Tech-Talks BREGENZ - Ewing Liu, Everlight, Technical Marketing Manager

LED manufacturers have different strategies and approaches for their product portfolios depending on from which business they are originated. Everlight has a very long experience in optoelectronics as packaging company. Accompanied by Christopher Keusch, Director of Lighting Business EMEA, Ewing Liu, Technical Marketing Manager at Everlight, talks about about the background of the company, the worldwide strategies and upcoming techologies.

LED professional: Could you give us some background information about Everlight?

Ewing Liu: Robert Yeh founded Everlight in 1983 to manufacture, market and sell LEDs. In 1983 we started with visible LEDs and a year later with IR LEDs, photo couplers and other products. This enabled us to be a complete optoelectronic manufacturer. We have between 5,000 and 6,000 employees worldwide and that makes us one of the largest LED manufacturers in Asia. Mr. Yeh has a background in production and is responsible for a lot of Taiwan’s LED market. For example, Epistar, the largest chip manufacturer in the world, only made 4 element chips at first. When everyone started to shift towards 3 element InGaN chips Epistar didn’t have the capital to buy MOCVD machines. Robert Yeh stepped up and supported Epistar in terms of creating the blue LED business. If that hadn’t happened, the white LED business would be very different, right now. Mr. Yeh was on the Board of Directors of Epistar for quite some time and he’s also the owner of Everlight. In 1990 Everlight was publicly traded on the Taiwan stock exchange. Since Epistar is the largest chip manufacturer in the world and we are one of their largest customers, this enables our capacity to be one of the largest in the industry as well. By the end of November 2014 we were selling 4 billion LEDs per month.

LED professional: Everlight’s main business is packaging. What are the main fields of applications that you supply to and what is the approximate share for each in terms of lighting, medicine, displays and so on?

Ewing Liu: Yes, our main business is packaging and we are vertically integrated with Epistar. 75% of the chips we use come from Epistar. Our largest segment is backlighting at the moment. This includes TVs, laptops, cellphones and even navigation units. That is about 25% of our business. The next largest would be our infrared business - which is about 22% and then lighting comes in at about 13% to 15%. We also do a little bit of automotive and signage. The rest are standard commodity indication type LEDs. In 2014, Everlight was ranked 8th in the world by a market survey and showed the highest growth in the industry across all areas. Most of our growth comes from lighting.

LED professional: Cost reduction, longer lifetimes and higher efficiencies are always a topic for industry. What are the main packaging trends and challenges?

Ewing Liu: Cost is a given since everyone tries to make bigger profits so the price per component has to go down. Longer lifetimes are not necessarily true any longer for a lot of lighting products. Of course there are different segments in lighting; you have consumer products, professional lighting type products and industrial type products. You may have to maintain a high lifetime for professional and industrial products, but for consumer products reliability is not a main issue anymore. It is all about cost. For example, everyone wanted a minimum of 50,000 hours for a light bulb and this came at a certain cost but people are now dropping down to 15,000 hours, and for some specific cases they only require 8,000 hours. When you allow lifetime to be at a certain level there is a cost advantage. You can use a different type of LED and different type of packaging material. So there is a cost lifetime trade-off depending on the market.

I think for large manufacturers with billions of pieces per month, the quality level is on a set path. Unless we drastically change a chip, material or bonds there will not be a big difference in reliability.

LED professional: There is a trend, also due to cost optimization, to eliminate the package entirely and just put the dye on the substrate, directly on the heat sink. Are you also moving in this direction?

Ewing Liu: In the overall scheme of things Everlight’s focus is still on components but Everlight does have a lighting fixture business. In the USA and Europe it is called Zenaro. In China it is called Everlight Solid State Lighting. So we are headed in that direction. It has to do with survival because at some point there won’t be too much demand for packaging in lighting, with the exception of very low-cost products. It takes huge capital investment to be able to do chip on heat sink or chip on substrate and no one has the capacity to do it on a large scale as yet. It might not even make sense in terms of the investment into facilities and labor.

