Primary and Secondary Optic Materials - LED Luminaire Performance and Lifetime

Numerous articles have been published regarding the lifetime of Light Emitting Diode (LED) luminaires, however, the primary focus has typically been on the lifetime of the LED die itself. Given that the LED luminaire is a system, it is important to recognize all aspects of the system that can affect or limit lifetime.

Most luminaire designers are familiar with the need to optimize thermal performance evidenced by the large number of articles written on the subject. LED die lifetime has been shown to be driven primarily by junction temperature and to a lesser extent by current density, although the affects of current density and current spreading have been largely overlooked. LED luminaire designers are much less aware, however, of the importance of selecting the proper optical materials for the primary and secondary optics that comprise the luminaire with respect to lifetime degradation due to aging of the optics. The spectrally dependant loss in transmission due to aging is particularly acute in the blue and blue-green regions. In addition to a loss in total lumen output with time, the yellowing of the optics results in a decrease in Correlated Color Temperature (CCT), which can result in an unacceptable color change with time. The luminaire designer must be aware and take proper account of both of these material aging issues.

The greatest commercial demand for LED luminaires will be for broad spectrum white lights to replace conventional lighting products. The most efficient and common way to produce broad spectrum white LED light has changed very little since it was first invented and is based on conversion of blue light to yellow via one or more phosphors. The combination of the blue and yellow light produces white light. The short wavelengths emitted by the LED die below the order of 450 nm, however, cause a yellowing of the plastic optics with time which results in a loss in lumen output. LED phosphors have been shown to exhibit greater efficiency when excited by LED die with peak radiometric wavelengths below 460 nm. These shorter wavelength LED die result in a more rapid aging of the optics. The primary optics are typically positioned in close proximity to the LED die and therefore exhibit the most significant yellowing or aging affects due to the proportionally higher flux. In outdoor applications, the secondary optic is often exposed to harmful ionizing radiation from the sun, so consideration must be given to the potential aging issues for the secondary optics as well.

A number of system level trade offs must be considered to achieve a long life and low cost luminaire suitable for high volume production. For example, the choice of a shorter wavelength LED die would be expected to increase efficiency of a given luminaire initially, but may actually result in lower efficiency in the later half of a luminaire’s useful life if the lumen output degrades sufficiently as a result of yellowing of the optics and can result in a significant color change if the CCT changes appreciably. The challenge to developing improved optical materials will become more acute as LED die technology advances with ever increasing wall plug efficiency allowing for even higher optical flux. This article focuses on educating the LED luminaire design community as to the importance of selecting the proper optical materials for a given application and discusses relevant trade offs that must be taken into consideration.

Motivation for Considering Aging Affects for Primary and Secondary Optics

A limited survey and accelerated life testing of candidate high performance moldable optical polymers for high volume commercial lighting applications was carried out by Innovations in Optics beginning in June of 2008. The results of that effort led to the identification of two new polycarbonate materials LED2045 and LED2245 , developed from Bayer MaterialScience, as comprising the best overall combination of characteristics for the predominance of commercial LED luminaire applications. These materials are characterized by low cost, excellent mechanical properties, resistance to yellowing/aging due to exposure to high flux and short wavelength blue LED light, high temperature performance, high internal transmission and excellent molding characteristics. Bayer MaterialScience, as the company responsible for the invention of polycarbonate, has a long standing world wide reputation for developing innovative polymer products and for being proactive in meeting the needs of the lighting community as is evidenced by the recent development of the LED specific polycarbonates LED2045 and LED2245. In fact, if it were not for the recent development of these products, many high volume opportunities would not have continued to successful product launches. Other materials were identified that could have met most of the requirements, but cost would have been prohibitively high for some, or maximum temperature too high for others. Future optical material surveys should include a wider and more comprehensive evaluation of all relevant classes of optical grade moldable polymers to see if other equally suitable optical polymers exist.

