Advanced Optical Plastics Materials for LED Lighting Applications by Styron LLC

Across a range of lighting solutions, Light Emitting Diodes have emerged as the clear choice for industry and consumers alike. Government regulations and consumer preference for more environmentally-conscious, energy-efficient products have caused manufacturers to develop solutions for the marketplace that offer new levels of energy efficiency, durability and long life. While the technology has evolved, so have the materials that go into the finished product. Claude Van Nuffel, Eric Wu, Peter Jackson and Marta Sans Peña from Styron LLC discuss versatility and one-of-a-kind properties of plastic – especially polycarbonate and polycarbonate blends – and why they have become the “materials of choice”.

The needs of manufacturers and fabricators for LED lighting components are extremely complex and typically include a variety of considerations such as:

• Protecting the costly LED light source

• Ensuring excellent ignition resistance

• Providing for long-term heat stability

• Meeting industry regulations and standards

• Accommodating movement and jarring

• Balancing clarity and diffusion

• Meeting thermal requirements

• Offering great design freedom and light weighting of parts

Very few materials can fulfill these needs. Polycarbonate and polycarbonate blends are now used in a variety of LED applications because they have the balance of properties to meet these demanding and varied requirements. The latest developments in managing this critical performance triangle between optimal light transmission, meeting haze requirements and flame retardancy will be discussed. Also shown will be how these developments resulted in the commercialization of new grade resins like Styron’s EMERGE™ PC 8830LT Advanced Resin. At the same time, the current state-of-the-art grades, and considerations when working toward UL 94 certification of V-0 (at 1.0 mm) will also be discussed.

Managing the Critical Performance Triangle

One crucial challenge in current resin developments in LED applications is achieving high flame retardancy (ignition resistance) in combination with the necessary optical properties, e.g. high transmission combined with the needed level of haze (e.g. low or high diffusion depending on the targeted application).

Figure 1: Achieving high flame retardancy in combination with the necessary optical properties

Figure 1: Achieving high flame retardancy in combination with the necessary optical properties

An LED can be a very bright, unidirectional source, and lamp/ luminaire manufacturers need materials that either make it possible for the light to shine directly through a surface for maximum brightness (high transmission, no diffusion), or create a uniform light distribution with no evidence of the light source (high haze, high diffusivity), for a more diffused effect. Adjusting material properties is often a careful balance because additives for light diffusion can impact light transmission, flammability rating and other properties. On the other hand, various technical routes to achieve outstanding flame ratings, will inherently not allow for good light transmission.

It is the lens or the enclosure of the LED source that plays a primary role of the amount of light that is transmitted or diffused. While achieving optical properties is of primary importance, requirements for flame retardancy also have to be met to accommodate these high-powered LED light sources that can operate at temperatures as high as 80-110°C. For lower voltage applications using Class 2 power sources with UL 94 HB and V-2 flammability requirements, polycarbonate, acrylics and styrenic-based resins such as SAN can be considered as materials for lenses, covers, and optics. However, for more demanding LED lighting applications where Class 1 power sources are used, the material requirement for optics and lenses is UL 94 V-0 and, in some cases, even UL 5VA.

Industry requirements are continuously increasing up to a point where a variety of light applications need to meet UL 94 V-0, 5VB and 5VA standards at reduced lens thicknesses. Since lighting applications are increasingly becoming thinner and thinner, customers are looking for grades that have the transparency of a ‘neat’ polycarbonate while offering good flame retardancy at a thickness of 1 mm. Furthermore, it is desired that these formulations are bromine- and chlorine free.

R&D Track to Create Flame-Retardant Polycarbonates with High Total Luminous Transmittance