Christopher Keusch: We have developed all the packaging technology at Everlight and this is still our focus, but we have discontinued the so-called ‘old packages’ with high thermal impedance or high thermal resistance because they didn’t provide the required efficiency. Therefore, all of the LED packages currently provided have an internal heat slug that allows the chip heat to be transferred directly to the heat sink.

A metal piece located right underneath the chip allows the chip to dissipate heat directly to the heat sink. In earlier designs, heat had to travel all the way through the heat frame and this has been eliminated. We can achieve 30% to 40% better thermal resistance with this design.

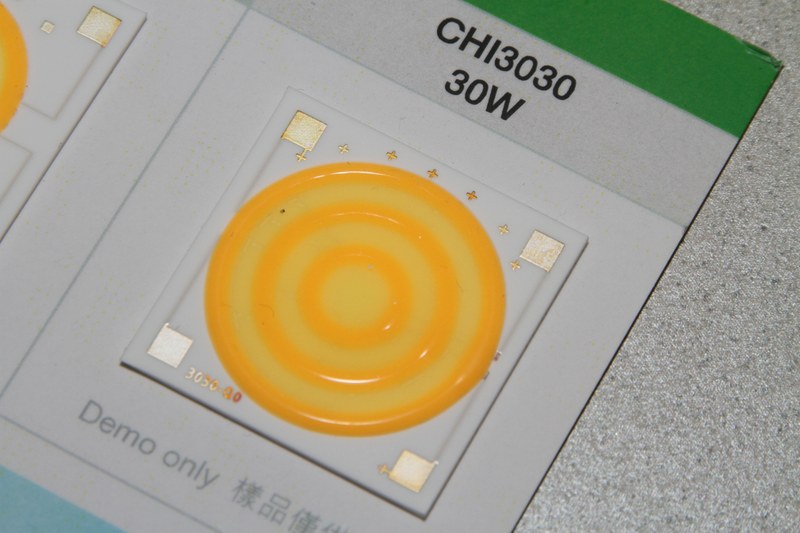

Figure 1: Ewing Liu brought brand new demo samples of Everlight’s latest products. The Color Choice® Series makes designing CCT tunable luminaires easier

LED professional: How do you decide whether to have a separate or integrated heat slug with the cathode? What are the pros and cons and are they application specific?

Ewing Liu: When you have a thermally isolated lead frame like a heat slug, the cost is slightly higher. So cost is one consideration. For many of our low to mid power components, we originally started with thermally isolated products and it still remains for a lot of higher efficiency applications that need better thermal resistance and better thermal dissipation. If the product is more cost conscious, we switch to a newer version that is not thermally isolated and we’re dissipating the heat through the anode or cathode. That’s the main difference. A lot of the cost conscious products won’t need thermal isolation because they can have a higher case temperature for the LED for a lower cost. Those with long lifetime, high- grade product requirements might choose the heat slug.

LED professional: Do you use single dies or multiple dies in a package?

Ewing Liu: There are many different types of combinations. Everlight has one of the largest capacities on the market so it is hard to have a single, focused product or combination for any type of LED. We are very modular and flexible. We set some parameters but in the lighting market everybody wants something slightly different. Each application is very different so it usually depends on what the customer wants. We select a particular chip, lead frame, specific package material and phosphor to create a combination that works for the customer. The lighting industry moves too fast for us to have one set LED with a very clear family line.

LED professional: How big do the volumes have to be for customization?

Ewing Liu: It is quite easy if it is just a matter of switching out a smaller chip for a bigger one so that it’s a bit brighter and customers can underdrive for higher efficiency. We can open that up for a particular customer. As an example, we have started to serve low power packages with high CRI since we see a trend towards more light quality. We can easily follow this trend and simply adapt the phosphor that we developed for the low power, to COBs with high CRI - it depends on what the customer wants. Our marketing team also maps out what the requests could be from the market. For example, most requests for CRI 90 come from Europe and mid–power mainly comes from Europe, Korea and Japan.

