How to Design with LEDs: Concurrent Engineering Yields Fully Optimized Lighting Systems

LEDs are often viewed as a replacement for other light sources. The right starting point for designing an appropriate replacement is crucial to the result. Brian S. Jasenak, Optical and Process Engineer at Kopp Glass, describes a concurrent engineering approach that optimizes the optics and other system components, and may help to reduce the number of LEDs needed as well as the overall cost of the LED lighting fixture.

LEDs are often viewed as a replacement for other light sources. As a result, the approach that many optical design engineers take when redesigning incandescent fixtures asks “What LED will replace the incandescent we were previously using?” However, the question that they should ask is “What light output am I trying to achieve?”

By beginning with the end in mind, engineers can evaluate all aspects of a lighting system that influence the LEDs and vice versa. The ultimate performance of an LED fixture is determined by different components of the lighting system, including the LED and electrical components, optical lens design, lens material, LED array design, and the thermal management design.

Light output is directly related to optical design, and because optics can increase the efficiency of the system, and even reduce the number of LEDs needed, their influence should be considered early in the design process. If one uses optical design as the starting point and then move forward to the other components, the lighting system can be fully optimized, from both a performance and cost perspective. However, the process is not perfectly sequential; because the components of a lighting system are interrelated, it’s important to continuously assess the design choices and modify a design accordingly.

Optical Lens Design

The first step in developing an LED system should be to evaluate the need for an optical lens; this can be done by examining the light output requirements of the system. Depending on the beam distribution, angles, and intensity required, an optical engineer can determine what type of optic is necessary. During this step, it is beneficial to engage the optic designer and manufacturer.

Often, the optical lens designer and manufacturer are separate parties, which can make it difficult to achieve a fully optimized design. The optical lens designer may create an optimized optical design that would produce ideal light distribution, but it is not well-suited for manufacturing. As a result, the optic could be more costly or even impossible to produce without design modifications. To produce an optic that is optimized for both manufacturing and light output, it is important for all parties to work closely together to reduce development time, prevent costly redesigns, and increase manufacturing yields.

