Potting Processes as a Part of LED-Based Lighting Module Manufacturing Methods by ViscoTec Pumpen and Dosiertechnik GmbH

Many manufacturing processes need very accurate dosing. One such dosing process concerns the potting of LED-modules. Numerous parameters affect the potting quality. Willi Huber from the Business Unit Adhesives & Chemicals at ViscoTec Pumpen- u. Dosiertechnik GmbH explains casting equipment, critical parameters and appropriate potting methods.

The specific objective of the potting of LED-modules is to protect the unit against environmental influences. The goal is to encapsulate the functional area for stable operating conditions. Surrounding factors which may affect the functionality or lifetime of the LED-assemblies and which need to be kept away are humidity, water (spray, condensation), oils/oil mist, chemicals, environment dirt, weathering, dust or mechanical stress from the outside. The protective function of LED modules using the potting approach is realized through the so-called casting compounds, of which there are a large variety.

Short Introduction to Common Potting Concepts

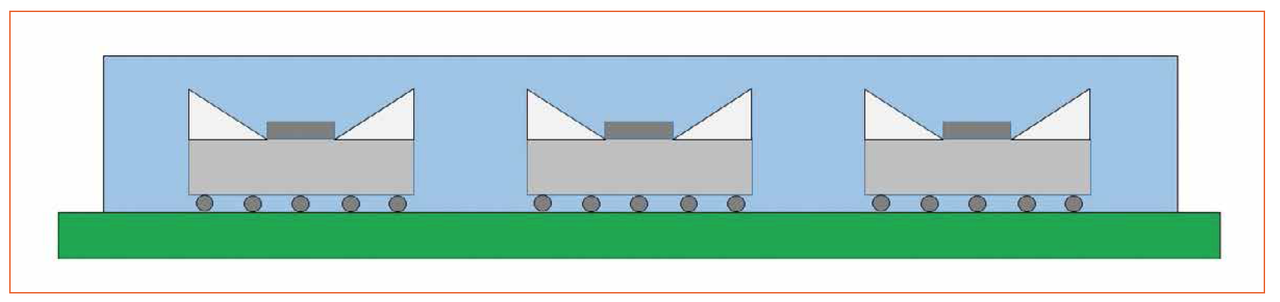

Fully potted with complete encapsulation of a module: The potting level is above upper component level.

Figure 1: Complete module encapsulation

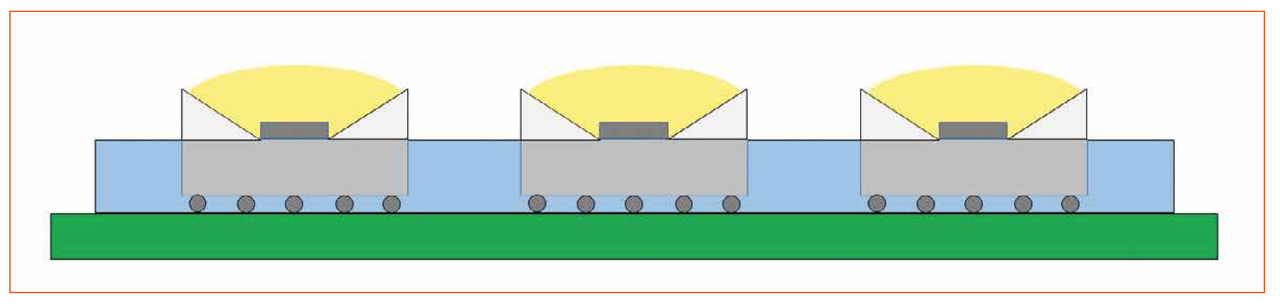

Partially potted with partial encapsulation of a module: The potting level is between lower and upper component level:

Figure 2: Partial module encapsulation

Figure 2: Partial module encapsulation

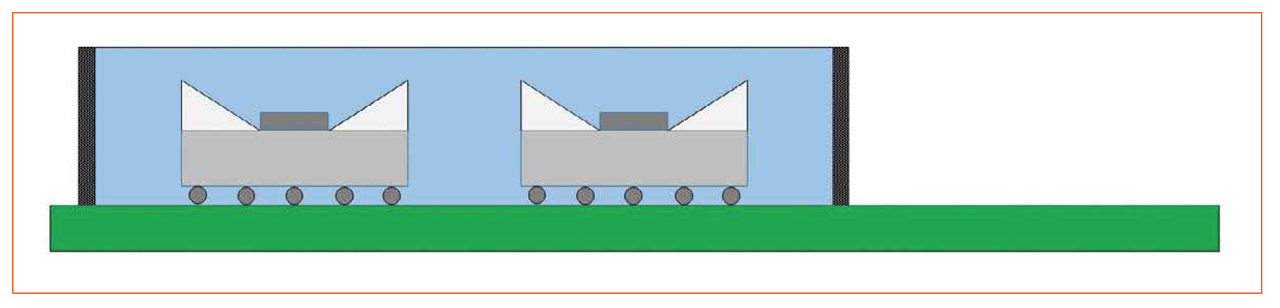

Selective encapsulation: Only a section/partial area of a module is encapsulated above the upper component level.

Figure 3: Selective encapsulation

Figure 3: Selective encapsulation

Potting compounds are applied in viscous consistency and cure to definable hardness values according to the set hardness mechanism. Potting materials are available in 1-component as well as 2-component types.

There is a significant number of process parameters that can influence the quality of a potting process in terms of a repeatable unit production. As a major aspect, the dosing volumes are relatively large in relation to the component or module size. The nature of a potting process is to fill a module completely with compound compared to bonding applications with dot or bead dosing shapes and related smaller dosing volumes. Consequently, LED-potting processes generate two basic requirements with respect to the process design.

Two basic requirements to the LED-potting process design:

- High precision of a selected dosing system to keep the accuracy in the full range up to high dosing volumes

- High material flow rates in order to keep acceptable cycle times for the production set-up

Figure 4: Buffer container of material conditioning systems

Figure 4: Buffer container of material conditioning systems

Potting Applications Realized by Industrial Production Processes

The process can be realized, in general, by two different process concepts. They come along with significant differences in their system configurations of the potting cell.

Process concept number one concerns the so-called atmospheric casting concept, also referred to as open casting concept. The reconstituted casting compound is introduced at atmospheric pressure from top into the LED-module (casting mold), using the force of gravity. Alternatively, it can be applied upward from the module bottom side by a respective dosing pressure. Appropriate dosing systems are capable of generating so-called dosing profiles, by means of which the molding process is controlled by varying flow rates and activation times. Dosing profiles help to control the compound flow with the result of reduction of air pockets on encapsulated LED-modules. Air pockets on unprocessed units can also be eliminated before or during the atmospheric casting process by further measures. Effective methods are suitable component designs (avoidance of dead space areas) or a well-chosen component position (e.g. skew) during the potting sequence.

In case the atmospheric casting approach cannot guarantee a bubble-free process, the alternative is the switch to a vacuum based potting technology. In this method, an assembly is cast in a vacuum chamber under process vacuum down to a few mbar. In particular, enclosed air pockets at an assembly, which cannot be edged out during atmospheric potting, are removed (sucked-put) by the evacuation step of the process. But this article will only consider the atmospheric casting as a common concept for encapsulating of LED-assemblies.

System Technologies of Casting Equipment

This section introduces dosing technology for industrial, fully automated potting lines only. A potting cell within a process environment for industrial volume production includes a material supply unit, a material conditioning system and the dispensing unit. Handling systems (automation systems) are required in addition, in case of automated component handling. The following chapters describe the system components of the dosing unit (without the handling equipment) in detail and highlight the relevant influencing variables for an optimized process design.

Material supply system

Potting materials are generally self-leveling fluids. They can be filled into storage containers manually, transferred into a storage tank by a vacuum system and suction lance or can be handled by a bin emptying device/pump. Pressure vessel systems increase the risk of air injection into the fluid and do not offer significant process advantages. The requirement of batch handling of filled materials in order to keep the ratio liquid and filler is a minor aspect of LED-casting applications. Casting compounds for LED-products are quite limited in terms of filling components due to the required optical material properties. 2-component casting system configurations require a duplication of the system components in order to handle the respective A/B material components.