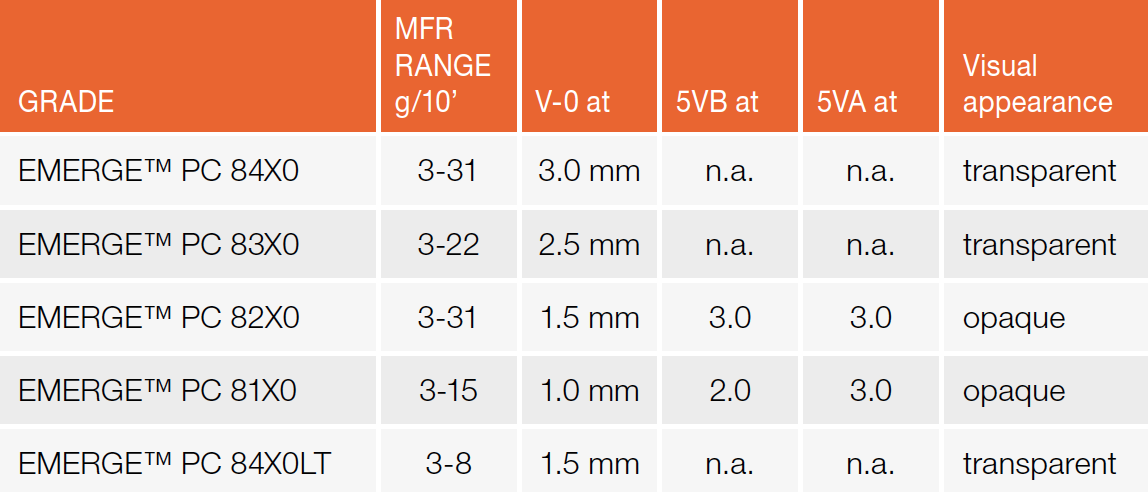

Current state-of-the-art polycarbonate compositions have been employed for various applications with balanced flame retardancy and/or transparency requirements. Examples of such polycarbonate compositions are described in Table 1. As shown in Table 1, the compositions meet a wide spectrum of property balances which find broad acceptance in the lighting market. However, there is need of further optimization, for instance, for transparent formulations that meet UL 94 V-0 at 1.0 mm, as well as for formulations which offer a high level of light transmission combined with a high level of light diffusivity, still meeting UL 94 V-0 at 1.0 mm.

Table 1: State-of-the-art (bromine- and chlorine free) polycarbonate compositions and their relative results in performance tests, key in today’s LED market (n.a.: not available; MFR: melt flow rate)

Table 1: State-of-the-art (bromine- and chlorine free) polycarbonate compositions and their relative results in performance tests, key in today’s LED market (n.a.: not available; MFR: melt flow rate)

Furthermore, there are no such formulations available which meet both UL 94 V-0 at 1.0 mm and 5VB or 5VA at 2.5 mm or 3.0 mm. Thus, there is a clear need for materials that offer improved flame retardancy combined with strong optical properties.

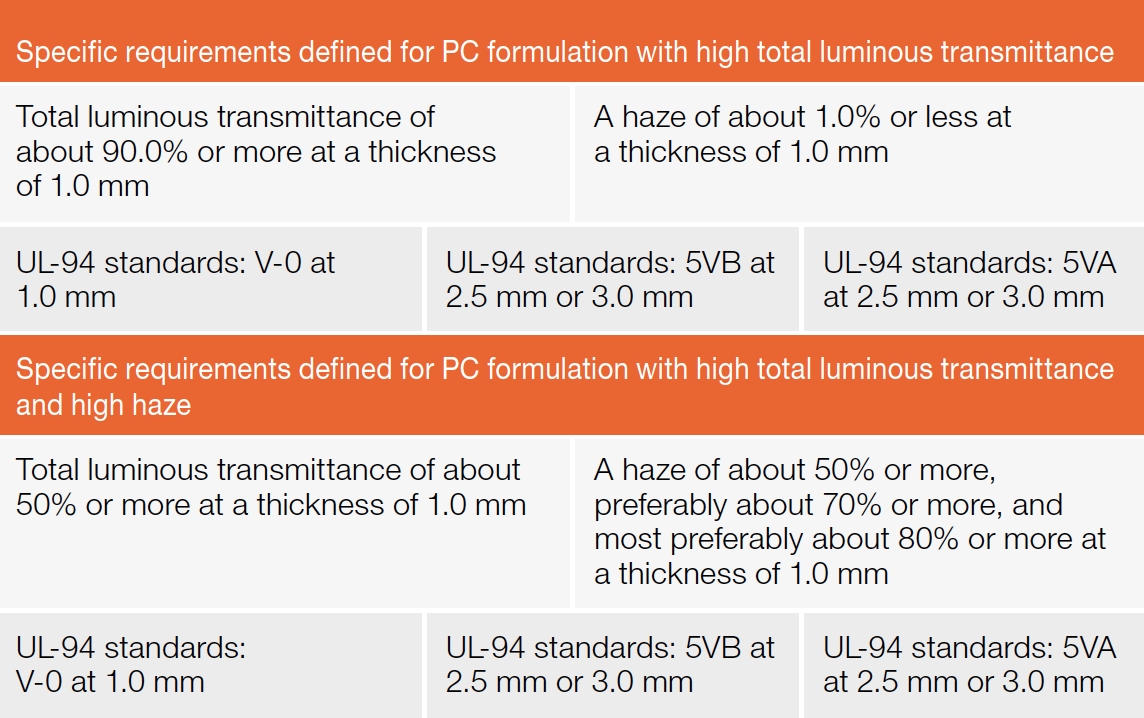

Defining the application needs

Increased requirements emerging from customer projects have indicated a clear need for a highly-transparent, flame-retardant polycarbonate product, which offers high total luminous transmittance, very low haze and good flame retardancy (and therefore meets the requirements for one or more of the following UL 94 standards: V-0 at 1.0 mm, 5VB at 2.5 mm or 3.0 mm, or 5VA at 2.5 mm or 3.0 mm.

At the same time, customers also require a flame-retardant polycarbonate composition that has a high level of haze and good flame retardancy (achieving the requirements for one or more of the following UL-94 standards: V-0 at 1.0 mm, 5VB at 2.5 mm or 3.0 mm, or 5VA at 2.5 mm or 3.0 mm).

Development track followed

Relative to transparent formulations, starting from the products disclosed in Table 1, it needs to be investigated whether a flame-retardant additive package can be developed to meet the more stringent flammability requirements of UL 94 V-0 and 5VB/ 5VA while maintaining transparency performance.

There are a number of challenges to overcome for the development of such flame-retardant polycarbonate compositions.