Optical lens material

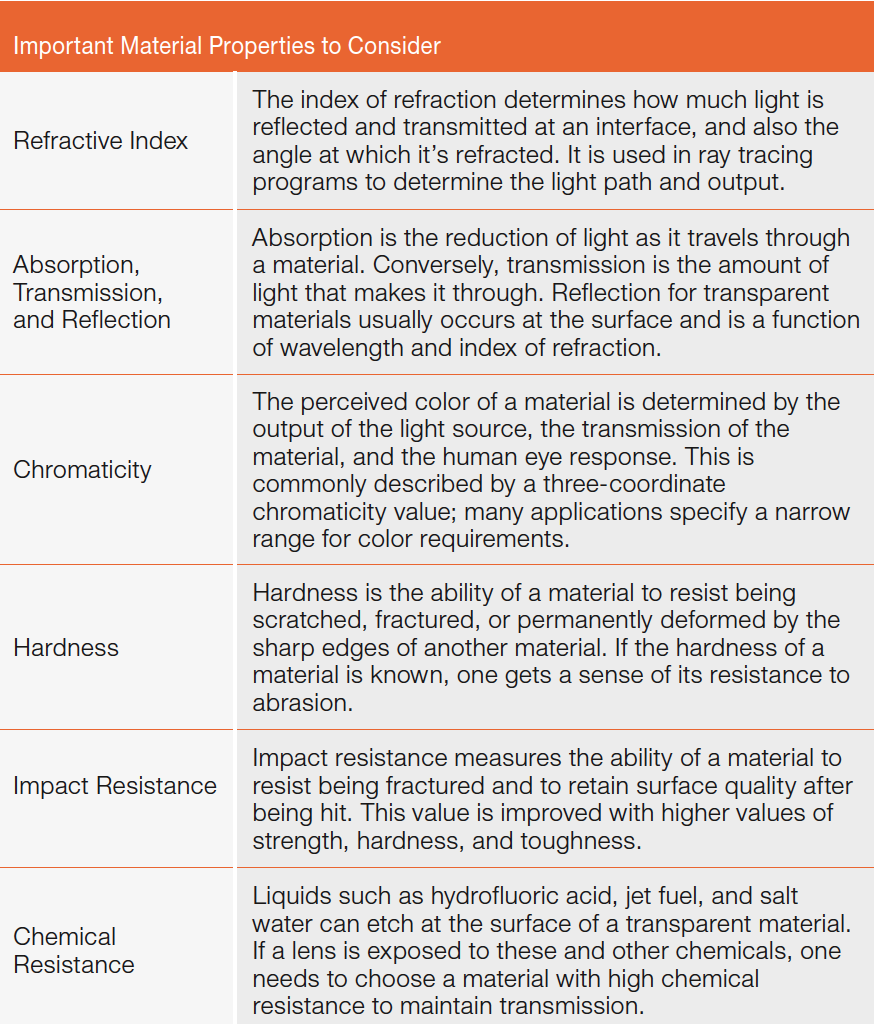

There are many transparent materials out there to consider when designing a lens for a lighting application. On the surface, they may look similar. However, not all transparent materials perform the same. They have unique properties that dictate how they control light; below is a table that reviews important properties to consider when evaluating optical lens materials (Table 1). Table 1: Explanation of the most important optical material properties that need to be considered in a design process

Table 1: Explanation of the most important optical material properties that need to be considered in a design process

The design of the optic can also change the light output; for example, if the optic is too thick, it may change the color of the emitted light or decrease its intensity. In applications with specific color requirements, such as transportation signaling or airfield lighting, this could cause the light to shift out of specification.

When it comes to transparent materials, there is no one-size-fits-all solution. Every lighting system has its set of requirements and an operating environment that will influence the selection. It is important to understand the temperature range, light output, and durability requirements for the optical lens.

LEDs are still relatively expensive, and they contribute most of the cost of LED systems. Optimization of the optic and other system components can reduce the number of LEDs needed, allows using less powerful LEDs, or even using fewer LEDs in an array design. As a result, more affordable LED systems can be created. The following sections will demonstrate how optics can impact other components in the lighting system and improve the overall performance of the entire system.

LED Selection

The light color and intensity when using an optic is determined by both the spectral distribution of the light source and the optical properties of the lens material, as discussed in the table above. If one just thinks, “What LED will replace my incandescent bulb?” then one might fail to remember that the two light sources have different spectral power distributions. On top of that, every LED has a unique spectral power distribution. Selecting the best LED for the application should be an iterative process as the optic’s material and design can change the light output.

At the beginning of an LED light fixture design, it is important to select an LED that best meets the application’s requirements. After creating the initial optic design, the LED selection should be revisited. Once it is known which results can be achieved with an optic, the LED that will perform best in the application can be determined.

When the light source’s spectral power distribution is known, the optical design can be modified to achieve the desired chromaticity and photometric results. If the material is not optimized to the LED, slight changes in color could require to select another LED entirely or to change the LED bin. The optic manufacturer and designer can help determine any color shifts due to the optic and ensure to make the best LED color choice.