The recent development of moldable lens grade silicones offers another choice for applications that are not price sensitive, however, they are deemed too expensive for high volume and low cost luminaires due to the long required cycle times and high cost of material and are not addressed further. Silicones should be considered as a viable alternative for less price sensitive applications, however. It should be also noted that there are some Cyclic Olefin Copolymers (COC’s) that showed great promise, but would likely be too expensive for many commercial applications such as the Zeonex 350R recently developed by Zeon Chemicals. The 350R was specifically developed as a lens material for 405 nm laser diodes for optical storage devices and demonstrated excellent resistance to yellowing. Unfortunately, the 350R’s glass transition temperature is the order of 24°C lower than the Bayer material’s 147°C and costs significantly more per kilogram making it unsuitable for many high volume applications requiring extended temperature performance and low cost. With respect to temperature, it is important to understand that the LED die temperature can be significantly above the ambient temperature and this is a major driver in the need for high temperature materials. Additionally, a number of acrylic materials showed great promise with respect to resistance to yellowing such as UVT920 and UVT825-100; however, their low glass transition temperature on the order of 85°C makes them unsuitable for many commercial applications. These excellent optical grade acrylics should be given close consideration in applications that have limited temperature ranges as they are low in cost, mold well, and have low dispersion relative to polycarbonates which would result in less chromatic aberration when used for imaging optics relative to the polycarbonates. The COC’s are attractive in that they resemble the polycarbonates mechanically, but are closer to the acrylics with respect to optical properties. In general, lower refractive index optical materials are preferred as they result in lower Fresnel (air/glass interface) reflective losses. One drawback of the polycarbonates relative to the acrylics and COC’s is their higher index of refraction on the order of 1.58 relative to acrylics’ 1.49 and the COC’s 1.53. Further improvements in the polycarbonates should also focus on achieving lower refractive index without giving up other desirable properties, if feasible.

There are many aspects of an LED luminaire that must be given careful consideration to result in a high performance, low cost and long lived product consistent with the Department of Energy’s (DOE) long term solid state lighting (SSL) initiatives. One of the most significant hurdles in meeting the longevity goals is the availability of suitable polymer materials out of which the high efficiency primary collection optics as well as secondary optics of next generation luminaries will be comprised. Based on accelerated life testing, the extrapolated expected lifetime of the LED die is already in excess of the 50,000 hours at greater than 70% initial brightness for the best commercially available LED die for typical and even aggressive operating conditions. The excellent thermal performance and low cost LED Chip-on-Board technology manufactured by companies such as The Bergquist Company and used by Innovations in Optics and other industry leaders is capable of exceeding 50,000 hours with today’s technology for high flux and high brightness luminaries with respect to the long term performance of the LED die themselves. That is not to say further improvements are not warranted with respect to LED die performance, as they are, but the focus of this article is on the primary and secondary optic materials, which are recognized as significant contributors to luminaire aging manifest as both a loss in lumen output and a decrease in color temperature.

Recent improvements in the index matching silicone gels by companies such as Nusil, Shunitsu and others can also meet the demands of >50,000 hour white light luminaries. There is work required for extending the silicone gel performance down to shorter wavelengths in the ultra-violet (UV). White luminaries, however, are generally more efficient when comprised of blue absorbing phosphors, than UV absorbing phosphors. Thus, for the most significant white light applications, the best available silicone gels used today are already sufficient for long lived luminaries. The fact that UV excited phosphors are fundamentally limited by physics to being lower in efficiency for white light applications is related to the quantum deficit in energy that exists when an absorbing photon of one wavelength is emitted and Stokes shifted to longer wavelengths. For example when a UV photon at 380 nm is absorbed by a phosphor of unit quantum efficiency and then the energy is converted by the phosphor and emitted as a green photon at the photopic peak of 555 nm, there is an energy loss of 31.5%. The balance is converted to heat. When, however, a blue photon at 450 nm is absorbed by a phosphor of unit quantum efficiency and then converted to 555 nm, there is an energy loss of only 18.9%, thus the production of white light, to first order, is fundamentally more efficient when using blue excited phosphors due to this quantum deficit. This is the reason that red emitting phosphors are generally characterized by poor radiometric conversion efficiency.