Material treatment systems

The material conditioning technology represents an essential process area for the composition of reliable production processes within potting cells. The material treatment system implements the functionality of material buffer, material conditioning and material feed to the downstream dosing system. The material buffer function is realized by a buffer container/tank that includes the functional components for the material conditioning process as well.

The storage tank can be filled manually by the operator or automatically using a vacuum system and suction lance. Filled casting materials require a transfer of the entire container volume into the buffer container at once in order to keep the mixing ratio of fluid and filler. The lower fluid level monitoring/display (“refilling necessary”) is usually carried out by the system itself. For manual filling, the compliance with the upper filling level (“container full”) must be controlled by the operator itself. The upper material filling level is monitored and controlled in contrary by the process monitoring system within an automatic process set-up. The material preparation technique is composed of the process steps stirring/homogenization, degassing, recirculation and temperature control.

The requirements of the individual process components are as follows:

Stirring/homogenization:

The stirring/homogenization process is to maintain a balanced distribution of the material components within the fluid and thus to ensure the material homogeneity and properties. The requirement for this process step is given due to the separation behavior of fluids. The effect of material separation of dispensed materials is reinforced by the tendency to lower viscosity of casting compounds. A homogenization step is also required in case the compounds with a strong tendency for material separation are transferred into the fluid buffer without a prior mixing process inside the delivery container. Otherwise, the homogeneity and correct distribution of the ingredients of the material is given only in the case that the entire container/batch volume is transferred into the buffer at once.

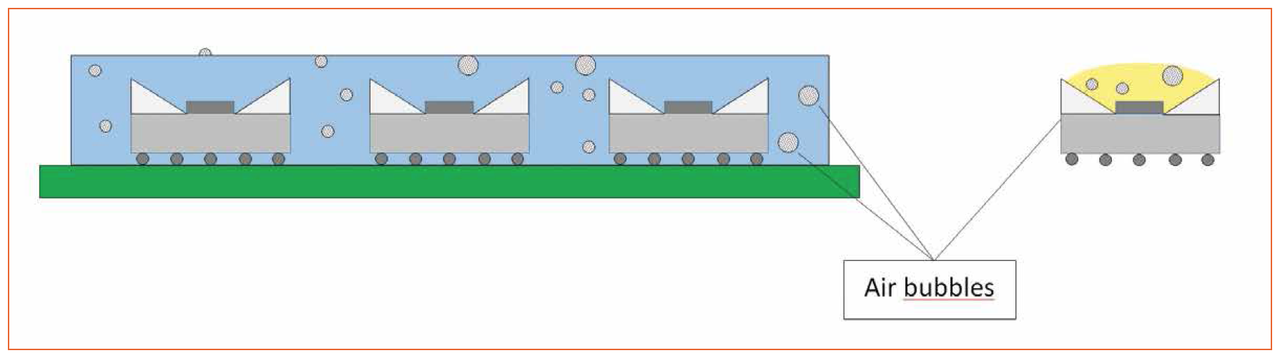

Figure 5: Air bubbles in non-degassed casting compounds

Figure 5: Air bubbles in non-degassed casting compounds

Material degassing:

The approach of material degassing ensures that the applied casting material is free of air bubbles. The presence of air bubbles in finished assemblies or module sections can lead to a significant reduction of the functionality or product lifetime; in the worst cases, even to an overall product failure. It should be referred to the fact again, that module encapsulation is considered here in the context of a protective function and that this function is no longer given with air inclusions. Equal critical for LED-modules is the major reduction of the optical quality of casted units caused by air bubbles.

Process and product quality are only ensured of absolutely properly conditioned material. Multiple, strong requirements are combined with the quality of the degassing process.

Requirements to support the quality of the degassing process:

- The level of the process vacuum must be sufficient in order to ensure the functionality and quality of the degassing process

- In the case of a vacuum casting approach it is required that the level of the degassing vacuum is lower than the level of the chamber vacuum of the potting cell. Otherwise the casting material would be exposed to an additional degassing process in the potting vacuum chamber

- The process vacuum cannot generally be set low without any limitations. There is a risk to remove gaseous constituents from the fluid at a too low degassing vacuum level. The vacuum level is to be kept reliable by the equipment in a narrow process window

The majority of material conditioning systems is based on the concept of batch processing. These systems can be used as single process system with one process chamber or as a dual process system with the need for two process chambers. The single process system handles the process steps material filling, conditioning and material feed sequentially. The system is not available for material supply during the filling/degassing process and vice versa. Dual process systems are capable for material filling/ conditioning in one process chamber while the second process chamber supplies the dosing station with pre-prepared compound in parallel. However, these systems require two separate process chambers with doubled efforts for system components and system maintenance.

