SSL Growth Strategies and USDA Corn Breeding Objectives

The SSL horticulture lighting industry has become one of the fastest growing branches of lighting worldwide. Much research has already been done in regards to horticultural SSL technology and continues to be rigorously explored. While most other inputs for plant growth are monitored and controlled based on plant needs, it is still common practice for light control to be rudimentary (on/off). Brandon Newkirk, Marketing Communications Manager at LumiGrow Inc., gives a short overview on the current state of dynamic LED lighting with a focus on USDA corn breeding trials and objectives.

It has become commonly understood that supplemental lighting is an efficient way to address the shorter days and longer nights that winter’s invasion brings. Seasonality carries with it diminished light intensity from the sun at various times of the year. Artificial lighting can be used to provide supplemental light in addition to sunlight to plants. Artificial light can also be the sole source of radiation for various indoor growing environments.

The main aspects to consider when providing light for plants indoors is the quality, intensity, and photoperiod. Quality refers to the actual wavelengths of light provided to plants. Total intensity of light at the plant canopy is crucial and is a function of light fixture intensity, beam angle, fixture arrangement, and daily light integral (DLI), which is the amount of PAR received each day as a function of light intensity. Photoperiod refers to the amount of time the plant receives light throughout a 24-hour timeline.

Different crops have different photosynthetic saturation points, where additional light beyond this point becomes wasted. For this reason, it’s important to monitor the DLI to optimize energy-use versus plant photosynthetic rates. Research institutions, commercial growers, and commercial research teams such as LumiGrow’s in-house plant science research group are laying the foundational knowledge to understand how best to use light as a growth variable for specific growth goals. As horticultural LEDs move into the ag-industry spotlight, we are in the midst of a technological paradigm shift due to increased efficiency and controllability that LED solutions offer.

Figure 1: Corn breeding at the USDA lab using LED illumination

Figure 1: Corn breeding at the USDA lab using LED illumination

USDA Uses Artificial Lighting for Corn Breeding

There has already been much written about light requirements for crop production, but plant breeding remains a topic less explored. Plants have adapted to grow in certain climates, from subtropical to northern climates. Thus, the time it takes to grow from a seed to harvest can differ among different varieties, typically longer for subtropical and shorter for varieties grown in the north, as growing seasons are typically shorter in the north. Light intensities and photoperiods can further affect this, as the same variety can flower at different times if grown under different photoperiods. Although corn will flower under most photoperiods (day-neutral plant), the time to form tassels and silks (male and female flowers, respectively) will differ based on varieties. This presents a challenge for breeders who would like to cross corn, as they need flowering times and tassel formation to synchronize. Requirements are different for every corn variety but, in general, they need a high intensity of light to produce a healthy corn plant.

The USDA-ARS Station is home to the largest collection of maize germplasm in the world, which they make available for national and international research. The maize collection consists of over 20,000 accessions from all over the world. The USDA Station is using artificial lighting to aid in the development of new and more nutritious corn varieties for organic producers finally using a property called gametophytic incompatibility. They’ve made major advancements in the ability to prevent organic corn from being pollinated by unwanted pollen, a problem that’s been prevalent in recent years due to GMO seed.

Researchers at the USDA have been using supplemental light to improve greenhouse light quality and intensity. They have used LEDs to decrease the high levels of heat from their HPS fixtures. HPS and heat is a problem with tall varieties of corn. As the corn grows closer to the high levels of heat emitted, the pollen can often become damaged. Some varieties of corn only grow a few feet in height, but others can get well over 10 feet tall. For tall varieties of corn, high ambient heat from lighting fixtures brings challenges in successful germplasm regeneration. Cooler LED fixtures offer a solution to this production system issue common to many crop breeders.

Researchers at the USDA-ARS Station have begun to experiment testing the effects of spectral variability with some interesting preliminary results. Using controllable LED fixtures to adjust the ratios of wavelengths of red and blue light emitted, they have seen increased control over growth characteristics in specific treatments. Preliminary results at the USDA Station have seen that blue light treatments can potentially induce corn to flower 3 days earlier, and plants grown under red light can have thicker stocks and more vegetative growth. More data must be gathered before any conclusive statements can be made about the significance of the results, but this is just one instance where light spectra have been used to achieve similar control over desired crop characteristics.