Meeting the more demanding flammability requirements

• Maintaining the high level of transparency (total light transmission) as for ‘neat’ polycarbonate

• Limitation to bromine- and chlorine free flame-retardant packages

Each of these challenges brings with it limitations in the number of design parameters for the formulations.

First, in order to meet the more demanding flammability parameters, one needs to investigate what can be achieved using the state-of-the-art flame retardant packages. Therefore, it is necessary to have a good understanding of how the flammability tests are conducted and what flame-retardancy mechanisms help to meet the desired performance.

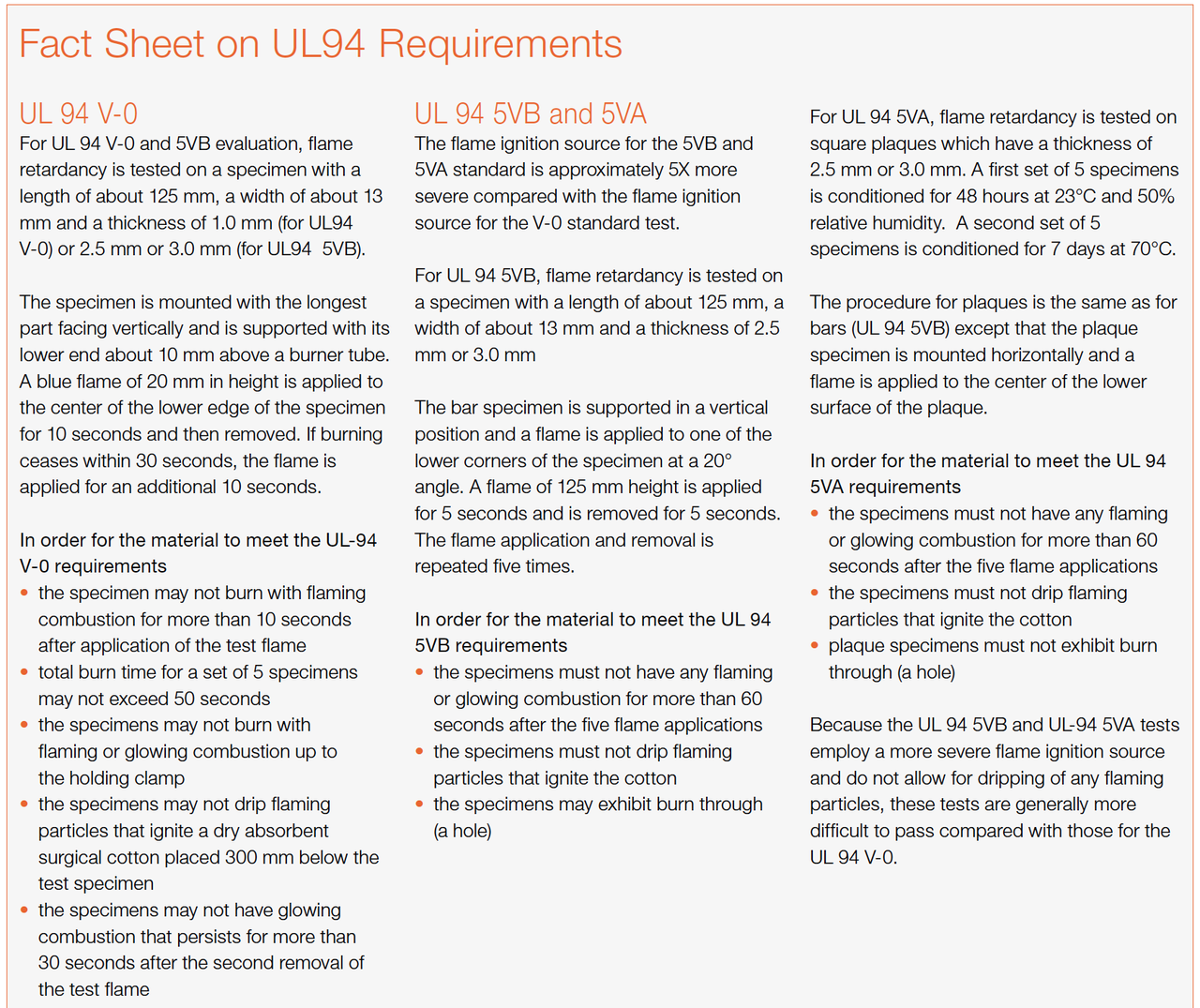

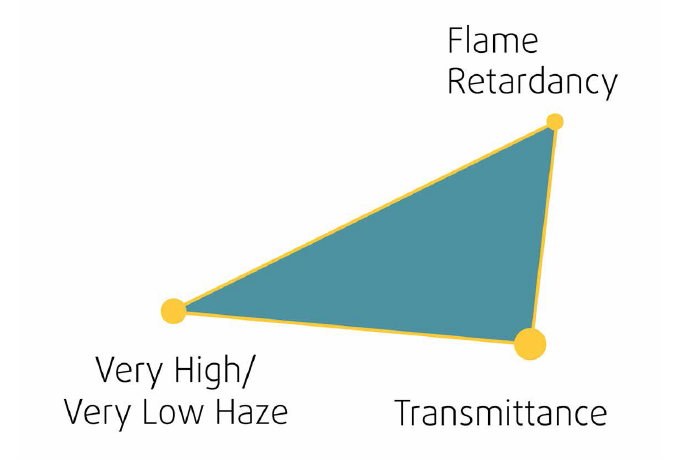

A brief description of the UL 94 test criteria, as well as the UL 94 test set-up (figures and tables) is provided.

