Fischer Elektronik Introduces New Active Heat Dissipation System for LEDs

Fischer Elektronik is now specifically expanding its comprehensive product portfolio for weight-sensitive applications with an active LED heat dissipation concept. It allows easy mounting for Zhaga-compatible modules and uses a special low-noise fan.

The service life of LEDs directly depends on their heat dissipation concept. Drastic temperature fluctuations will considerably shorten it, and overstepping the permitted chip temperature has a direct impact on the light yield. The use of extruded aluminium heat sinks for free convection already serves as an effective LED heat dissipation concept today.

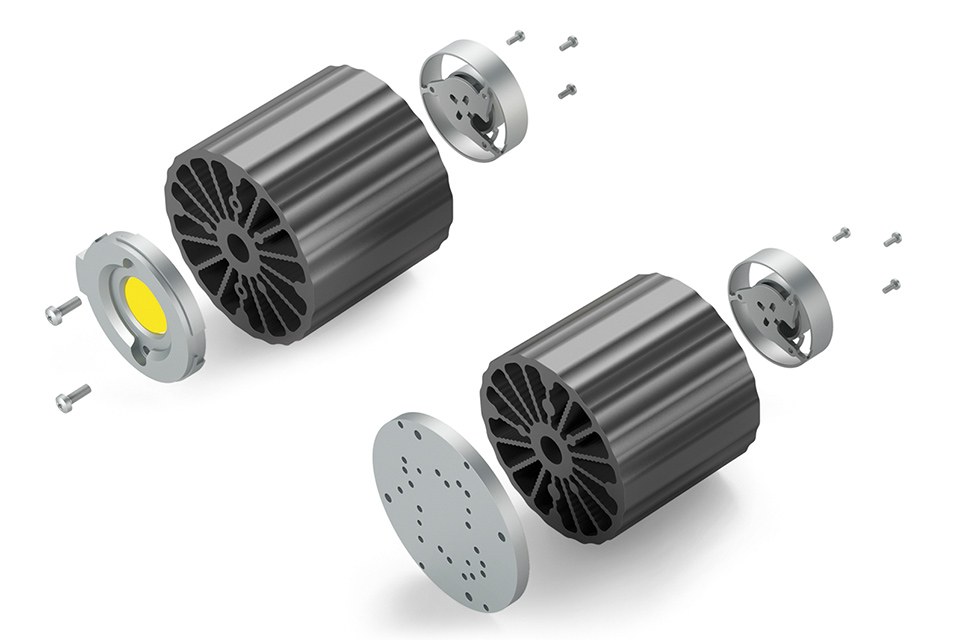

With an active LED heat dissipation concept under the article number LA LED 68, Fischer Elektronik expands its comprehensive product portfolio for weight-sensitive applications. The base is made from a thermotechnically optimised aluminium hollow-chamber profile. Zhaga-conform LED modules can be directly bolted to the front of this by way of additional threads. There is also the option of fastening various LED modules from different manufacturers, as well as their holder systems, to the pre-threaded mounting plate with the help of an adapter screwed into the base section.

A special low-noise fan motor in a round design is integrated in and fastened to the back of the base section. The motor has a double slide bearing and is designed for the special requirements of LED applications where noise and lifetimes are concerned. Mechanical processing, cover panels with ventilation slits, customised designs and surface coatings are also all available for your application.

The product specialists at Fischer Elektronik www.fischerelektronik.de will be happy to assist you with any queries you may have or any additional information you require.

About Fischer Elektronik:

Fischer Elektronik is a leading producer of thermal management solutions for the whole electronic industry. High Power LED applications are our latest field of activities with all our almost 40 years of experience in the background. On the edge of this new technology, we can give support right from the start with the knowledge of our application engineers and as well as with our sophisticated 3D simulation and drawing programmes. Our core capabilities: - all articles in standard or customs design versions available - own surface treatment facilities - wide standard programme (more than 700 profiles) of extruded heatsinks - machining according to customers request - heatsinks for LED, cooling aggregates and thermally conductive foils. We also have a large selection of connectors for PC boards that is complemented by a diverse range of casings with functional designs. In addition to standard catalogue items, we also provide customer-specific solutions in all areas.