabling innovative package design and material property identification or facilitating lifespan estimation.

"Up-to-now, measuring LED thermal resistance has been complex, time-consuming and could only take place in the laboratory at the product design stage," said James, Mu Tao Chu, division director of the opto-electronics device and system applications division at ITRI. "With ICTA, manufacturers can now screen defective products on the production lines in real-time, optimizing production processes, increasing efficiencies to significantly lower LED lighting defect rates. This technology ensures, creating higher quality and more stable LED lighting products, for the delivery of best quality products to end-users, and finally, wider adoption of LED technology worldwide."

ICTA is the most efficient thermal analyzer, offering the critical thermal characteristics such as junction temperature and thermal resistance for semiconductor devices, including LEDs, High-Electron-Mobility Transistor (HEMT), Metal-Oxide-Semiconductor Field-effect Transistor (MOSFET), and Insulated-Gate Bipolar Transistor (IGBT).

ITRI has given the first technology transfer and patent licensing contract to leading global manufacturer MPI Corporation. The company is engaged in technology cooperation that has yielded the world's first transient thermal structure and in-line thermal resistance analyzer. This equipment is expected to get into the mass production stage by the end of 2014, which will both satisfy R&D and production authentication requirements.

"Future LED illumination applications will require greater power needs in packaging, meaning that thermal resistance will become increasingly important. Since heat impacts the life and quality of a product, accurate measurement of LED thermal resistance will have a clear impact on product quality and cost," said Anderson Fan, vice general manager of equipment operation division at MPI Corporation. "This cooperation with ITRI has successfully brought thermal resistance measurement technology out of the laboratory and to automated machinery. In the future, thermal resistance will be able to be measured in an automated process on the production line, significantly boosting the quality of LED products."

According to the U.S. Department of Energy, widely adopting LED lighting could save the country $265 billion and reduce electricity demand by one third in the next 20 years.1 ICTA's powerful, cost efficient and high performance solution can make this technology a more attractive choice for home and office lighting.

Commercialization of ICTA Technology is currently underway. The technology is available for transfer to companies worldwide. ITRI holds seven international patents on ICTA Technology including in Taiwan, China, and the U.S. Companies interested in licensing ICTA Technology should contact ITRI at 415 986 7212 or ITRI@graham-associates.com for more information.

About Industrial Technology Research Institute (ITRI):

The Industrial Technology Research Institute (ITRI) is a nonprofit R&D organization engaged in applied research and technical services. Founded in 1973, ITRI has played a vital role in transforming Taiwan’s economy from a labor-intensive industry to a high-tech industry. Numerous well-known, high-tech companies in Taiwan, such as leaders in the semiconductor industry TSMC and UMC, can trace their origins to ITRI.

ITRI focuses on six research fields including Information and Communications, Electronics and Optoelectronics, Material, Chemical and Nanotechnology, Medical Device and Biomedical, Mechanical and Systems, Green Energy and Environment. ITRI has aggressively researched and developed countless next-generation technologies. In addition, ITRI’s Flexible Electronics Pilot Lab and Nanotechnology Lab provide international-level research platforms where R&D can be conducted jointly with partners. ITRI has also seen significant growth in its intellectual property and new ventures in recent years and is devoted to creating a model that will make Taiwanese manufacturing even more competitive in the international arena.