LED Array Design

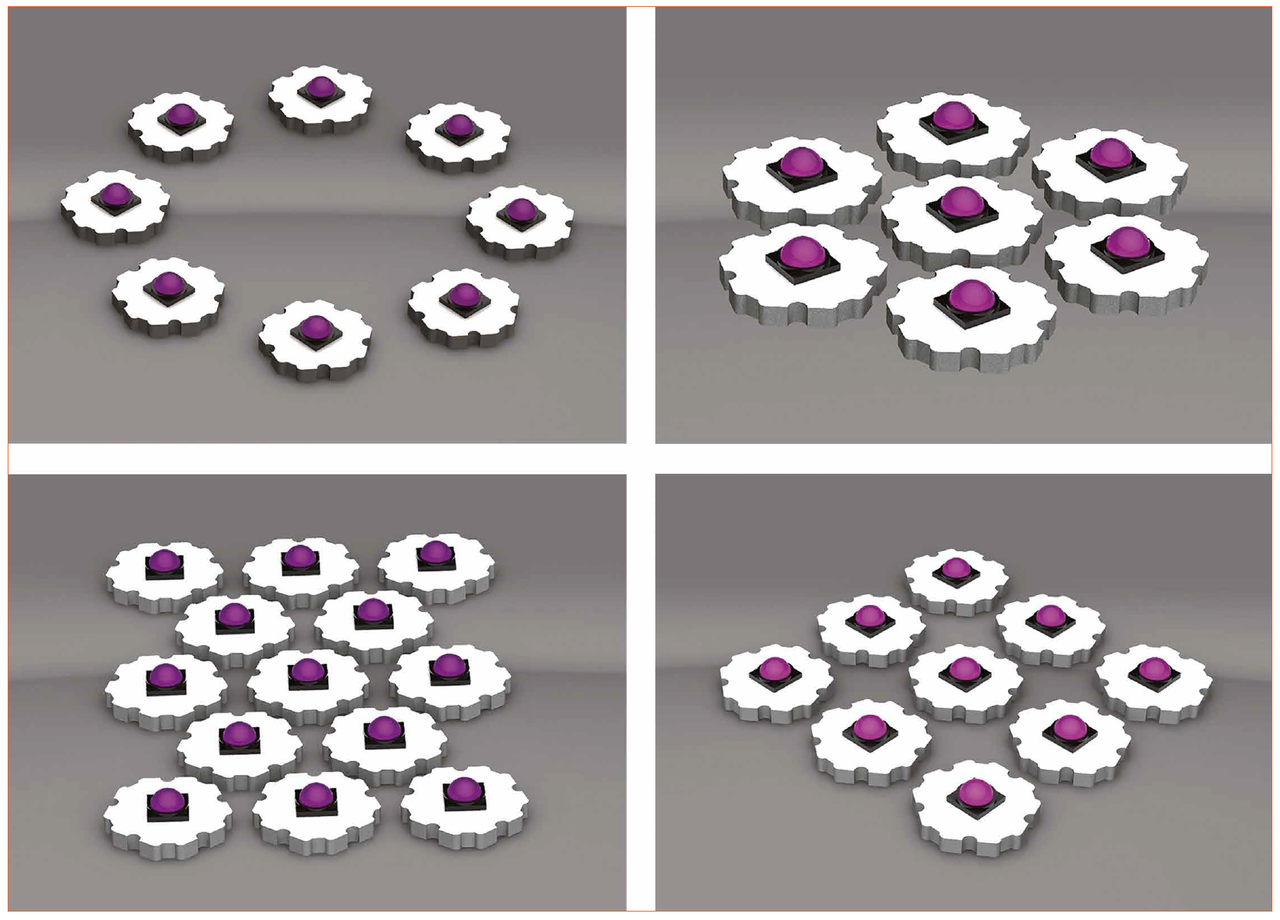

There are three components to an array design that should be considered simultaneously: spacing of LEDs, the number of LEDs, and their direction. The optic has a significant influence on these three aspects of LED array design.

Spacing

LED spacing determines the efficiency and cost of the system, as well as the quality of the light emitted from the array. Simply, if LEDs are spaced too closely to one another in an array, one will have excess light. To correct this, the space between the LEDs could be increased and the number of LEDs reduced. The use of an optic ensures that one will still meet the light output requirements, but with fewer LEDs. This combination reduces the number of costly LEDs needed as well as improves the overall efficiency of the system.

In contrast, if LEDs are spaced too far apart, there could be quality concerns due to inconsistent light distribution patterns. Again, an optic can be used to improve the uniformity of the light distribution pattern while still limiting the number of LEDs used.

