Safety Concept for LED Street Lighting by Phoenix Contact

Street and building lighting has profited greatly from the advantages of LED technology. While modern LED lampposts have dielectric strengths of up to 6 kV, surge currents and voltages occurring in the grid can be significantly higher. Andreas Schamber, Product Manager for surge protection at Phoenix Contact, presents and discusses a comprehensive power surge protection concept to prevent blackouts during power surges and to protect investments in LED lighting based on the company’s product portfolio.

LED technology has become prevalent in many areas due to its significantly longer service life and higher energy efficiency. Street and building lighting has benefited in numerous ways from the advantages of this new technology. LED modules have also made lights much more compact and they can be dimmed by sensors, allowing them to be adapted to the needs of the user. While the dielectric strengths of modern LED lampposts is up to 6 kV, power surges in the grid caused by direct and indirect lightning strikes or switching action can be significantly higher.

The destruction of sensitive lighting electronics or the LED modules by power surges will increase the time for ROI. The cost of replacing LED equipment is also higher than replacing conventional lighting technology. Preventing downtime from power surges and to protect the investment in LED technology, a comprehensive surge protection concept is highly recommended, even for street and building lighting. The consequences in security-relevant areas can be severe (Figure 1).

Figure 1: LEDs have become the common technology for street lighting. Specific protection devices are used to protect these sensitive systems

Power Surges and Their Consequences

Undesirable power surges have various causes. A distinction is made between direct and indirect effects of lightning strikes and switching operations. There can be a low number of direct lightning strikes, depending on the region. Nevertheless, these kinds of strikes are always high-energy, usually resulting in greater damage. Lightning strikes can indirectly affect devices up to distances of 5 km.

Power surges typically result from:

- Direct lightning strikes to lights or power lines

- Indirect effects of lightning, ground feedbacks, or electromagnetic induction

- Switching operations in the power grid

Lampposts are generally placed in highly exposed locations, leaving them susceptible to direct lightning strikes that can affect the entire streets. If there are no suitable protective devices in place, the lightning current can be dispersed across the entire installation (due to galvanic coupling) and cause enormous damage.

