Cambridge Nanotherm Ltd Launches Its Industry-Leading Nanotherm™ Metal-Backed PCB Series

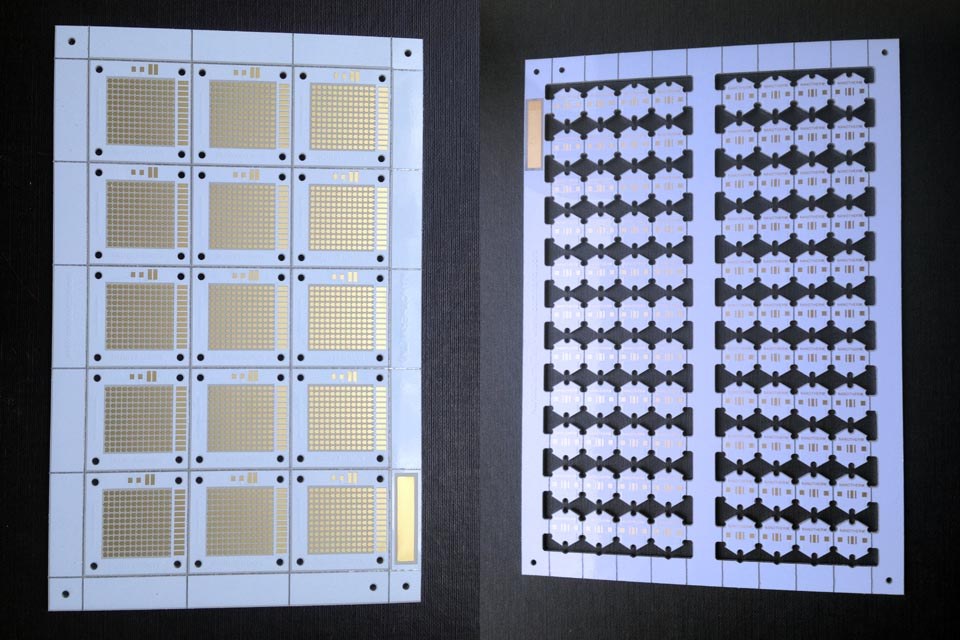

Cambridge Nanotherm has launched Nanotherm™ MBPCB (Metal-Backed Printed Circuit Board), the culmination of two years of innovative development using Cambridge Nanotherm’s ceramic dielectric technology. This has resulted in an innovative thermal management material, with a dielectric thermal conductivity of 7 W/mK, which is able to significantly reduce LED die temperatures – even in the most thermally challenging Luminaire designs.

The company’s core IP exists in its unique process for converting Aluminium into Alumina (Aluminium Oxide [Al2O3]). This process allows the surface of an Aluminium plate to be converted into a layer of Alumina – which acts as a dielectric. A range of standard Printed Circuit Board fabrication techniques can then be used to apply circuitry onto the nano-ceramic dielectric layer.

“This nano-ceramic dielectric not only provides excellent electrical isolation, but also has a thermal performance which is much improved over the standard filled epoxies used for conventional thermal management dielectrics”, explained Dr Pavel Shashkov, CEO and Founder, Cambridge Nanotherm. “The ceramic layer has a bulk thermal conductivity of 6-7 W/mK and can be applied in thicknesses as low as 10 micron, resulting in a thermal resistance as low as 0.012°Ccm2/W.”

Independent testing of the Nanotherm™ MBPCB, in LED lighting applications, has shown that it offers a 20% reduction in substrate thermal resistance over some of the best available metal-backed PCBs. In back-to-back comparison testing with other metal-backed PCBs, LED temperatures were seen to be reduced by as much as 20°C, thus allowing designers to increase component density and power or give longer lifetime guarantees.

Cambridge Nanotherm sees its new thermal management material as an important addition to its customers’ material toolboxes – reducing the need to move to more expensive Copper-backed PCBs as thermal challenges arise.

Steven Curtis, Nanotherm’s Head of Product Development added: “We are quickly moving ahead with the development of our next generation product, Nanotherm™ PLUS, which, by direct metallisation of the nano-ceramic layer, produces an MBPCB with a thermal performance approaching that of Aluminium Nitride (AlN) ceramic tile.

“This substrate material will offer an alternative to those designers who need the excellent performance of AlN in their packages or arrays, but need to meet very tight cost targets.”

About Cambridge Nanotherm Ltd:

Cambridge Nanotherm Ltd, was established in 2010 to commercialise proprietary nano-ceramic technology for use in the electronic industry. The company was the UK winner of the 2011 Clean Tech Open Competition, sponsored by Silicon Valley Bank. The technology has been developed by internationally renowned scientists who have a track record for setting up successful high technology companies and commercialising innovative IP. The company was supported by TSB, EEDA and ERDF grants and was a member of the Carbon Trust Fast-track Entrepreneur Programme. Cambridge Nanotherm Ltd is financially backed by Enso Group. www.camnano.com