LED-Retrofit Based on AlGaN/GaN-on-Si Field- Effect Transistor Drivers

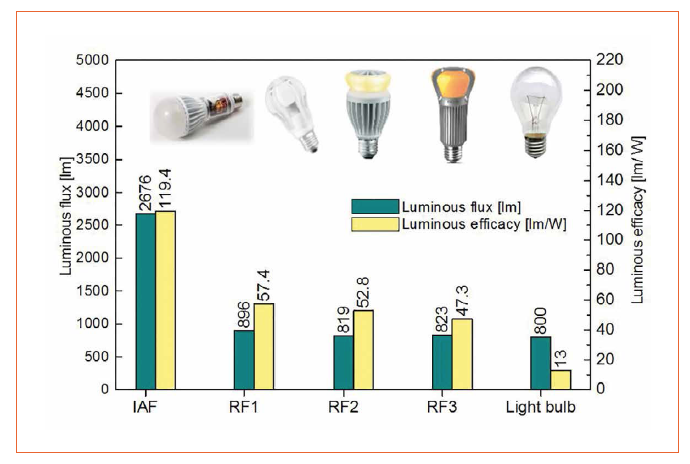

Efficient driver technologies for LED systems are still a relevant topic. Several new approaches are proposed and new technologies are under development. Andreas Zibold, PhD student at the Fraunhofer Institute for Applied Solid State Physics IAF, and his co-authors, M. Kunzer, R. Reiner, B. Weiß, P. Waltereit, R. Quay, J. Wagner, and O. Ambacher demonstrate the suitability of AlGaN/GaNon- Si field effect transistors (FETs) for their use in LED drivers. The transistors are tested in an isolated buck converter and an efficiency of 86% is measured for the full converter circuit. The driver circuit is combined with an LED module based on a laser-structured Aluminum Nitride (AlN) ceramic board onto which 21 high power white-emitting LED chips are mounted. This combination resulted in an LEDRetrofit lamp with a total light output of 2676 lm at an efficacy level of 119 lm/W. The results compare favorably to state-of-the-art commercial solutions.

In contrast to conventional light sources that can operate under alternating current (AC), LEDs need a driver circuit to convert the AC line voltage into a constant current. There is a high cost pressure on LED luminaire manufacturers, which also affects the available budget for LED driver solutions. For many lighting applications it is of utmost importance that the driver is small in size, because either only limited space is available in the luminaire, or the design flexibility for innovative lighting solutions can be increased. An ideal LED driver is highly efficient, has low production costs, and yields a small form factor. All these properties can be achieved using wide-bandgap semiconductors, such as Gallium Nitride (GaN) or Silicon Carbide (SiC) in LED drivers instead of Silicon devices. The physical properties of these materials like the breakdown electric field strength or the electron mobility are superior compared to Silicon (Si) for the use in power electronics [1]. However, conventional Silicon devices are still dominating the market since this technology is highly sophisticated and inexpensive compared to wide bandgap materials. Especially in price sensitive markets, such as solid-state lighting, a competitive cost structure compared to silicon devices is mandatory for a market penetration of such wide-bandgap semiconductors. Especially GaN-on-Si transistors are attractive for LED drivers, since they exhibit low conduction losses and enable high switching frequencies, while they are expected to become cost competitive to Silicon devices in the near future (Figure 1 and Figure 2). It is expected that the cost gap between Si and SiC based devices will remain significant in the foreseeable future.

GaN-on-Si Transistors

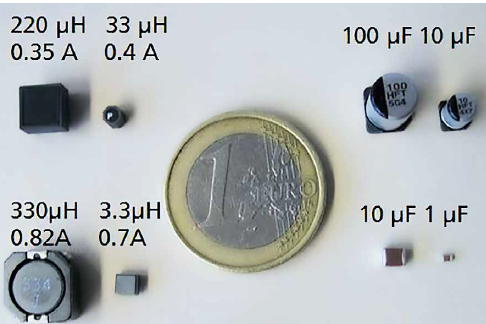

With increasing switching frequencies passive components can be shrunk (Figure 3), which saves costs and leads to more compact solutions.