Designing for UL94 Compliance

It is clear that there are two key elements in the UL 94 test requirements as explained in the fact box:

• Short burn times

• Preventing flaming drips

In order to have short burn times, a highly effective flame retardant package is required. Many flame retardants are available, but only a few are effective in polycarbonate. These are bromine- and chlorine free flame retardants; hence there remain only a few candidates for flame retardants that shall be discussed in detail.

The most important three categories of flame retardants for rendering polycarbonate flame retardant are:

• flame retardants which contain phosphorous

• additives containing sulfur

• siloxanes

However, phosphate esters are rarely used in plane polycarbonate because of partial loss of clarity, tendency to stress-cracking and reduced hydrolytic stability. Typically, high concentrations (>4wt%) are also required to make polycarbonate flame retardant, which causes embrittlement of the polycarbonate. This eliminates the phosphates from the list of potential candidates.

Flame Retardants containing sulfur are typically referred to as charring salts. These are reported to be quite effective even at very low loadings (<0.2 wt%). But, it is also disclosed that they may cause some haziness.

Various siloxanes are also potential flame retardants for polycarbonate. However, little is disclosed on their effective concentrations and on how they may impact transparency.

To prevent flaming drips, effective flame retardants which cause short burn times will also contribute. In many cases, however, PTFE [poly(tetrafluoroethylene)] will be used as an additional anti-drip agent. Unfortunately, the addition of PTFE will cause the polycarbonate to become opaque.

Therefore, PTFE should be left out of the composition when a high level of transparency is desired.

Another parameter affecting the dripping tendency of polycarbonate is its melt strength. A higher melt-strength will help to prevent flaming drips. Melt strength is controlled by the molecular weight and the degree of branching of the polycarbonate.

For the high haze (or Light Diffusing) polycarbonate compositions, light diffusing agents are typically added. There are a number of different light diffusing agent technologies available. However, many have a negative effect on the flammability performance, for example, core/shell acrylic rubbers (EP634445B1) or cross-linked PMMA (polymethylmethacrylate) particles.

Table 2: Specific requirements defined for PC formulation with high total luminous transmittance

Table 2: Specific requirements defined for PC formulation with high total luminous transmittance

Hence, from a composition point of view, there are a number of variables to be considered, such as:

• Type of primary flame retardant

• Type of secondary flame retardant

• Level ratios of flame retardant types

• Type of light diffusing agent

• Level of light diffusing agent

• Molecular weight of the polycarbonate

As discussed above, key property requirements are the flammability performance (UL 94 V-0, 5VB and 5VA) at the various sample thicknesses and the light properties (transparency [total light transmission], % haze, light diffusivity, etc.), also as a function of thickness.

In addition:

• Flammability performance is determined according to the findings above.

• Determination of transparency and % haze is done on injection-molded plaques.

• Transparency is determined by total luminous transmittance as measured according to ASTM D1003, at a thickness of 1.0 mm.

• Haze is measured according to ASTM D1003 (standard test method for haze and luminous transmittance of transparent plastics), also at a thickness of 1.0 mm, when the haze is about 30% or less. If haze is greater than 30% then it should be tested in accordance with Practice E2387 (ASTM E2387 Standard Practice for Goniometric Optical Scatter Measurements).

In the evaluations, the following components were used:

• Primary flame retardant

o Type A

o Type B

• Secondary flame retardants

o Type C

o Type D

• Light Diffusing Agents

o Types E, F, G, H & I

• Polycarbonate resins

o CALIBRE™ 200-3: High Molecular weight Polycarbonate

o CALIBRE™ 200-22: Low Molecular weight Polycarbonate

Compositional Parameters – Influence on Key Property Requirements for Transparent Applications

As indicated above, there are many compositional parameters that affect the key functional requirements on flammability, transparency and haze. Their effect was investigated in a series of experiments. Once the effects were elucidated, compositions meeting all key functional requirements could be defined with further experimentation.

Compositional parameters studied are the type of flame retardants, the level flame retardant, and the molecular weight of the polycarbonate.

In a first series of experiments, the performance of the flame retardants was investigated, as well as the effect of concentration levels. It was demonstrated that amongst the flame retardants, types A and C performed the best in terms of flammability, total light transmission and % haze performance.

Furthermore it was found that additional levels of both components needed to be optimized and limited to a narrow concentration range in order to maintain the desired flammability rating, as well as the high level of total light transmission and the low level of % haze.

