Tech-Talks BREGENZ - Dr. Scott Wade, Technical & Certification Manager, DiiA

Dr. Scott Wade has been the Technical & Certification Manager for DALI/DiiA since 2013 and has been an industry expert member of the IEC62386 standardization team for about 14 years. He was invited to hold a lecture at the LpS 2018 about the founding of DiiA for the purpose of taking over the DALI trademark from ZVEI and discussed measures that were taken to further develop the standard and its certification process and make the DALI concept future proof with DALI-2.

LED professional: Thank you for taking the time to be here. I think it might be interesting for our readers if you could give us some background information on DiiA (Digital Illumination Interface Alliance).

Scott Wade: Yes, of course. As you might already know, DiiA was founded about two years ago and took over the DALI trademarks from the ZVEI, the previous organization. The number of members has grown very quickly currently, we have more than one hundred and sixty members, worldwide. So it is a global organization. The main aim of the organization is to promote the use of lighting-control technology, based on the latest version of IEC 62386, which is very commonly known as the DALI standard.

LED professional: ZVEI also had members. Did you take those members over or did you have to recruit new ones?

Scott Wade: ZVEI stopped the DALI organization known as DALI AG and the vast majority of members have already transferred across to DiiA. DiiA member companies are almost all in the lighting control industry. Original members from years ago would be mostly control-gear manufacturers. But now we have many control-device manufacturers as well. Control gear includes products such as LED drivers, ballasts and electronic transformers, while control devices are products such as sensors, routers, and gateways. So we have a good mixture of manufacturers covering all those types of products now.

LED professional: What about all the responsibilities DiiA took over from ZVEI?

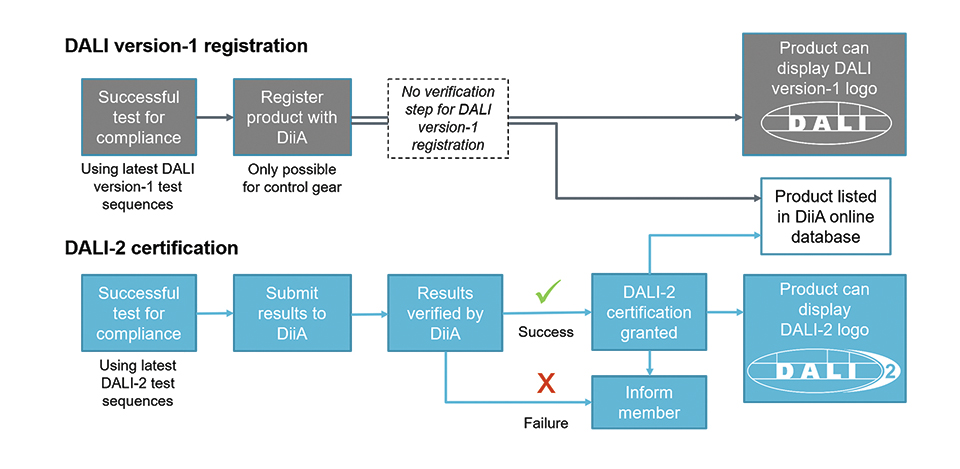

Scott Wade: Initially, the DALI version-1 tests were taken over and the use of the DALI version 1 trademark was allowed by our DiiA members. However, in August 2017 we launched the DALI 2 certification program. We developed a new set of tests for DALI-2. Initially, many LED drivers were certified for DALI-2 and then we had the first DALI-2 application controllers. Those first ones were single-master application controllers you can only have one of those in a system. However, in August 2018 we extended the certification program to include multi-master application controllers for the first time. Application controllers are the decision makers, and you must have at least one in a system. They send the commands to the lights, through the control gear, to tell them what level, what scene or what fade time to use. In DALI version 1, these were not part of the standard so they were all proprietary, but now they are part of the standard and they are part of the DALI-2 certification process, as well.

DALI-2 certification includes a verification step to confirm that the test results provided by the DiiA member are fully compliant with the DALI-2 test specifications

DALI-2 certification includes a verification step to confirm that the test results provided by the DiiA member are fully compliant with the DALI-2 test specifications

LED professional: If we talk about differences between the systems it might be interesting to know how a DALI version-1 system and a DALI-2 system work.