Thus, GaN-on-Si based drivers may potentially become a low-cost solution with even lower system costs than silicon-based drivers. Furthermore, LED luminaires are long lasting with lifetimes of up to 100,000 hours and therefore the use of short-lived electrolyte capacitors has to be avoided. However, the high capacitances needed for conventional driver designs, can hardly be reached with the long-lasting ceramic capacitors. Thus, the lifetime of the whole lighting system can be increased by the usage of GaN-on-Si transistors in combination with a high switching frequency and ceramic capacitors.

In this study AlGaN/GaN-on-Si HFETs, which are developed, fabricated [2] and characterized [3] at Fraunhofer IAF, are implemented in fast-switching power converters. A high device performance is achieved as can be seen from their static-and dynamic-parameters in comparison to commercial state-of-the-art silicon power devices. Compared to their Si-based counterparts, the GaN-devices achieve a factor of 3 lower static area specific on-state resistance RON.A, and by a factor of 3 lower static on-state resistance times gate charge product RON.Q.

LED Retrofit Based on GaN-on-Si Transistors

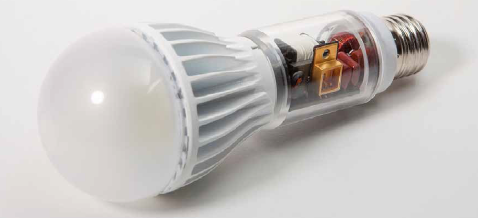

In order to demonstrate the capability of these power switches for solid-state lighting applications, a compact GaN-based LED driver circuit in an offline-isolated flyback topology has been developed and tested. Utilizing this driver, an LED retrofit lamp with an E27 socket (see Figure 4 and Figure 5) for light bulb replacement is demonstrated and compared to commercially available retrofits.

GaN-on-Si based LED driver

The driver circuit contains a power factor correction and a normally off cascode. Compared to Si-based counterparts, the GaN-HFET based demonstrator reveals an improved electrical conversion efficiency of 86 %. A maximum output power of 22.4 W is reached. An isolated topology with a transformer is used, as is state-of-the-art for standard Si-based drivers. This provides a high handling security but limits the switching frequency because hysteresis losses, which are proportional to the switching frequency, occur. In this work the switching frequency was set to 85 kHz. An alternative to transformer based isolated topologies are non-isolated topologies, which omit the transformer and the associated hysteresis losses. However, the handling security has to be guaranteed by isolating the electronics from all touchable parts, which may result in an increased packaging effort. Non-isolated GaN based LED drivers are discussed in more detail in [5].

LED module based on ceramic PCB

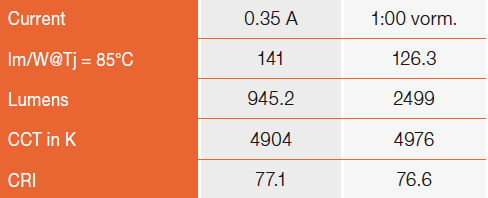

The LED module consists of 21 LUXEON TX [6] high power LEDs with specifications shown in Table 1. The LEDs mounted on a laser-structured Aluminum Nitride (AlN) ceramic board with a thermal conductivity in excess of 200 W/mK.

Table 1: Optical parameters of the LED module

Table 1: Optical parameters of the LED module

![Expected average selling price of a single 600V/10A transistor based on Si, SiC and GaN [4]](https://www.led-professional.com/media/resources-1_articles_led-retrofit-based-on-algan-gan-on-si-field-effect-transistor-drivers_screen-shot-2017-07-12-at-10-52-37.png/@@images/image-1280-68516452d9b904d3e04c565ab09e17cd.png) Figure 1: Expected average selling price of a single 600V/10A transistor based on Si, SiC and GaN [4]

Figure 1: Expected average selling price of a single 600V/10A transistor based on Si, SiC and GaN [4]

![Comparison of several physical properties of Si, SiC and GaN [4]](https://www.led-professional.com/media/resources-1_articles_led-retrofit-based-on-algan-gan-on-si-field-effect-transistor-drivers_screen-shot-2017-07-12-at-10-52-41.png/@@images/image-1280-68516452d9b904d3e04c565ab09e17cd.png) Figure 2: Comparison of several physical properties of Si, SiC and GaN [4]

Figure 2: Comparison of several physical properties of Si, SiC and GaN [4]

Figure 3: Physical size comparison of inductors and capacitors with different inductivity and capacity