However, these limitations can be eliminated by a full in-line processing system. This system provides an in-line process, in which the functions of material filling, material stirring/homogenization, especially the degassing process and then material feed towards a downstream dosing unit can be realized in a fully parallel, continuous process with a single process chamber only.

The process chamber is continuously operated in a vacuum mode. The individually required vacuum level per each casting material type can be defined within the software-based system configuration and is controlled precisely via the system control unit to this predetermined value. Vacuum fluctuations are suppressed and a stable chamber vacuum is given. The achievement of the necessary level of degassing vacuum is ensured; this also allows complying with vacuum maximum values in order to eliminate the change of material properties in case of exceeding such maximum values. The material transfer from the delivery container into the process chamber can be arranged under the use of the chamber vacuum (via suction lance) in parallel to the homogenization and degassing process. The filling process is started and stopped automatically for a fully filled chamber via material level sensors. Adequate valve technology precisely controls the compliance with the process parameters.

Besides a continuous material degassing method in particular, the introduced in-line process technology allows the additional, parallel take-out of material from the evacuated process chamber down to lowest vacuum levels. Already degassed casting material can be taken-out for the supply of the dosing station simultaneously with the ongoing evacuation process. This method offers considerable advantages for system users. A continuous production process can be achieved with the in-line technology with only one system/ process chamber in contrary to batch systems with the required number of two process units/ chambers. The material preparation process is entirely software controlled. Filling, homogenization, degassing and material supply are realized in a continuous process. Process continuity raises the process quality to higher levels. In addition, the elimination of recurring evacuation and ventilation cycles as of a batch process type reduces the amount of injected humidity into the process chamber.

Figure 6: In-line process material conditioning systems

Figure 6: In-line process material conditioning systems

Recirculation:

The recirculation of fluids ensures that material properties of the material to be supplied to a casting station inside tubes/hoses are kept in line with the process requirements. Such material can stay in hoses over a prolonged period sometimes (system down times, weekend break) and thereby may change its properties. This includes, for example, separation or cooling effects of pre-heated material. Recirculation redirects the material flow back into the purification system, where the material will be processed again to its required conditions.

Temperature control:

The temperature control of casting materials is used to align their material conditions with regards to an optimized production process for casting applications. Pre-heating of the casting compound mainly reduces their viscosity, thus achieving an improved flow behavior and degassing quality. In addition, process variations by changing ambient temperatures can be eliminated throughout the stable fluid temperature. Adverse effects of fluid temperature increase are accelerated separation processes (of medium and fillers) and reduced reaction times (e.g. reduced pot life) of the casting compound. The adverse approach of material cooling is also a part of temperature control in order to stabilize a production process.

A recirculation path is essential in order re-heat or re-cool material back to the set- temperature if the tempering step is performed locally at the treatment system only. Alternatively, a complete heating/ cooling line can be realized from the material preparation system, via the supply hoses, manifolds etc. all the way up to the connected dispensing unit. The material supply path needs to be realized as defined for one time for a 1-component potting process. For 2-component applications the path for material transfer from the delivery container, material conditioning and material feed is to be implemented in duplicate for component A and component B.

Dosing system:

First of all, the selected casting compound generally defines whether the dosing process has to be based on a 1-component or a 2-component system configuration. Notwithstanding this basic system configuration, the same rules apply for the technical and quality requirements for the dosing systems for both - 1-component as well as 2-component potting processes.

