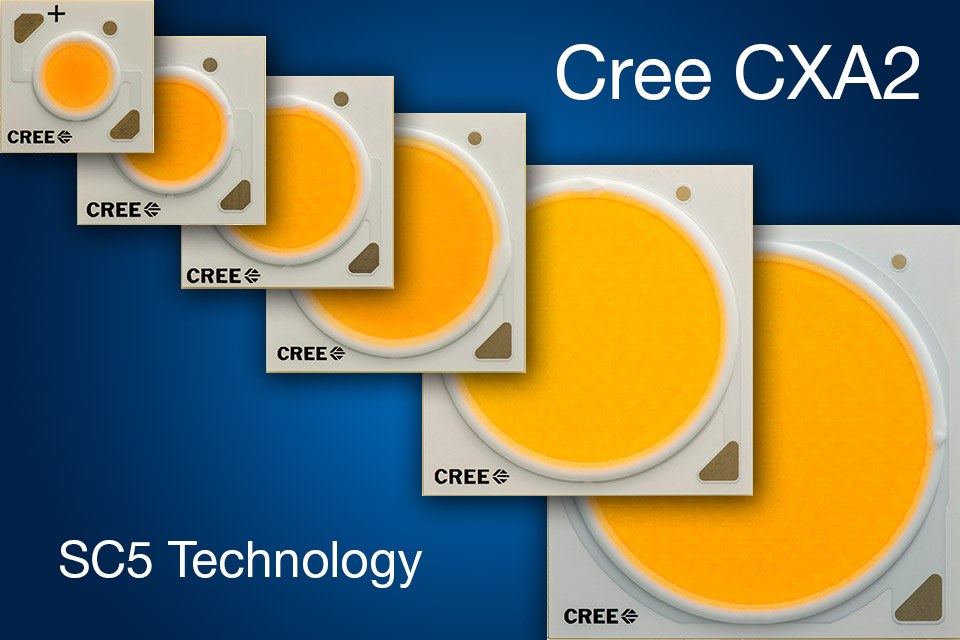

Cree Updates CXA Platform with SC5 Technology To Enable Significant System Cost Savings

Cree, Inc. introduces a new addition to its industry leading CXA LED array family, CXA2 LED arrays, delivering up to 33 percent higher efficacy in the same form factors. Utilizing elements of the Cree SC5 Technology™ Platform, this improvement in lumen density enables better performance and radically reduces system size and cost. The new chip-on-board (CoB) LEDs allow lighting manufacturers to rapidly deliver more innovative solutions for applications such as track, downlight and outdoor lighting.

“We are working together with Cree to evaluate their latest CoB technology,” said Massimo Parravicini, R&D director of Reggiani Illuminazione. “I believe that the new CXA2 LED arrays, which deliver excellent performance in such small LES [light emitting surface], would be a great solution for the new generation of indoor luminaires we are currently developing.”

With the new CXA2 LED arrays, lighting manufacturers can achieve the same or better performance with a smaller LES compared to earlier products. For example, a 3800 lumen output from a larger 19 mm LES LED can be replaced with a smaller 12 mm LES LED, resulting in up to 60% system cost savings from lower LED, mechanical and optic material costs.

“The new CXA2 LED arrays make it possible for lighting designers to radically reduce system costs in the next generation of industry-leading lighting products,’ said Dave Emerson, vice president and general manager for Cree LEDs. ‘By giving our customers innovative LED solutions instead of incremental LED improvements, we enable them to differentiate their products in the marketplace and deliver more value to their end customers.”

CXA2 LED arrays share the same physical design as earlier arrays, allowing lighting manufacturers to leverage the existing optical, mechanical and electrical design elements to accelerate time to market without additional cost. LM-80 data is available for all CXA2 LED arrays for lighting manufacturers seeking Energy Star® qualification. The CXA2 LED arrays are also UL®-recognized components and feature a level 4 rating.

Through improvements in the light conversion process, Cree has reduced LED-to-LED color variations and, among other options, offers CXA2 LED arrays in 2-step and 3-step EasyWhite® bins. XLamp® CXA2 LED arrays are available in 2700 K to 6500 K, CRI options of 70, 80 and 90 with multiple voltage options in LES ranging from 6-30 mm with a lumen range of 250-19,000 lumens to address a wide variety of applications. Product samples are available now, and production quantities are available with standard lead times.

