High-End White Light Sources Fiber Optics Technology for Medical Applications

Often technologies that are too expensive for the mass market at the beginning are already adopted in medical applications. When reaching a certain level of maturity, costs usually become more reasonable and adaptations for the consumer market begins. Holger Laabs, Oliver Mehl and Henning Rehn from Osram GmbH present a light source technology and its prerequisites for fiber optics that could become one of these technologies.

Over 170 years ago the Swiss physicist Jean-Daniel Colladon set the foundation for modern fiber optics. He demonstrated optical experimental wave guiding through total internal reflection in a water jet illuminated by the sun [1].

Today there are many applications of optical fibers. Besides single fibers with certain spatial profiles of the index of refraction (e.g. step- and gradient index fibers) there are also structured fibers. These structures can be either perpendicular to the fiber axis (e.g. photonic crystal fiber) or along the fiber axis (e.g. fiber with Bragg grating). Single fibers can be clustered to fiber bundles, in a regular or irregular arrangement; or they come as ridged waveguides in macroscopic dimensions. As an alternative to large diameter fiber bundles, flexible, liquid filled fibers are available as well.

New lighting technologies enable fiber light sources with higher efficiency and lifetime and smaller fiber diameters. These are especially useful for endoscopy and industrial metrology.

Uses of Optical Fibers

Fibers for communication are ubiquitous with data rates up to 100 Tbit/s from a single fiber [2]. Not only high data rates but also high optical power can be transmitted through fibers; fiber optical cables for high power laser are commercially available for radiant power up to e.g. 20 kW [3].

For bio photonics and medicine there are well known applications in microscopy, endoscopy and fiber-illuminated headlamps. More recently new applications in photodynamic therapy and opto-genetics are enabled by optical fiber technology.

Instead of using fibers for the transmission of data or optical radiation, fibers can also serve as sensing devices for things like mechanical stress, vibrations and temperature. For these applications signals of optical scatting processes (Rayleigh-, Brillouin-and Raman scattering) are either measured along the full fiber in conjunction with the run time measurement, or locally with fiber Bragg gratings [4].

Changes in Lighting Technology

In many applications lighting technology is changing from incandescent, halogen or discharge lamps towards LED and laser technology. This can be combined with a digitalization and cross-linking of lighting control gear. OSRAM offers various light sources, like halogen lamps, LED- and laser light sources for the medical market. In the following we present the technology of newly developed light sources for fiber illumination.

Endoscopy is a good example to illustrate the technological advancement in light sources. First endoscopes were made with miniature incandescent lamps at the distal end. With the introduction of fibers in combination with cold light the light source was moved out of the body in order to reduce the thermal load onto the tissue. Today the light is generated with modern type xenon lamps, LED- or laser light sources and is guided by a system of fibers to the distal end of the endoscope.

Coupling Light into Fibers

Based on fundamental laws of Étendue preservation, the maximum flux of light that can be coupled into a fiber can be estimated by the product:

φ = Lsource ∙ UF

with Lsource being the luminance of the light source and UF the Étendue of the fiber:

UF = (π ∙ r ∙ NA)2

with fiber core radius r and numerical aperture NA.

Due to the small Étendue of used fibers, light sources with high luminance are required to flow for high luminous flux of the transmitted light.

Traditional Light Sources for Fiber Illumination

Traditional light sources for fiber applications include halogen lamps, xenon discharge lamps and mercury discharge lamps (Figure 1).

Figure 1: Examples for conventional fiber optics light sources: MR16 64607 50 W 8 V, XBO R 300 W/60 C OFR, HXP R 120 W/45 C VIS

These light sources are employed according to the special requirements in microscopy, for example, in cold light sources, endoscopy, boroscopy, medical head lamps, or for point curing of glues. The advantage of traditional light sources lie in their spectral characteristics, their high luminance and sometimes in their favorable price/performance ratios. A disadvantage is the limited lifetime and the need for regular lamp replacement. Lamps used for fiber light applications usually have a reflector that collects light from the burner and focuses it onto the end of a fiber or optical systems making the application of lamps rather easy.

