Hybrid Quantum Dot Light Emitting Electrochemical Cells

Several new light generation technologies that are overshadowed by LEDs and OLEDs are investigated. Most of these technologies are in a very early stage of research. One such technology, the LEC technology, was presented at LpS 2017. Light emitting electrochemical cells can be compared to OLEDs, but they are based on a much simpler inorganic architecture. The innovation in the presented approach lies in the combination with quantum dots, resulting in a hybrid solution. This novel attempt with all its consequences and future prospects was the reason that the LpS Scientific Award jury voted to bestow the award on Dr. Ekaterina Nannen, Group Leader of the Research Group „Solid State Lighting“ at the Nano-Energie-Technik- Zentrum (NETZ) of the University Duisburg-Essen and her research team, Julia Frohleiks and Svenja Wepfer.

The solution based processing makes light emitting electrochemical cells (LECs) a promising device alternative for large area flexible lighting solutions. Compared to organic light emitting diodes (OLEDs) and Quantum Dot (QD) LEDs, LECs exhibit a much more simple device architecture comprising ionic components, which facilitate charge carrier injection into the device under an applied electrical field. Despite the potential benefits of LECs as well as recent advances, the market entry of these types of devices is challenging mainly due to the lack of coinciding efficient, bright and long-term, stable emitter materials of different colors. We present an all solution based hybrid device concept implementing colloidal QDs as an additional active light emitting layer in Ir-iTMC based LECs. The hybrid devices show light emission from both QDs and LEC emitter. Electro- and photoluminescence measurements indicate that in the chosen device architecture, charge carriers can be injected directly into both light emitting species, which is beneficial for the implementation of QDs with various band gaps, and thus creation of white light emitting hybrid devices. The additional QD layer furthermore improves the electron injection into the active LEC layer which leads to a faster device turn-on and an improved charge carrier balance, resulting in an increased luminance and device efficiency. Hybrid devices containing yellow emitting iTMC and blue QDs emit white light at a maximum CRI of 78 with an external quantum efficiency of 0.03 %.

Introduction

Future lighting applications exceed the pure creation of light and get more and more inspired by innovative design possibilities due to large-area and at the same time flexible lighting technologies. The prototypes of light-emitting stickers, wallpapers and windows as well as animated rear lights are becoming reality [1-4]. Along with cost-effective and easy solution-based fabrication techniques, the next generation of lighting technologies can overcome challenges of epitaxial LEDs in flexible and shapeable design applications, leading to space-saving installation of light-sources in multiple applications. Light-emitting electrochemical cells (LECs) [4-7] represent a promising alternative for large-area device concepts, besides the more common organic light-emitting diodes (OLED) [8,9]. In contrast to OLEDs, the active layer of the LECs comprises ionic components in addition to the light emitting species (polymers or transition metal complexes). The incorporated ions start moving due to the electrical field at applied voltage and thereby facilitate charge injection into the light-emitting component, so that the multiple charge injection and transport layers, which need to be carefully controlled, specifically optimized and are thus mandatory for OLEDs, can be omitted. The whole layer stack can be simplified (even down to a single layer), only by the addition of mobile ionic species. Furthermore, air-stable electrode materials can be implemented and thickness variations of the active layer can be tolerated, so that easy solution-based fabrication procedures such as spin-coating, spraying, printing or slot die and dip coating can be established even in ambient conditions [4-7,10,11].

Since the charge carrier injection and transport in this type of device is initiated by the movement of the ionic species, the response and turn-on time of LECs is comparatively long, making LECs more applicable in lighting technology rather than high-end displays [5,12]. Based on the active light-emitting material, two different classes of LECs can be defined as it is also the case for OLEDs: polymer LECs (p-LECs) or ionic transition metal complex LECs (iTMC-LECs). iTMC-LECs are able to harvest both singlet and triplet excitons and thus allow for intrinsically higher quantum efficiencies than fluorescent p-LECs, resulting in typically higher brightness above 1000 cd/m2 [10,13-16]. In case of yellow iTMC-based LECs, intramolecular π-π stacking interactions led to a stable emitter complex and, together with the introduction of a pulsed operation mode, yielded yellow LEC devices with lifetimes exceeding 4000 hours at maximum luminance over 650 cd/m2 and sub-second turn-on times [15,17].

