Avoiding Brightness and Color Mismatch with Proper RGB Gamut Calibration

For well over a decade, proponents of Solid-State Lighting (SSL) have been offering bullish forecasts concerning the adoption of LEDs for general and specialized lighting applications. Recent years have seen those rosy predictions come true, with LED lighting now almost completely dominating the market for new construction, retrofit, and many replacement lighting applications. For many of these applications accurate color calibration is required. Rood Bouten, CTO at Admesy, explains the reasons and how to perform a proper RGB gamut calibration.

The pace of adoption has surprised even industry insiders. In 2016, the U.S. National Academies of Sciences, Engineering, and Medicine described the “rapid adoption and the accompanying diversity of applications of SSL” as surprising. A 2015 Danish Energy Agency report on European LED Market Evolution noted, “The LED market has started to become a mass market,” driven by a “10 year acceleration in affordability of LED lamps”. This rapid adoption promises significant energy savings and also holds out hope for new applications of light with color tunability, for example, creating new options for the innovative use of light in aesthetic, commercial, and health-related areas.

A New Way of Lighting

LEDs offer unprecedented control over various lighting characteristics such as distribution, timing, and, perhaps most importantly, color. But control over LED color does not necessarily guarantee the precision and quality of LED color. Validating the spectral performance of LEDs is a necessary step in maintaining color performance.

Color calibration is essential for many current applications of LED lighting, and may be even more important in the future. An accurate, traceable spectrometer is a vital part of a color calibration process. Color calibration is a straightforward undertaking, given the proper spectrometer. Once calibration is complete, users can have confidence that LEDs are providing exactly the right color when and where it is needed.

The Success of LEDs

LED developers continue to innovate, offering new capabilities - and new flexibility - in the use of light. Much of the flexibility of LED illumination stems from the small size of the light-emitting diodes themselves. That small size allows LED lighting products to be integrated and used in almost any shape. Additionally, RGB LEDs bring possibilities for multi-color tunability to the LED lighting designer.

Human centric lighting (HCL) is one force driving new applications. HCL is the blanket term for lighting whose intensity and color are adjusted to optimize human productivity, mood, or health. Examples of multi-colored LED applications can be found in airplanes, automotive interiors, workplaces, and residential mood lights. The character of lighting influences many aspects of the human experience. Changes in light levels and colors can create relaxing atmospheres, as, for example, in airplanes during long haul flights or domestic journeys. Lighting can also increase the level of concentration among students in schools or staff in work environments. Changes in LED illumination can even provide information about a current state, indicating changes in the use of a space or signaling the need for scheduled actions.

Tunable LED lighting also enhances the ability to define, market, and reinforce brand identity. Color is a key feature of marketing campaigns, and color matching is critical for enhancing customer recognition of specific brands. Tunable LEDs are perfectly suited to create the color environment that supports marketing messages.

Multi-colored LED lighting applications are poised to become increasingly important, but their promise comes with a unique set of challenges. White point and RGB Gamut calibration are the tools necessary to meet those challenges.

New Capabilities Create New Problems

RGB LEDs can create just about any visual color, but creating the right color is a major challenge. And once the correct color is defined, it remains a challenge to maintain color and intensity consistency across all the LEDs in a specific implementation. Some tasks, for example, depend on a specific color temperature of white light, and brand identities are built on color consistency. So the exact tunability of RGB LEDs at a specific color is of high importance. Additionally, when multiple RGB LEDs are used to create this determined color over a large area, color consistency between LEDs has to be guaranteed as the human eye can detect subtle differences in color or brightness. The eye is especially sensitive to differences in color or brightness among individual LEDs located near each other.

Figure 2: Even subtle color differences are detectable by the human eye. Lighting system designers must address this issue when using color tunable LEDs

Visible differences in color or brightness create an impression of lower levels of quality. For that reason, color and brightness consistency within luminaires is of high importance for LED lighting product manufacturers.

The Source of the Problem

One of the causes of color difference is related to the production process of LEDs. LEDs are mass-produced and minimal variations in material structure, composition, or thickness will lead to slight differences in color and brightness. LEDs are binned - basically a sorting process - to keep variations of color and brightness of a particular group of LEDs within defined acceptance criteria. The level of binning is defined by the value of the accepted tolerances for color and brightness. Although small tolerances lead to tighter binning and more uniform LED color, they also influence the price of LED lighting products: Small LED bins result in higher prices.