LED Technology

Driven by the limited lifetime of traditional lamps as well as advancements in LED technology, in particular luminance, light emitting diodes are becoming suitable light sources for fiber coupling.

In contrast to traditional light sources LEDs radiate only into one hemisphere. This enables the use of lenses instead of (elliptical) reflectors. Lens systems can be corrected for aberrations allowing for high coupling efficiency in Étendue limited applications.

Due to demanding luminance requirements only cold white LEDs with low color rendering where employed in the beginning of fiber sources with LED technology. Many applications require warm white light with high color rendering, but high luminance in conjunction with superior color rendering is difficult to achieve with a single LED source. One solution is spectral multiplexing of LEDs with different colors. The LED spectra can be optimized to result in high color rendering indices (Ra=80-95). Moreover, control of individual LED channels allow for CCT (correlated color temperature) tuning between 3000 K and 8000 K.

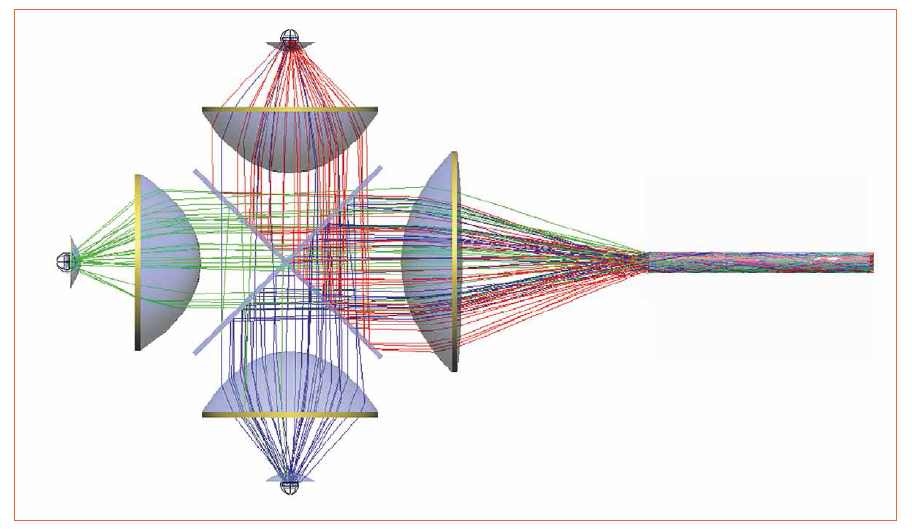

LEDs can either be placed very close to each other or, for highest illuminance; their light is combined with dichroitic mirrors (Figure 2) resulting in a luminance of up to 280 cd/mm2.

Figure 2: Model of a RGB LED light source for fiber applications. The light of each individual LED is collimated, combined with a dichroitic mirror and refocused into a fiber. With a color management system the target color coordinates can be addressed and maintained over time

Figure 2: Model of a RGB LED light source for fiber applications. The light of each individual LED is collimated, combined with a dichroitic mirror and refocused into a fiber. With a color management system the target color coordinates can be addressed and maintained over time

PHASER Technology

Besides scaling just luminous light flux (e.g. by increasing the area of the source in two dimensions) many applications require higher luminance (more flux from a small area into a small solid angle) as explained earlier. Such an Étendue-limited application is fiber coupling where higher luminance results in more luminous flux from a small fiber with small numerical aperture.

High power white LEDs allow for luminances between 100 and 300 cd/mm2 and are based on blue InGaN chips [5], which excite a broadband phosphor in the yellow spectral range [6]. However, even at 300 cd/mm. only 25 lm of white light can be coupled into a fiber with a core diameter of 500 μm and a numerical aperture of 0.37. If higher luminous fluxes are required, other light sources with luminances exceeding 300 cd/mm2 have to be employed. Such a light source may still use a broadband yellow phosphor, but a higher pump power density has to be accomplished at the luminescent material. The increase in pump power density is enabled by blue InGaN semiconductor lasers. Their very small beam parameter product M2 or Étendue allows for a small excitation area on the phosphor even at high levels of optical power [7]: e.g. 10 W of optical pump power of the laser incident onto a round area of 500 μm results in a power density of 50 W/mm2. The acronym PHASER for this laser - phosphor technology results from a combination of “PHosphor” and “LASER”. Application areas are video projection, fiber based medical applications [9] or automotive laser light [10].