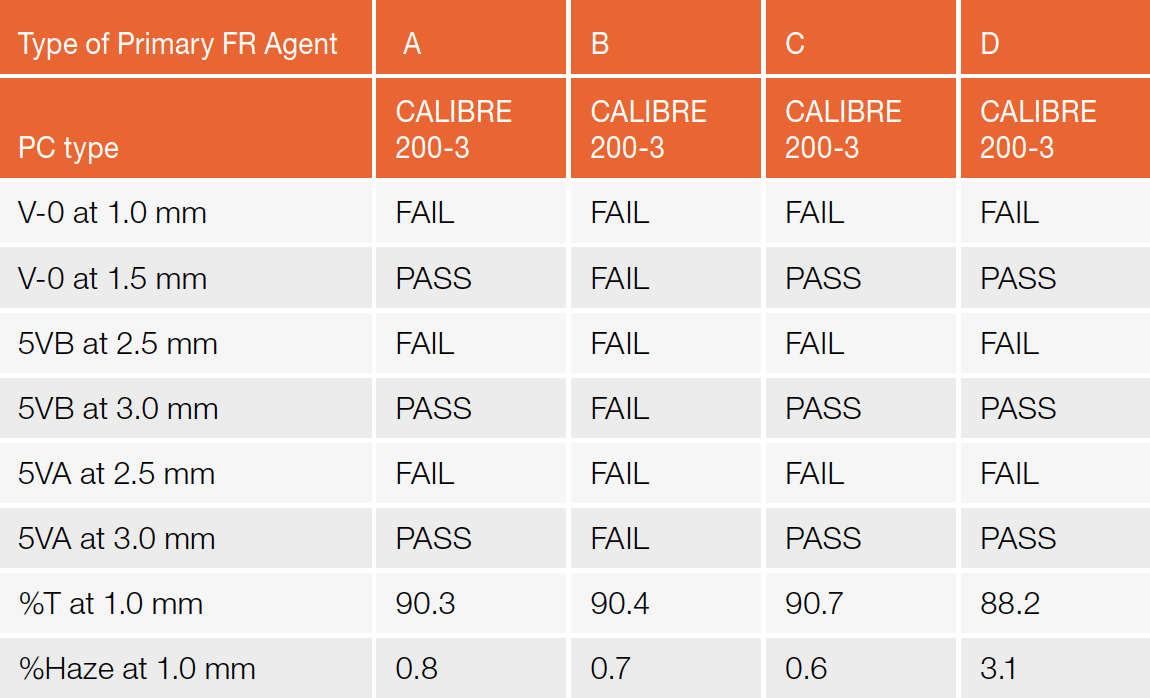

A selection of the performed experiments, demonstrating the above findings, is reported in Table 3.

Table 3: Series of experiments to investigate performance of flame retardants and effect of concentration levels

It is clear from the experiments from Table 3 that the requirements on level of total light transmission and % haze can be met and that also UL 94 V-0 and 5VA/5VB performances are excellent, but that the required flammability performance at the lower thicknesses (V-0 at 1.0 mm and 5VA at 2.5 mm) is not achieved.

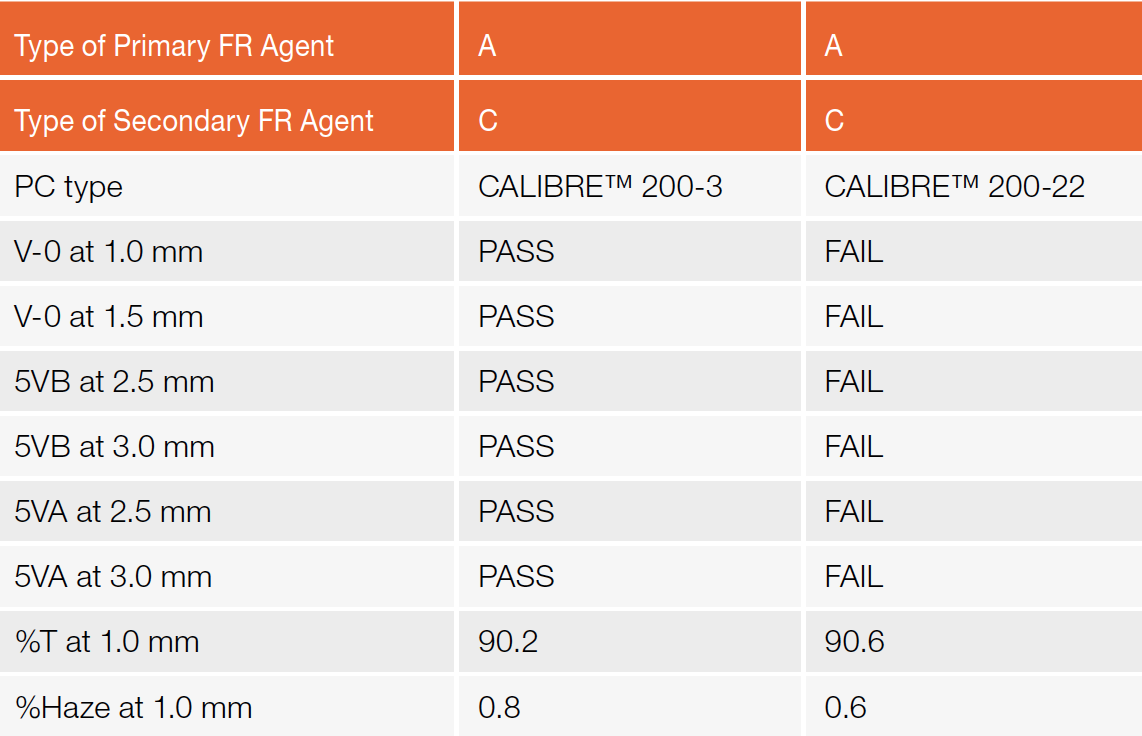

In subsequent experiments, combinations of the flame retardant A and C are evaluated. Different polycarbonate feedstocks are also used. Flammability and light properties were measured on these materials. Results are reported in Table 4.

