Most Thermally Efficient and Most Cost-Effective MCPCB Enters General Lighting Market

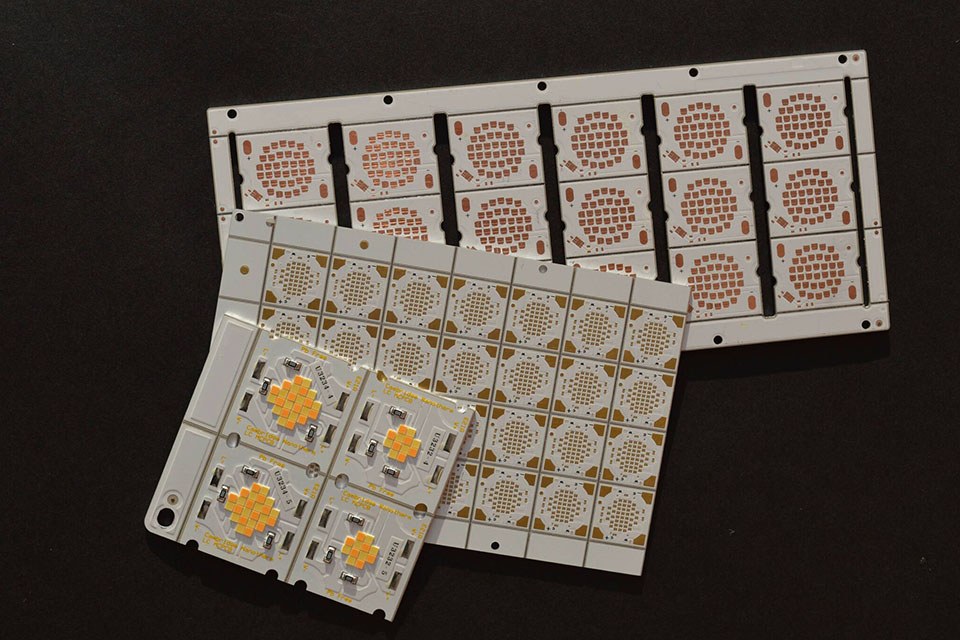

LED thermal management innovator Cambridge Nanotherm today launches Nanotherm MCPCB — the lighting industry’s most thermally-efficient and most cost-effective metal-clad PCB. Thanks to a recent technological breakthrough regarding the company’s patented electro-chemical process, which creates a 20μ-thick dielectric layer of alumina atomically bonded to the aluminium board, Cambridge Nanotherm has been able to radically drive down the cost of Nanotherm MCPCB, which is now available to customers at a lower cost but better efficiency than even the best MCPCBs on the market. Samples are available immediately.

Nanotherm MCPCB offers an industry-leading thermal efficiency of 120 W/mK, offering electronics designers better than 56% of the thermal conductivity of an aluminium plate. Nanotherm MCPCB also offers a robust stability at an operating temperature of 130°C, and is lead-free solder compatible and ROHS and UL recognised.

This price reduction brings Cambridge Nanotherm’s revolutionary ceramicised aluminium boards, which used to be only affordable for high-power applications, solidly within the price range of all general lighting applications for the first time.

Cambridge Nanotherm sales and marketing director Mike Edwards said: “The fact that our Nanotherm MCPCB is now available to the general lighting market is testament to the hard work and research our scientists have put in over the past three years. One of our greatest strengths at Cambridge Nanotherm is that we can easily ‘swap in’ our thermal management technology to customers’ existing MCPCB machining processes, but we are particularly dominant when it comes to integrating CSP designs into tuneable white solutions. Where a company may have previously used a traditional MCPCB, now they can use Cambridge Nanotherm’s technology, gaining greater thermal efficiency at a lower price, with no costly retooling and minimum integration effort.”

Nanotherm MCPCB is now available for prototyping and mass production orders. Industry-standard copper finishes, solder mask and feature sizes are all available - as are double-sided substrates containing a dielectric surface and wiring traces on both sides of the MCPCB.

For further information visit http://www.camnano.com/

About Cambridge Nanotherm:

Cambridge Nanotherm manufactures the most efficient thermal management technology for high-powered electronics. A patented electro-chemical oxidation (ECO) process creates a super-thin nanoceramic layer on the surface of aluminium to form a dielectric with exceptionally high thermal conductivity. This combination of the industry’s thinnest dielectric with the highest thermal conductivity yields the lowest thermal resistance and provides the platform for Cambridge Nanotherm’s core products.

Cambridge Nanotherm’s thermal management technology provides the foundation for applications ranging from LED packaging and modules, to automotive and power electronics applications.

Cambridge Nanotherm was set up in 2010 to commercialise the electro-chemical oxidation process with innovative IP, and is backed by Enso Ventures.