Despite the potential benefits of the iTMC-LECs as well as recent advances [5], the market entry of these types of devices is challenging mainly due to the lack of at the same time efficient, bright, and long-term stable emitter materials of different colors, resulting in challenges in the realization of white emission [18,19]. Combining the stability of semiconducting materials with their solution-based properties, colloidal quantum dots (QDs) offer an alternative approach for large-area lighting concepts due to their high color purity which is tunable over a broad spectral range by tailoring their size, shape and composition [20]. The expansion of the iTMC-LEC device by incorporation of colloidal QDs of different colors opens an alternative path not only for the variation of the LEC emission color. Even white light-emitting or color tunable hybrid devices can be realized depending on the chosen QD type and device geometry.

Development of Quantum Dot LEC Hybrid Devices

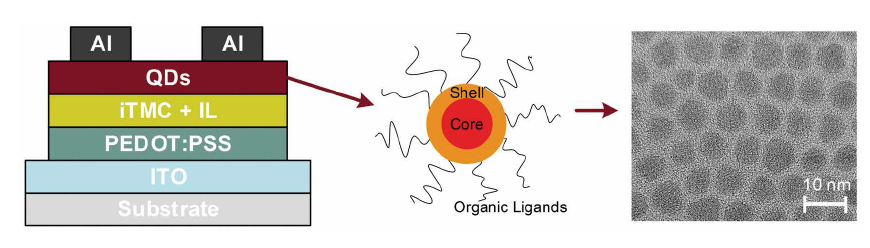

The device concept of a Quantum Dot LEC Hybrid Devices (QLEC) was presented to potentially improve two critical issues of the iTMC-LEC, the performance and the emission color, simultaneously. Therefore, the typical LEC device design, comprising the transparent ITO, coated by the poly(3,4-ethylenedioxy-thiophene): poly(styrenesulfonate) (PEDOT:PSS) as an anode, and the active LEC layer (iTMC + ionic liquid, IL), is complemented by an additional QD layer prior to the Aluminum cathode (Figure 1). In this case, the iTMC layer can be expected to act as a hole injection and transport layer for the QDs [2], on the other hand the QD layer can also improve the electron injection into the iTMC. Additionally, the device design gives the opportunity to combine the emission of two active light-emitting species, which enables the color tuning of the QLEC device.

Figure 1: Schematic of the device design, schematic of core shell QDs and TEM image of QDs

Figure 1: Schematic of the device design, schematic of core shell QDs and TEM image of QDs

Figure 1 shows the schematic device design of the QLEC. The glass substrate is covered with a 150 nm thick sputtered ITO layer, serving as the device anode. The anode is followed by PEDOT:PSS (Clevios by Hereaus, filtered, annealed at 150°C for 20 minutes), iTMC+IL ([Ir(ppy)2(pbpy)]+[PF6]-, [BMIM]+[PF6]- dispersed in acetonitrile, filtered) and QDs (dispersed in toluene) which are all deposited subsequently via the spin-coating procedure. The selected CdSe/CdS QDs were synthesized with a slightly modified procedure from the literature [22]. They have typical core/shell structure and are capped with insulating ligands as schematically shown in figure 1. The QDs have average size of 7 nm (TEM image), with CdSe core radius of 2.1 nm, 6 monolayers CdS shell and zinc blende crystal structure.

