Quality and Health Aspects of LED Lamps for the European Residential Lighting Market

Because of shortfalls in regards to consumer information about high quality, energy efficient, substitute products for incandescent lamps, there has been a significant amount of irritation on the side of the consumer. As part of the Intelligent Energy Europe Program of the European Union, Prof. Dr. Georges Zissis from the Paul Sabatier - University Toulouse and his team investigated 370 LED lamps. All relevant parameters of 95 different lamp types from store shelves in 12 European countries were measured and evaluated regarding quality and health issues.

Solid State Lighting (SSL) is currently revolutionizing the field of lighting and its practices. In the long term, inorganic and organic light emitting diodes (LEDs), will become the most widely used light sources. White LEDs have shown a steady growth of their luminous efficacy for more than fifteen years; promising to make significant energy savings as they replace older lighting technologies. The EU-regulations on Eco-design and Labeling for lighting provide an essential framework for supporting energy efficient lighting solutions in the domestic sector. The Eco-design regulation defines the phase-out of inefficient incandescent lamp technology while the Labeling regulation supports the demand for highly efficient light sources. However, due to shortfalls regarding guidance of consumers to high quality energy efficient substitute products for incandescent lamps significant irritation has occurred among buyers and a negative attitude against substitution technologies, namely CFLs and LEDs, has been enforced. This negative perception of the energy efficient technologies has been further amplified by the fact that for both CFL and LED lamps many low quality products are still flooding the market, and by some announcements concerning heath issues for such products. A smooth transition from old inefficient lighting technology to highly efficient lighting requires further supportive measures and information services for the consumer. Making good energy efficient products for residential lighting visible for the consumer by product testing can prevent this. To this end, comprehensive testing of LED high efficiency products has been done and will be presented in the first part of this paper. The second part of the paper will deal with some health issues related to LED lighting, namely blue light hazard and light flickering.

LED Lamp Quality Evaluation Campaigns

To support the promotion of high quality LED lamps for residential lighting the IEE-project PremiumLight implemented a broad market-oriented action in twelve EU countries which was focused, among other things, on selecting high quality LED lamps from each participating country market and systematically testing them in a laboratory. The geographic region of the action covered 12 countries represented by the Austrian Energy Agency (Austria), Berlin Energy Agency (Germany), SEVEn (Czech Republic), Politecnico Milano (Italy), Energy Saving Trust (UK), Energy Piano (Denmark), Motiva (Finland), University Toulouse 3 (France), EKODOMA (Latvia), ISR-University Coimbra (Portugal), Ecoserveis (Spain), TEM (Sweden) [i].

PremiumLight, however, focused on the lamp performance of two product classes; namely LED omnidirectional lamps and LED spots. Testing results provide concrete essential consumer information on good products comprehensively fulfilling consumer needs in terms of quality, energy efficiency, environmental aspects etc. Testing results were included in all dissemination activities in the consortium and via key actors.

The PremiumLight project focused on high quality lighting products that were commonly available in the EU markets where they were purchased. For this purpose, the project developed criteria to define an efficient, high-quality lamp. The criteria were designed to cover the main product characteristics that are relevant and observable by the consumer. Several of these criteria were defined earlier as, for example, by the Quality Charter for Solid- State Lighting [1] or the tier scheme proposed by the International Energy Agency 4E-SSL Annex [2]. Additionally, the eco-design regulations 244/2009 and 1194/2012 [3] [4] also recently established minimum standards. These minimum standards define the minimum requirements that must be met by any lamp that is sold on the EU-market today.

The following aspects were considered for establishing PremiumLight criteria.

Lamp efficacy:

The lamp efficacy describes how much light the lamp produces per watt of electric power. It is expressed in lumen per watt (lm/W). In the early days of LED technology efficacy was often measured for cold lamps under laboratory conditions. However, the efficacy of a lamp at 25°C is much higher than for lamps at typical operating temperatures. The PremiumLight criteria established for LEDs for the purpose of the project were efficiency class A+ following EU Directive 92/75/EC calculation method based on the value of Energy Efficiency Index (EEI). If today, the most efficient LED lamps can reach more than 100 lm/W under real-life use conditions, it is not possible to give a single value in terms of associated luminous efficacy in lumens per watt because the EEI value differs for the various product classes.

Average lifetime and lumen maintenance:

For LEDs intended for domestic lighting purposes, manufacturer declared lifespan ranges between 10,000 and 50,000 hours. It would take one or more years to test lamps to determine whether such declared lifespans are accurate. Therefore, this kind of testing is not helpful for the consumer, since lamp models are typically replaced every few years. However, the useful lifetime of LEDs is not only defined by the total time until lamp failure but by the decrease of lumen output over time as well. When lamp lumen output has declined to 70% of the declared value the effectively useful lamp lifetime has been reached. Thus the lamp lifetime of LEDs is often declared by “L70B50“ values, respectively the number of hours that it takes for at least 50% of the lamps to experience an at least 70% decline from the initial lumen output. Testing shall follow IEC/PAS 62612 Ed.1 [5] including a temperature cycling shock test and a supply voltage switching test with a number of cycles equal to half or all of the rated lamp life hours. The PremiumLight quality suggests a lifetime of least 20,000 h for premium-quality LEDs. A shorter lifetime of e.g. 15,000 hours might therefore be acceptable for LEDs in case they are sold at comparably low prices. The drawback of this is the fact that a low (15,000 h) lifespan determined by L70B50 may include a sample where 25% of the sample fails at 5,000 h and this of course is not acceptable for high quality products.

Color rendering:

The Color Rendering Index (CRI) indicates how well the human eye can identify specific colors when illuminated by a specific lamp. A CRI value of 100 is achieved by standardized daylight or by a standard lalps (incandescent lamps are used as standards). Other light sources typically have lower CRI values. The eco-design regulation requires a minimum CRI of 80. The UK EST LED program required CRI > 85 in 2011 and CRI > 90 in 2012. Today there are already LED lamps available with a CRI between 90 and 95. PremiumLight set a minimum CRI selection criterion at 80.

Correlated color temperature:

The color temperature of a lamp indicates the appearance of white light that may range from yellowish warm white to bluish cold white. With reference to IEC/PAS 62612 Ed.1 [5], the Quality Charter [1] for Solid-State Lighting requires CCT (Correlated Color Temperature) ratings for lamps for domestic use should be between F2700 (CCT=2,720 K, x=0,463 and y=0,420), F3000 (CCT=2,940 K, x=0.440 and y=0.403) or F3500 (CCT=3,450 K, x=0.409 and y=0.394). However, color temperature is not a quality criterion properly speaking, it is linked to the ambiance that the lamp will create and it directly influences the consumer’s satisfaction. The selection of a specific color temperature depends primarily on consumer preference. For household lighting in northern European countries warm white light with CCTs ranging from 2,700 K to 3,000 K is preferred. However, it has been reported that in southern European countries, in particular, more neutral to cool white lamps with CCTs of 5,000 K and above are requested. A quality criterion, however, is the uniformity of the color temperature for a specific lamp model, thus the deviation of the color temperature from the declared values should be small. This is important to avoid visible color variation in a multi-LED spots, lamps, or even luminaires.

Other issues:

Another criterion that has been addressed by PremiumLight is the dimmability of LEDs. Dimmability is not a quality criterion and there are dimmable and non-dimmable lamp models on the market. Dimmability is also dependent on the type of dimmer used. Additional criteria that have partly been tested in the PremiumLight project are flicker and power factor. These aspects are less easily checked by consumers since the relevant information is normally not provided on lamp packaging. LEDs may differ considerably regarding these two criteria. Thus some lamp models show strong flicker and low power factor whereas other lamps perform quite well.