Scott Wade: The DALI version 1 standard was only for control gear. Examples include LED drivers, fluorescent ballasts, electronic transformers for halogen or HID lamps, and color control gear. The limitation was that there was no standard for the control devices. The devices that make the decisions, as well as the sensors, the push buttons, the sliders all of these types of control devices were not in the DALI version 1 standard. DALI-2 made two big steps: The first one was a big increase in interoperability for control gear. We removed ambiguities from the standard, and we increased the amount of tests. As an example, in DALI version 1, an LED driver takes around one day to test, but for DALI-2 certification, an LED driver takes around three days to test it fully. Most of the testing is automated. The end result of the improvement in the standard and the greater number of in-depth tests is a much higher level of interoperability in DALI-2. The second big step is that control devices are included. This means that the new standard includes all control gear, the control devices, and the bus power supplies. DiiA provides tests for all of these, and includes them in the DALI-2 certification program.

Truly an expert talk: Dr. Scott Wade and Dr. Guenther Sejkora

Truly an expert talk: Dr. Scott Wade and Dr. Guenther Sejkora

LED professional: Is the bus system different?

Scott Wade: The bus itself is the same two-wire bus, carrying power and data. The signals on the bus are better specified in DALI-2 so there's less ambiguity. But actually, DALI-2 is backwards compatible with DALI version 1. You can mix products, you can have DALI version 1 control gear and DALI-2 control gear in the same system (on the same bus), and they will work together. No problems are expected. You can even replace DALI version 1 control gear with DALI-2 control gear.

LED professional: So the DALI-2 controller is not defined in DALI version 1, but a DALI-2 controller would work together with an old system?

Scott Wade: That's correct, yes. The DALI-2 control devices will be able to work with the DALI version 1 control gear, because the backwards compatibility has been maintained we've taken very little out of the DALI version 1 standard. There was only one feature we removed that wasn't used, but we asked all of our members first. In DALI-2 we have made the standard much clearer and also added more features. For example: the fade time. In DALI version 1 there is a standard fade time from 0.7 seconds up to 90 seconds. All control gear has to follow those fade times. But also in DALI version 1, LED drivers had a fast fade time, much faster than 0.7 seconds. However, that was only available to LED drivers. Now, in DALI-2 we recognized that all lamp types could make use of this. We have added an extended fade time for DALI 2 control gear, allowing fades from 0.1 seconds to 16 minutes to be recalled with a single command. However, the original fade times from 0.7 seconds up to 90 seconds still exist in DALI-2. So in that way we have maintained backwards compatibility.

LED professional: If you have an old system one that isn't standardized and you replace one single control gear, would it work or might there be a problem with the protocol of the controller?

Scott Wade: Due to the backwards compatibility, it will work. No problems are expected. In fact, you're likely to have fewer problems replacing your DALI version 1 control gear with DALI-2 control gear. The reason is that we've improved interoperability of the products by making the standard clearer and the tests more detailed. So that will most certainly reduce the chance of problems. But you're right that old controller will work with both the DALI version 1 and the DALI-2 control gear. Of course it's not likely to make use of the new features that we brought into DALI-2. LED professional: But I think it's also important to be able to replace a control device in an old system if it breaks. Scott Wade: That's exactly right. Now we can't absolutely guarantee it, but the tests and the certification that we do with the DALI-2 products help to ensure interoperability.