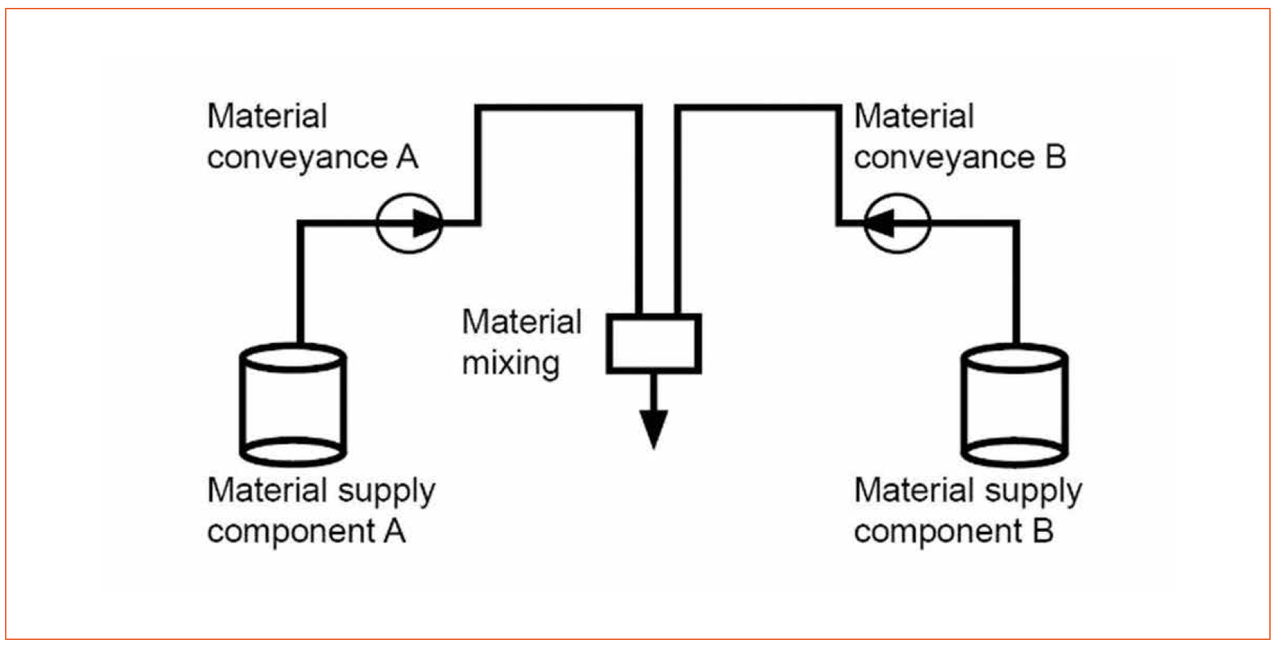

Figure 7: System configuration for a 2-component casting set-up

Figure 7: System configuration for a 2-component casting set-up

Casting processes are coming along with rather larger dosing volumes, especially at fully encapsulated modules. Despite these larger dosing volumes, there is the need to keep the dosing precisions on high accuracy levels. The casting process requires a match with the defined filling levels as an essential aspect for the final product functionality and product quality. The demand for surpassing dosing precisions is based on the fact that any system inaccuracy is scaled upward with increasing dosing volumes, so that in absolute terms large dosing volumes could result in significant overall inaccuracies. The selection needs to be for dosing concepts that can be over a high linearity over a wide range of dosing volumes and also a high reproducibility of such dispensing precisions.

A special task along with potting applications is the ability of dosing technologies to implement so-called dosing profiles. As identified previously, inclusion of air chambers in the casting compound can be reduced, for example, by a vacuum casting method. However, vacuum casting demands an extended system configuration and additional equipment parts compared to atmospheric casting. The objective is therefore to realize casting applications as much as possible under atmospheric pressure.

An essential requirement on dosing systems in this case is the ability to work with dosing profiles. This means that the material flow of the casting compound needs to be controlled in a way that will prevent the injection of air chambers from outside or to even eliminate (push out) existing air chambers at the LED-module. Technically, dosing profiles allow the control of flow rates and start-stop sequences. Dosing profiles in combination with aligned handling/robot units allow the creation of material flows in one predefined direction and to consequently fill module sections from one direction only. The approach is capable of pushing out existing air pockets at the assembly and eliminating the generation of cavities in parallel.