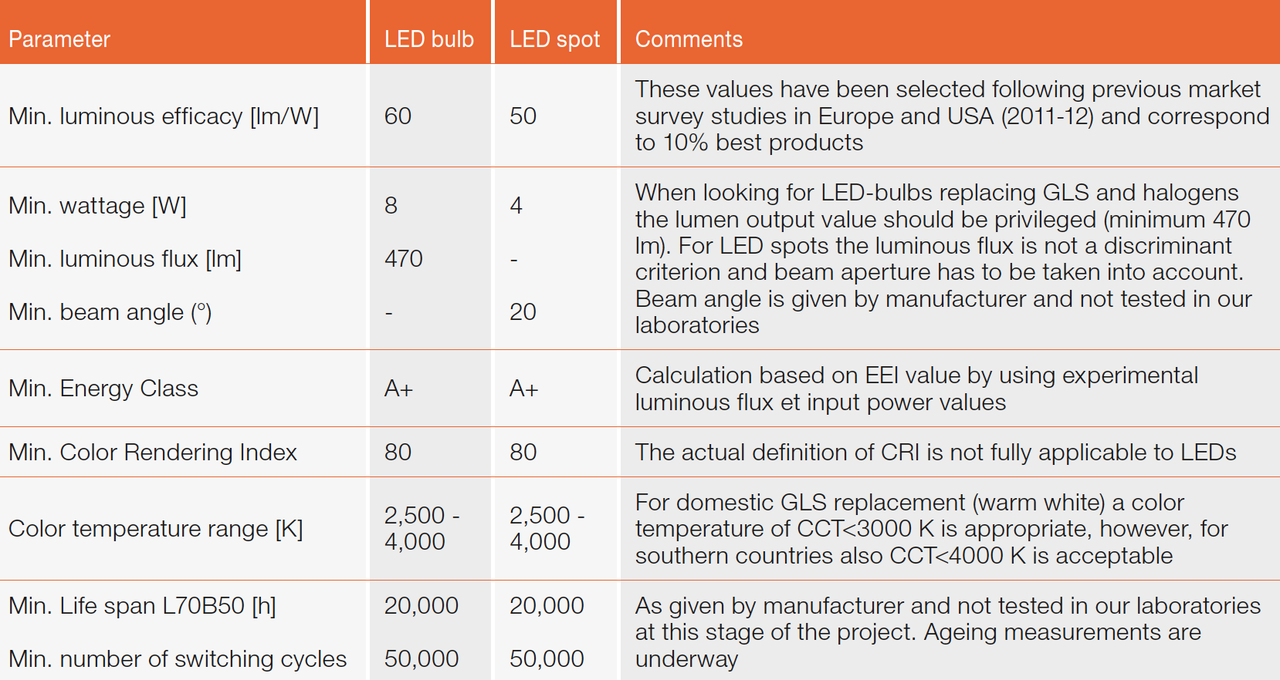

Table 1 shows all criteria used for the anonymous selection of PremiumLight quality lamps for testing. Table 1: “PremiumLight Quality Criteria”

Table 1: “PremiumLight Quality Criteria”

The PremiumLight project measured the following properties / quantities and compared them to manufacturers’ declarations.

- RMS Voltage (V) and Current (A)

- Electrical input power (W)

- Power factor - PF and cosφ

- Total luminous flux (lm)

- Luminous efficacy (lm/W)

- Correlated Color Temperature - CCT (K)

- Color Rendering Index - CRI

- Chromaticity difference - Δu’v’

- Light Flicker percentage (%)

Power factor, chromaticity difference and Light Flicker Percentage were included as an option for all products as they were defined to be important for Europe. Manufacturers do not usually declare these values.

All laboratories involved in the project used the IEA 4E SSL Annex Test Method version 1.0 [6]. This Test Method includes the strictest requirements of many SSL test methods imposed by various national and regional metrology standards. The Annex Test Method encompasses all the requirements contained in the SSL test methods already available in the USA, Japan, China, and also including the draft of the SSL test method being developed jointly by International Commission on Illumination (CIE) and Comité Européen de Normalisation (CEN). The terms used in this section follow definitions in CIE S017 [7], IEC 62504 [8], IEC 60050 [9] and LM‐79:08 [10]. Product conformity was tested in the three laboratories that have all the necessary, certified equipment for these types of measurements: Toulouse University - LAPLACE laboratory (France), Swedish Technical Research Institute (Sweden) and the Laboratory of City of Vienna (Austria). The three laboratories compared their performance in a round-robin campaign on three test-lamps previously defined according to the project needs: Each laboratory measured the luminous flux, Correlated Color Temperature and Color Rendering Index for all three test-lamps. The results from 3 laboratories were collected and analysed. These results showed that (1) values for Luminous flux in lumens deviated at maximum of ± 6,0 %; (2) values for Correlated Color Temperature in kelvin deviated at maximum of ± 4,0 %; (3) values for Color Rendering Index deviated at maximum of ± 1,5 %.

The following paragraphs summarize the most important features of the testing protocol and the key definitions.

Ambient Conditions:

The ambient temperature during the measurement of the product shall be maintained at (25±1) °C. The temperature sensor shall be placed at the same height and within 1 m of the LED lamp under test. Airflow around the tested lamp shall be maintained at less than 0,2 m/s such that normal convective airflow induced by device under test is not affected.

Position & Stabilization:

The operating position of lamps shall be specified according to the normal use conditions of the product. Prior to taking measurements, the product under test shall be operated at the rated condition and allowed to stabilize so that the changes in electrical power and total luminous flux are less than 0,5% over a 30-minute window, based on one-minute monitoring. If necessary, longer stabilization time can be considered and in the case that the lamp is not stabilized the measures are taken 2 h after the switch-on time.

Electrical measurement conditions:

The lamps under test have been operated at the rated voltage (230 V AC) and frequency (50 Hz). The tolerance of the test voltage for AC‐input is ±0,2% of the rated value and the tolerance of frequency is ±0,2%. AC power supplies used for this testing shall have a sinusoidal voltage wave shape at the prescribed frequency with the total harmonic distortion not exceeding 3% under a resistive load. If the product has dimming capability, measurements shall be performed at the maximum input power condition. The RMS voltage (V), current (A), power (W), and power factor, shall be measured at the time photometric measurements are taken. The AC power meters used for this testing shall have a sampling rate that is capable of resolving the current wave for the tested product: 61000‐3‐2 [11] states that the electrical characteristics of lighting products should be analyzed in a frequency range covering the fundamental (50 Hz) and up the 40th order (2 kHz). EN/IEC 61000‐4‐7 [12] indicates that power measurement equipment should be able to analyze components up to 9 kHz.

Photo-colorimetric measurement conditions:

For the measurement of total luminous flux, CCT, chromaticity tolerance (Δu’v’) and CRI a sphere‐spectroradiometer shall be used at each testing laboratory. These devices shall be calibrated with a total spectral radiant flux standard traceable to a National Metrology Institute (NMI). The pectroradiometer used shall cover the wavelength range of at least 380 nm to 780 nm, and the bandwidth (full width half maximum) and scanning interval no greater than 5 nm. Wavelength scale uncertainty shall be within 0.3 nm. Color quantities measured for tested products include correlated color temperature (CCT), and general Color Rendering Index (CRI).

Useful luminous flux definition:

This quantity is used only for directional lamps, other than filament lamps, and it is defined by EU regulation No 1194/2012 [13] as follows: directional lamps with a beam angle ≥ 90° and carrying a warning on their packaging in accordance with point 3.1.2(j) of the above sited EU regulation Annex: rated luminous flux in a 120° cone, other directional lamps: rated luminous flux in a 90° cone.

Luminous efficacy definition:

The luminous efficacy, η, is expressed in lumens per watt (lm/W) of the product under test.

Luminous efficacy is determined by the following relation:

η = φ : P

where P and Φ are respectively the electrical input power and the total luminous flux, measured following the above described methodology.