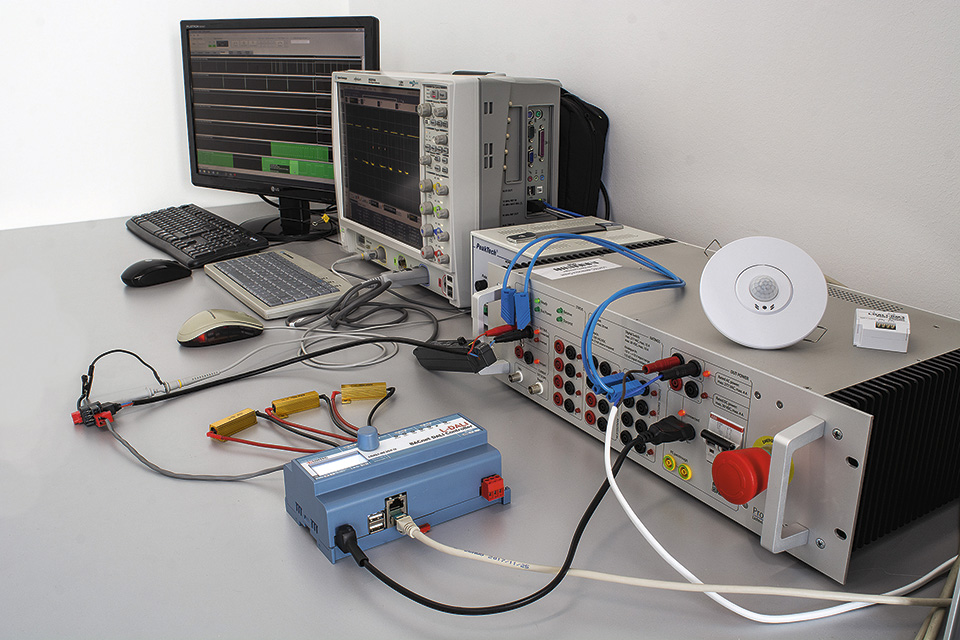

Typical set-up for DALI-2 testing, showing a DALI-2 application controller (center front) and a ProbitLab2 tester from Lichtvision Engineering (right) (Image credits: LOYTEC electronics)

Typical set-up for DALI-2 testing, showing a DALI-2 application controller (center front) and a ProbitLab2 tester from Lichtvision Engineering (right) (Image credits: LOYTEC electronics)

LED professional: What new possibilities are offered in the application by the new system?

Scott Wade: For the control gear, we have added features such as the extended fade time. So that opens up new opportunities for applications going to faster and slower fade times. We have also just published five new specifications, which are available on our website. These specifications are especially useful for outdoor luminaires, but also for indoor use. We've also started collaborating with the Zhaga organization because of their expertise in the connectors and the sockets and our expertise in the protocol and the power supplies. Although those are not strictly new applications, there are new features to help in those applications and also to bring more benefits for IoT applications. For example, one of the new specifications is luminaire data which is very useful for asset tracking. So now, using this new specification, you can query lots of information about the luminaire and the lamp: for example, its color temperature or the nominal light output in lumens. There are also new specifications for energy and power metering as well as maintenance and diagnostics. So these are all new specifications opening up new applications or improving existing applications.

LED professional: Correct me if I'm wrong, but I heard that a major difference between DALI version 1 and DALI-2 is that before they didn't allow active sensors on the bus. The controller had to send a request and the sensor would give an answer.

Scott Wade: This is a fairly common misunderstanding about DALI version 1. There was no standardization of the sensors or the controllers in version 1. Manufacturers could choose how to implement those: whether to allow only one in a system we call it a single master or to allow more than one a multi master system. Both are actually allowed in DALI version 1, there just isn't a standard for it. And both do exist. DALI-2 also allows both ways, but now it's standardized. Part 103 of the standard so that's IEC 62386-103 describes both the single master and multi-master requirements. Application controllers can be either single-masters or multi-masters. The sensors, the push buttons, the rotary controls, the slider controls these are input devices and must be multi-masters, automatically allowing more than one of them to be used on the DALI bus at the same time. So if you're designing a system where you want to have lots of control devices, you can have multiple input devices as well as multiple application controllers, if you wish. But that depends on your application. It's quite common to have one application controller, the decision maker the brain, making the decisions for all of the lighting in that system. But you can also have distributed intelligence. Both possibilities are still there. The difference is that now we have standardized it.

LED professional: Is there also a difference between DALI version 1 and DALI-2 when it comes to being able to control multiple channels?

Scott Wade: Yes. In DALI version 1, the control gear could only have one DALI address we call it the short address, and you could have up to sixty-four of those on one DALI bus. Now, you can have multiple short addresses within one product. We call those logical units. As an example, you could have an LED driver with three logical units. Each logical unit needs one DALI address and might be controlling one lamp. Each of those logical units controls its lamp independently of the other two logical units in that control gear. With DALI 2 you can now design, test and certify those products that have multiple DALI short addresses.