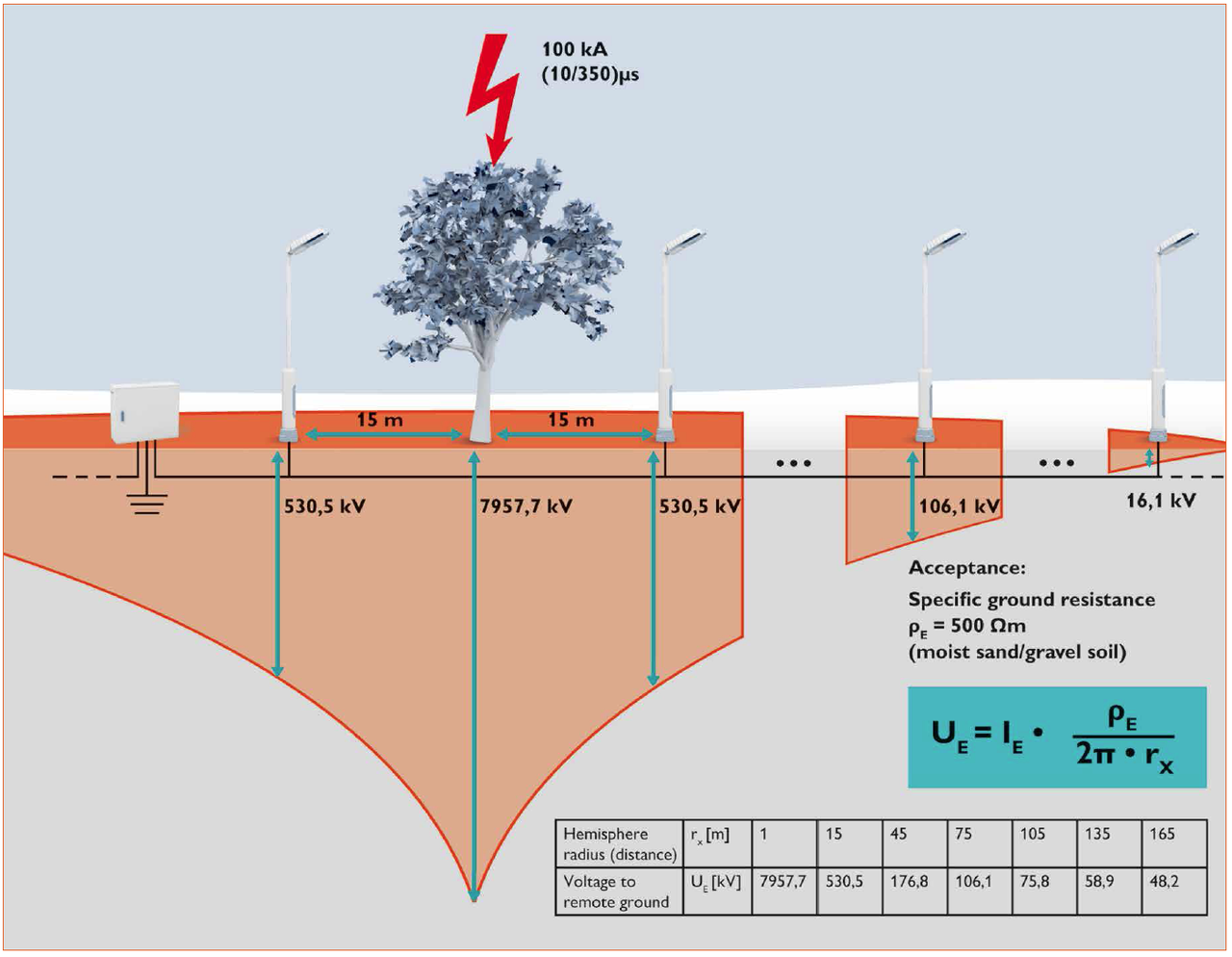

Lightning strikes cause the voltage to increases by several thousand volts at the point of impact. This voltage decreases exponentially and depends largely on the soil conditions and the distance from the point of impact. For example, if lightning strikes a building with an external lightning protection system or a nearby tree, this raises the ground potential (Figure 2). If the insulation resistance of the components is exceeded, a flashover can occur, and the insulation will be damaged.

Figure 2: A lightning strike directly in or close to the street lighting system raises the voltage potential and endangers the street lighting

If the insulation of the supply cables, the junction box or the electronics has been damaged, it can usually only be determined during the next routine check. Insulation failures pose a lethal risk and, in the worst case, can lead to electric shock if contact is made with metallic parts such as a light pole.

Inductive coupling in the power supply cable can also generate power surges. This is caused by the magnetic field of the lightning current flowing to the ground. For instance, the current through a downed conductor, or even a tree, generates an electromagnetic field around the conductor, which induces energy in cables running in parallel. These surges are strong enough to damage the electronic components connected to those wires.

The other main cause for power surges is switching operations in the power distribution network. These can cause power surges of several kilovolts. These transient power surges occur far more frequently than lightning strikes and have a lower energy density and shorter duration. Nevertheless, they still cause damage due to the high number of incidents that stress the components.

These transient power surges can have various causes:

- Switch-on and switch-off operations in nearby electrical devices and at large-scale plants

- Switching conventional discharge lamps on and off

- Ground faults and short circuits in the alternating current

- Triggering of the fuses

- Conductor-to-conductor errors in the medium- or high-voltage grids

Most street and outdoor lighting is connected to the low-voltage grids, which sometimes run over long distances. When it comes to conductor-to-conductor errors in the high and medium-voltage grids, sometimes the voltage impulses reach the consumer, which significantly speeds up the aging process of the components. Other occurrences, such as switching operations at large-scale plants and unforeseeable ground faults or short circuits in the alternating current, can also cause power surges to reach and overload the consumer. Grid operators work in accordance with the guidelines specified in EN 50160 to ensure the required grid quality. However, due to the limitations of the technical means currently available, grid operators are far from able to protect all consumers from unforeseeable power surges. A comprehensive lightning current and power surge protection concept protects LED lights from early failure.

