Standardized Programming of Lighting Components Using NFC Technology

LpR 70 Article, page 88: NFC programming of LED drivers is rapidly gaining popularity as a fast, feature-rich, flexible and easy method to set the operating characteristics of LED drivers inside luminaires. Arnulf Rupp, Chair of MD-SIG, describes how the MD-SIG specification for NFC programming of lighting components makes it easy for luminaire manufacturers to use NFC programming in a production line where multiple brand drivers are used one after the other.

The Module-Driver Interface Special Interest Group (MD-SIG) is a global lightingindustry consortium. MD-SIG is a sister organization of the Zhaga Consortium and aims to meet the growing demand in the market for harmonization by introducing a standardized, multi-vendor electrical interface for LED drivers and LED modules.

MD-SIG is harmonizing existing setting methods and powerinterface definitions for LED drivers, and introducing new setting and programming methods. The consortium has already released specifications for critical definitions and for an analogue method of current setting, and has now added a specification for digital Near Field Communication (NFC) programming.

Introduction

NFC is a set of communication protocols that enable two electronic devices, one of which is usually a portable device such as a smartphone, to establish communication by bringing them within 4 cm of each other. NFC is best known for its use in wireless payment systems. Increasingly, NFC is being used in the lighting industry, e.g. for identification, control, or configuration of components such as drivers.

MD-SIG members include leading global vendors of LED drivers, and some of these companies have already introduced to the market different approaches to NFC programming of LED drivers. However, these approaches brought to market are proprietary solutions based on different NFC protocols requiring software and hardware which is specific per driver brand. This makes it complex for luminaire manufacturers to use these programming methods in a production line where multiple brand drivers are used one after the other.

To counter this complexity, these MD-SIG companies have agreed to harmonize their programming methods, and developed the NFC specification for lighting components. The specification is based on the ISO/IEC 15693 standard for NFC, and was approved by MD-SIG in March 2018.

By issuing this specification, MD-SIG aims to harmonize NFC programming methods resulting in a single industry choice for NFC programming of luminaire components. All NFC programmable devices that comply to this standard can be programmed by any of the Qualified NFC Readers defined in this standard. At the same time, this standard leaves a wide space open for vendor differentiation by means of both driver features as well as programming software.

NFC Programming of Drivers

Manufacturers of LED luminaires currently use a variety of programming methods to set the operating characteristics of LED drivers inside luminaires. NFC programming is a new and promising method to do so. It is faster than traditional methods of LED driver programming, more feature-rich and flexible than resistor-setting techniques, and has a reduced training requirement for production-line staff. This technology could also offer new in-field services in the future e.g. installation and maintenance of street-lighting luminaires.

NFC allows the manufacturer to wirelessly set the LED driver operating parameters, such as operating current, constant lumen output and dimming levels. This can be done on a manufacturing line without the need to apply mains voltage to the driver, reducing effort in the production line to protect the workers from mains voltage.

Figure 2: NFC programming of drivers - system overview

Figure 2: NFC programming of drivers - system overview

The NFC system is depicted in figure 2. It comprises an NFC reader and an NFC tag integrated into a driver. The NFC reader is a hardware device for exchanging data with an NFC Tag. The NFC tag is an IC that can be used as data store which can be read, and under some circumstances written to, by an NFC Reader. The tag is a passive device and activated by the energy contained within the signal emitted by the NFC reader. In contrast to what the term suggests, an NFC Reader can both read from and write to an NFC Tag.

In the NFC programming system, the NFC reader is connected to a host PC, and receives its instructions from this PC. The NFC reader wirelessly transfers the programming data to an NFC tag inside the LED driver. The parameters are programmed using an NFC reader in combination with software that is specific to the LED driver vendor. This software typically runs on a standard host PC. After such a programming phase, the LED driver operating parameters are at the desired settings.

MD-SIG NFC Specification: System Overview

The MD-SIG NFC specification for lighting components follows the general approach to NFC driver programming outlined above and depicted in figure 2, but makes it more specific by defining a number of the interfaces. The major interfaces being the one used by the programming software to access the system features and the interface between the NFC reader and the NFC programmable device.