Table 4: Series of experiments on flame retardant A and C

Table 4: Series of experiments on flame retardant A and C

It is demonstrated that when flame retardants A and C are used in combination with each other, all required properties on flammability, total light transmission and % haze are met, when the low MFR polycarbonate feedstocks are used. When the high MFR PC feedstock is used, the required flammability performance is not achieved.

This illustrates the need to choose a careful selection from particular combinations of various flame retardants with different chemistries, and at very well defined concentrations, and limit the polycarbonate Melt Flow Rate to lower values, in order to obtain the optimal property balance required for LED applications.

In a subsequent effort, light diffusing compositions are to be developed which have a similar flammability performance, and offer a combination of high total light transmission and high light diffusivity.

It has been explained above how the flammability performance and the total light transmission are quantified. For the quantification of light diffusivity, the % haze measurement can also be used. An even more accurate measurement technique is the determination of the D50 angle.

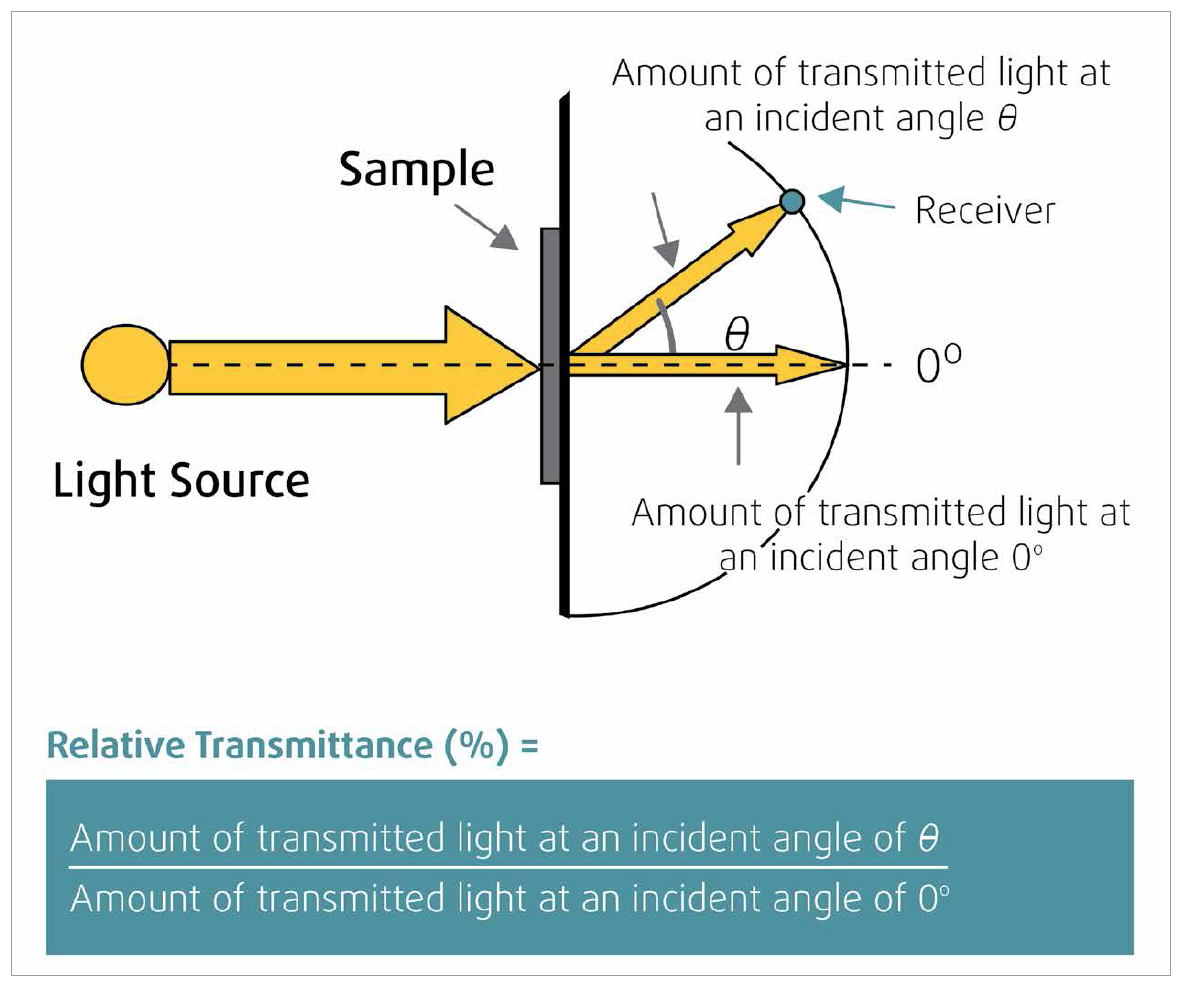

Figure 2: Diffusion is evaluated by measuring relative transmittance (%)

Figure 2: Diffusion is evaluated by measuring relative transmittance (%)

D50 is the angle at which the amount of transmitted light is 50% of the amount of the transmitted light at angle 0°. This can be measured using a variable angle photometer such as GP-200 from Murakami Color Research laboratory. It should be emphasized here that for a perfect diffuser, the D50 angle is 60°, which means that the D50 value cannot exceed 60°.