Fiber Light Sources with PHASER Technology

Today, light sources based on PHASER technology have started to replace xenon lamps. For example, the ITOS PHASER 3000 substitutes a 300 W xenon lamp, but with a power consumption of only 180 W and a life time up to 30 khrs. PHASER systems can be engineered to a modular system, hence enabling the mixing of additional wavelengths for supporting special image processing modes. The additional wavelengths are quickly switchable in comparison to mechanical filter wheels allowing new modes of operation in various applications. As an additional benefit, PHASER light sources do not emit ultraviolet or infrared radiation rendering additional filters known from conventional light sources obsolete.

The ITOS PHASER 3000 is designed for a fiber bundle diameter of 4.8 mm and a numerical aperture of 0.37 (+/- 22°), but can also be adapted to other fibers.

Technology Comparison

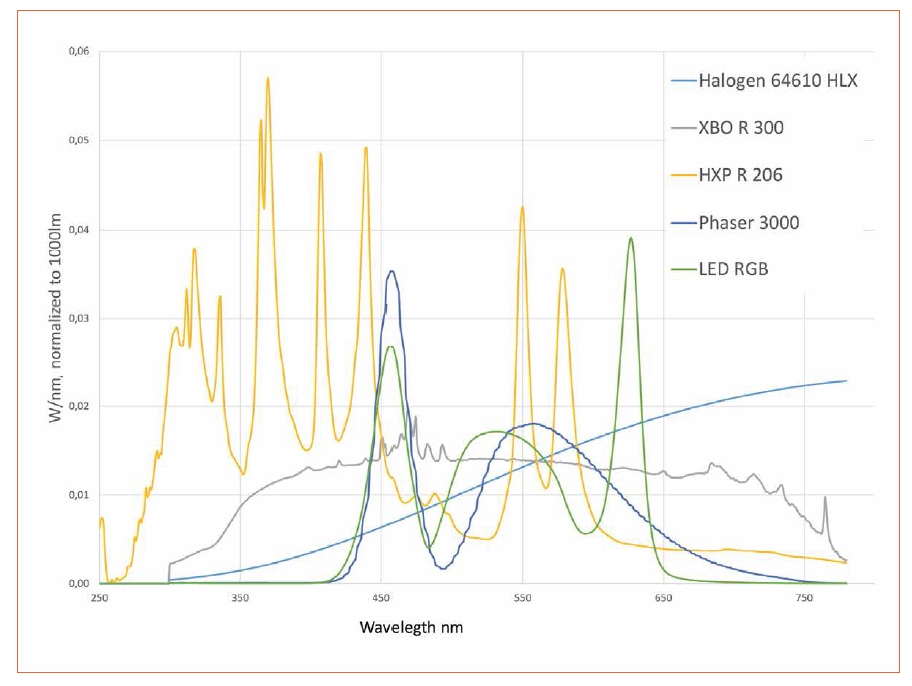

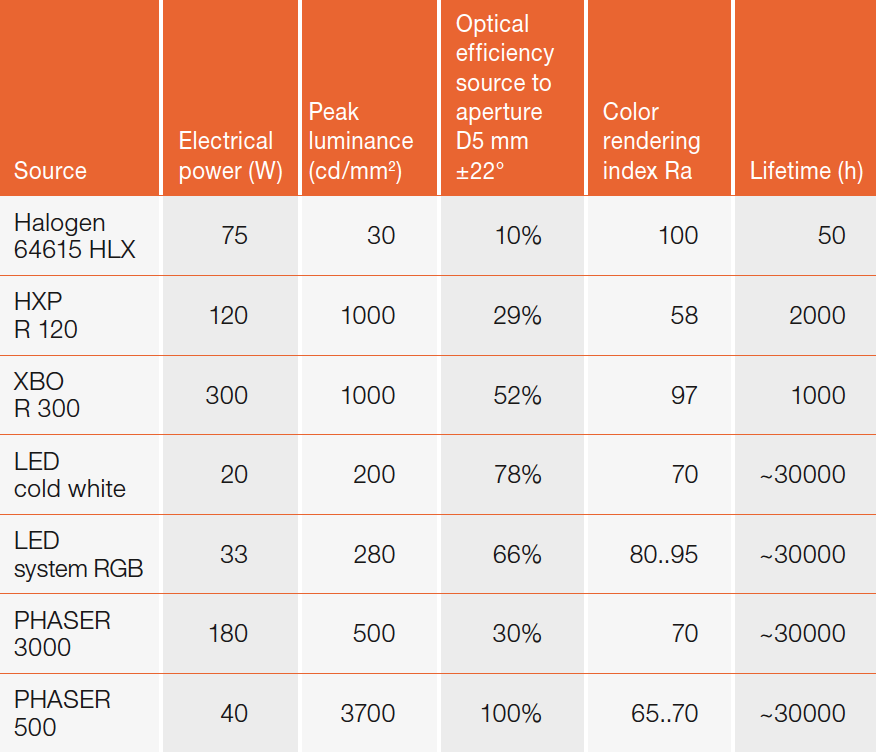

In fiber light applications, semiconductor-based light sources are increasingly succeeding. Table 1 compares properties of different light sources. LED and PHASER light sources easily achieve the performance of halogen and discharge lamps but have a much longer lifetime. The power required for generating the light is much reduced and system efficiency is increased. The spectral characteristics of the different light sources vary strongly as shown in figure 4 and need to be considered based on the intended application.

Figure 4: Comparison of spectra from different fiber light sources

Figure 4: Comparison of spectra from different fiber light sources

Table 1: Fiber light source properties overview

Table 1: Fiber light source properties overview

For camera-based applications (e.g. most of medical endoscopy) the perceived difference in color reproduction can be overcome by white balancing and image processing. In other applications where the light is detected by the human eye (microscopy or surgery), the spectral properties can be enhanced - as mentioned before - either by addition of wavelengths or by spectral filtering with customized transmission filters.