There are other considerations including the increase in scattering (and thus backscattering losses) with decreasing wavelength and the general increase in absorption cross section for most (commercially available) phosphors with decreasing wavelengths that must also be taken into consideration. Therefore, when it comes to developing more efficient luminaries, development dollars should be focused on inorganic blue excited phosphors with enhanced absorption cross section, reduced backscattering, high quantum efficiency, and low thermal quenching, over those designed to excite in the UV. Furthermore, the silicones used to attach the phosphors for UV excited phosphor luminaires degrade in transmission themselves, as all silicones developed to date degrade much faster when exposed to UV energy than when exposed to blue energy. That is the reason that high flux UV LED die can not be encapsulated as the silicone gel encapsulants typically used in the visible would lead to catastrophic failure as validated by UV accelerated life tests conducted at Innovations in Optics.

The motivation for this discussion is that the choice of phosphor and excitation wavelengths necessarily affects the requirements imposed on optical polymers used in luminaires. Improvements in phosphors will increase luminaire life and wall plug efficiency, but if anything the improvements in the LED die efficiency and phosphors will result in even higher flux on the molded optics, presenting a greater and ever increasing challenge to the SSL community to develop new polymers that can resist the flux induced yellowing/aging observed by varying degrees in all of today’s commercially available moldable polymers.