Another cause of color difference relates to the processes of driving and dimming LEDs. The relation between forward voltage and forward current is non-linear. In addition, the relationship between forward current and brightness - light output - of an LED is also not linear, which introduces more complexity. Minor changes in forward voltage can then directly affect the LED’s brightness and color point.

Often, Pulse Width Modulation (PWM) is applied to control RGB LEDs, which enhances the stability of driving and dimming LEDs. One of the advantages of driving LEDs with high frequency pulses is to enhance their lifetime. A reduced duty cycle lowers the average junction temperature. High junction temperatures can directly result in a shift in peak wavelength, thus color, and lowers the expected LED lifetime.

Calibration is the Key

Two methods work to overcome the problems in color consistency both among individual LED packages and in large scale luminaires.

These methods are:

- White point calibration

- Gamut calibration

White point calibration:

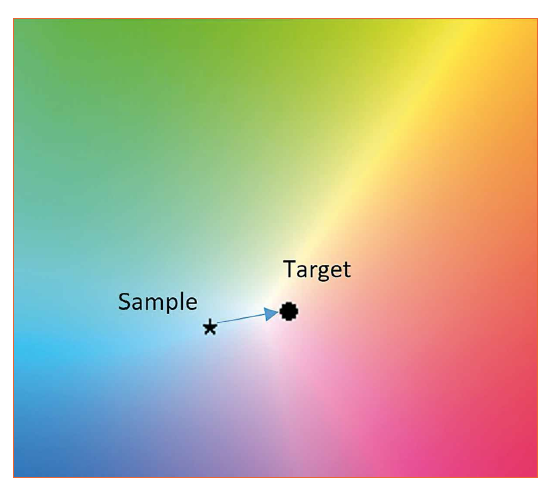

Calibrating the white point of a light source is basically moving the color point of a sample towards a target color point, as shown in Figure 3. The first step in changing the color point to the right value is to precisely measure both the sample and target CIE xyY color coordinates. A spectrometer can measure and determine the XYZ values, which can then be used to determine the CIE xyY coordinates.

Once the color coordinates are known for both the sample and target light source, the calibration can be carried out. By changing the brightness of each individual LED (Red, Green and Blue) of the luminaire, the color point of the sample light source can be changed until it matches the target light source, as illustrated in Figure 4.

This calibration process provides a compensation factor for each individual LED inside the RGB LED.

The white point calibration process provides a compensation factor for each individual LED inside the RGB LED.

Rnew = A * Rori

Gnew = B * Gori

Bnew = C * Bori

Calibrating the individual LEDs can be done at different levels:

- Adjusting the current though the LED

- Adjusting the pulse width of the PWM signal

- Adjusting RGB values of the input to new RGB values

This method is a relatively straightforward way of balancing the colors between two different luminaires. This is a simple method of determining the compensation factors, especially when choosing the correct RGB bins to ensure the primary colors match. A disadvantage, however, is when applying this method to RGB LEDs from different bins. In that case, even with an identical white point the saturated colors can appear different.

Figure 3: Sample white point and target white point

Figure 3: Sample white point and target white point

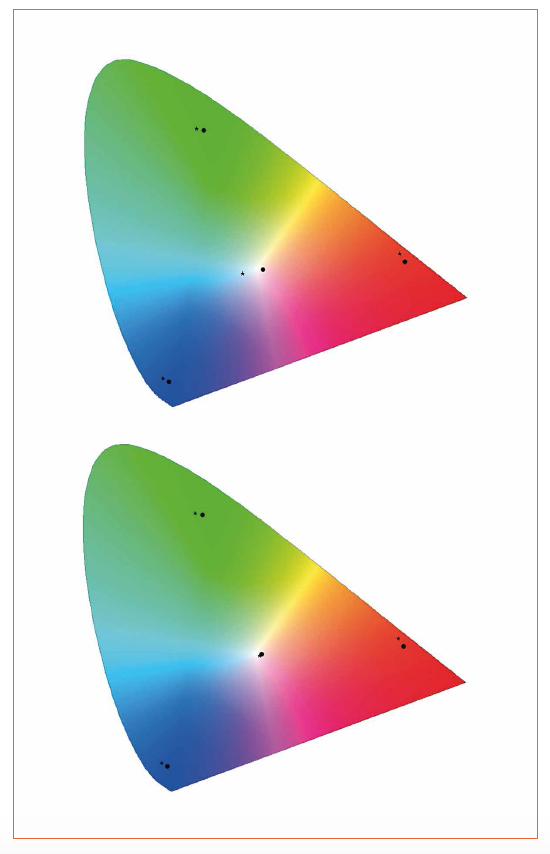

Figure 4: Sample and target light source before calibration (top) and after calibration (bottom)