Power Factor definition:

The power factor (PF) and cosφ are defined as follows:

PF = P : VI and cos φ = P : V₀I₀

where P, I and V are respectively the RMS electrical input power, current and voltage; I₀ and V₀ are the voltage and current sinusoidal terms at 50 Hz.

Results from Testing Campaigns

Comprehensive testing of the high efficiency lamp products is now complete. More than 330 lamps of 85 different types were tested during the project. For each model a sample of three to five lamps were tested. For each brand the sample size can be considered as relatively small but for products like lamps manufactured at large batches by industrial machines it can be considered as representative. Increasing the sample size implies larger testing times and higher testing cost. Our results shown that for all lamps of the same brand the standard deviation for each studied quantity stayed at acceptable low level (<5%).

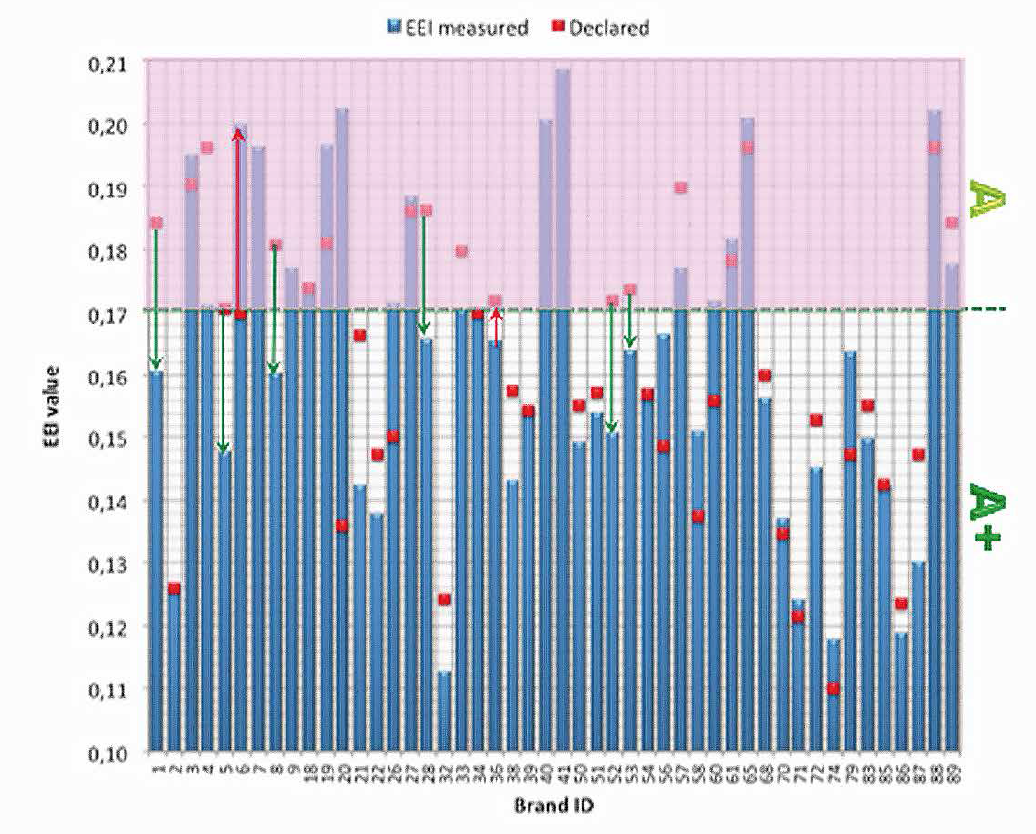

Figure 1a&b: (a)Measured luminous flux (lm) vs measured electrical power (W) for LED omnidirectional lamps (each point is the average of 3 to 5 measured lamps) (b) Measured luminous flux (lm) vs measured electrical power (W) for LED spots (each point is the average of 3 to 5 measured lamps)

Figure 1a&b: (a)Measured luminous flux (lm) vs measured electrical power (W) for LED omnidirectional lamps (each point is the average of 3 to 5 measured lamps) (b) Measured luminous flux (lm) vs measured electrical power (W) for LED spots (each point is the average of 3 to 5 measured lamps)

Lamp types included:

- 49 types of LED omnidirectional and candle-type lamps (sockets E27, E14, B22d and B15d)

- 35 types of LED spots (sockets: E27, E14, GU10, GU5.3, GU5 and GU4) and 1 model of AR111 downlight

Figures 1a and 1b show the measured total luminous flux versus the measured input power for omnidirectional LED lamps and LED spots. For spots the maximum luminous efficacy was found to be 94 lm/W and the minimum value was 30 lm/W. In the case of omnidirectional lamps these values were 104 lm/W and 47 lm/W respectively. We also saw that some omnidirectional LED lamps offered a luminous flux equivalent to a 75 W GLS lamp (1,000 lm). Furthermore, the AR111 downlight produce a flux of more than 1,000 lumens.

Based on the above measurements, we found that globally, the average observed luminous efficacy for LED bulbs passed from 71 lm/W to 77 lm/W and thus increased by 8% within the year lapse between the 2 testing rounds. For LED directional lights this passed from 53 lm/W to 66 lm/W corresponding to improvement of more that 30% in a year.

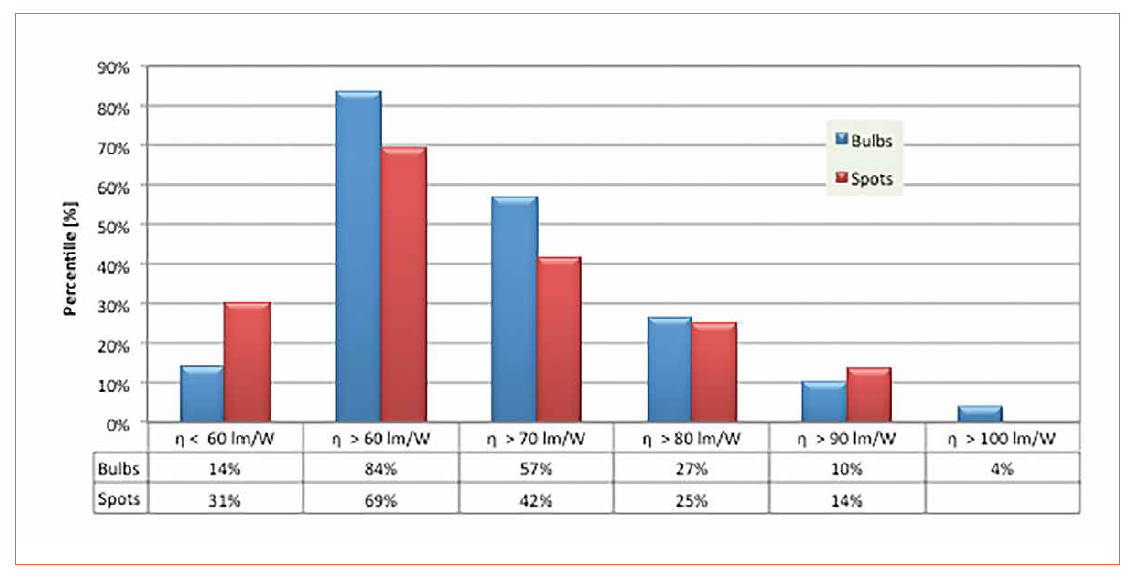

Figure 2: Distribution of measured luminous efficacies (lm/W) for LED bulbs (blue bars) and LED spots (red bars)

Figure 2: Distribution of measured luminous efficacies (lm/W) for LED bulbs (blue bars) and LED spots (red bars)

Figure 2 shows that for LED omnidirectional lamps 15% of the batch had an efficacy lower 60 lm/W and for LED spots 31% of the batch had efficacy lower than 50 lm/W.