Example for a Suitable Protection Concept

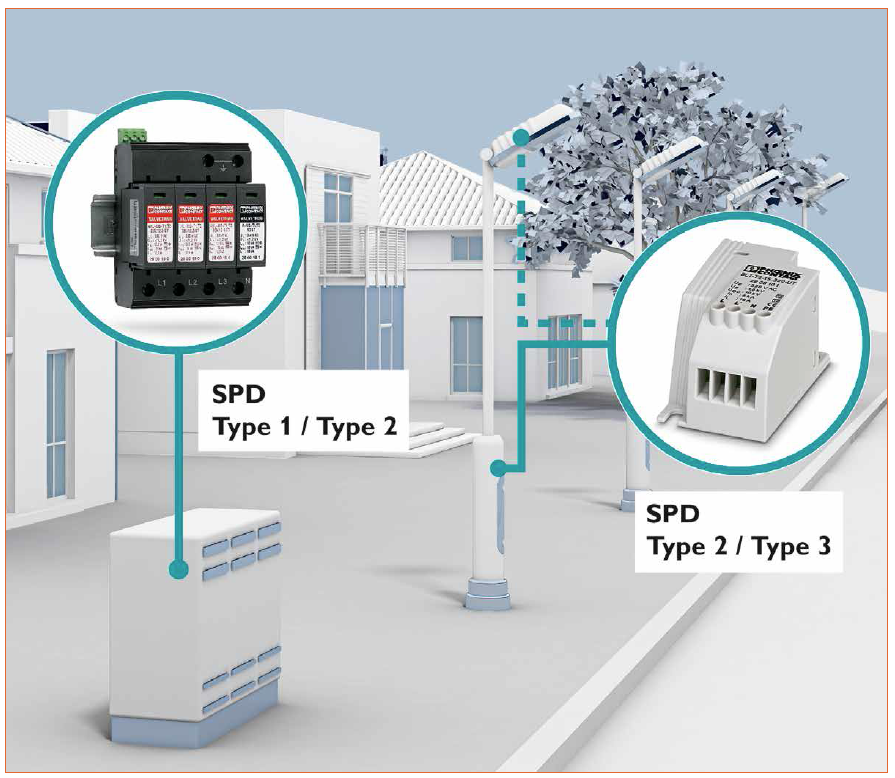

A comprehensive protection concept with coordinated components is necessary for protecting an entire streets’ worth of LED lights with several light points. This kind of multi-level power surge protection concept revolves around three installation locations (Figure 3).

Figure 3: Possible areas of application for power surge protection in the street lighting system - a multi-level power surge protection concept secures the entire installation for the long term (SPD = surge protection device)

The three installation locations are:

- In the control cabinet

- Directly in the LED light

- In the cable junction box at the base of the pole

Combinations of Type 1 and Type 2 arrestors are advantageous for protection installed in control cabinets - the arrestors provide protection from direct lightning strikes and transient power surges caused by the indirect effects of a lightning strike or switching operations in the distribution network. This setup ensures that all powered LED lights are protected against the direct and indirect effects of lightning.

Integrating a Type 2 or Type 3 power surge protection device protects the electronic components directly in the light from power surges caused by the indirect effects of nearby lightning strikes. The light manufacturer directly influences the positioning of matched components; he or she can protect the lights and their sensitive electronic components from unforeseeable power surges.

The cable junction box is also a suitable location for installing a power surge protection device. When a power surge protection device is installed here, there is an additional advantage - compared to when it is installed directly in the light - in that the protective ground conductor also goes into the cable junction box. The protective ground conductor, which is wired to the ground, can be used to effectively protect Protection Class II LED lights against transient power surges. This setup is also easy to access for inspection or retrofitting.

The described power surge protection devices are suitable for the entire installation concept. All of the components are optimally coordinated with one another. They are also tested and certified for security and reliability by an independent testing agency. Some of these components belong to the pluggable Type 1 and Type 2 product family and come either with or without remote signaling for use in the control cabinet. Meanwhile, the specially developed Type 2 and Type 3 arrestor product family features compact design and flexible types of wiring. Because of this, these product types are perfect to install directly in the LED light or in the cable junction box in the pole. Reinforced insulation means that these protection devices can be used in Protection Class II LED applications without additional measures.

