Lackwerke Peters Showcasts New and Proven Products at SMT

Especially predestined for various LED applications, Lackwerke Peters presents their crystal-clear embedding with casting resins VT 3402 KK-NV, conformal coatings ELPEGUARD® SL 1307 FLZ/2, black and white opaque ELPEGUARD® conformal coatings SL 1347 and SL 1397 and black and white solder resists ELPEMER® SD 2491 SG-TSW-R4, SD 2496 TSW and SD 2446.

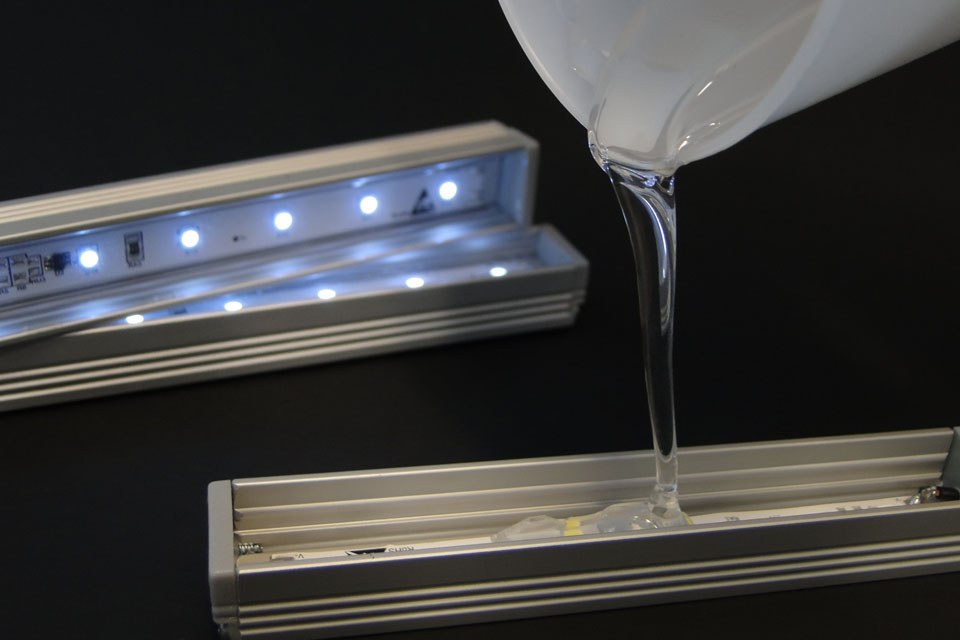

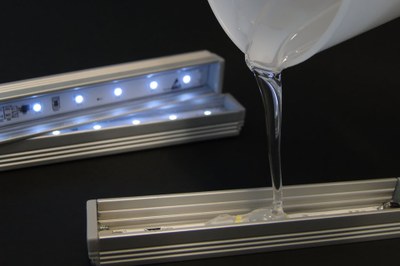

Crystal-clear embedding with casting resin of the series VT 3402 KK-NV:

Encapsuling with the crystal clear casting resins of series VT 3402 KK-NV enables the reliable use of LEDs in outdoor. Due to the extremely high transparency, even with weathering and UV radiation, these resins are used in applications that demand the highest optical properties.

The unusual high water and hydrolysis resistance and high mechanical strength even allow underwater use. With a turbidity paste and different dye concentrates a specific color or light-scattering effects can be achieved.

Particularly for the use in aluminum profiles VT 3402 KK-ALU was designed with a significantly improved adhesion on aluminum respectively Aluminum profiles. With this solvent-free two-component system significantly improved adhesion values can be achieved without further pretreatment compared to previously used PUR - casting compounds.

The flammability setting of VT 3402 KK-SB corresponds to the best flame class UL 94 V-0 and can therefore be used in fire-prone areas (e.g. for emergency lighting).

The “sprinter” among the conformal coatings:

Fast drying at room temperature and easy to repair, with special adjustments for special tasks - the ELPEGUARD® conformal coatings of the series SL 1307 FLZ/2 are a good choice all round.

These yellowing-resistant conformal coatings for assembled printed circuit boards can be easily soldered-through or removed by the product-specific thinner.

The thixotropic version SL 1307 FLZ/3 ensures high climatic resistance by optimal edge coverage even on sharp-edged component leads.

The ultra-thixotropic adjustment ELPEGUARD® SL 1307 FLZ-T (also available in cartridges) can be easily and precisely applied by means of a dispenser.

This way, dams can be built around connectors, components and pads to prevent the penetration or spreading of a subsequently applied conformal coating (dam and fill).

ELPEGUARD® SL 1307 FLZ-S in practical spray cans is always to hand for service and repair work and for the fast coating of pilot and low-volume series'.

Black and white opaque ELPEGUARD® conformal coatings:

Selective coating with the white opaque conformal coating ELPEGUARD® SL 1397 ensures maximum luminous efficacy: The LEDs are left uncoated while dark components are hidden, thus amplifying the luminous efficacy (reflectivity) considerably. As key characteristics, ELPEGUARD® SL 1397 boasts very high reflectivity ratings (> 0.9 at 460 nm) along with high UV and thermal stability.

Application of the black opaque, mat conformal coating ELPEGUARD® SL 1347 ensures a strong contrast to the base material. With this material, it is possible to coat selected areas of assemblies (which are usually coated with green solder resist) in black to achieve a strong contrast of the LEDs to the non-reflective base material. This is of particular advantage in applications with emphasis on high optical quality, such as information panels, traffic lights, etc.

Black and white solder resists for optoelectronics:

If the colour stability of LEDs is of particular importance, the substrate around the illuminants needs a colour-stable coating which improves the radiation characteristics of the LEDs. By using pure white, yellowing resistant lacquers with high covering power, you achieve a high light efficiency whereas a black coated substrate can increase the contrast to the LEDs.

From the area of the high-resolution photoimageable solder resists the latest development ELPEMER® SD 2491 SG-TSW-R4 exhibits a high remission factor of 92 % at 460 nm as well as low ΔE values with exceptional yellowing resistance, even at thermal stress. As black extension of this series the colour-stable version SD 2441 SM is available.

Expecially stable under UV radiation are the thermal curing 2-pack solder resists SD 2496 TSW and SD 2446. Consequently they are particularly suited at the exposure to sun light at the subsequent use.

For additional information please contact Lackwerke Peters at peters@peters.de or visit www.peters.de