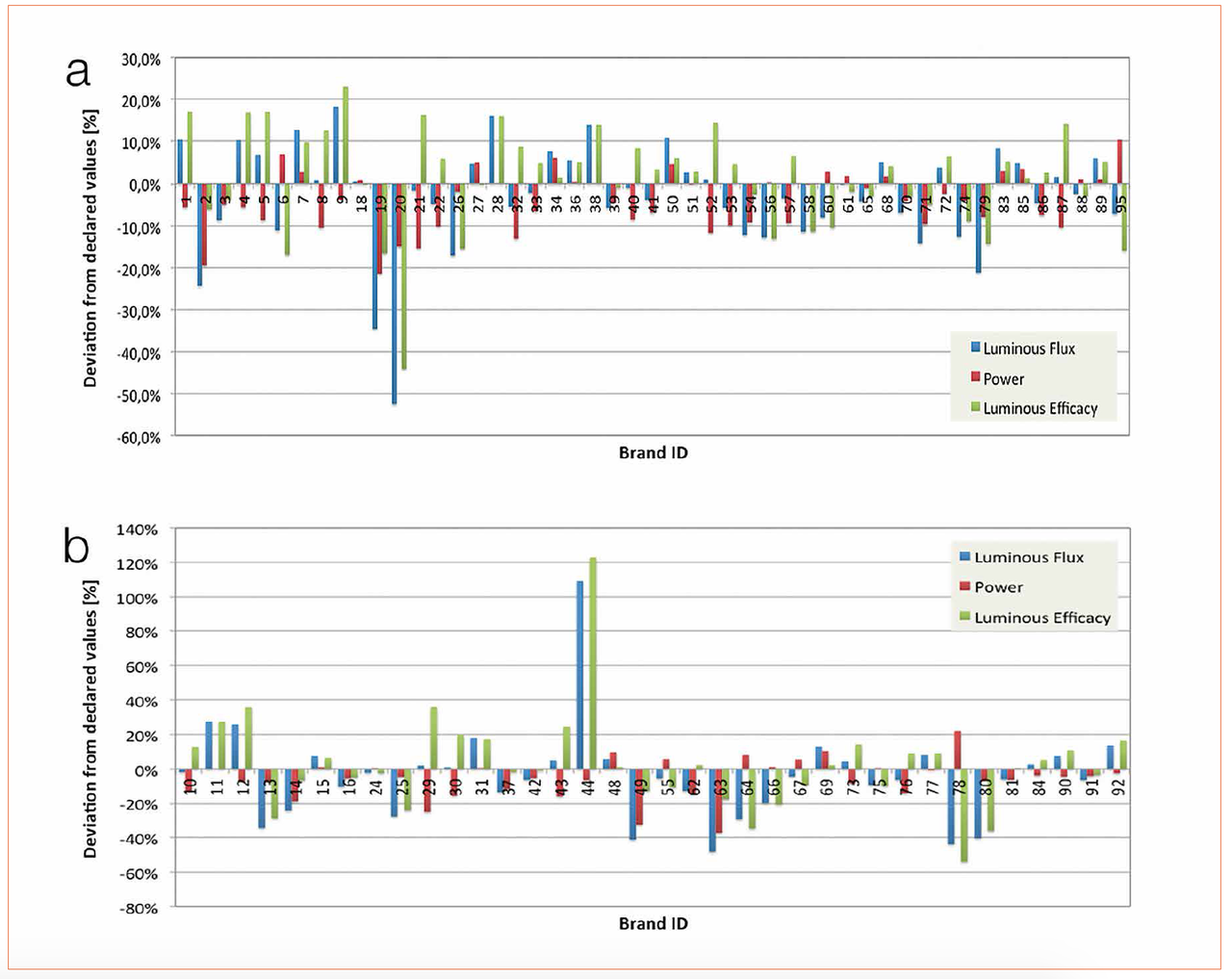

As shown in Figure 3a and 3b, input power declarations by manufacturers were found to conform generally to measurements within a ±10% commonly accepted confidence interval. For instance, we found one model of LED omnidirectional lamp that showed a 21% deviation for input power. However, almost 33% of the LED spots were outside of this interval.

Figures 3a&b: (a) Observed deviations between declared and measured for input power, luminous flux and luminous efficacy values for LED bulbs (b) Observed deviations between declared and measured for input power, luminous flux and luminous efficacy values for LED spots

Figures 3a&b: (a) Observed deviations between declared and measured for input power, luminous flux and luminous efficacy values for LED bulbs (b) Observed deviations between declared and measured for input power, luminous flux and luminous efficacy values for LED spots

The situation is different for total luminous flux values: 63% of the omnidirectional LED lamps and only 39% of LED spots were within a ±10% interval of manufacturer declared values as imposed by EU directive 2009/125/EC [14]. For one LED spot model this deviation goes up to 109% (that leads to 123% deviation on luminous efficacy).