Figure 4: Sample and target light source before calibration (top) and after calibration (bottom)

The light output curves for RGB LEDs from different bins vary with higher and lower current. The white point calibration for these LEDs provides a set of drive currents for each LED - the currents at which the LED will output white light of the desired color temperature. When operated away from the calibrated white point, however, the different output response of the individual LEDs from different bins will lead to variations in output color. For this specific reason, it is recommended to select LEDs from the same bin to keep color differences of saturated colors within limits.

But selecting LEDs from the same bin isn’t the only way to match color appearance. Calibrating the color gamut is a powerful technique to match color appearance regardless of the source of the LEDs.

Color Gamut Calibration

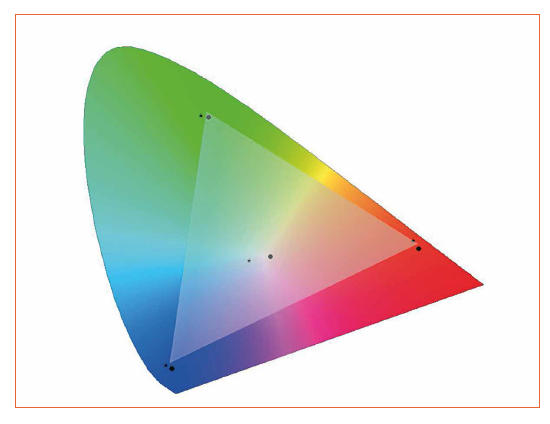

The gamut of an RGB LED light source is defined as a triangle within the color space. The shape of the triangle as shown in figure 5, the gamut, depends on the color points of each individual LED.

Figure 5: Gamut of the target light source: The triangle defined with vertices at points corresponding to each of the R, G, and B LEDs

Figure 5: Gamut of the target light source: The triangle defined with vertices at points corresponding to each of the R, G, and B LEDs

Gamut calibration is fundamentally similar to the process of white point adjustment, but now applied to each individual red, green, and blue LED. The color coordinates of each saturated LED may be different than the individual LEDs of the target light source, but the net color characteristics can still be matched. By adding small amounts of green and blue to red, for example, the red of the sample can be calibrated towards the target. The same holds for calibrating the green and blue color points. The final result is an exact overlap of the gamut of the sample and target light source. With reference to Figure 5, a perfect color gamut match means the ‘triangles’ of both the target and sample light sources perfectly match one another.

As with white point calibration, the method for gamut calibration is straightforward:

- Calibrate the white point

- Measure and apply matrix [M] based on RGB color input values and RGB color target values

The first step is the same white point calibration as explained previously. Carrying out the white point calibration in advance will set the sample luminaire to a good default state. The second step is calibrating each red, green and blue LED towards the desired RGB primaries of the target source. This results in XYZ values for each target primary and each sample primary color. These XYZ values are the input for creating the [M] matrix, which is used to (re) calculate the input RGB values to the right RGB output values.

RGBoutput = [M] * RGBinput

This is how the matrix is created:

- Define XYZ values of target primary colors

- Measure XYZ values of sample colors

- Calculate 3 x 3 matrix [M]

A major advantage of gamut calibration is that two RGB luminaires can be matched. Because the color coordinates of each primary LED are measured, it’s relatively simple to create a matching gamut. One disadvantage, however, lies in the practical difficulty of achieving the desired result.

The difficulty of color calibration is increased by factors such as the gamma curve, which represents the nonlinearity of light output as a function of forward current. Dimming to low luminance or low individual RGB values also introduces complexity. For such reasons, we recommend starting with white point calibration only. Combined with good LED binning, one can expect good results in color matching and consistency between luminaires.