Useful Product Features

Several million Protection Class I and II light points are installed worldwide. In the past, Protection Class II lights were frequently installed for a variety of reasons, depending on the region and country. Light installation requires double or reinforced insulation for all electrical components in accordance with IEC 60598-1. Today, these requirements can also be applied to the power surge protection devices for Protection Class II. Doing so ensures that future standard requirements will also be fulfilled.

Differences between installations mean that conductor cross sections ranging from 0.5 to 2.5 mm. are found in the field. This usually affects the standard lights. Because of this, devices with flexible connection technology that can take this connection area into account during retrofitting are required.

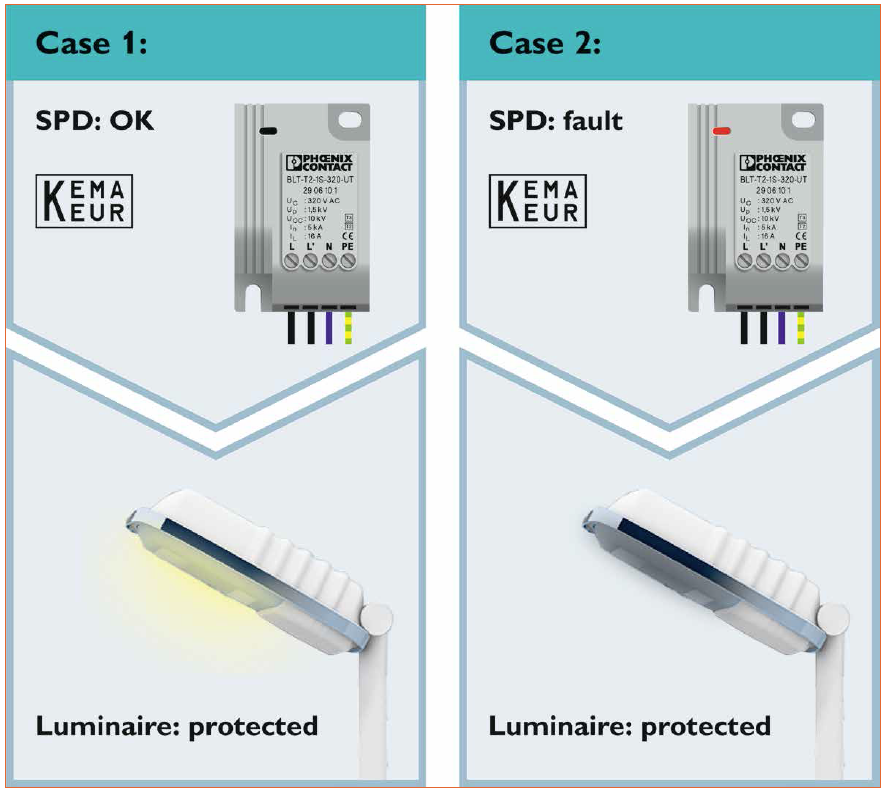

One product feature in particular should be prioritized: the visual indicator on the power surge protection device. This advantageous feature is prescribed by standards and allows the function status to be read directly off the device. The indicator needs to be easy to read even when the device is in a dead state, since maintenance work is not usually performed while the device is live. If the power surge protection devices are directly integrated into the lights and are only accessible with the help of tools, then the signal can be transmitted to the lamp. For example, if the power surge protection device’s disconnect device is securely triggered due to an overload, the light is also switched off. The functions of the power surge protection device can then be recognized during routine inspection of the light (Figure 4).

Figure 4: Signals can be transmitted to the lamp via the so-called L connection. If the disconnect device has been disconnected from the power surge protection device due to an overload, the light is also electrically isolated from the network and thereby protected from further power surges

Last but not least, product approval plays an important role in lighting installation. This is because the approval mark on the product indicates that the product’s quality and security have been confirmed by an independent testing agency. As such, this approval mark lets the user know that the product’s technology is state-of-the-art. Moreover, securing product approval for the power surge protection device can reduce the cost of certifying the entire light. Certification bodies typically acknowledge the results of quality tests conducted on power surge protection devices. If these bodies see that the protection devices have already been approved, then they reduce the cost of approving the entire light (for example, in accordance with ENEC, or European Norms Electrical Certification). The IEC 61643-12 installation guidelines should also be acknowledged when installing protection devices. Lightning current and power surge protection devices are only guaranteed to function properly and provide suitable protection if these installation guidelines are followed.