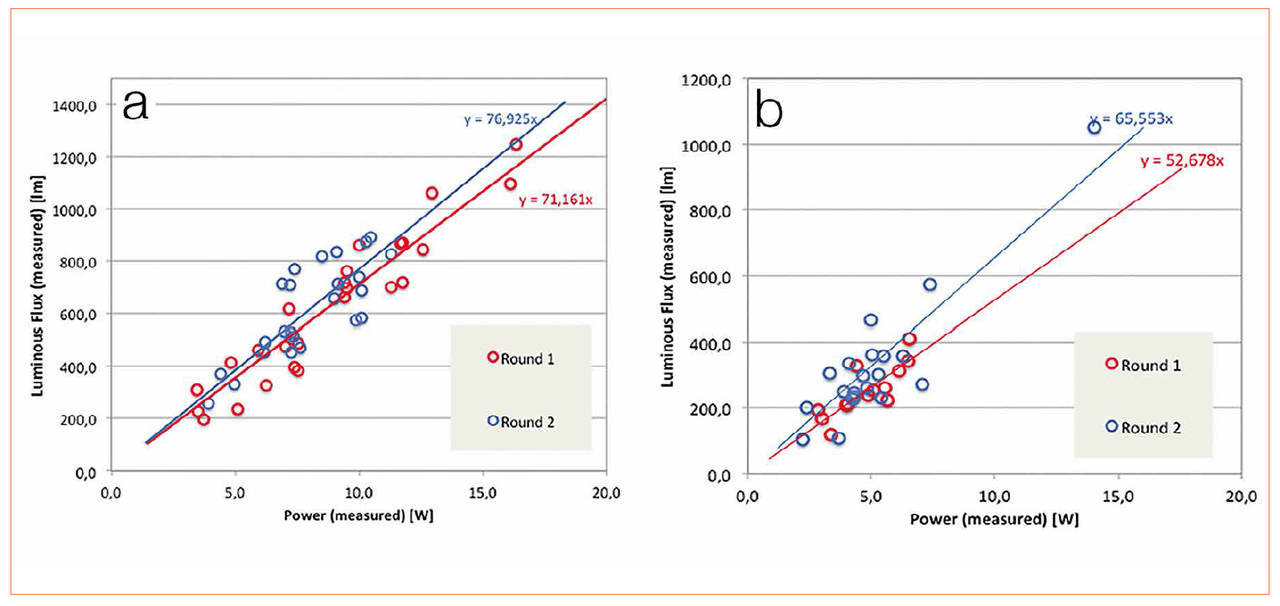

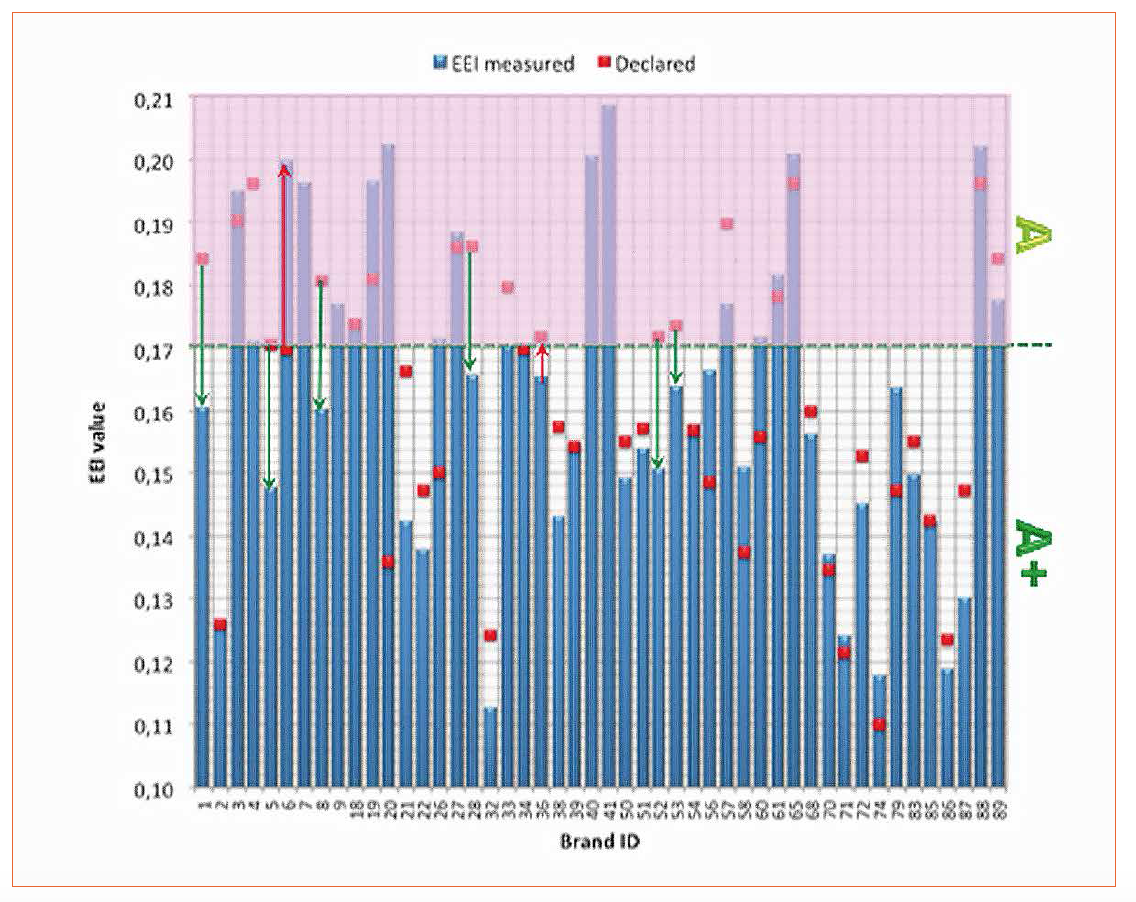

Figure 4: EEI value and energy class measured (blue bars) and declared (red dots)

Figure 4: EEI value and energy class measured (blue bars) and declared (red dots)

Figure 4 compares the EU Directive 92/75/EC [15] EEI values declared for omnidirectional LED lamps to our measurements. Significant deviations are detected but only 6 models are labeled incorrectly (four models are declared to be A class, but we found them to be A+ class, and two models were declared to be A+ and we found them to be A). The majority of studied lamps are A+ products (70,8% of the batch) and no B energy classes were found in the full batch. However 29,2% of the models are class A and don’t fulfill PremiumLight quality requirements.

Concerning light color characteristics, all tested lamp types, but one, were warm white (CCT<3,100 K). Only minor deviations between declared and measured values were observed. Color temperature only varied within ±5% confidence interval.

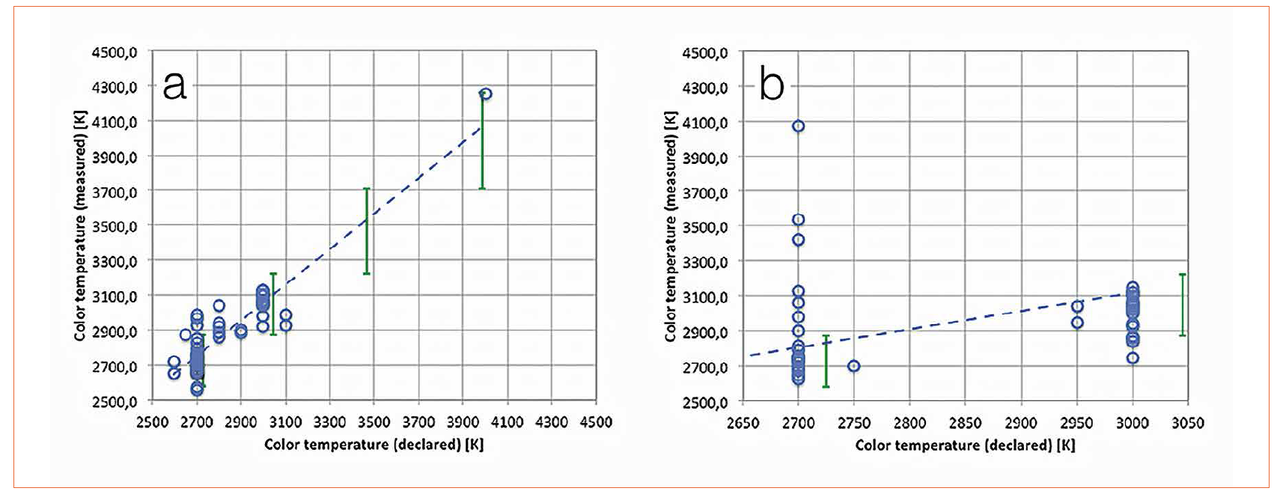

Figures 5a&b: (a) Declared and measured correlated color temperatures for LED bulbs. The green error bars represent the ANSI acceptable deviation (b) Declared and measured correlated color temperatures for LED spots. The green error bars represent the ANSI acceptable deviation

Figures 5a&b: (a) Declared and measured correlated color temperatures for LED bulbs. The green error bars represent the ANSI acceptable deviation (b) Declared and measured correlated color temperatures for LED spots. The green error bars represent the ANSI acceptable deviation

Figures 5a and 5b show the results concerning correlated color temperature for LED bulbs and LED spots. It can be seen that if for LED bulbs the declarations are rather conform, the situation is worse for LED spots.

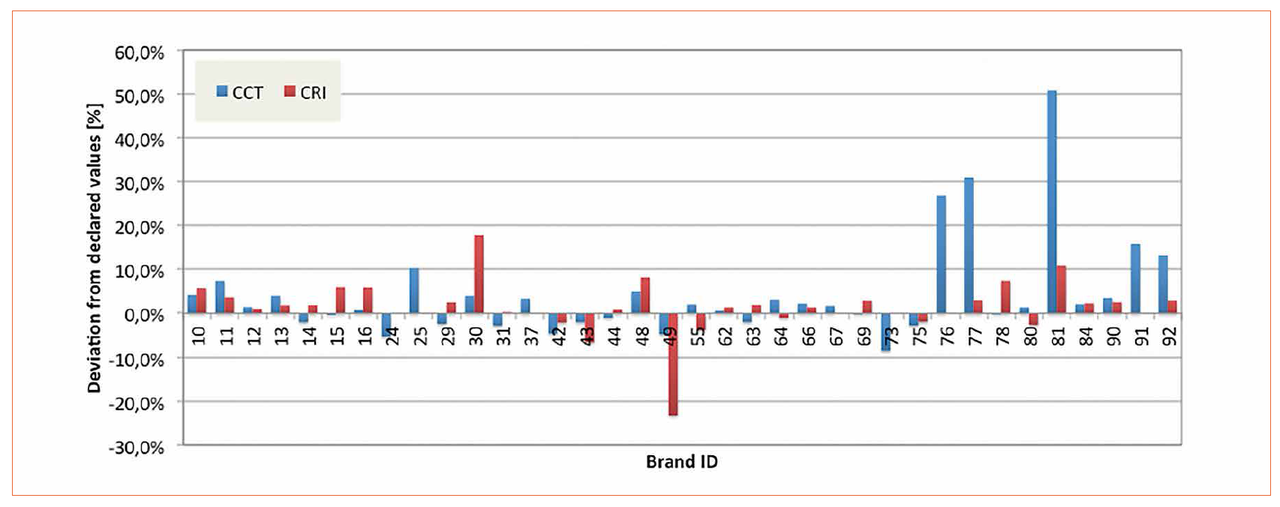

Figure 6: Observed deviations between declared and measured for correlated color temperature (CCT) and color rendering index (CRI) for LED spots