Red QLEC: Color tuning properties and operation mechanism

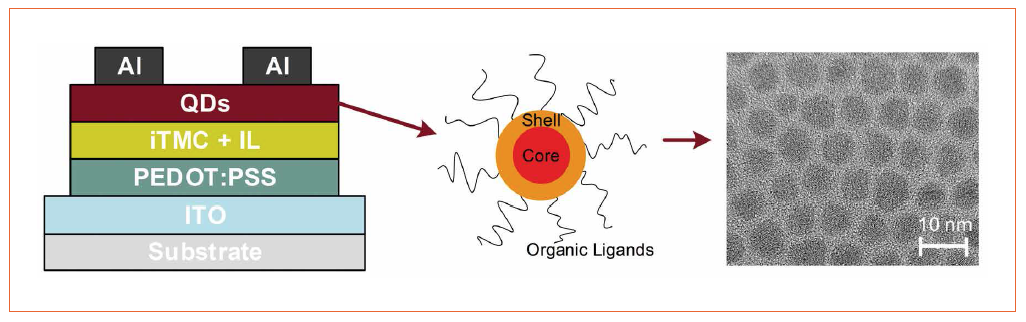

The combination of QDs and iTMCs in a hybrid device (QLEC) by adding an additional QD layer prior to the cathode to the conventional iTMC LEC architecture already showed promising results for the implementation of red QDs. We observed light emission from both light-emitting species which can be adjusted by the applied voltage (inset in Figure 2). For an applied voltage in the range of 2.5-3 V the device shows large area red emission which is caused by the red QDs. In this voltage range the device seems to operate as a QLED with active, light-emitting QDs and an iTMC layer acting as a hole injection and transport layer for the QDs. With increasing applied voltage, the iTMC contribution is raised so that the emission color of the device is shifted from red to orange. At a voltage higher than 5 V the emission is dominated by the iTMC, so that the device shows large-area yellow emission (inset of Figure 2).

Figure 2: Luminance of QLED, QLEC and LEC with increasing applied voltage. Inset shows the prepared QLED, QLEC and LEC devices under UV illumination as well as photographs of the light-emitting QLEC with increasing applied voltage

Figure 2: Luminance of QLED, QLEC and LEC with increasing applied voltage. Inset shows the prepared QLED, QLEC and LEC devices under UV illumination as well as photographs of the light-emitting QLEC with increasing applied voltage

The voltage dependent luminance behavior of the QLEC is shown in figure 2 in comparison with the reference LEC (device structure ITO/PEDOT:PSS/iTMC+IL/Al) and reference QLED (device structure ITO/PEDOT:PSS/poly-TPD/QDs/Al) devices ( also photographs in the inset). While the QLED and LEC reference devices show maximum luminance at 8 V of 342 cd/m2 and 548 cd/m2 respectively, with a tendency of further increase at higher voltages, the QLEC reaches its brightness maximum of 385 cd/m2 at 7.7 V followed by a slow reduction of the luminance at higher voltages, e.g. 335 cd/m2 at 8 V. Nevertheless, the QLEC exhibits a higher brightness compared to the LEC reference device over a wide range of operating voltages. Moreover, the additional QD layer has a significant impact on the turn-on voltage of the device. The reference LEC shows a turn-on at about 4 V, whereas the QLEC starts emitting light already slightly below 2 V. The reduction in turn-on voltage can be attributed to pure QD emission in this low voltage range with the iTMC layer working as a hole injection and transport layer. At the same time, the injection and transport of holes by the iTMC layer into the QDs in the hybrid device is obviously less efficient than in case of the poly-TPD layer: the reference QLED has a turn-on voltage of 1.5 V in agreement with state of the art red QLEDs [21,23]. In addition, it shows more than one order of magnitude higher luminance in the low-voltage regime compared to the QLEC.

At voltages above 3.5 V, the contribution of the iTMC emission to the total emission of the QLEC increases and even becomes several orders of magnitude higher than the iTMC emission from the reference LEC in the range between 3.5 V and 6 V. We attribute this behavior to the improved electron injection into the iTMC layer by the QD layer, which was also observed during long-term measurements at constant applied voltage [24]. Thereby, an improved charge carrier injection into the iTMC layer results in a faster build-up of the doped regions, resulting in a faster turn-on of the devices.