The DALI-2 mark may only be used if the certification test results are verified by DiiA and compliance to the testing requirements is 100% guaranteed

The DALI-2 mark may only be used if the certification test results are verified by DiiA and compliance to the testing requirements is 100% guaranteed

LED professional: Is the number of short addresses still restricted to sixty-four?

Scott Wade: No, this has also changed. There are still sixty-four short addresses for control gear, but now we have added a further sixty-four addresses for the control devices. So there are sixty-four control-gear addresses and sixty-four control-device addresses that can be on the DALI bus at the same time.

We also have sixteen groups for control gear and thirty-two groups for control devices, as well as a broadcast address to which all control gear or control devices will respond. There's also one new addressing mode known as broadcast unaddressed, which can help to speed up the commissioning process. Further grouping is possible at what we call the instance level. A push-button panel, for example, might have eight push buttons on the same product, and each of those buttons is one instance. They all share the same short address, but each of them has its own instance number.

LED professional: I think that point is interesting because, with the current trend of trying to connect more and more sensors, more and more devices, it looks like the requirements might be beyond sixty-four plus sixty-four.

Scott Wade: That's right. Now, this complexity in addressing wouldn't be seen by the end users of a system. Even the commissioning engineers depend on the software developed by the manufacturer. In my opinion, good commissioning software will hide all the complexity of groups and addresses. It's possible to show the system in a more user-friendly way.

LED professional: I think that with this DALI-2 standard, the DALI version 1 is more or less obsolete or will certification for DALI version 1 last for a while?

Scott Wade: For DALI version 1 we talk about registration, while certification is only for DALI-2. There is one big difference: In DALI-2 certification, the members must send us the test results from the product and we verify that they are genuine and all tests have passed. In DALI version 1, that's not done. The companies are self-testing or possibly using a test house. They can then apply the DALI version 1 trademark logo to the device and they register it on our web-site.

DALI version 1 is not obsolete, yet. I estimate that most manufacturers are now developing DALI-2 control gear instead of DALI version 1. But some parts of the standard are still being transferred to DALI-2. For example, color control is not updated to DALI-2 yet that's something we're working on now. So a color control gear is still developed according to DALI version 1.