Figure 6: Observed deviations between declared and measured for correlated color temperature (CCT) and color rendering index (CRI) for LED spots

Finally, figure 6 shows the declaration errors for the colorimetric characteristics (CCT and CRI) for LED spots. Deviations higher than ±5% are not acceptable. It is evident that compliance CRI requirements, with a maximum observed deviation 25,4%, is much more difficult for manufacturers than consistency with CCT declarations (maximum observed deviation 10,5%).

Concerning Color Rendering Index, most tested lamps showed a measured CRI of around 80, therefore above the minimum level currently required by the eco-design regulation. Thus the CRI of most of the LEDs tested is at a standard level and not particularly high. However, in the studied batch lamp models available with a CRI around or above 90, we found were significantly better.

Health Issues for LED Lighting Systems

As any new or emerging technologies, LED lighting products should be proven to be at least as safe as the products they intend to replace. In new lighting applications where older technologies could not be employed, the safety of LED products should be assessed considering new or unusual conditions of usage.

The potential risks posed by LEDs to human health can be classified in the following categories:

- Electrical safety

- Potential risks due to exposure to electromagnetic fields

- Potential risks due to the emitted optical radiations: interactions of the optical radiations with the skin and the eye (photobiological safety), undesired effects of optical radiations on vision (glare and flickering effects in particular), effects of optical radiations on circadian rhythms

The first two points are due to the specific spectral characteristics of white LEDs as compared to other artificial light sources. This section of the paper focuses on the last point of the above stated list, and more especially on the blue light hazard and flickering.

Blue light hazard

Photobiological hazards are related to the effects of optical radiation on the eye. LEDs currently used have the advantage of emitting a negligible amount of ultraviolet and infrared radiations. Therefore, only the effects of the visible light have to be considered. Blue light is recognized as being harmful to the retina, as a result of cellular oxidative stress. Due to the high brightness of LEDs, the retinal illuminance levels are potentially high and must be carefully considered. Blue light is also suspected to be a risk factor in age-related macular degeneration. For all LEDs and products using LEDs, a photobiological blue light risk assessment must be carried out to determine whether or not the MPEs can be exceeded in the conditions of usage. The IEC 62471 standard [16] defines two different criteria to determine the viewing distance. Light sources used in general lighting should be assessed at the distance corresponding to an illuminance of 500 lx. Other types of light sources should be assessed at a fixed distance of 200 mm. The choice of the viewing distance in IEC 62471 is discussed in this paper, as it is sometimes ambiguous and not always realistic in the context of the real usage conditions.

Based on IEC 62471, lamps and lamp systems are classified into risk groups for various photobiological hazards. The risk group depends on the maximum permissible exposure time (MPE time) assessed at a given viewing distance.

IEC 62471 risk groups:

- Exempt Group (RG0: no risk): MPE not exceeded within 104 s

- Risk Group 1 (RG1: low risk): MPE not exceeded within 102 s

- Risk Group 2 (RG2: moderate risk): MPE not exceeded within 2,5x10-1 s (eye blink time)

- Risk Group 3 (RG3: high risk): MPE exceeded even for momentary or brief exposure (less than 2,5x10-1 s)

For the past few years, blue light exposure data have been provided by LED manufacturers, professional lighting associations, independent laboratories, and governmental agencies. It was found that the retinal blue light exposure levels produced at a distance of 200 mm from the user by blue and cold-white LEDs (bare LEDs and LEDs equipped with a focusing lens) exceed the MPEs limits set by ICNIRP after an exposure time comprised between a few seconds for high power blue LEDs to a few tens of seconds for high power cold-white LEDs.

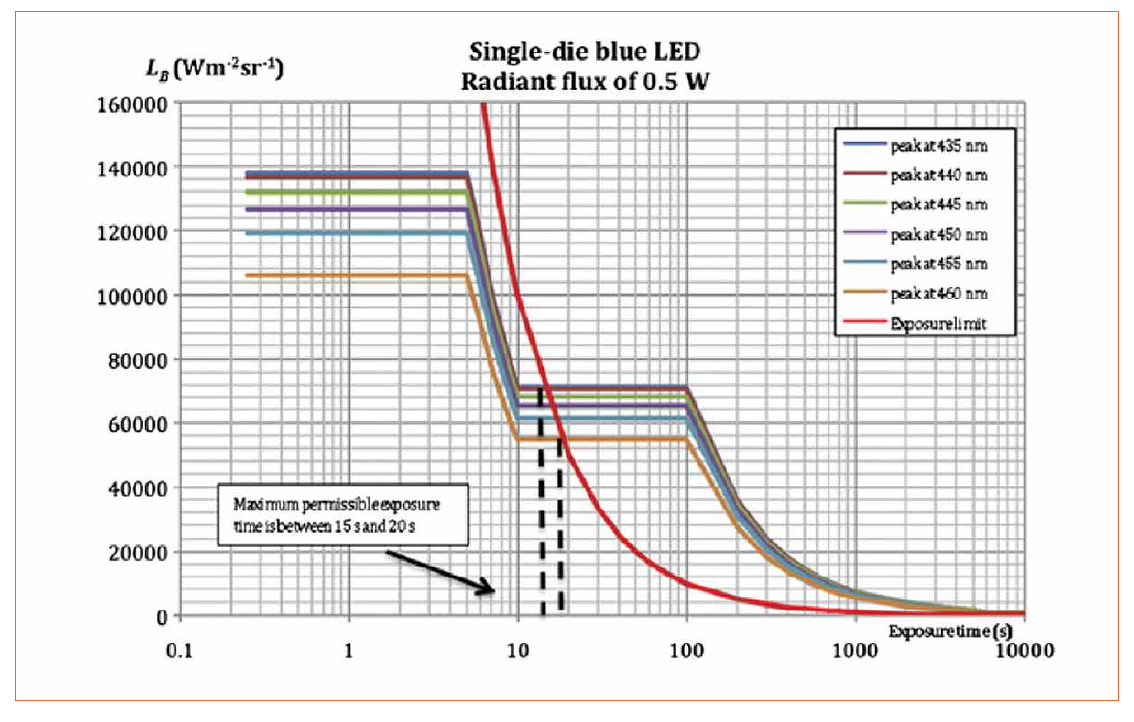

Figure 7: Variation of blue-light weighted radiance LB with the exposure time determined for six types of blue LEDs (as function of the position of blue peak wavelength). The red curve is the exposure limit value. The intersect point corresponds to the maximum permissible exposure time. It can be used to determine the risk group

Figure 7: Variation of blue-light weighted radiance LB with the exposure time determined for six types of blue LEDs (as function of the position of blue peak wavelength). The red curve is the exposure limit value. The intersect point corresponds to the maximum permissible exposure time. It can be used to determine the risk group

Figure 7 shows blue-light weighted radiance LB as defined by ICNIRP [17] or the six blue LEDs chosen by the ANSES working group [18] and published in [19]. In this example, the LEDs were operated such that they emitted a radiant flux of 0.5 W, which is about half the rated maximum value.

