Fisher Elektronik Provides Housings for Linear LED Modules

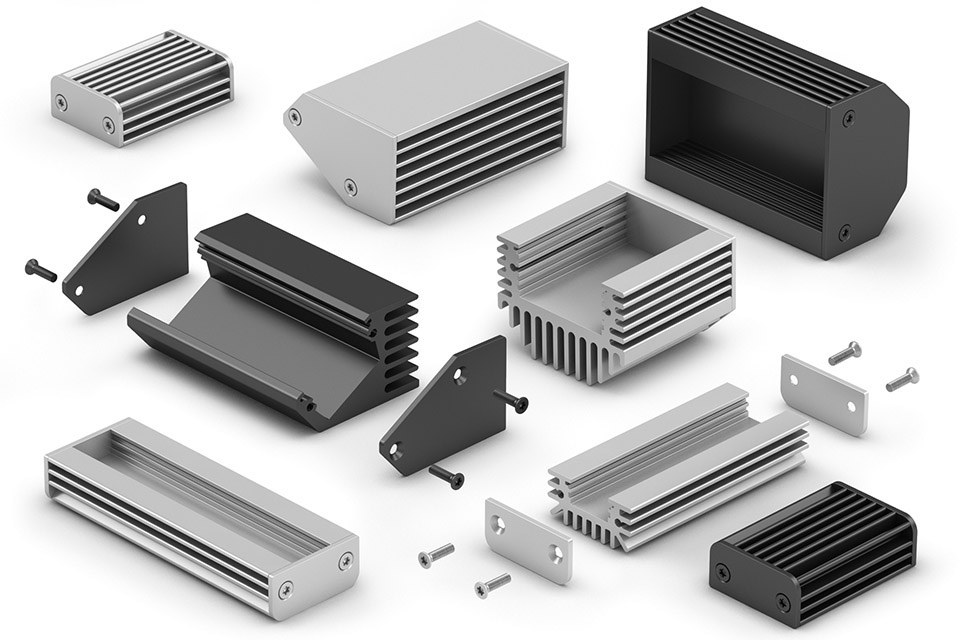

Fischer Elektronik has expanded its product range of heat discharge housings by adding an additional housing series, the G LED range. In order to avoid overheating of LEDs, these special housings offer efficient heat management, which help to optimise the heat discharge.

Thanks to their wide range of applications, modern LED lighting systems have gained general acceptance in many areas, such as for example industrial design, architecture, the internal furnishings sector and advertising as well as many others. Despite an improved level of efficiency, a large part of the electrical power with LEDs is still converted into heat. As result, an efficient heat management is still impoartant.

The new U-shaped housing profiles, which are open on one side, have integrated guide grooves to take LED line modules and slot-in cover plates or plexiglass discs, which can vary in their material thickness. The plexiglass discs and LED line modules are fixed by means of the lid plates at the front, which are screwed onto the housing profile. The housing profiles also have external cooling ribs, which ensure that the heat is fully discharged to the environment.

The G LED housing series is available as standard in three different versions and three lengths (50, 80, 100 mm), as well as in two surface versions (natural-coloured and black anodised). Other lengths, surfaces and types of mechanical processing and printing can be manufactured to the customer's request.

The product experts at Fischer Elektronik will be happy to answer your queries and provide you with further information

About Fischer Elektronik:

Fischer Elektronik is a leading producer of thermal management solutions for the whole electronic industry. High Power LED applications are our latest field of activities with all our almost 40 years of experience in the background. On the edge of this new technology, we can give support right from the start with the knowledge of our application engineers and as well as with our sophisticated 3D simulation and drawing programmes. Our core capabilities: - all articles in standard or customs design versions available - own surface treatment facilities - wide standard programme (more than 700 profiles) of extruded heatsinks - machining according to customers request - heatsinks for LED, cooling aggregates and thermally conductive foils. We also have a large selection of connectors for PC boards that is complemented by a diverse range of casings with functional designs. In addition to standard catalogue items, we also provide customer-specific solutions in all areas.