The QLEC exhibits pure QD emission at a voltage range, where the LEC reference does not emit any light at all. This excludes color conversion as a possible mechanism for light generation and gives further confirmation of direct charge injection. In addition, time-resolved PL measurements indicated that the emission is not dominated by energy transfer excitation (e.g. Förster transfer) but rather by direct charge injection into both active layers which is contrary to mixing concepts as suggested for p-LECs by Norell Bader et al. [25] and for pure QDs by Qian et al. [24, 26]. Thus, the excitation mechanism of the QLEC device enables the application of blue QDs yielding white light-emitting hybrid devices.

Towards efficient white QLEC: integration of blue QDs

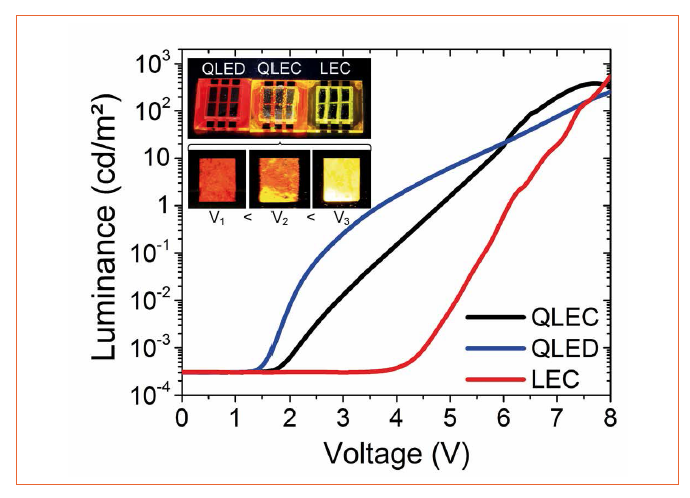

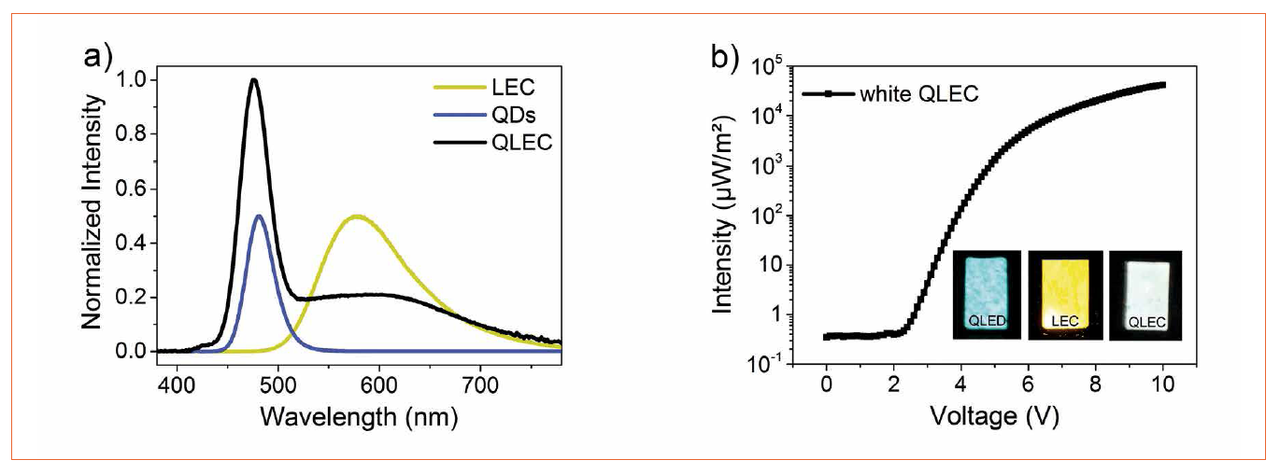

Since charge carriers can be injected directly into both light-emitting species in the QLEC device geometry, the implementation of QDs with various band gaps should enable the creation of white light-emitting hybrid devices. For this purpose, the red QDs were replaced by blue ZnCdSe/ZnS core/ shell QDs with emission wavelength of 488 nm. The normalized emission of the blue QDs and the iTMC based yellow LEC are shown in Figure 3a. The iTMC shows a broad emission (FWHM > 100 nm) in the yellow color range, which is typical for iTMC emitters based on charge transfer transitions [27]. The first hybrid device shows superposed emission from both light-emitting species. A maximum CRI of 78 can be reached when the proportion of the QD emission is almost doubled compared to the LEC component emission. The voltage dependent light intensity of the white QLEC is shown in Figure 3b. The QLEC shows light emission at a slightly increased turn-on voltage of about 2.5 V. The emission intensity increases with increasing applied voltage, reaching the maximum intensity at 10 V. All three devices (LEC, QLED and QLEC) show large area emission as shown in the photographs of the light emitting devices in the inset in Figure 3b. Although the maximum CRI values, turn-on voltage and the emission profile of the white QLEC hybrid already show promising characteristics, it should be admitted, that the hybrid device shows yet a maximum external quantum efficiency (EQE) of only 0.03 %. We attribute this mainly to imbalanced charge injection and transport within device. Especially hole injection into the blue QDs with significantly higher injection barrier, compared to red QDs, needs to be improved in future devices.

