Bridgelux Introduces Ground Breaking New High Performance Array LED Platform

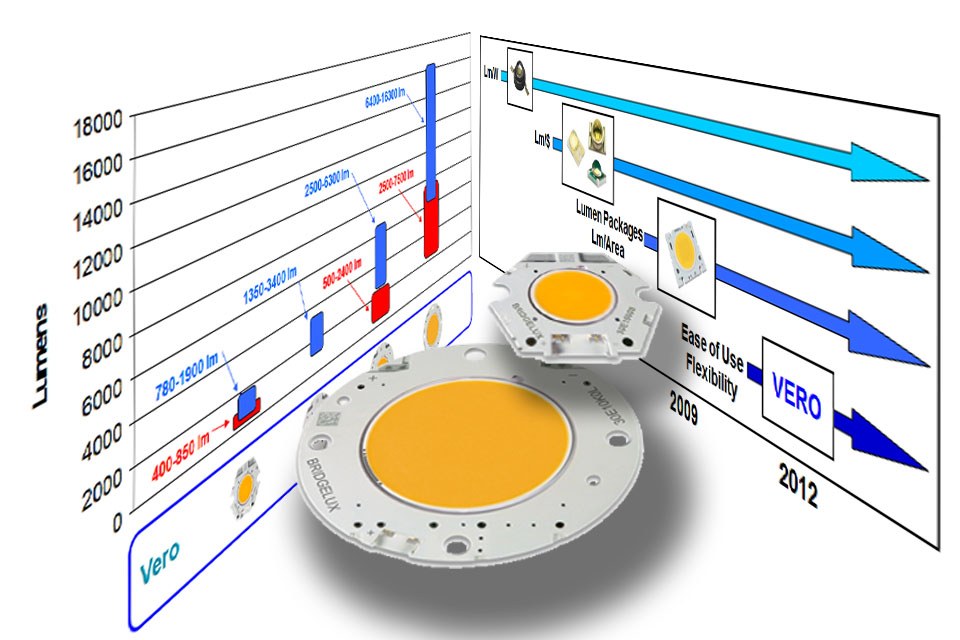

Today, the well-known array LED specialist, Bridgelux, announced that it is extending its existing portfolio with a game-changing next generation product line. Bridgelux is convinced that the new Vero (BXRA-5) LED will add a new quality to array LEDs. In addition to the three currently recognized criteria; efficiency, costs per Dollar and lumen per package, the new concept offers ease of use and flexibility. Combining these four disciplines will optimally advance the mass adoption of solid state lighting.

Vero design goals could be fully realized:

- Efficacy

– 110+ lm/W 3000K 80 CRI at rated current

- Design Flexibility

– Enable design optimization on lm/W, lm/$, lm/area or any combination

- Flux Density

– Higher lumen density to enable improved optical control and narrow beam optics for precision lighting and miniaturized luminaires

- Light Quality

– Radial die spacing to improve optical fill and light beam quality

– 3SDCM Color control standard

- Ease of Use

– Improve solder capacity and non-soldering options for connectivity

– Improve inventory control and reduce SKU counts for arrays and drivers

- Cost of Light

– Engineer platform to reduce cost on day one and into the future

The Vero platform provides complete application coverage from four form factors, delivering the light output and color temperatures required for retail, hospitality, commercial, industrial, residential and outdoor lighting applications. The arrays will initially be available with performance ranging from 800 lumens in warm white (3000K) up to 20,000 lumens in cool white (5000K) with multiple CCT and CRI options, including the 97 CRI Decor product option.

The brand new and innovative step:

“What we have done is, in effect, separated the “engine” from the “body.” BXRA-5 is still an MCPCB based chip-on-board product, but we have decoupled the mechanical interface and mounting features from the engine, or in other words, the ‘body’ from the ‘heart’ of the array,” explained Jason Posselt, Bridgelux Vice President of Marketing. “We will deliver the product as an assembly, with the two components reflow soldered together in our factory. This ensures integrity and reliability and frees the client from the task of soldering on a MCPCB.”

The BXRA-5 is an MCPCB based C.O.B. and the plastic component is, in effect, an insert molded lead frame. Both technologies per se are nothing new, but the skillful combination of these two technologies has its advantages and opens new opportunities. The solder pads are mounted on top of plastic, thermally isolated from both the MCPCB and the heat sink. No longer does the array need to be placed on a hot plate for soldering – it can even be pre-mounted to the heat sink prior to soldering. We have also designed a connector port directly into the plastic to enable solder free electrical connectivity.

Bridgelux made some significant changes in the array design, as well to foster the ease of use and flexibility. “While the new design also leads to more lm/W and better lm/$, it increases lm/area dramatically and, in parallel, extends flexibility, makes handling more convenient and reduces driver issues.” Mr. Posselt is very enthusiastic about the new product.

There are two key measures. First, the BXRA-5 is based on a new and improved MCPCB technology. Second, Bridgelux is now using an increased quantity of slightly smaller LED chips. This enables greater flexibility in how the chips can be placed in the package, resulting in a radial die pattern for improved optical fill and light quality as well as a significant improvement to the thermal uniformity of the package. This improved thermal uniformity is part of what enables these products to be driven reliably under a higher current operation of up to two times the nominal rated test current.

The engineers have not only managed to neatly configure the arrays and align them with industry standard drive currents and voltages but they also managed to reduce the complexity and quantity of drivers required when using this family of products.

Jason Posselt also said, “While the plastic component is just an insert molded lead frame, it could also be considered as a printed circuit board because electronic traces can be routed through the material. While we don’t know exactly what will be required in the future, we do expect to see convergence occur in solid state lighting, just as it has with consumer electronics. As such, it is likely that we will see a need to incorporate additional functions, sensors, communications, or other features into the LED light engine.”

Asked for other ideas like a high voltage alternating current (HV-AC) version or if GaN-on-Si technology will also be part of the Vero Module, Mr. Posselt said, “While we are thoroughly checking out and discussing the demands for that, we don’t know exactly what will be required in the future. But at the moment neither HV-AC versions nor the use of GaN-on-Si based LEDs are planned.”

For additional information check out www.led-professional.com or visit www.bridgelux.com

About Bridgelux:

Bridgelux is a leading developer and manufacturer of technologies and solutions transforming the $40 billion global lighting industry into a $100 billion market opportunity. Based in Livermore, California, Bridgelux is a pioneer in solid state lighting (SSL), expanding the market for light emitting diode (LED) technologies by driving down the cost of LED lighting systems. Bridgelux’s patented light source technology replaces traditional technologies (such as incandescent, halogen, fluorescent and high intensity discharge lighting) with integrated, solid-state lighting solutions that enable lamp and luminaire manufacturers to provide high performance and energy-efficient white light for the rapidly growing interior and exterior lighting markets, including street lights, commercial lighting and consumer applications. With more than 650 patent applications filed or granted worldwide, Bridgelux is the only vertically integrated LED manufacturer and developer of solid state light sources that designs its solutions specifically for the lighting industry. For more information about the company, please visit www.bridgelux.com