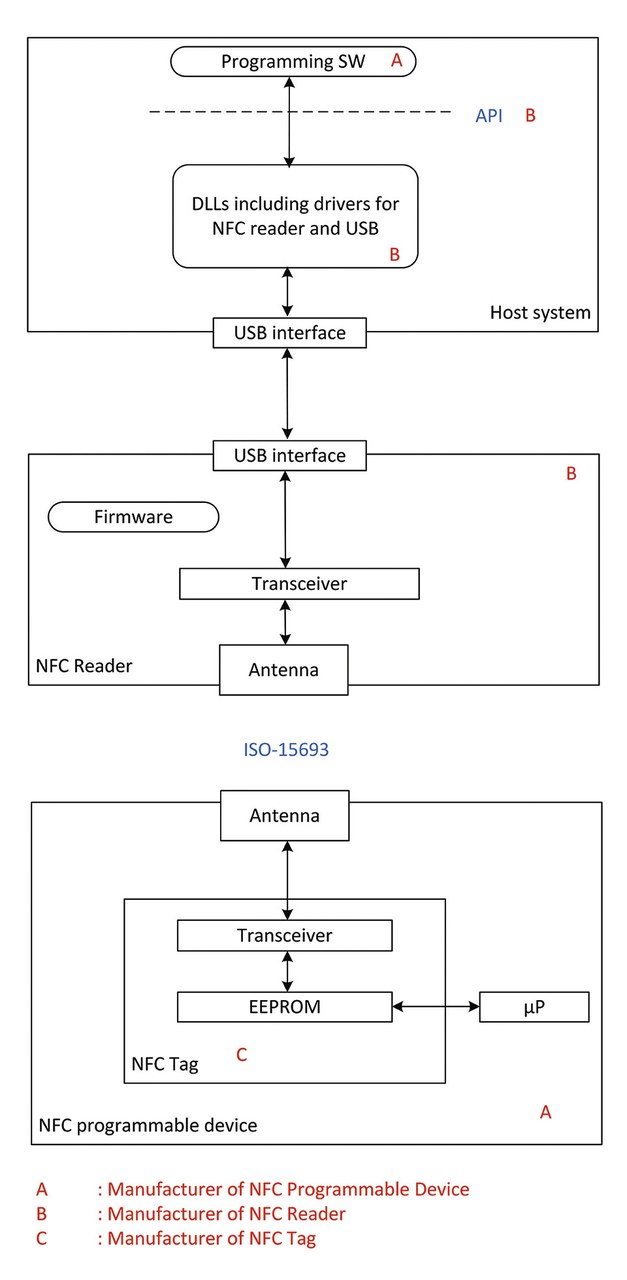

A block diagram of the NFC programming system is depicted in figure 3. The device to be programmed is labeled "NFC Programmable Device" at the bottom of this diagram. This can be any electronic device. The target application is the programming of LED drivers; sensors and network transceivers would also be in scope.

The NFC Programmable Device features an NFC Tag and associated antenna. The antenna is mounted in the device in such a way that it can be used for NFC data transfer without opening the device. The NFC Tag holds an NFC transceiver interfacing to the antenna and an EEPROM for storage of data. The NFC Tag also features an interface that allows the microprocessor of the NFC Programmable Device to access the data in the EEPROM.

The hardware required for NFC communication with the NFC Tag is implemented in the NFC Reader. This device holds an antenna and a transceiver for NFC communication, an interface to the host system and a memory component storing the Firmware of the NFC Reader.

The rest of the system is implemented in software running on a host system, typically a PC. Software libraries (DLLs) and drivers allow for control of the NFC Reader. The DLLs provide an Application Programming Interface (API) which is used by the Programming Software. This Programming Software holds the user interface for NFC programming.

Figure 3: NFC Programming system - overview

Figure 3: NFC Programming system - overview

Figure 3 is the basic block diagram of the NFC programming system. The standard is more flexible and allows variations for some of the details. E.g., the USB interface between host system and NFC Reader is just an example. In practice it can be any common computer interface like TCP/IP. Similarly, the NFC antenna of both the NFC reader and the NFC programmable device may be implemented internally or externally, as a separate device.

MD-SIG NFC Specification: Separation of Concerns

It is good to point out various providers come into play to implement an NFC programming system. This is also depicted in figure 3.

To implement an NFC programming system requires hardware and software from:

• The manufacturer of the NFC programmable device

• The manufacturer of the NFC reader

• The manufacturer of the NFC tag

For a good understanding of the MD-SIG NFC specification for lighting components it is important to realize that the different components in the NFC programming system are provided and are under control of different providers. Manufacturer A supplies and has control over the NFC Programmable Device and the Programming SW for programming NFC Programmable Devices of brand A. Manufacturer B supplies and has control over the NFC Reader hardware, the NFC Reader firmware, the NFC Reader software libraries including drivers for the NFC Reader, and the Application Programming Interface (API). Manufacturer C supplies and has control over the NFC Tag.

The MD-SIG NFC specification defines interfaces to provide for the appropriate separation of concerns between these different providers. By adhering to the standard interface specification, they can develop their products in relative isolation; yet, the products can be used together to implement an NFC programming system.

MD-SIG NFC Specification: Additional Details

The LEDset NFC specification describes the appropriate interfaces between the components in the NFC system and features a list of mandatory requirements and recommendation for the LED driver interface (or another NFC programmable device), the interface to the NFC reader and the programming software.

The interface between the programming software and the NFC reader is specified through a list of supported software commands. These commands are supported by all qualified readers through the provided software libraries, and ensure that the programming SW of a specific brand is compatible with all Qualified NFC Readers. Next, the specification has a number of recommendations to ease the co-existence of multiple NFC programming software packages on one host PC.

The communication protocol between NFC reader and LED driver is specified to ISO/IEC 15693. A minimum set of ISO/IEC 15693 commands is selected to be supported by LED driver and NFC reader. It is also required that NFC Reader manufacturer shall support download of firmware in the NFC Reader by the Programming SW. There is no requirement for a minimum programming distance between NFC Reader antenna and the NFC Programmable Device. Information on programming distance should be provided in the datasheet of the device.

MD-SIG NFC Specification: Market Update

MD-SIG has published a list of compliant NFC products. These comprise qualified NFC readers and qualified NFC tags, to be used in the drivers. The MD-SIG website maintains a list of qualified readers. The MD-SIG NFC specification comprises a list of tags that have been qualified. A number of driver manufacturers have already introduced compliant drivers and programming software to the market.

Conclusion

The MD-SIG has created a specification for NFC programming of LED drivers, which makes it easy for luminaire manufacturers to use NFC programming in a production line where multiple brand drivers are used one after the other. LEDset NFC compliant equipment and software enables luminaire makers to streamline their production and to use LED drivers from different vendors using the same programming hardware. Drivers and software complying with this standard are on the market already from leading driver manufacturers.

Members of MD-SIG have access to the NFC programming specification [1], which describes the system setup and the requirements that are mandatory to achieve compliance of the programming software, the NFC reader, and the LED drivers and other luminaire components.