Outlook

PHASER technology already allows for luminance levels beyond 5000 cd/mm. in the lab environment and is therefore comparable to highest pressure discharge lamps [12].

A recent technology demonstration yields 370 lm white light flux in a 400 μm fiber core diameter and a numerical aperture of 0.5, corresponding to a luminance of 3700 cd/ mm2 (Figure. 5).

Figure 5: ITOS PHASER 500 technology demonstrator with 370 lm out of a fiber (400μm diameter and NA 0.5) recently reached record luminance levels for fiber optics light sources

Figure 5: ITOS PHASER 500 technology demonstrator with 370 lm out of a fiber (400μm diameter and NA 0.5) recently reached record luminance levels for fiber optics light sources

For medical applications with flexible endoscopy the required area for illumination can be significantly reduced. A fiber with only 200 μm, for example, and a numerical aperture of 0.5 will be able to transmit a luminous flux over 100 lm if a PHASER light source with 5000 cd/mm. is employed. By choosing phosphors in combination with filtering or wavelength multiplexing the spectral power density can be tailored to the requirements of specific applications.

References:

[1] Wikipedia: Jean-Daniel Colladon

[2] Jeff Hecht, Ultrafast fiber optics set new speed record, NewScientist, 2809, April 2011

[3] www.optoskand.se

[4] J. Wallace, Fibers for sensing extend their reach, Laser Focus World, Jan 2016, 83ff

[5] Wikipedia: Indium gallium nitride

[6] OSRAM product catalog: LED OSRAM OSTAR headlamp, www.osram-os.com

[7] Wikipedia: Beam parameter product

[8] OSRAM Ostar Projection Power datasheet, Version 1.11, August 2015

[9] OSRAM product catalogue: ITOS PHASER 3000

[10] http://www.osram.com/osram_com/news-and-knowledge/automotive-special/trends-in-automotive-lighting/laser-light-new-headlight-technology/lasertechnology-functionality-and-advantages

[11] www.osram.com/osram_com/products/led-technology/specialty-lighting/led-modules/itos/itos-phaser-3000/

[12] Wikipedia: Luminance