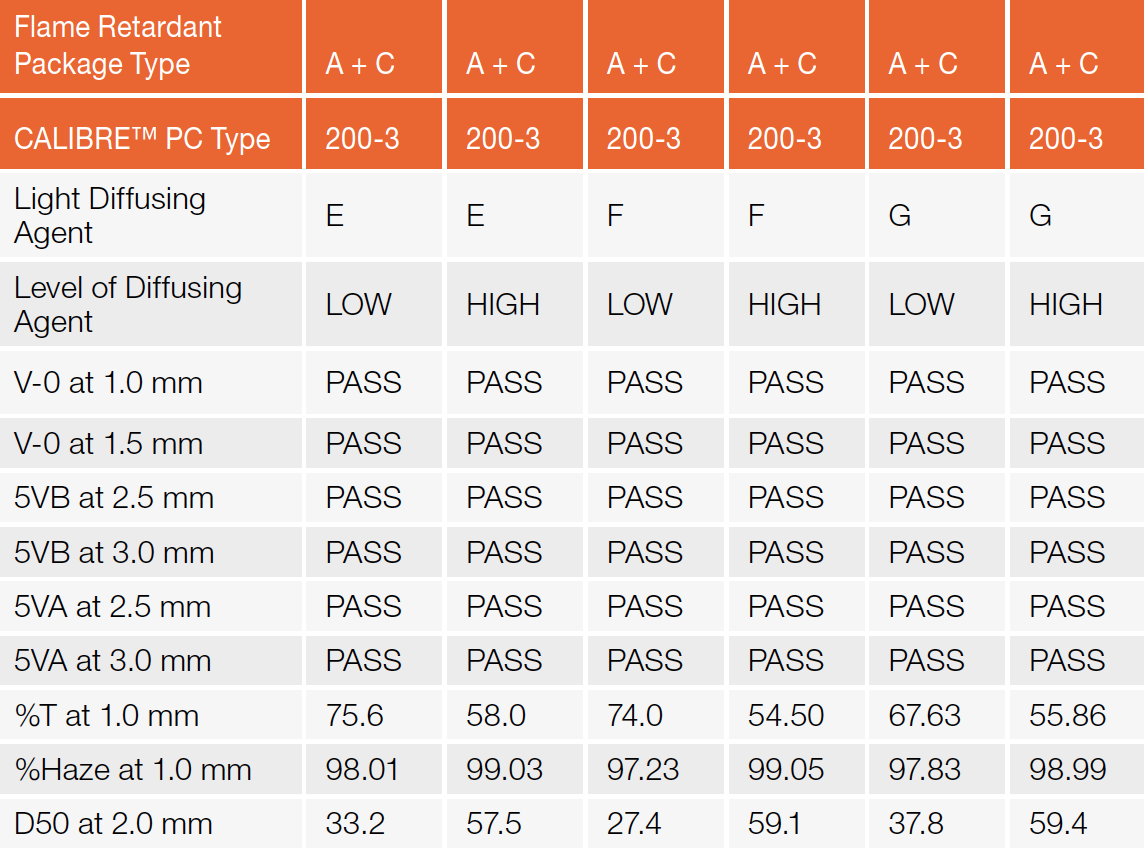

In this set of experiments, polycarbonate formulations were prepared and evaluated in which various light diffusing agents were added at various concentrations to the preferred formulation of Table 5, i.e. both flame retardant A and C were used.

Table 5: Series of experiments to measure flammability and light properties (optimized compositions)

Table 5: Series of experiments to measure flammability and light properties (optimized compositions)

Flammability and light properties, including D50, were measured on these materials. The D50 was measured on injection-molded plaques of 2 mm thickness. Results are reported in Tables 5 & 6.