Figure 3: Physical size comparison of inductors and capacitors with different inductivity and capacity

Figure 4: LED lamp in E27 bulb form factor with a power converter based on a GaN HFET in TO-220 package (section containing the power converter extended for demonstration purposes)

Figure 4: LED lamp in E27 bulb form factor with a power converter based on a GaN HFET in TO-220 package (section containing the power converter extended for demonstration purposes)

Figure 5: LED module with 21 Lumileds LUXEON TX white high-power LED chips mounted on a ceramic circuit board

Figure 5: LED module with 21 Lumileds LUXEON TX white high-power LED chips mounted on a ceramic circuit board

Figure 6: Conversion efficiency and electrical power consumption of the present LED lamp with GaN-based driver (left) and commercial LED lamps from different Retrofit manufacturers (RF) with Si-based driving electronics

Figure 6: Conversion efficiency and electrical power consumption of the present LED lamp with GaN-based driver (left) and commercial LED lamps from different Retrofit manufacturers (RF) with Si-based driving electronics

Spectral photometry measurements reveal that with the same lamp size a luminous flux of 2676 lm is achieved, which is three times higher than that of commercial retrofits, with an overall luminous efficacy of 119.4 lm/W (Figure 6).

Due to the electrical isolation of ceramic board, the packaging effort can be reduced even with non-isolated topologies. The LEDs were vacuum soldered using Sn62/Pb36/Ag2. The LED module reaches a measured electro-optical efficiency of 141 lm/W at a current of 350 mA. The Correlated Color Temperature (CCT) of the LEDs is close to 5000 K, i.e. the LEDs are emitting cold white. A Color Rendering Index (CRI) of 77.1 is achieved with the LED module.

Conclusions and Outlook

GaN-on-Si devices offer excellent properties regarding low switching and conduction losses. Compared to their silicon counterparts the GaN-devices achieve, by a factor of 3, a lower static area specific on-state-resistance RON.A, and by a factor 3 lower static on-state resistance times gate charge product RON.Q. In contrast to SiC, GaN-on-Si is expected to become cost competitive in the near future. Therefore it has the potential to be employed in consumer market applications with high cost pressure. The GaN-technology is still at the beginning of its development and epitaxial growth, design and assembly technology can be further improved. In this work the suitability of GaN-HFETs for LED Retrofit drivers has been demonstrated. GaN based drivers have passed the performance of commercial state-of-the-art silicon devices.

However, to fully raise the potential of GaN transistors the switching frequency has to be increased significantly to shrink the passive component size and cost. Therefore, future work concentrates on techniques to handle switching frequencies in the MHz-range, like spread-spectrum control schemes and non-isolated driver topologies.

Acknowledgement:

The authors would like to sincerely thank all the people at Fraunhofer IAF who were involved in the fabrication of the devices. Furthermore, this work was financially supported by the Ministry of Science, Research and Art Baden-Wuerttemberg (MWK) through the Sustainability Center Freiburg and the ‘‘SusLight’’ project.

References:

[1] B.J. Baliga, “Power semiconductor device figure of merit for high-frequency applications“, Electron Device Letters, IEEE, Issue Date: Oct. 1989, vol. 10 iss10, pp. 455 – 457.

[2] P. Waltereit, et al., “GaN-based high voltage transistors for efficient power switching”, Phys. Stat. Sol. C 10, No. 5, 831-834, 2013

[3] R. Reiner, et al., “Benchmarking of Large-Area GaN-on-Si HFET Power Devices for Highly-Efficient, Fast-Switching Converter Applications,” in Proc. of CSICS 2013, pp.1¬4, Oct. 2013

[4] Yole Développement SA, “Power GaN: GaN technologies for power electronic applications: Industry and market status & forecasts”, pp. 54, 94-97, 2014

[5] A. Zibold et al., ” High Voltage GaN-Based Schottky Diodes in Non-Isolated LED Buck Converters”, in Proc. of EPE 2016 ECCE Europe, 5-9th Sep. 2016

[6] Lumileds, “Extreme efficacy and best performance with compatibility to LUXEON T”, 2015 [Online]. Available: http://www.lumileds.com/ uploads/438/DS133-pdf. [Accessed Nov. 3, 2015]

(c) Luger Research e.U. - 2017