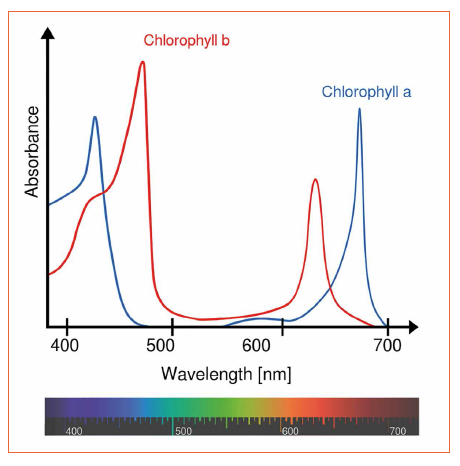

Figure 2: Absorbance spectra of Chlorophyll a and Chlorophyll b

Figure 2: Absorbance spectra of Chlorophyll a and Chlorophyll b

Functional Differences of SSL vs. Non-SSL Lighting Strategies

Whether your goals are for breeding or production purposes, the variables between SSL and non-SSL lighting strategies remain similar. As a new technology and not simply a refinement of an existing one, SSL technology implementation requires that new variables be considered. Given the leaps and bounds that SSL technology has made in efficiency and quality compared to conventional horticultural lighting, the agricultural industry is learning fast.

As mentioned before, traditional lighting such as HPS produces more heat than LED technologies. This reduction in heat can provide major benefits, but this change can significantly affect the growth environment. Traditional growing methods have treated HPS lamps as a heat source, albeit an extremely inefficient method for temperature regulation. When implementing SSL in the form of LEDs, it’s important to take note of the reduction in ambient heat, and adjust your temperature control systems accordingly.

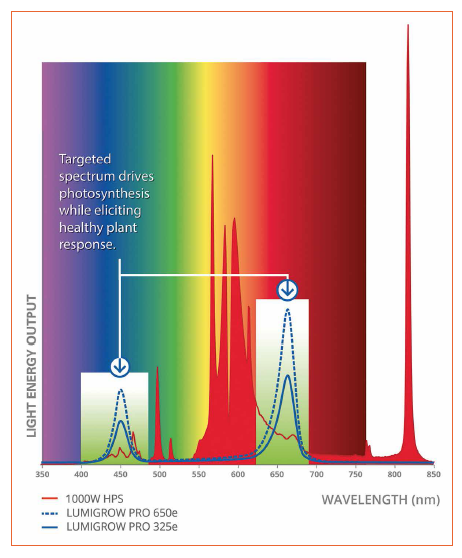

Spectral distribution is another variable when choosing to use LEDs. Different wavelengths of light have varied efficiencies in regards to photosynthesis. Rather than the human eye response curve, horticultural lighting uses Photosynthetically Active Radiation (PAR) as the primary measure. PAR refers to the spectral range from 400 to 700 nanometers, the range that plants use in the process of photosynthesis. LED technology offers the ability for lighting manufacturers to design products that target this PAR range.

Figure 3: Comparison of the spectra of two LED growth lights and one HPS system with the photosyntetically active spectrum range of healthy plants

Figure 3: Comparison of the spectra of two LED growth lights and one HPS system with the photosyntetically active spectrum range of healthy plants

About State-of-the-Art SSL Grow Light Systems

The most up-to-date horticulture lighting fixtures take advantage of the capability for spectrum tuning and perfect intensity control to adapt for the required photosynthetic active radiation spectrum of a plant. Moreover, in high end solutions the spectral controllability can be aligned with the stage of plant growth, i.e. in some crops a blue light treatment towards the end of flowering elicits beneficial plant response. Other plants may need a different spectral profile or prefer different light intensities during different stages of their growth. This task asks for sophisticated controls for dynamic lighting.

Dynamic and sophisticated control solutions

Using modern control systems such as wireless solutions like LumiGrow’s SmartPAR™ Wireless Control System, growers can automate lighting schedules in regards to light intensity, as well as spectral ratios as mentioned above. Furthermore, such systems allow the user to create different lighting zones from any phone, tablet or computer. Such cloud-based Horticultural lighting control systems are designed to enable growers to be more specific and dynamic with their growth strategies while providing a robust monitoring platform.

Conclusions

When considering artificial lighting solutions for horticulture, it’s important to understand the efficiency of your solution, as well as the science behind how it works. As SSL technology continues to improve, so will the automated systems that support the use of lighting tools to drive plant growth. The dialogue between plant science and lighting technology will remain important as the industry continues to rapidly evolve. It’s important that horticultural experts and lighting specialists work with each other so that growers are given the best tools to continue improving their own production and research goals. Some ongoing research, for instance, takes into account biological feedback systems that could monitor how efficiently the plants are using the light for photosynthesis. It is certainly an exciting topic for the future.