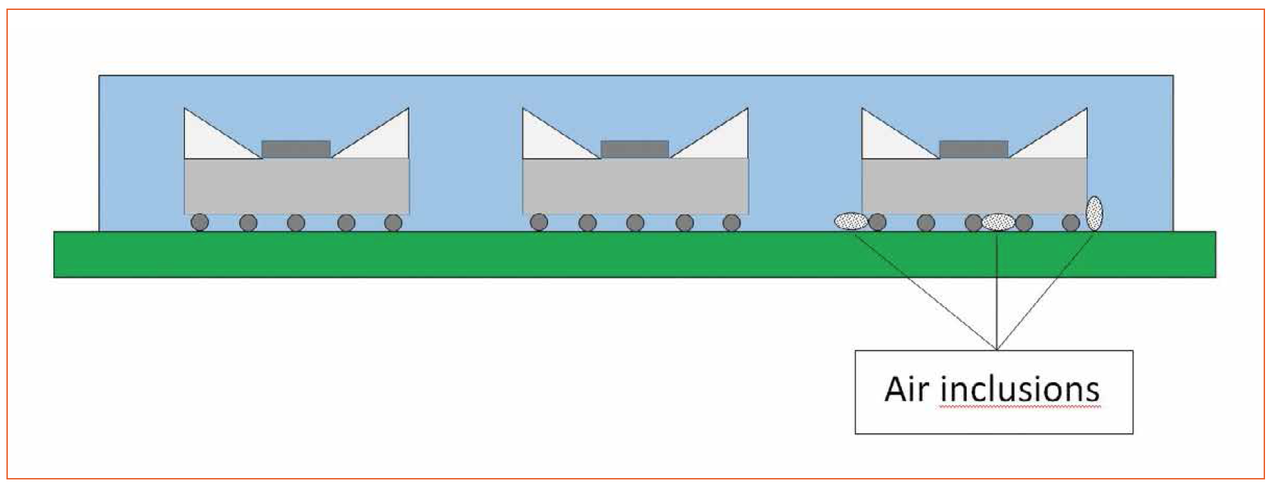

Figure 8: Undesired air inclusions at an LED-module can affect thermal performance

Figure 8: Undesired air inclusions at an LED-module can affect thermal performance

The key aspect for this purpose is the ability of the dynamic operation/ control of dosing systems. This feature refers to the possibility of a dosing system to dynamically adapt the dosing flow rate during the potting cycle. If the process requires, for example, a low flow rate at one point in the potting process in order to achieve a certain flow behavior, such a dynamic dosing operation allows for the reduction of the dosing speed within the process sequence. If a high flow rate is required in another process stage the dosing speed can be increased dynamically in the potting cycle. The dynamic adjustment of the material flow rate can only be realized by high end dosing technologies which are capable of ultimately keeping the high dosing accuracies in such a dynamic operation mode at any time.