Technical discussion about the SC5 technology and the new CXA2 platform

In a product preview, given for LED professional by Paul Scheidt, Leader of Product Marketing at Cree, several aspects of the new SC5 technology and product release were discussed. Since the introduction of the first SC5 technology based components, the XLamp MHB, in September 2014, all relevant product families followed. The launch of the CXA2 Array LEDs is the last step in this line. The introduction of this new technology was always promoted with lowering system costs, but how should that be achieved and how does this technology contribute? Are there pitfalls and drawbacks?

Cree's proposal for cost savings is to reduce the number and size of components in a system, and here primarily to reduce the costs for peripheral components and not for the LEDs. When LED professional asked Paul Scheidt if this approach works well in any case and for any application, he stated: "There are certainly some applications like troffers where this approach might not be fully applicable, but in more than 85% of the market relevant applications it is and leads to significant cost reductions." Then he explains, "As heat sinks are meanwhile often the component that contributes most to the system costs, a reduction in size is very effective. In parallel PCB size and the number of optics is reduced, leading to additional savings. Let me demonstrate this with an example.” Mr. Scheidt showed a slide in his presentation, associated to this topic and continued “We helped a client to redesign a roadway light that originally used XP-G2 LEDs with our new XHP50. While maintaining the same performance and reliability, 77% less aluminum for the heat sink, 78% fewer optics and 89% less PCB were needed. However, that's not all. In roadlighting the poles are the most costly part. With every kg that the lamp becomes lighter, $25 can be saved. We expect a similar potential for redesigns using our new CXA2 series in their applications."

Coming back to the question how the SC5 technology leads to this savings, there are several reasons to mention: Power density and hereby lumen density of the products were heavily increased. Using the same footprint and light emitting surface (LES), for instance the XLamp XHP50 can provide up to 2500 lm at 132 lm/W compared to an XM-L2 with 1200 lm at 116 lm/W. But this alone does not explain the savings. A good part of the savings has been achieved by driving the LEDs harder and operating them at higher temperatures. For instance in the before mentioned example, instead of 14 XP-G2 LEDs only three XHP50 LEDs are consuming the same amount of power, namely 25 W. Tsp of the new concept increased to 76°C from originally 51°C.

These facts caused some crucial questions regarding optical properties, lifetime and reliability of the proposed strategy. When LED professional asked Paul Scheidt if he not apprehends that increased lumen density and a reduced number of light sources might cause glare. He argued convincingly “It is true that glare can be an issue in bad designs, but high lumen density is nothing new to the industry. – Just think on HPS or HID lamps with some 100 watts. – For high quality luminaire manufacturers this is absolutely no issue, they are used to handle high lumen densities and can prevent glare very well.”

Thus, LED professional faced Mr. Scheidt also with the issue that efficiency, but especially reliability and lifetime should not be sacrificed. He dispelled these doubts when he explained “That is absolutely correct. One of the most important advantages of our new SC5 technology is that efficiency, reliability and lifetime can be maintained or even improved despite higher solder point temperatures (Tsp). For example, the MH series LEDs provide an L90 of 35 khours even at 105°C Tsp. If we are looking on the exemplary redesigns, we can see that performance and lifetime don’t suffer, even if the Tsp increases by 20-25°C. Regarding reliability, I want to bring also into mind that a reduced number of components results in a reduced number of solder points which are one of the most frequent failure sources.”

What makes the difference and leads to the savings finally is not one single attribute or parameter. It is the combination of all these improvements. The implementation of this technology into the CXA2 product line is expected to have the same effect for their applications as the implementation in the XHP and MH series had in their fields. Finally, one very important advantage of the new CXA2 series is that in many applications the LES can be reduced. For instance, the new CXA2–1820 offers similar performance like the CXA–2540, and thus allows a reduction of the LES from 9 mm to 6 mm. Beside all above discussed advantages of the SC5 technology, this makes also optical design easier and optics more efficient, especially for narrow angles.

Please visit www.cree.com/cxa2 to learn more.

About Cree:

Cree is leading the LED lighting revolution and making energy-wasting traditional lighting technologies obsolete through the use of energy-efficient, mercury-free LED lighting. Cree is a market-leading innovator of lighting-class LEDs, LED lighting, and semiconductor products for power and radio frequency (RF) applications.

Cree’s product families include LED fixtures and bulbs, blue and green LED chips, high-brightness LEDs, lighting-class power LEDs, power-switching devices and RF devices. Cree® products are driving improvements in applications such as general illumination, backlighting, electronic signs and signals, power suppliers and solar inverters.

Please refer to www.cree.com for additional product and company information.