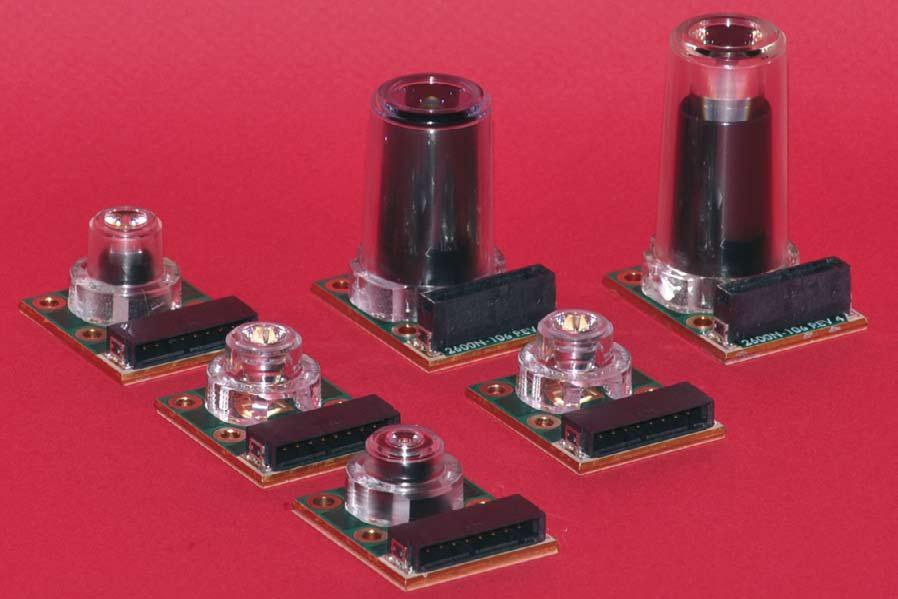

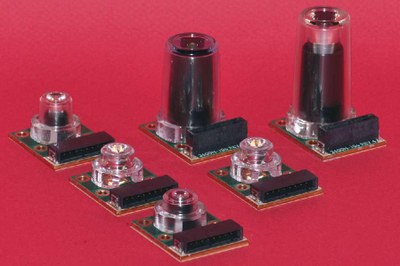

Figure 1 shows the recently released LumiBright LE light engine product line which incorporates a primary collection optic as part of the device and is representative of next generation high performance LED modules and is suitable for high volume commercial lighting applications. For example, this light engine can be incorporated into a recessed lighting fixture to deliver high efficiency and uniformity white lighting to residential and commercial fixtures. The integrated light homogenizing and high efficiency collection optic results in an excellent beam profile with no additional optics, or alternatively could be combined with secondary optics to shape the beam into other desired forms and beam profiles. These light engine incorporates an on-board thermistor and photosensor for monitoring or closed loop control if desired. The LED die are attached directly to the gold coated copper heat spreading substrate for excellent thermal performance. The patented and patent pending molded optics redirect some of the light back toward the onboard photosensor such that the sampled light is representative of the combined output from the entire LED die array and also would account for a loss in output over time due to LED die or optical plastic aging affects. Thus, a simple control loop circuit could allow this device to emit constant output over the lifetime of the product. For products not requiring temperature or light monitoring or control, the components could be left off the board for reduced system cost. The product line is representative of state-of-the-art LED technology that will be incorporated into tomorrow’s next generation lights and has been developed to use the Bayer Makrolon LED2045 and LED2245 materials.

Figure 2 shows a rendered cross sectional view of one of the LumiBright LE light engines. The square input aperture of the primary collection optic is positioned just above the LED die array which is attached to the metal core board. The flux through the entire homogenizing section of the optic is close in magnitude to that emitted by the LED die array until it is decreased as it travels up the optic by virtue of spreading out in area. The combination of high collection efficiency and homogeneity of the light exiting the output aperture makes this device very suitable as the heart of a high volume recessed lighting fixture, for example, but could be used in many other commercial applications as well.

Accelerated Life Testing of LED Optical Materials

One of the most critical developments necessary to achieve low cost, long lived LED luminaries is in the area of polymer development as motivated above. The development of advanced polymers that will be capable of meeting next generation LED luminaire requirements necessarily requires an understanding of the underlying limitations and operating conditions of representative luminaries. A primary failure mechanism with respect to achieving long life and stable color for a LED luminaire is the aging of the polymer materials with exposure to high intensity blue and long wavelength UV photons emitted by the LED/phosphor matrix and entering the input aperture of the primary molded polymer optics in a manner shown in Figure 2, where the flux and temperature is typically the highest. Relevant accelerated life testing protocols must necessarily be developed to evaluate the suitability of a given polymer sample.

It is necessary to quantify acceleration factors for any legitimate accelerated life testing. The method used to evaluate the LED2045 and other selected material candidates was to first establish the current density for normal operating conditions for a representative LED luminaire application. A standard Cerium Yttrium Aluminum Garnet (Ce:YAG) phosphor with a mean particle size of 5 microns was assumed in conjunction with a blue LED die with a peak photometric wavelength of 455 nm using a standard 42 mil LED die with a nominal operating current density of 800 mA/mm^2. This luminaire example was designed to emit white light, so the amount of blue and UV light entering the input aperture of the optic would be reduced by the phosphor matrix due to backscattering of the non-absorbed light and conversion of much of the blue light to longer wavelengths.

Initially, various blue LED die were tested with a range in peak wavelengths without using a phosphor to determine the portion of the blue spectrum which results in the greatest aging effect. As expected, shorter peak wavelengths (higher energy) resulted in greater degrees of yellowing, and thus would decrease the lifetime of the luminaire faster than longer peak wavelengths. In general, shorter blue excitation wavelengths result in increased efficiency due to the spectral dependence of the absorption cross section of the phosphors. That is, shorter peak blue wavelength LED die increase the device efficiency to some extent, but they also decrease its lifetime due to the faster rate of bond breaking occurring due to the higher energy photons.

The reason that the shorter wavelength excitation works better is that the increased absorption cross section results in a decreased phosphor layer thickness which in turn results in reduced backscattering of the excitation light back into the LED die where it has an opportunity to be reabsorbed before it is scattered back into the phosphor for a second chance at either being absorbed by the phosphor or scattered through the phosphor to add to the phosphor’s yellow emitted light and thus produce the perception of white light. The author recognizes that this seems contrary to the discussion on quantum deficit and that this shows that competing effects can play a role. The shift toward shorter wavelengths considered here is only on the order of 10 to 20 nm. The increased absorption cross section in this case more than compensates for the increased quantum deficit with decreasing excitation wavelength, but in general, the quantum deficit discussion is valid. With typical commercially available phosphors, this affect also overcomes the increased scattering that would occur at shorter wavelengths as the wavelength shift is not that great.