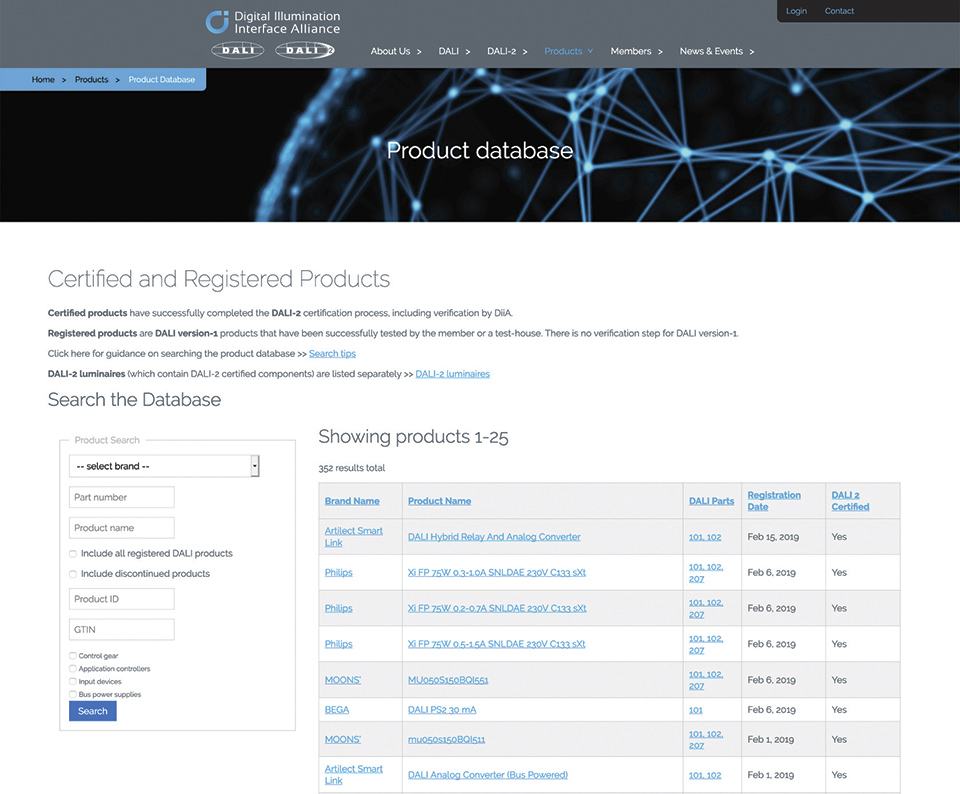

The number of DALI-2 certified components is continuously increasing

The number of DALI-2 certified components is continuously increasing

LED professional: On the subject of testing, there are the standard test procedures that have to be fulfilled, but is there also standard test equipment that the manufacturer can buy?

Scott Wade: Yes, they can. There are two types of test equipment. There's the ProbitLab and the ProbitLab2. The ProbitLab is the older one, and is only for control gear testing. ProbitLab2 can test all types of products. DiiA doesn't sell the test equipment; it comes from our technology supplier, Lichtvision Engineering. DiiA members that are self-testing are provided with the test-sequence software from us. It's part of the membership benefits to provide the latest version of the test sequences as well as updates.

The alternative is to send products to a test house. We list DiiAaccredited test houses on our website. Once the product has been tested, the members send us the results through their account on the DiiA website. Once the information is verified, certification is granted. As soon as certification has been granted, the product is automatically listed as DALI-2 certified. If it's listed, it means the member can apply the DALI-2 trademark to the product.

LED professional: DALI is a well-established protocol. But aren't there limitations in respect to system size that might restrict it for a lot of applications?

Scott Wade: This has never been a restriction of DALI. If you look, even going back to the early 2000's, there have been lighting-control systems for whole buildings or even across multiple buildings. DALI is a subnet within the building. So you would have multiple subnets within one building joined into devices called routers or hubs or gateways. So DALI is a very good fit to a wholebuilding, lighting-control system. The backbone of that system could be another protocol such as Ethernet or a WiFi-based protocol.

LED professional: When you get to that point it is often argued that you would need another node a router or a gateway which is another critical point for hacking and some failures.

Scott Wade: Actually, in my view, this can make the system more robust, because DALI is a subnet. If, for example, a fault occurs within a gateway, each DALI subnet can continue to operate independently. You don't have to have a system that stops working just because one gateway stops working. The sensors and the push buttons still operate within that room.

On the security side, that's out of the scope of DALI physical access to the bus or devices is necessary to make changes to the system. We recognize that there are other protocols that have solved the security problems. So it makes sense to use one of those protocols as the backbone, joining the DALI subnets together into a larger system.

LED professional: DALI is a 2-wire bus system. Then there is the wireless method. It seems that the mainstream is moving away from anything that is wired. How do you see this situation?

Scott Wade: If you listen to some in the industry, they believe that commercial lighting will move totally across to wireless. Personally, I don't see that happening in the near future. The enormous advantage that a wired system, such as DALI, has is that when you install it, it works. With a wireless system, you don't know if it's going to work. You don't know if there's going to be interference or if the signal strength is going to be an issue. So wireless is a bit of a gamble going into a building and installing it throughout the building. Whereas, with a wired bus, such as DALI, you wire the components to it and you don't have an interference problem, or a distance problem, or a latency problem.

With DiiA taking over the responsibility for DALI certification, DALI-2 has been established, further improving compatibility between DALI components

With DiiA taking over the responsibility for DALI certification, DALI-2 has been established, further improving compatibility between DALI components

There are applications where it makes sense for parts of a building to be wirelessly connected. This is true for certain building types, for example an old cathedral where you don't want to put new wiring in. There it might make sense to have some of the controls connected wirelessly. But as for the whole building I don't see it at the moment.

LED professional: What about the cost difference between a wired system and a wireless system?