Figures 3a&b: Normalized emission spectra of LEC, QDs and QLEC device (a); Intensity of white QLEC depending on the applied voltage and photographs (inset) of blue QLED, yellow LEC as well as white QLEC (b)

Figures 3a&b: Normalized emission spectra of LEC, QDs and QLEC device (a); Intensity of white QLEC depending on the applied voltage and photographs (inset) of blue QLED, yellow LEC as well as white QLEC (b)

Conclusions

In conclusion, we demonstrate large area, solution-processed hybrid devices made of red and blue core/ shell CdSe-based QDs and an Ir-based iTMC that shows light emission from both QDs and yellow LEC emitters. The additional red QD layer prior to the device cathode facilitates the electron injection into the active LEC layer, which improves the LEC device performance. This demonstrates the possibility of creating color tunable iTMC LECs by implementing additional QDs and simultaneously improving the device operation. The direct charge injection into both light-emitting species enables the electrical excitation of blue QDs together with the yellow iTMC component and thus creation of white light-emitting hybrid devices. Although the performance of the developed white QLEC devices needs further improvement, they already exhibit large area emission with promising CRI values of 78.

References:

[1] X. Yang, E. Mutlugun, C. Dang, K. Dev, Y. Gao, S. T. Tan, X. W. Sun, H. V. Demir, ACS Nano 2014, 8, 8224

[2] J. Liang, L. Li, X. Niu, Z. Yu, Q. Pei, Nat. Photonics 2013, 7, 817

[3] G. M. Farinola, R. Ragni, Chem. Soc. Rev. 2011, 40, 3467

[4] A. Asadpoordarvish, A. Sandström, C. Larsen, R. Bollström, M. Toivakka, R. Österbacka, L. Edman, Adv. Funct. Mater. 2015, 25, 3238

[5] S. B. Meier, D. Tordera, A. Pertegás, C. Roldán-Carmona, E. Ortí, H. J. Bolink, Mater. Today 2014, 17, 217

[6] A. Sandström, L. Edman, Energy Technol. 2015, 3, 329

[7] Z. Zhang, K. Guo, Y. Li, X. Li, G. Guan, H. Li, Y. Luo, F. Zhao, Q. Zhang, B. Wei, Q. Pei, H. Peng, Nat. Photonics 2015, 9, 233