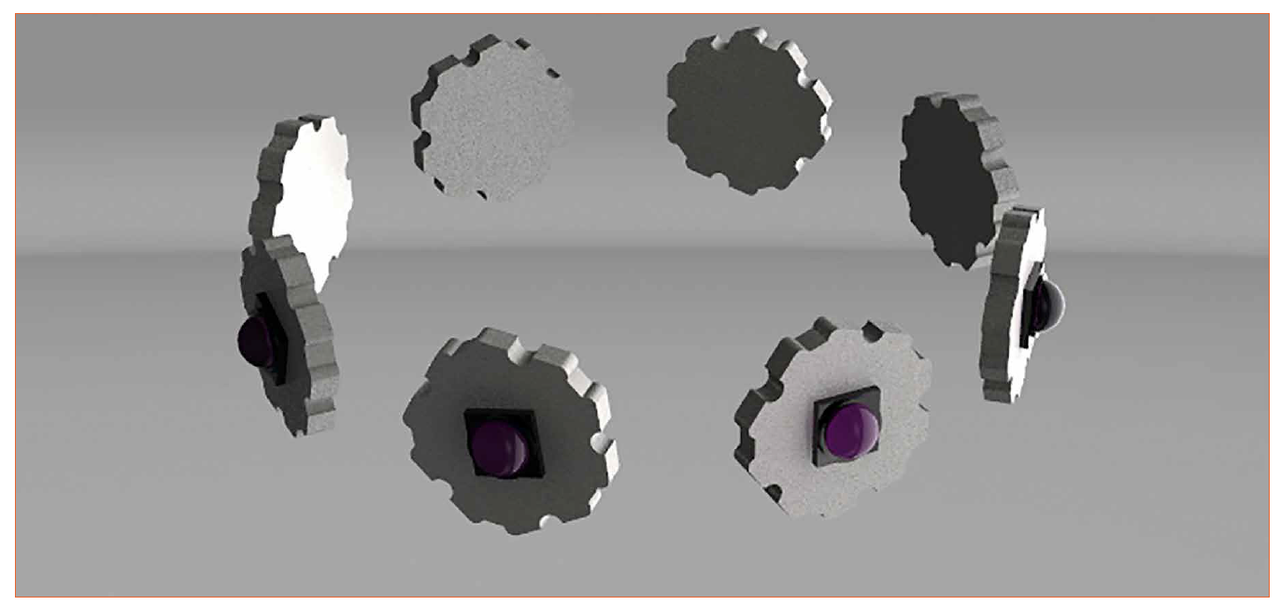

Figures 1: Some examples of how LED arrays can be arranged so they provide very different system properties

Figures 1: Some examples of how LED arrays can be arranged so they provide very different system properties

LEDs provide ample design flexibility; so consider all array possibilities. Depending on the desired output distribution, the LED array can be positioned in an infinite number of ways (Figure 1): circular, rectangular, offset rectangle, honeycomb, etc.

Number

It shouldn’t be a surprise to learn that the number of LEDs also works side-by-side with LED spacing. The increased power output that an optic provides can increase the efficiency of the system and allows decreasing the number of LEDs in an array. Optimization of the number of LEDs and their spacing will produce an array that maximizes space and efficiency. The number of LEDs also dictates the level of thermal management that is required. Selecting fewer LEDs or a lower drive current can increase the useful life of the LED system [1, 2], which is discussed in the section on thermal management.

Direction

Since LEDs are directional light sources, they need to be positioned so that the light exits in the desired direction. The simplest arrays are positioned on a flat surface with all LEDs directed in the same orientation. However, some arrays can take advantage of the unique flexibility that individual LEDs provide. For example, an omnidirectional fixture that positions LEDs in a ring (Figure 2) pointing away from the center rather than using an upward facing array would reduce the need for a reflector to direct the light outward.

Figure 2: A three dimensional arrangement of the LEDs is also possible and leads to omnidirectional light distribution

Figure 2: A three dimensional arrangement of the LEDs is also possible and leads to omnidirectional light distribution

There are many array design options; some are more practical and affordable than others. optics play a big role in determining what is most feasible with the lowest manufacturing cost. When designing a new LED light, it is important to consider how an optic works with an array and how it can help to achieve the best performance.