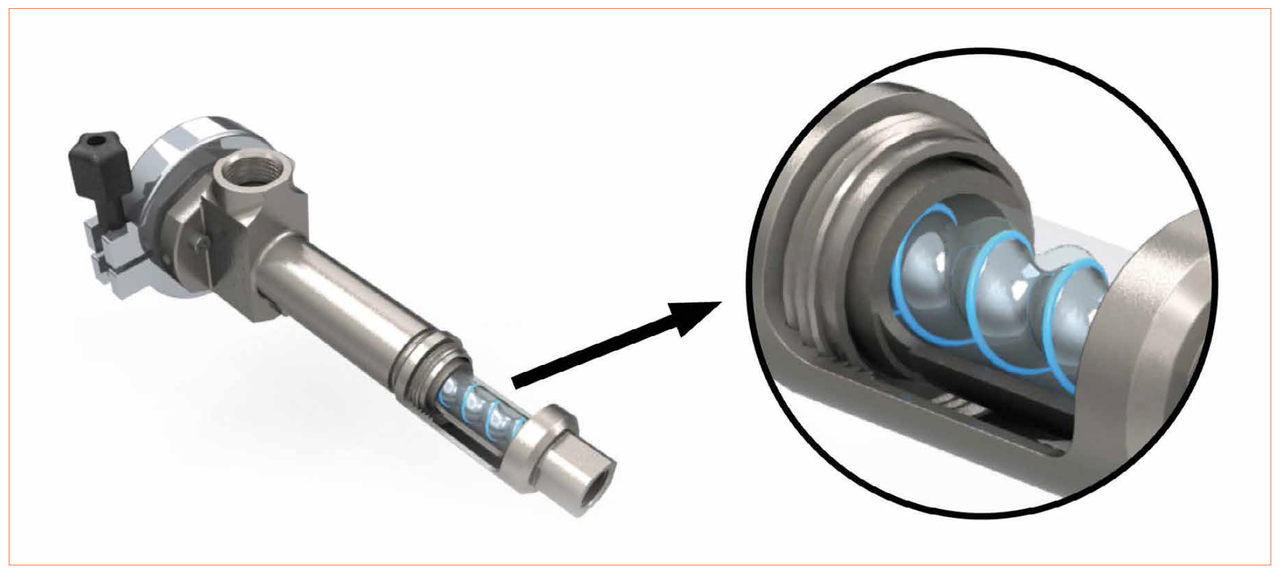

Figure 9: Sealing line on dispensing pump with endless piston technology

Figure 9: Sealing line on dispensing pump with endless piston technology

Excellent conditions for dosing applications in the area of LED-module encapsulation are given by the endless piston technology used by ViscoTec as the preferred dosing technology. The dosing units are characterized through a volumetrically absolutely precise dosing principle, providing highest and reliable dosing accuracies independent of the material viscosity. The special arrangement of a rotor and a stator unit each provides so-called closed dosing chambers with absolutely identical chamber volumes, which do not change during the dosing process. Steady chamber volumes directly result in identical, repeatable dosing volumes. This enhanced pump geometry guarantees a pulsation free material flow. The rotor/stator combination already creates a sealing line inside the pump (closed chambers) and thus represents a valveless dosing principle.

The dosing volume per rotor revolution is defined by the chamber volume: A full turn of the rotor applies the volume of one filled dosing chamber. In logical consequence, a change of the rotor speed causes an immediate and linear change of material flow rate. In fact, the flow rate is controlled proportionally to the speed of the drive unit and infinitely adjustable under the use of appropriate drive units. The introduced dosing principle is well suited under these technical conditions for the dynamic control of the material flow rates for the use of flow profiles in LED-potting applications.