A significant difference in the aging rate for polymers subjected to lower energy 473 nm peak dominant wavelength LED light was observed in comparison to the proportionally higher energy 455 nm peak dominant wavelength LED spectrum. Thus, one of the trade offs between lifetime and efficiency is related to the choice of wavelength for the blue LED die used to excite a particular phosphor in a white light application. Therefore it is necessary to recognize that it is the difference in the flux at the shorter wavelength side of the typical blue spectrum that is most important with respect to aging affects and in the calculation of the acceleration factors. It is also important to recognize that the spectrum of the blue light component that scatters through the phosphor and makes its way into the collection optic is necessarily modified by the non-spectrally flat absorption of typical phosphors in the spectral region of interest. A radiometrically calibrated spectrometer was used to quantify the integrated power at wavelengths below about 465 nm entering the input aperture of the collection optic with and without the phosphor matrix present. This resulted in a factor of 7,3, meaning that if the phosphor is left off the LEDs then the input aperture of the polymer optic would be subjected to 730% the amount of light in the shorter spectral band that is responsible for aging which manifests as increased yellowing, assuming the LED die is run at the same current density in both cases. The factor is dependant on the amount of phosphor used, so the CCT is a factor. For the above analysis, a nominal CCT of 5,700 Kelvin was used.

It is desirable to achieve high acceleration factors in order to minimize the total time required for a given accelerated life polymeric material characterization, but they do need to be based on practical and representative luminaires. From the above discussion we can see that, for a CCT of 5,700 Kelvin, the acceleration factor just due to the decreased blue flux in the presence of the phosphor layer is the order of 7.3. This factor is also a function of the degree of backscattering which is related to the particle size relative to the incident wavelength. Smaller particle sizes generally lead to decreased backscatter, which in turn results in enhanced efficiency. This assumes the resulting phosphor particles do not have increased surface dislocation losses due to the process of decreasing the particle size. Thus, smaller mean particle sized Ce:YAG phosphors have generally been found to be more efficient than larger particle sizes and thus would result in reduced acceleration factors, which need to be taken proper account of.

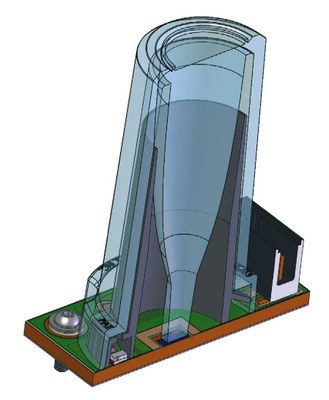

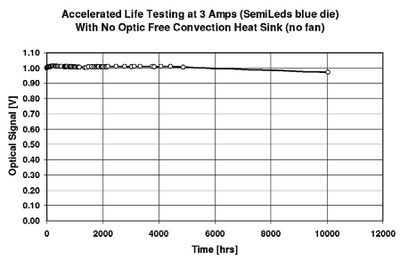

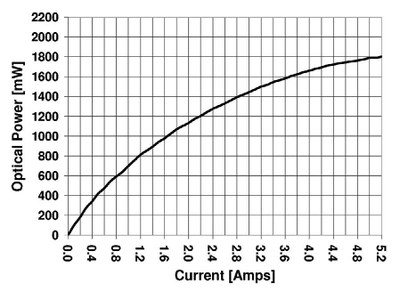

Now, as noted above, the particular device being characterized had a nominal operational current density of 800 mA/mm^2. The LED die industry has standardized on a current density of about 350 mA/mm^2 under normal operating conditions. This is partially historical due to the fact that many of the older generation LED packages used very poor thermal dissipation methods and were encapsulated by epoxy resins that degraded precipitously at junction temperatures approaching 125°C, thus relatively low current densities became the standard for defining LED characteristics. The best LED die available, of which the SEMILEDS 42 mil blue die is representative, can be operated at many times this current density continuously. This is shown in Figure 3, for which the LED die was running at room temperature on a heat sink cooled only by free convection at a current density of 3 A/mm^2 which was over 8.5 times the 350 mA nominal operating current of its associated data sheet. The junction temperature at this high current density was on the order of 125°C. Thus it is possible to increase the flux further beyond that produced at 800 mA by running the LED die at the order of 3 A/mm^2.