[8] S. Reineke, M. Thomschke, B. Lüssem, K. Leo, Rev. Mod. Phys. 2013, 85, 1245

[9] P. Kathirgamanathan, L. M. Bushby, M. Kumaraverl, S. Ravichandran, S. Surendrakumar, J. Disp. Technol. 2015, 11, 480

[10] R. D. Costa, E. Ortí, H. J. Bolink, F. Monti, G. Accorsi, N. Armaroli, Angew. Chem. Int. Ed. 2012, 51, 8178

[11] G. Hernandez-Sosa, S. Tekoglu, S. Stolz, R. Eckstein, C. Teusch, J. Trapp, U. Lemmer, M. Hamburger, N. Mechau, Adv. Mater. 2014, 26, 3235

[12] S. van Reenen, R. A. J. Janssen, M. Kemerink, Org. Electron. 2011, 12, 1746

[13] M. Baldo, D. F. O’Brien, Y. You, A. Shoustikov, S. Sibley, M. E. Thompson, S. R. Forrest, Nature 1998, 395, 151

[14] T. Hu, L. He, L. Duan, Y. Qiu, J. Mater. Chem. 2012, 22, 4206

[15] D. Tordera, S. Meier, M. Lenes, R. D. Costa, E. Ortí, W. Sarfert, H. J. Bolink, Adv. Mater. 2012, 24, 897

[16] A. M. Bünzli, E. C. Constable, C. E. Housecroft, A. Prescimone, J. A. Zampese, G. Longo, L. Gil-Escrig, A. Pertegás, E. Ortí, H. J. Bolink, Chem Sci 2015, 6, 2843

[17] H. J. Bolink, E. Coronado, R. D. Costa, E. Ortí, M. Sessolo, S. Graber, K. Doyle, M. Neuburger, C. E. Housecroft, E. C. Constable, Adv. Mater. 2008, 20, 3910

[18] L. He, L. Duan, J. Qiao, G. Dong, L. Wang, Y. Qiu, Chem. Mater. 2010, 22, 3535

[19] J. Wu, F. Li, Q. Zeng, C. Nie, P. C. Ooi, T. Guo, G. Shan, Z. Su, Org. Electron. 2016, 28, 314

[20] Y. Shirasaki, G. J. Supran, M. G. Bawendi, V. Bulovic, Nat. Photonics 2012, 7, 13

[21] B. S. Mashford, M. Stevenson, Z. Popovic, C. Hamilton, Z. Zhou, C. Breen, J. Steckel, V. Bulovic, M. Bawendi, S. Coe-Sullivan, P. T. Kazlas, Nat. Photonics 2013, 7, 407

[22] O. Chen, J. Zhao, V. P. Chauhan, J. Cui, C. Wong, D. K. Harris, H. Wei, H.-S. Han, D. Fukumura, R. K. Jain, M. G. Bawendi, Nat. Mater. 2013, 12, 445

[23] W. Ji, P. Jing, L. Zhang, D. Li, Q. Zeng, S. Qu, J. Zhao, Sci. Rep. 2014, 4, 6974

[24] J. Frohleiks, S. Wepfer, Y. Kelestemur, H. V. Demir, G. Bacher, E. Nannen, ACS Appl. Mater. Interfaces 2016, 8, 24692

[25] A. J. Norell Bader, A. A. Ilkevich, I. V. Kosilkin, J. M. Leger, Nano Lett. 2011, 11, 461

[26] G. Qian, Y. Lin, G. Wantz, A. R. Davis, K. R. Carter, J. J. Watkins, Adv. Funct. Mater. 2014, 24, 4484

[27] R. D. Costa, E. Ortí, H. J. Bolink, S. Graber, S. Schaffner, M. Neuburger, C. E. Housecroft, E. C. Constable, Adv. Funct. Mater. 2009, 19, 3456.

(c) Luger Research e.U. - 2017