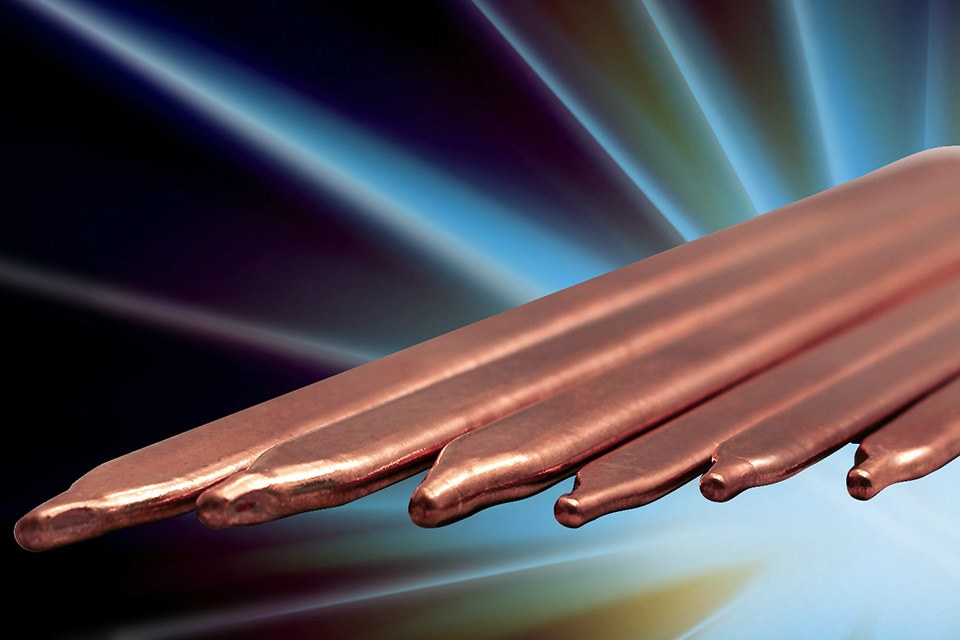

ATS' New Round and Flat Profile Heat Pipes Cool Hot Components at Minimal Temperature Difference

Advanced Thermal Solutions, Inc., ATS, has introduced a series of copper heat pipes for transporting power dissipation away from hot electronic components. Thirty-three round and flat profile heat pipes are available to meet application needs.

The new ATS heat pipes transfer component heat to heat sinks with minimal temperature difference. They also distribute heat efficiently across the length of heat spreaders. Liquid in the heat pipe turns to vapor by absorbing heat and removing thermal energy from hot component surfaces. The vapor travels to the cold end of the pipe where it releases latent heat and condenses back to liquid. The liquid returns to the hot interface along an internal copper wick to provide continuous thermal management.

The cold end of the copper heat pipe attaches easily to most heat sinks, providing effective cooling when a heat sink can’t be applied directly on a heat source. All heat pipes are easily hand or machine-shaped to meet application needs. They can be friction fit, clamped, soldered, or adhesively attached.

Each model in the new heat pipe series has been characterized by ATS for both thermal resistance and maximum heat transport capability. The transport property is determined as a function of the working temperature and the pipe’s angle of inclination.

Every heat pipe consists of a sealed copper tube, internal copper wick structure, and distilled water as its working fluid. Round profile heat pipes come in lengths from 200-300 mm and diameters from 4.0-8.0 mm. Flat profile heat pipes range in length from 100-250 mm, widths from 8.2-10.5 mm, and heights from 2.5-4.5 mm. Weights range from 8-33 grams. They are effective in temperatures ranging from 30-120°C. Other fluids and sizes can be accommodated with custom heat pipe designs by ATS.

The heat pipes are available separately from ATS or in thermal solutions integrating the company’s widely-used Push Pin and maxiFLOW heat sinks The new heat pipes have no moving parts and require no maintenance. They can be ordered online at Qats.com or by calling Advanced Thermal Solutions: 781-769-2800.

About Advanced Thermal Solutions:

Advanced Thermal Solutions is a leading engineering and manufacturing company supplying complete thermal and mechanical packaging solutions from analysis and testing to final production. The company provides the maxiGRIP and superGRIP heat sink attachment systems for use with high performance maxiFLOW heat sinks. Qats.com