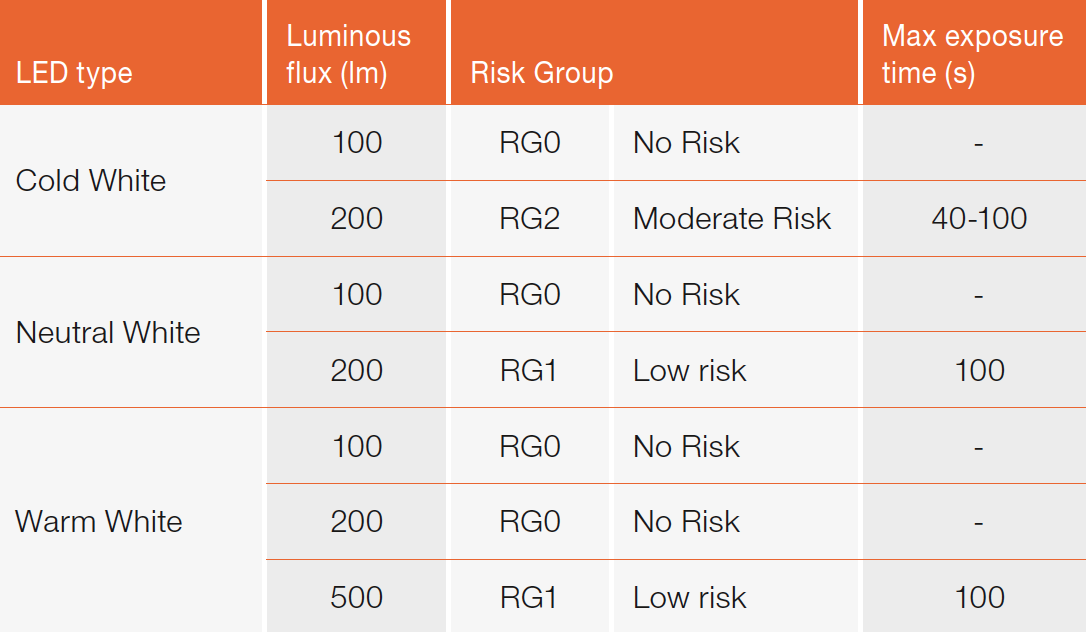

For this study, we used various single LEDs under conditions of constant luminous flux. When cold-white LEDs were operated such as to provide a luminous flux of 100 lm, the exposure limit value was never reached and the risk group was always 0 (no risk). By increasing the luminous flux to 200 lm, all the cold-white LEDs fell into risk group 2 (moderate risk) with maximum permissible exposure times comprised between 40s and 100s. Similarly, neutral-white LEDs operated at a luminous flux of 100 lm all fell in risk group 0. When operated at 200 lm, the exposure limit value was reached at an exposure time of about 100 s, thus the studied products fell into the risk group 1 (low risk). Warm-white LEDs never exceeded the exposure limit value and were always in risk group 0 (no risk), even when they were operated at a flux of 200 lm. In fact these warm-white LEDs should reach a luminous flux of at least 500 lm to belong to risk group 1 (low risk). Table 2 recapitulates these results.

Table 2: Risk groups and maximum exposure times for various LED lamps as measured by CSTB in the frame of ANSES working group

Table 2: Risk groups and maximum exposure times for various LED lamps as measured by CSTB in the frame of ANSES working group

None of the studied single-die LEDs presented a high risk (risk group 3). Blue LEDs and cold-white LEDs may belong to risk group 2, according to their color temperature and their operating point. Likewise, neutral-white LEDs may belong to risk group 1. On the contrary, all warm-white LEDs belonged to risk group 0.

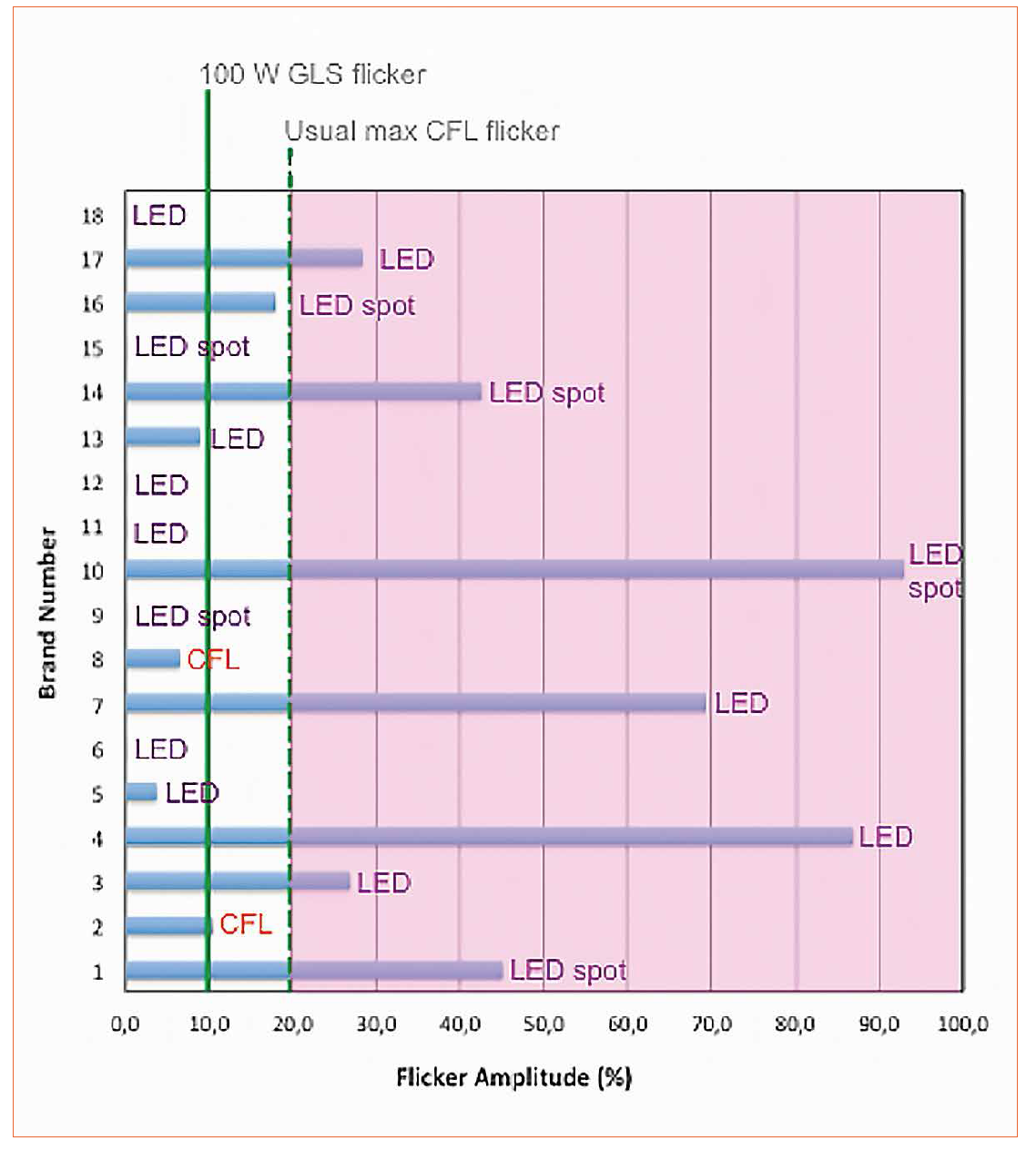

Figure 8: Some experimental percentage flicker values of various lamp technologies as obtained in LAPLACE laboratory and EU-PremiumLight project

Figure 8: Some experimental percentage flicker values of various lamp technologies as obtained in LAPLACE laboratory and EU-PremiumLight project

Light Flicker

Flicker is the modulation of the light output that can be induced by fluctuations of the mains voltage supply, residual ripples in the DC current powering, or deliberate modulations of the LED input current such as the pulse-width modulation (PWM) used for dimming applications.