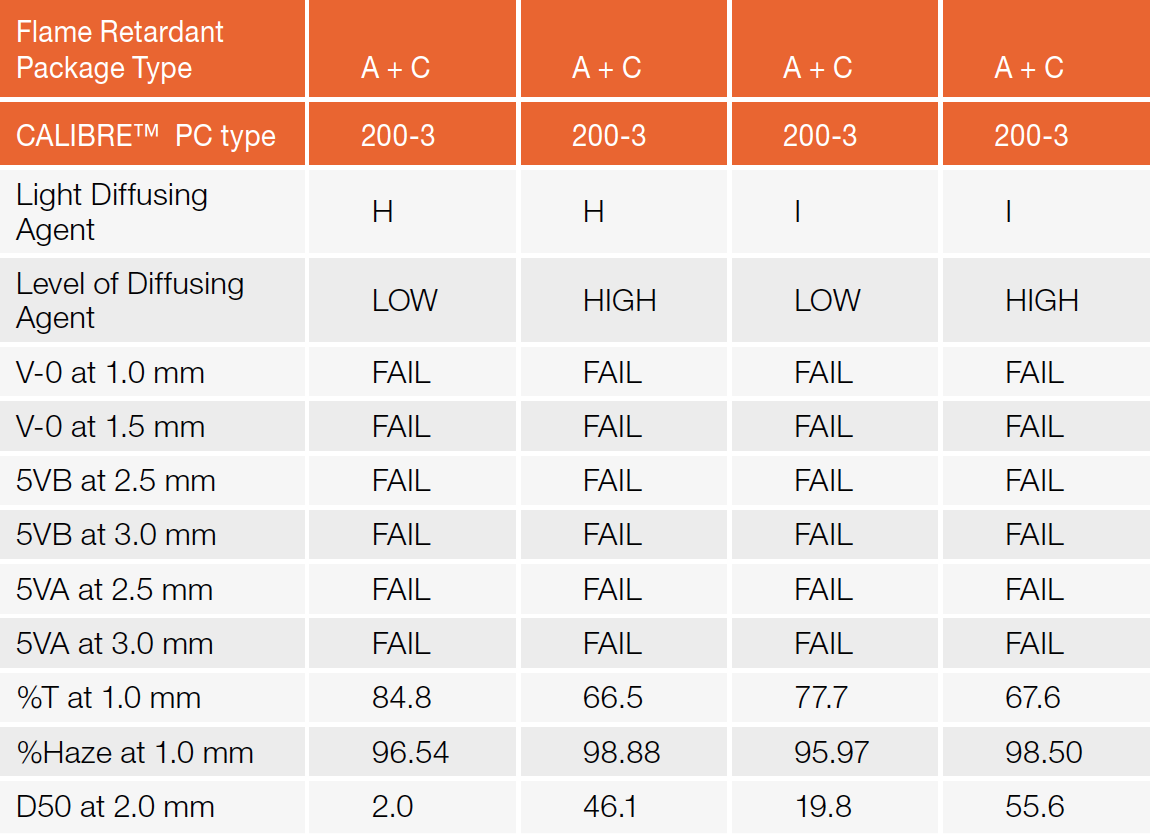

Table 6: Series of experiments to measure flammability and light properties (not optimized compositions)

Table 6: Series of experiments to measure flammability and light properties (not optimized compositions)

The data from table 5 demonstrates that, using the optimized composition for the transparent flame retardant polycarbonate, light diffusing formulations can also be designed that offer excellent combinations of total light transmission and light diffusivity, as well as the desired and unique flammability performance.

To achieve that, the proper light diffusing technologies need to be selected, as demonstrated by the data in Table 6. Light diffusing compositions from Table 6 do not offer the same flammability performance and also have inferior light diffusing properties.

It is demonstrated that both transparent and light diffusing bromine-, chlorine-and phosphate-free, flame retardant polycarbonate compositions are designed offering a unique balance of flame retardancy and light properties (in terms of total light transmission and light diffusivity, if applicable). This is done by careful selection of the type of functional components in the formulation and their addition levels.

These developments have been the subject of a recently filed patent application and, in the meantime, have been UL certified, including f1 and RTI listings.

Meeting the Requirements Set by the Industry

There are many compositional parameters that impact the key functional requirements on flammability, transparency and haze that a material supplier needs to take into account. These effects have been elucidated through extensive testing, resulting in compositions meeting all key functional requirements that could be defined using extensive experimentation. As a result, R&D has designed a transparent flame-retardant composition including about 94% to about 98.9% weight polycarbonate, based on the total weight of the composition, and a sufficient amount of one or more flame retardants for the composition to meet the aforementioned requirements. This development has resulted in the launch of new and advanced resins that will serve as a technology platform for future grades of PC Compounds for the LED Lighting Industry.

Conclusion

A significant R&D effort is necessary to meet the current and future needs of the LED industry’s leading and emerging companies. Manufacturers and designers are continuously looking at materials that offer a combination of properties which will allow them to produce thinner covers with excellent light transmission. Whether the goal is uniform light diffusion or crystal-clear transmission, outstanding ignition resistance (or flame retardancy) is a priority. The key is to master the critical performance triangle. In light of these new requirements, the new grade compositions meet the challenge of combining excellent optical properties, excellent flame retardancy and thinner lenses for the lighting system designer.

References:

Progress in Polymer Science 35 (2010) 902–958: Polymer/layered silicate (clay) nanocomposites: An overview of flame retardancy; P. Kiliaris, C.D. Papaspyrides*

Polym Int 54:981-998 (2005): Overview of recent developments in the flame retardancy of polycarbonates; Sergei V Levchik and Edward D Weil

Polym Int 56:1404-1414 (2007): Flame Retardancy mechanisms of triphenyl phosphate, resorcinol bis(diphenyl phosphate) and bisphenol A bis(diphenyl phosphate) in polycarbonate/acrylonitrile-butadiene-styrene blends; Kristin H Pawlowski and Bernhard Schartel

Flame Retardants for Plastics and Textiles; Practical Applications; Edward D Weil and Sergei V Levchik; ISBN 978-1-56990-454-1