Spark Launches LED Lighting Solution for Warehouse

As the integration of transportation, warehousing, freight forwarding and information industries modern logistics is a complex service industry, modern logistics is a product of economic globalization and play an important role in promoting economic globalization. Warehousing is logistics enterprises’ core component and important pillar. It plays a vital role in the logistics system. In recent years, Warehousing’ s output growth rate continuous quick than the national growth rate of GDP, The growth of cargo throughput reached an average of nearly 20%, Warehouse business shows rapid development momentum.

In the context of logistics industry’ s unprecedented prosperity, Global logistics giants began to establish a high degree of automation, multi-functional, high-density modern logistics hub to improve the efficiency of logistics operations, which led to the warehouse lighting be needed grow 20% per year directly. Light function requirements of warehouse lighting is from the most basic "there is light," upgrading to high-quality, highly efficient and energy efficient LED lighting system to improve the efficiency of logistics operations, while play a crucial role in reducing the failure rate, to protect job security and reduce operating costs.

According to the height of the warehouse building, lighting installation can be divided into low roof, centre roof, high roof. Generally low roof height is less than 5 meters; the centre roof height is 5 to 10 meters; high roof height is 10 meters or more, need to use more than 300W lamps.

The Characteristic of lighting in Warehouse

Energy is shorter day by day in the current year, so the saving of industrial lighting system is good trending absolutely. Industrial lighting in high quality can not only fit the extreme environment in kinds of factories, cut down energy depletion, but also make a comfortable visual environment, help workers to alleviate fatigue of long time work, keep good work condition, as a result, production efficiency and pass rate are improved, working errors and safety accidents are cutted down, finally improve the performance of enterprise value.

For lighting, should be based on visual requirements, operating conditions and environmental, select the appropriate illumination, appropriate lighting brightness distribution and uniformity, to reduce unnecessary shadows, so that the visual space is clear; correct selection of illuminant and lamps, limiting glare improve the safety of lighting operations, activities, requires no flash, to reduce irritability and anxiety; rational use light to reduce negative impact of heat and ultraviolet radiation on people and objects; deal with color and color rendering index, to coordinate the light to harmonious, to create a good color vision environment for work and life. Beautiful light environment Let people feel relaxed, comfortable when work, activities.

When change the light source, we should consider the requirements of environment and saving energy to choose the longer life time led chip. Reduce the human and material resources for the lamp; improve visual conditions. So make people feel relaxed and happy in the light and reduce light pollution.

Consideration of Warehouse lighting

Meet the requirement of night working

Lots of visual works should be processed in house, no matter in night or day, artificial lighting is needed. But there’s a problem, artificial lighting cannot compare with natural lighting, work errors’ rate increased, production efficiency reduced, because illumination and visual environment is not good enough. High illumination is required.

Regarding the visual effect, lighting placing should be based on lighting standard and wise planning, ensuring lighting standard, cut down the work efficiency reducing which is made by poor lighting. In a relatively dark environment to ensure a certain color rendering index of light, in order to increase the optical efficiency.

Meet the needs of the brightness, while gives a visual sense of comfortable

Warehouse ceiling and wall lighting effect relate to the area of room. Proportion of a small room ceiling in the Vision is small, degree of impact control is small, while the proportion of wall in the vision, degree of impact control is large, so the small room can use high reflectance wall, low reflectance of the ceiling. Conversely, large rooms use high reflectance of the roof, low reflectance of the wall. Through effective lighting arrangement, to achieve appropriate and balance illuminance, Lighting requirements are bright and clearly, no glare and no ghosting.

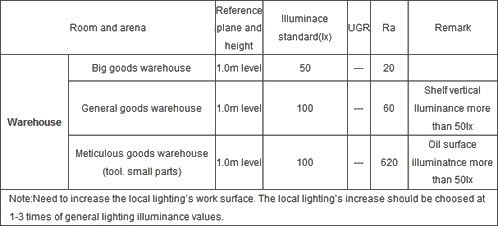

Warehouse Illuminance requirements are below:

Standard value of general lighting for industrial buildings

Traditional sodium lamp need preheat when start, If outage it need cooling and preheat then can start again. Current harmonics of Sodium lamp is high, the current send out harsh sound; temperature of lamp surface up to 360 ℃, the sodium lamp was significantly in high ambient environmental temperature; Low color rendering index, Color deflect under the lighting and poor visual effect. Serious harm since stroboscopic effect. Observation of small objects is blurring for naked eyes direct, glare, environmental suppressed. Clearly, People cannot be comfortable to work in the sodium lamp. It reduces work efficiency.

To save energy and be eco-friendly

As we all know, the major energy cost happens in industry. Reported by the media, the statistic shows 63.9% of the energy consumption came from industry in Guangdong province last year. Thus, it is significant for us to decrease industrial energy consumption and the widely promote the energy-saving lighting products.

The energy source situation in our country is getting more and more severe these days, the high consumption and shortage of energy have caused tremendous impact on manufacturing industry.

Take the Traditional Sodium Lamp (TSL) as an example. There are some disadvantages in it, such as the low lumen efficiency and intensity of illumination, unsatisfactory security, high consumption, low color rendering, high level of heat production, high change frequency and being unable to start it when the voltage is unstable.

The Application of Storage Light

Different storage lighting series should be chosen subjecting to different condition of the storage. We highly recommend our customers applying our LED High Bay Light to low ceiling storage, high power LED Light (SPT-140, SPL-288) to high ceiling storage.

Spark LED High Power Lighting adopts CREE LED from U.S.A., which performs high lumen efficiency as 85-90lm/w. Compared to Metal Halide, using our LED light saves over 75% energy. LED light possesses no pollution and almost 10 times longer life span than traditional light. It could supply plenty and uniform lighting for storages, production lines, sport fields, etc. People would still feel comfortable even being exposed for a long time period under LED light.

The external design of High Power LED light adopts special processing, which realizes the feature of both artistic and good heat dissipation and anti-corrosion.

Furthermore, High Power LED Light adopts wide voltage range from 100V to 240V to maintain the good function under the bad factors that could cause unstable lighting source.

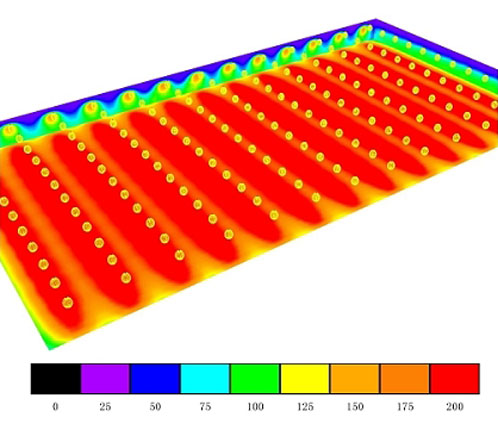

Light Distribution Effect in Storage

Result of the Spark Lighting design for low ceiling storage project for a storage height of 5m and an average illumination intensity of 200lux

In early January of 2011, all the SPARK products passed the test and were highly valuated by NIPPON EXPRESS. As the first corporation using LED- light- only in the world, SPARK helps NIPPON EXPRESS realize the goal of “Low Carbon Logistics”. See more details at: www.spark-oe.com.