It is known that exposure to light flicker (in particular at frequencies between 3 Hz and 55 Hz) can cause photosensitive epileptic seizures in various forms, depending on the individual and his visual pathology, the contrast, the wavelength and the viewing angle or distance [20].

According to literature, light flicker is not usually perceptible at frequencies higher than 70 Hz, but it can still affect people. For example, people suffering from migraines are more likely to be sensitive to flicker at high frequencies [21]. Also, for people suffering from specific medical conditions, flicker may have some serious consequences.

Light flicker combined to rotating motion or spatial patterns may be responsible for stroboscopic effects. Stroboscopic effects might induce hazards to workers in proximity to rotating machines and tools. Commercially available LED lamps may have serious light flickering behavior at twice the mains frequency (in Europe mains frequency is 50 Hz thus the observed residual flicker frequency is equal to 100 Hz). This light flicker is mainly due to the residual voltage fluctuation after the AC/DC rectifier in the lamp power supply. The measurements presented in this work show that there are a few commercial LED lamps without any flicker. However, a significant number of products demonstrated abnormally high flicker. Some products have fluctuations of about 100% of the luminous flux, corresponding to a light output varying from zero to the maximum value.

Our set of test lamps included LEDs as well as CFLs and incandescent lamps used as references. Figure 8 shows the experimental percentage flicker values for some tested lamps. It should be noted that a 100 W incandescent lamp has a flicker percentage of 10% due to the filament temperature variation that follows the power waveform. Good quality CFLs may reach a percentage flicker of 20%. The highest Flicker Index value for tested CFL lamps was found to be 0.14, a value rather compatible with US recommendations. The situation is completely different for LEDs. As can be seen in Figure 8, LEDs had completely arbitrary behaviors. Some of them feature high quality power supplies that include reliable AC/DC rectifiers and filters. They displayed very low flicker, close to zero (not measurable). Other devices had percentage flicker values up to 100%. In this case, the light output goes off every 10ms. Eight LED lamps were found to fully respect the conditions imposed by the Energy Star requirements (Flickering Index < 0,1), whereas all examined CFLs fulfilled that condition.

Conclusions

Overall, PremiumLight’s extensive lamp testing showed that very efficient, high-quality, LED lamps are available today with efficacy levels up to 104 lm/W (for an omni-directional LED bub), CRI up to 95 and up to 1040 lm output for an AR111. Many LED bulbs were confirmed to be A+ class and to have Power Factors higher than 0,5. Our measurements showed that many tested products had a Color Rendering Index of 90 and even higher. Thus the light quality offered by the lamps tested, at least in terms of color rendering, is already approaching levels close to halogen lamps and the standard incandescent lamp. The performance of the LED products tested conform, in large part to the manufacturers’ declarations, but some singular cases of significant deviations from declared performance were found. Although the majority of the tested lamps showed high quality and efficacy, our results also indicated that some brands do not provide the quality and efficacy claimed by manufacturers. Such products showed problems regarding efficacy, luminous flux, color rendering and other quality aspects.

Concerning the blue-light hazard, and more particularly, in consumer applications (retrofit LED lamps for instance), we strongly support the adoption of a regulation to limit the risk group to RG1 at the minimum viewing distance encountered at home, which is 200 mm. The measurement campaigns carried out by the authors, as well as by several other independent laboratories, showed that most indoor LED lamps and luminaires already comply with this requirement. It is not a critical issue for the LED industry. However, the notion of a safety distance would actually be more appropriate to communicate to the installers and to the users, especially to the general public. The safety distance of an LED based product would be the minimum distance for which the blue light hazard risk group does not exceed RG1 and this value must be indicated on the package. For LED products handled exclusively by professionals, all necessary measures to limit the final risk group to RG1 have to be taken and guaranteed by the installers.

Concerning light flicker, we tested more than fifty different lamps for flickering. Our samples included LED lamps as well as some CFLs and incandescent lamps as benchmarks. The highest Flicker Index value for tested CFL lamps was found to be of 0.14. LED lamps had completely arbitrary behaviors. Some of them, built with high quality power supply, displayed zero flicker (not measurable) while some other devices reached per cent flicker values of up to 100%. In fact, only eight LED lamps have been found to fully respect the US recommendations (Flicker Index < 0.1), while all the tested CFLs fulfilled that condition. Consumers should be vigilant about that fact. In this paper, we described a rapid method to detect flicker using a smart phone camera.

Acknowledgements:

The project PremiumLight is co-funded by the Intelligent Energy Europe Program of the European Union (Grant n° IEE/11/941/SI2.615944). The authors wish to express their gratitude for this financial support.

Notes:

For more information on the IEE-project PremiumLight project see: www.premiumlight.eu

References:

[1] http://iet.jrc.ec.europa.eu/energyefficiency/sites/energyefficiency/files/files/documents/eu_led_qc_background_report_10_feb_2011_final. pdf

[2] International Energy Agency Annex 4E-Solid State Lighting, http://ssl.iea-4e.org/

[3] http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2009:076:0003:0016:en:PDF

[4] http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2012:342:0001:0022:EN:PDF

[5] IEC/PAS 62612 Ed.1 “Self-ballasted LED lamps for general lighting services with supply voltages > 50 V - Performance requirements”, IEC, 2013

[6] IEA 4E SSL Annex: Interlaboratory Comparison Test Method 1.0, 2013, http://ssl.iea-4e.org/files/otherfiles/0000/0059/ SSL_Annex_2013_IC_Test_Method_v.1.0.pdf

[7] International Lighting Vocabulary, Standard CIE S 017/E, 2011

[8] IEC 62504 “General lighting - Light emitting diode (LED) products and related equipment - Terms and definitions”, 2014

[9] Electropedia: The World’s Online Electrotechnical Vocabulary, http://www.electropedia.org/

[10] LM-79 Approved Method: Electrical and Photometric Measurements of Solid-State Lighting Products, IES, 2008

[11] IEC 61000-3-2 ed4.0 “Electromagnetic compatibility (EMC) - Part 3-2: Limits - Limits for harmonic current emissions (equipment input current ≤ 16 A per phase)” is an international standard concerning the harmonics emitted by electric equipment, 2014

[12] EN/IEC 61000-4-7 “Electromagnetic compatibility (EMC) -Part 4-7: Testing an measurement techniques - General guide on harmonics and interharmonics measurements and instrumentation, for power supply systems and equipment connected thereto”, IEC, 2002

[13] http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2012:342:0001:0022:en:PDF

[14] http://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32009L0125

[15] http://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:31992L0075

[16] CIE/IEC 62471, “Photobiological safety of lamps and lamp systems”, First Edition 2006-07

[17] Guidelines on Limiting Exposures to Non-ionizing Radiation, ICNIRP 7/99 (2006).

[18] Effets sanitaires des systèmes d’éclairage utilisant des diodes électroluminescentes (LED), Saisine n°2008-SA-0408, Rapport d’expertise collective de l’Agence Nationale de Sécurité Sanitaire de l’Alimentation, de l’Environnement et du Travail (ANSES), 2010

[19] Behar-Cohen F., Martinsons C., Viénot F., Zissis G., Barlier-Salsi A., Cesarini J.P., Enouf O., Garcia M., Picaud S., Attia D., Progress in Retinal and Eye Research 30(4): 239-257 (2011)

[20] http://en.wikipedia.org/wiki/Photosensitive_epilepsy