Scott Wade: That's a good question. I don't think anyone has good cost data for a wireless system, so far. This might be due to problems you have in installation, such as extra time to trouble-shoot the wireless problems and possibly add extra products to get the hopping distance that's required in a wireless system. Another issue for wireless in a lighting system is luminaires tend to be made of metal. So it can be quite difficult to get an RF signal out of a luminaire and to the next luminaire. That's where the wired bus of DALI has a great advantage. You wire the luminaires together and you know it's going to work.

Another big advantage of DALI over wireless or even other wired protocols is that DALI has power and data on the same two wires. It's not sufficient power to drive your luminaire, but it is sufficient to power sensors or push-button controls for example.

LED professional: Is it correct when I say that DALI is very common in indoor lighting but not so much in outdoor lighting or street lighting?

Scott Wade: That depends on the region you're looking at. I believe there are hundreds of thousands of streetlights in the U.S. now using DALI and these numbers are increasing rapidly. We have also just released five new specifications to our members, where the main driving factor was outdoor lighting. One of the main reasons for using DALI in outdoor lighting is that it's the only standard that specifies the light output dimming curve. In DALI, if you ask for a 50% level, the light output has to be 50% within a certain allowed tolerance.

The streetlight manufacturers see this as a huge benefit because they can choose their control gear, their LED drivers, from any manufacturer, mix them in the system, and when they ask for 50%, all of those streetlights, even though they have control gear from different manufacturers, all go to the same light output level.

Another strong reason is that DALI provides two-way communication allowing feedback from the luminaires this is very useful for maintenance, asset tracking and power monitoring.

LED professional: Are there any limitations in the length of the bus between streetlights, for example?

Scott Wade: In outdoor lighting applications, DALI isn't normally used to connect every pole. Instead, there is a very small DALI system within each streetlight. It might be just the control gear and a sensor, for example. Or it might even have a wireless-communication device. These products make up one complete DALI system. The new standards that we have developed allow lots of the luminaire data to be provided over the DALI bus and then that can be communicated wirelessly through other protocols.

LED professional: So the communication is mainly wireless and the control is DALI.

Scott Wade: Yes, that's right. The control within the streetlight is DALI control. Within the city it's likely to be a long-range wireless protocol.

LED professional: Are you intending to extend DALI beyond DALI-2?

Scott Wade: There are a number of extensions that are currently in progress. The five new specifications were developed by the DiiA. But we also plan to give those specifications to the IEC 62386 working group to make them international standards alongside the rest of the DALI protocol. The IEC working group, itself, is also working on new drafts. For example, a draft on firmware update is in progress, to allow the firmware the software within all devices to be upgraded in the field. So without having to remove products, you will be able to upgrade directly, over the bus. There are also new drafts for color control and other features in progress. There are no plans to change the name; these are all additions for DALI-2. As new parts of the standard are developed, the DALI-2 certification process will be extended to allow these new devices to be certified.

Any product that proved DALI-2 compliance in the certification process can be found on DiiA's products website with its extensive and user-friendly filter options

Any product that proved DALI-2 compliance in the certification process can be found on DiiA's products website with its extensive and user-friendly filter options

LED professional: I think the firmware update is a very important feature and it would be interesting to know when we can expect the standardization of the firmware update.

Scott Wade: I expect the publication of that standard will be sometime in 2019 but the date isn't set yet. The second draft was made in the middle of October 2018, so we have a new technical draft to review and discuss and update, if necessary. LED professional: Do the new features have to be supported by DALI-2? Scott Wade: New features such as firmware upgrade are optional, but if included, then successful testing is necessary to achieve DALI 2 certification. The manufacturers have the choice of whether or not to implement them. I expect the market will decide which way they should go.

LED professional: Thank you so much for this really interesting interview.

Scott Wade: Thank you.

Dr. Scott Wade

Dr. Scott Wade has been Technical & Certification Manager for DALI/DiiA since August 2013, and for around 14 years has been an industry expert member of the IEC 62386 standardisation team. Prior to DALI/DiiA, Dr. Wade was NPI Director for Electronics and Systems at Honeywell ED&S, and prior to that was at Helvar, most recently as R&D Manager for Lighting Controls. Dr. Wade holds a Ph.D. in Power Electronics and M.Eng. in Electrical and Electronic Engineering.