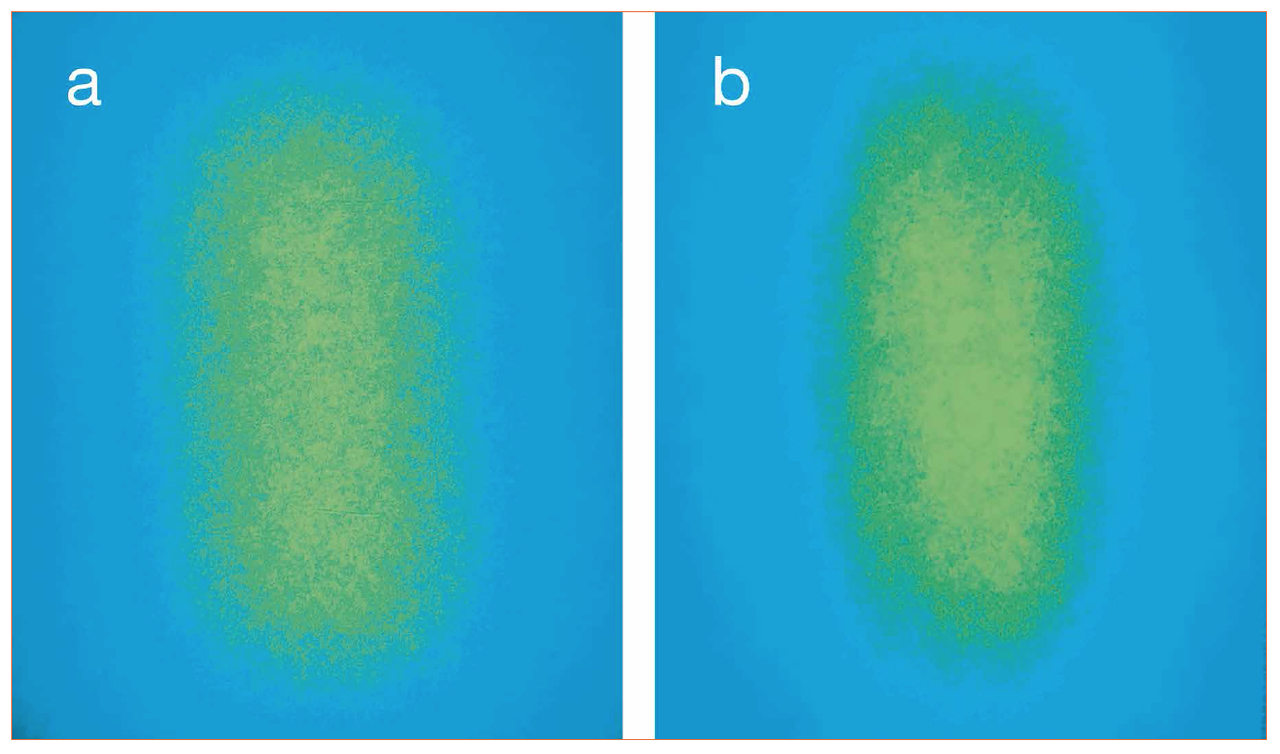

Figure 3: Pictured on the left (a) is an irradiance pattern produced without an optic. On the right (b), the irradiance pattern that is produced when an optic is added to the same array. The optic increased irradiance by 20%. This increase enables numerous benefits to the LED system, including reduced power consumption and lower thermal management requirements, and potentially longer LED lifetimes

Figure 3: Pictured on the left (a) is an irradiance pattern produced without an optic. On the right (b), the irradiance pattern that is produced when an optic is added to the same array. The optic increased irradiance by 20%. This increase enables numerous benefits to the LED system, including reduced power consumption and lower thermal management requirements, and potentially longer LED lifetimes

Thermal Management: Use Optics to Improve Efficiency

Unlike conventional light sources, visible LEDs do not produce infrared radiation. The semiconductor processes that generate light in an LED are not 100% efficient, and they do produce some heat in addition to light. If the internal quantum efficiency of an LED is 30%, then that means 70% of the input power is lost as heat.

So where does that heat go?

Heat sinks, heat pipes, vapor chambers, and other heat-spreading devices are commonly used to provide a path for the heat to escape through the backside of the LED. These thermal management controls come in many different materials, shapes, and sizes and are a crucial component in dissipating excess heat.

Research has demonstrated that the primary cause of light output degradation is heat generated at the pn-junction [3, 4]. Unlike conventional light sources - which fail catastrophically - the light output from LEDs degrades over time. To increase the useful life of an LED, it is mandatory to use efficient thermal management systems and consider the design of the system as a whole.

LEDs are rated for specific drive currents; however, it is easy to drive them either higher or lower than what is recommended by the manufacturer. Overdriving the LED to increase the light output increases the junction temperature of the LED. As a result, the LED will degrade more quickly.

An alternative is to identify the target light output, and then determine how an optic can optimize the LED array. As discussed above, optics can be used to harness and target an LED’s light output. This could allow decreasing the forward current to the LEDs, which would result in a reduction of heat at the pn-junction. One could also consider using an array design that allows reducing the number of LEDs in the light fixture. The addition of an optic allows maintaining the desired light intensity with fewer LEDs, and therefore, less heat that needs to be managed.

Conclusion: Start with the Optic for Fully Optimized LED Lighting Systems

Optical components are just one part of the LED lighting system, but they can have a powerful influence on the other components in the system. They can be used to create fully optimized LED lighting fixtures that are more efficient with longer useful lifetimes. This is why developing the optical component early in the design process is a necessity. Collaboration with the optical lens manufacturer not only reduces product development costs and time but ensures that one produces an efficient light fixture both for manufacturing and application purposes.

References:

[1] The Lighting Research Center. How are LEDs affected by heat? Available at: http://www.lrc.rpi.edu/programs/nlpip/ lightinganswers/led/heat.asp Accessed: 06/20/2016

[2] Philips Lumileds. Understanding power LED lifetime analysis. Available at: http://www.ledjournal.com/main/wp-content/ uploads/2012/05/Philips_Understanding-Power-LED-Lifetime- Analysis.pdf Accessed: 06/24/16

[3] Fukuda M., Reliability and Degradation of Semiconductor Lasers and LEDs, Artech House. 1991

[4] The United States Department of Energy. Energy Efficiency and Renewable Energy. Lifetime of White LEDs. Available at: http:// apps1.eere.energy.gov/buildings/publications/pdfs/ssl/lifetime_ white_leds.pdf Accessed: 06/10/2016