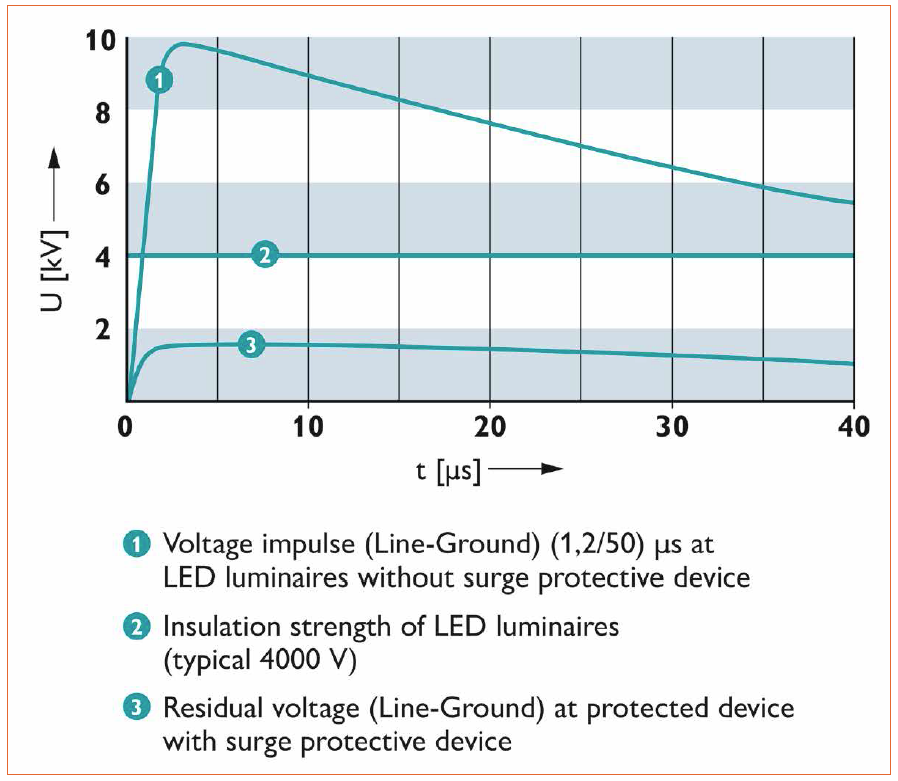

It is also important to take the protective effect of power surge protection devices into account during installation. A low protection level is required; it should lie beneath the surge voltage capacity of the light source and the LED driver. This also applies for the multi-level protection concept for Type 1 lighting arrestors in the control cabinet through to Type 2 and 3 lightning arrestors in the LED light. The appropriate devices are only effective if the incoming pulses through installed devices are successively limited to the reliable protection level, which thereby prevents the pulses from overloading the downstream end devices (Figure 5). And if the pulses reach the power limits of the protective devices, these devices need to be securely disconnected. When suitable protective devices - such as T2 and T3 Blocktrab components - are installed in the light or in the cable junction box, even end devices can be electrically isolated from the network (depending on the selected circuit), thereby protecting the lights from further pulses until the defective device has been replaced.

Figure 5: Residual stress curve for a surge voltage impulse (1.2/50 μs) - power surge impulses are limited to a voltage level sufficient for sensitive devices

Summary

All of the components necessary for the installation must be carefully selected in order for LED lights to be operated safely and efficiently for many years. A professional lightning current and power surge protection concept is recommended for all types of lighting: indoor, outdoor, tunnel, and building lighting. Suitable protective devices protect sensitive electronic components from undesirable and unforeseeable power surges and thereby help the user reach the planned payback period. Protective devices also contribute to personal and system safety and reduce maintenance and repair costs.