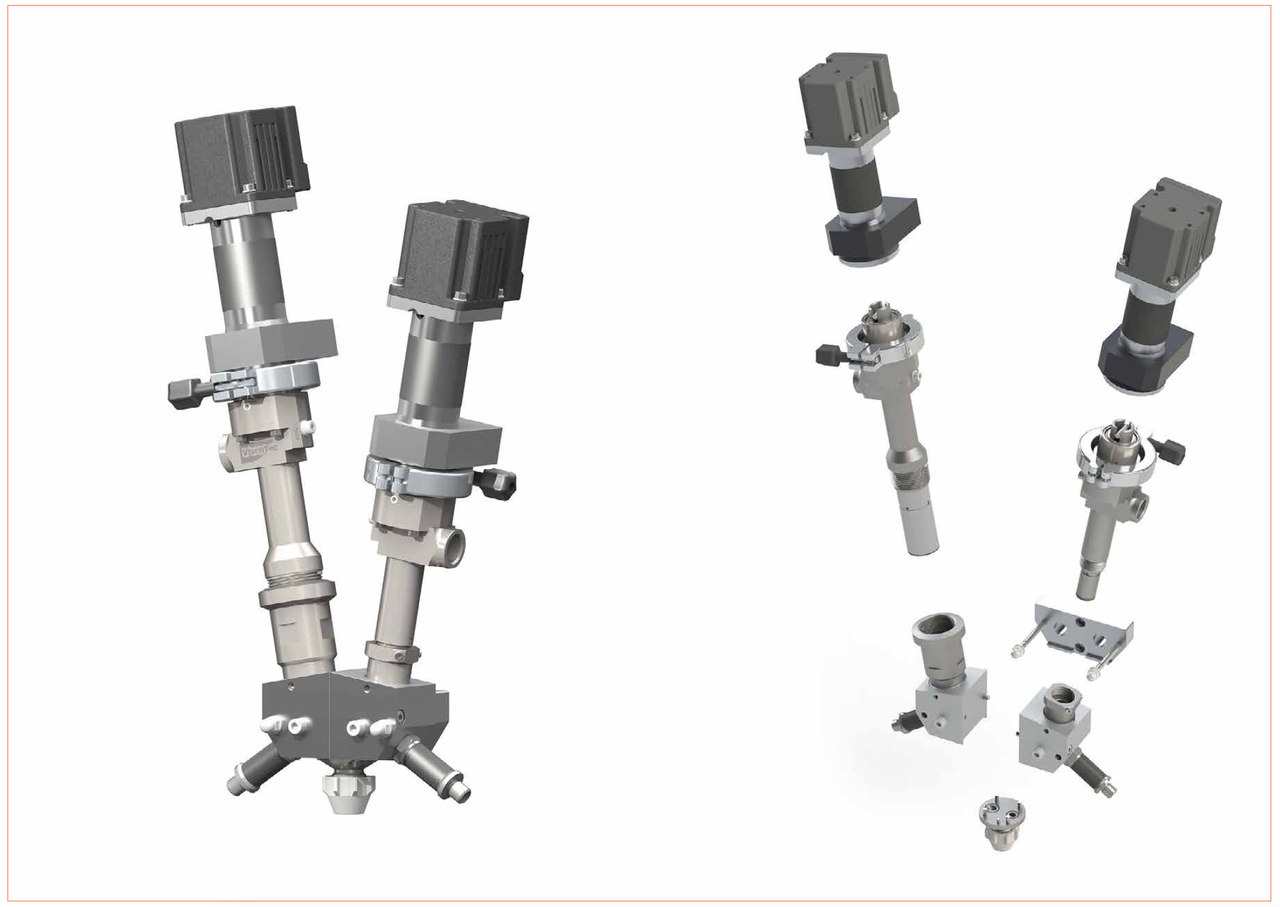

The endless piston technology allows the realization of both - 1-component as well as 2-component dosing applications: Two 1-component dosing pumps are arranged side by side and connected via the mixing head segment for the configuration of a 2-component mixing and dispensing unit. Material components A and B (2-component casting compounds consist of the resin and a hardener) are supplied separated from each other by two divided material channels by dead space optimized architecture towards the mixing head and static mixer unit. A special design of the outlet of the mixing head extends the separated material flow of component A and B into the static mixing tube and eliminates a mixing and curing reaction of the casting compound inside the mixing head itself.

Figure 10: 2-component mixing head from ViscoTec

Figure 10: 2-component mixing head from ViscoTec

The direct merge of the dosing pumps at the mixing head and the aligned realization of shortest channel lengths reduce potential dosing inaccuracies caused by long supply lines and resulting uncontrolled pressure profiles down to a minimum. The predetermined mixing ratios can be guaranteed on high accuracies with the highlighted system architecture.

The mixing principles of 2-component fluids are separated into static, static-dynamic and dynamic mixing. The static mixer process is based on the multiple re-layering of the flowing components by their repeated deflection as they flow through the mixing tube. Static mixers are structural elements of specially formed, rigid mixing element rows in tubular bodies. A good static mixing quality is given with the typical low material viscosities of casting compounds, in general. The advantages of the static mixing process lie in the simple structure and lighter weight of the mixing unit. With the dynamic mixing principle the material components are fed into a mixing chamber and are mixed actively by an agitator. In contrast to the static mixing tube, the dynamic mixer must be cleaned after dosing. An implementation on a robot system is eventually limited by the weight of the dynamic mixing unit. Finally, the static-dynamic mixing concept reflects a mixer concept where the mixing elements of a static mixer-like mixing unit can be rotated inside the mixing tube by an external drive unit.

Conclusions

Potting has a great influence of the final product quality, especially in respect to lifetime and reliability, but also efficiency. A number of decisions have to be made to choose the right potting material for an application and the appropriate dosing equipment. Accurate control of the different process parameters is inevitable. One of the biggest misjudgments would be to think that with larger dosing volumes accuracy would become less important. Dosing profiles and dynamic operation aligned with the robot units are key functionalities for a high quality production process. The endless piston technology offers the best preconditions for 1-component as well as 2-component dosing applications and is very flexible in its application.