From the plot of Figure 4, we can see the output power of a single blue 42 mil SemiLEDS die is a factor of 2.6 times higher at 3.0 A in comparison to that at 0.80 A. This factor of 2.6 in combination with the factor of 7,3 from the phosphor gives an acceleration factor of 19 times. Thus to first order, a polymer optic subjected to the flux from a closely spaced blue SemiLEDS die operated at a current density of 3.0 A/mm^2 would be expected to last about 19 times longer over the spectrum of the blue LED die with the phosphor located on the die.

Let’s assume for the sake of the present discussion, that the definition of lifetime for a given LED luminaire is the total cumulative running hours at nominal operating current, temperature and humidity for which the luminaire maintains at least 70% of its initial brightness. Then we can estimate the degradation curve for a given luminaire by multiplying the hours by a factor of 19 and determining when the output would fall by 30%. Now, we must consider that the definition is applied at the system level, so that any loss in light due to the LED die itself, the phosphor, or the phosphor matrix, index matching gel if used, or any other loss factors including the drive electronics must be part of the total loss budget. Therefore a power loss budget must be established for which only a certain fraction of the 30% total budget would be available for loss due to the polymeric optic.

For example, Figure 5 shows the decrease in output of the bare LED die for operation at 800 mA derived from data taken at 3.0 A assuming the ratio of currents as the acceleration factor. There are a number of assumptions here, including that the full degradation sensitivity for the LED die is entirely due to and linearly proportional to the current density. This, of course, may not be entirely true, as the conventional wisdom is that there is a lifetime dependence for LED die both from current density and temperature and potentially humidity as well. A controlled study is needed to differentiate between thermal and current density affects and in response, the author hopes to complete such a study in the near future. This also points out that it is critical to establish realistic models and experimental controls for the system level factors that affect lifetime of a LED luminaire when conducting accelerated life studies. The curve used to fit the data for extrapolating life is not necessarily linear either. Thus controls should be put in place to measure the degradation of the LEDs driven at a variety of junction temperatures, current densities, and possibly humidities as well to establish accelerated lifetime models of increased accuracy. Thus, for example, out of the total budget of 30% degradation of initial brightness in 50.000 hours, perhaps only the order of 5% to 15% would be available for the maximum allowable loss due to the polymer optic aging itself.

See Figure 5 (see LpR magazine)

Another consideration when determining reasonable acceleration factors is the affect of the increasing absorption of the polymer with time in the blue spectrum which manifests itself as the observed yellowing with time. At very high flux, this increased absorption can lead to heating of the optical polymer due to the fact that the absorbed energy is converted to heat in the optic, which in turn can play a role in how quickly the optic degrades. For example the aging due to blue flux may occur at a faster rate with increasing temperature. Furthermore, at too high a flux, the increased heat in the optic, which is inherently a poor thermal conductor, can lead to thermal run away and catastrophic failure of the optic. As this was found to be the case in the accelerated lifetime work conducted by Innovations in Optics in 2008, the decision was made for that study to use a current density of 1.0 A/mm^2 instead of the 3.0 A/mm^2 described earlier. Thus, the raw data for the luminaire example is shown in Figure 6 for the Bayer LED2045 material. The data shows the real time decrease in blue light emitted for the single 455 nm 42 mil LED die through the collection optic which had an input aperture area only 10% larger than the LED die itself. An index matching silicone gel was used between the LED die and the LED2045 collection optic to increase the flux into the optic. The loss of light appeared to be linearly related to the integrated flux with time.