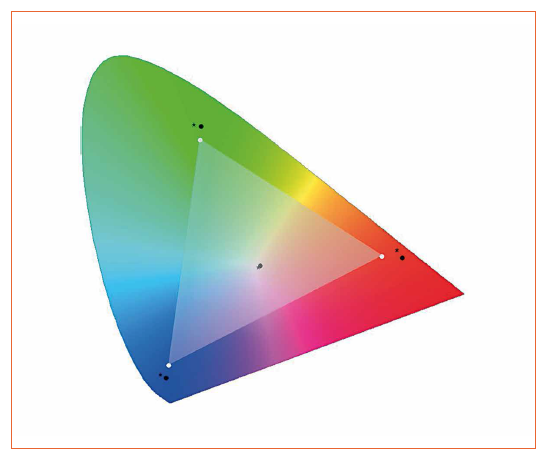

Figure 6: Gamut defined by three white dots, which all lie within the sample and target. Color gamut calibration improves the spectral accuracy of the light output, but with a corresponding slight reduction in the extent of the color gamut

Figure 6: Gamut defined by three white dots, which all lie within the sample and target. Color gamut calibration improves the spectral accuracy of the light output, but with a corresponding slight reduction in the extent of the color gamut

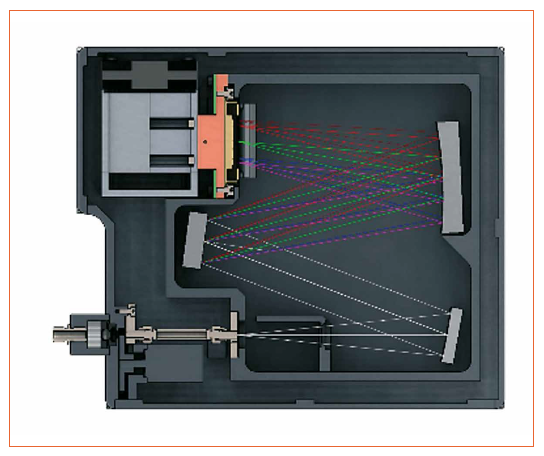

Figure 7: A spectrometer disperses incident light into its constituent wavelengths. Performance is determined by the quality of the dispersive elements, the optics and detector, and the overall system design

Figure 7: A spectrometer disperses incident light into its constituent wavelengths. Performance is determined by the quality of the dispersive elements, the optics and detector, and the overall system design

Making Calibration Possible

The preferred device for carrying out white point and gamut calibration is a spectrometer. A typical spectrometer is a device that uses a grating to disperse light into individual wavelengths. The proportions of each wavelength can be quantified by an electronic detector, making it possible to accurately measure color and brightness.

Theoretically a tri-stimulus colorimeter could be used to approximate these spectral measurements, but the variations across LED bins are too big for a colorimeter to measure them accurately. That’s why a spectrometer is the tool of choice. Spectrometers used for precise measurements should be accurate and have high resolution, and should also be calibrated correctly. Non-calibrated or poorly calibrated spectrometers could lead to inaccurate measurements and, consequently, incorrect color calibrations of luminaires. Besides, when using multiple spectrometers for white point or gamut calibration, the results might be completely different. Individual NIST-traceable spectrometers can still vary from one another, as a NIST calibration only calibrates spectral readings for the single condition of measuring a specific NIST traceable lamp. In such cases it is impossible to determine which system is good and which one isn’t.

A spectrometer used for calibration should have:

- Wavelength accuracy

- Low non-linearity

- Traceable absolute calibration

- Dark current compensation

- Excellent stray light performance

Note that absolute calibration is very important to ensure the spectral data of a light source is exactly the same for each spectrometer. Consider the term “traceability” carefully as it can sometimes be used rather casually, and does not always mean the device is at a good traceability level.

Conclusions - The Value of Spectral Calibration

LED lighting offers unprecedented control over various aspects of the illumination environment, including color. But control, in and of itself, does not imply accuracy. Poor control of color and brightness can produce an unpleasant or undesirable lighting environment or display appearance. The proper use of a high-quality spectrometer can make that problem disappear.

A spectrometer can be used to generate white point and color gamut calibration. Applying those calibrations to RGB LED light sources to match colors of different luminaires can enhance the user experience of lighting products. Considering this step during the production process or during installation can solve the potential problems of color and brightness mismatch. The result is a lighting environment that takes advantage of LED characteristics to produce lighting environments that enhance the user experience.

References:

[1] http://inhabitat.com/this-super-efficient-new-airplane-eliminates-jet-lag/

(c) Luger Research e.U. - 2017