See Figure 6 (see LpR magazine)

The accelerated aging plots shown above do not tell the compete story. In reality a relatively small portion of the total luminous output from a white LED is affected, as the change in transparency is typically most pronounced in the blue spectral region, but does extend up to the order of 600 nm to some extent. Figure 7 shows a plot of the spectral output of a representative white LED represented by the blue line with a CCT of 5,700 Kelvin as well as its relative lumens contribution in green as affected by the photopic response curve of the human eye as indicated by the red line. Figure 8 shows the same white LED spectrum at 5,700 Kelvin before exposure to prolonged blue light and after exposure as indicated by the red line. The black line shows the change in the transmission spectrum as a ratio of the spectral transmission after exposure divided by the transmission before exposure indicating the significant drop in the blue and blue-green spectrum and little effect in the red.

See Figure 7 (see LpR magazine)

See Figure 8 (see LpR magazine)

Of particular note with reference to Figure 8 is the resulting drop in CCT from 5,700 Kelvin before aging to 4700 Kelvin after aging the optical material. This is likely an unacceptable change in CCT for many applications. The problem would be even more acute if the luminaire started off at a lower CCT of around 4,200 Kelvin as the light would become decidedly yellow looking as opposed to white in appearance. If we were to convolve the two spectra in Figure 8 with the photopic response curve of Figure 7 and integrate the total relative lumen output, then we would see that there is only about a 5% change in output due to the significant loss of blue transmission. This relatively small effect is due to the fact that the blue spectrum has very little contribution to the total lumen output, but it does play an important role in color rendering and CCT.

See Figure 9 (see LpR magazine)

Figure 9 shows the accelerated life data for the LED2045 material taking account of the acceleration factors of 7.3 for the phosphor, 1,.8 for the increased flux at 1.0 A above the test conditions of 800 mA, and 1.25 for the fact that the optic used index matching gel between the LED die and the input aperture of the optic, which accounts for the increased extraction efficiency of the LED die due to the presence of the gel. This resulted in an acceleration factor of 10.8 times. An additional factor of 7 results from the spectral affects discussed above which accounts for the fact that lumen output is dominated by longer wavelengths that are not attenuated as much by aging as is the blue spectral region. Of particular note is that the standard optical polycarbonate still performs well below what is required in comparison to the Bayer Makrolon LED2045 which would result in only the order of 8% drop in lumen output over 100k hours. The life expectancy shown in Figure 9 accounts for only the aging affect of the optic and does not include any other affects such as LED die degradation as discussed previously. If we were to include other system level aging affects, this white luminaire would barely maintain 70% of initial brightness over the course of the 100k hours shown, but would be expected to meet the DOE’s goal of 50k hours at greater than 70% initial brightness.

The Need for Accelerated Life Testing Protocol Standards

It follows from the discussion above that there are many aspects of the accelerated life protocols that must be worked out in detail. Specifically, for more comprehensive LED optical material studies in the future, one would have to determine how many of each material to test, what range of discrete current densities, temperatures, and possibly elevated humidity would need to be included and how many and what type of controls should be used. Industry standard test protocols must be developed so that various materials can be compared on an equal basis from different manufacturers. The protocols should also be relevant to the drive conditions of high brightness LEDs. Lifetime data for commercially available optical polymers are typically not provided in a form that is generally useful and applicable to high power and brightness next generation LED luminaires. For example, often the only transmission data available is for very short path lengths on the order of 3 mm or less. Many LED luminaires incorporate polymer optics with significantly longer effective material path lengths, so it would be beneficial to communicate the needs of the SSL community to the polymer optics materials manufacturing community.

Another example of material specifications that are not appropriate to the SSL community is that of the yellowing/aging test protocols. Power densities on the order of 400 mW/cm^2 are typical for aging studies available from various polymer materials manufacturers. High power and brightness LED modules can expose the primary optics to as much as 500 times that power density. Thus, the aging data is often of little utility. It will take well thought out and communicated studies such as proposed in this effort to educate the materials community as to the needs of the SSL community.

Summary and Conclusions

The importance of primary and secondary optic material selection has been discussed with regard to aging affects that the luminaire designer must be aware of. In particular, the importance of both the decreased lumen output with time and the decrease in color temperature was discussed. The goal of this article was not only to make luminaire designers aware of these issues, but also to bring an awareness of the need for further improvements in optical materials for companies such as Bayer and others that will lead the material development effort toward ever improving LED lighting.