LED professional: What is the base material, the substrate and package itself and will that change?

Ewing Liu: We are right in the process of very large changes with packaging material because of the different design trends and directions on the market. Both directions mainly go towards more cost effective products. First we have to make the package smaller - the less silicon or phosphors you need to fill the cavity - the lower the cost. We’re going from sizes like 5630, 3528, 3020 right down to 2016 type sizes

(2 mm x 1.6 mm) this is a very small LED with a low to mid power chip in it but you save a lot of the packaging costs. When that happens you have less thermal dissipation. A standard PPA type of material might not be sufficient enough for some lifetime requirements so we may need to switch to a higher grade chip or we may need to switch to a different type of packaging material to dissipate heat from this chip so PPA goes to PCT with better heat dissipation. But these are still in the plastic realm. Another realm is called thermal molding; either epoxy molding compound (EMC) or silicone molding compound (SMC). There, thermal dissipation is significantly better than PPA and PCT. Everlight is focusing a lot more on thermal molding because performance is a lot better than plastic but price is not much higher. So everything is going in that direction. But in the next stage you want even better thermal dissipation and ceramic materials are probably the highest level you can get for an LED lifetime or reliability using a ceramic substrate. We offer all of these materials because, especially with ceramics, there are different types of applications. Our complete portfolio includes low, mid and higher power LEDs and COBs some with the EMC package already implemented. The size is smaller but we can still achieve 0.06 W to 0.5 W and potentially up to 1 W with the 2016. The higher the wattage, the better the material you need to use. But because it is so small it will still be more cost effective. Larger manufacturers like OSRAM and Philips who are very interested in these packages, also support this trend.

Another design trend is to increase the power of the package itself. This allows the customer to overdrive the package for more lumens while maintaining good performance. That means the lumen per dollar is a lot higher. So it is still the COB philosophy but instead of putting it on an aluminum or ceramic substrate we package it like standard LEDs in a 5050 type of package made of EMC. This can drive from 3 W all the way up to 9 W or 10 W and because standard EMC packaging material is a lot more cost effective then COB ceramic or aluminum, you have a much better cost vs. performance, high power product. This is on our latest roadmap.

LED professional: Another aspect is how tightly packed the LEDs are to get a low light emitting surface. Currently it looks like ceramic is the first choice for tightly packed systems. Is that also your view?

Ewing Liu: COB is one way that everyone is trying to get a smaller LES.

Cree has one that is 6 mm and Everlight has one that is 5.7 mm. Foralotofthe professional lighting products where you have to pair secondary optics, the smaller the package, the more lumens you can get. Everlight is doing that with our next generation of COBs. There is another concept of a smaller package with higher power called CSP or chip scale packages, where the substrate is 1.1 times the chip size used so you can make a very small LED. With that you have a lot of design flexibility. You can use one at very high lumens with optics, and control the light whenever you want or put a cluster together to have even more lumens from a small LES. Those are the two directions we are going to reach smaller or higher lumen density.

LED professional: Are you thinking about adding other components to the LED like optics, intelligence or drivers? What will come next?

Ewing Liu: I think for the European market there is more need for “value added”.

Labor here is more expensive and it would be easier to buy a board with LEDs and optics designed in the application. They can just put it into the assembly and it becomes a fixture. That is a high demand from countries where labor is expensive. Everlight is not going in this direction right now but we have the capabilities if the need arises.

LED professional: High voltage components were also mentioned. What is your view and understanding of this?

Ewing Liu: This whole idea initially started because the pressure on LED components was too much. Dropping 30% to 40% per year in terms of component cost is too much and causes a lot of manufacturers to drop out; mainly the competitors from China that came up so quickly. They are trying to slightly take attention away from component cost. The driver is a big cost, especially for consumer products. Using high voltage LEDs you don’t need to down convert or transform the different voltages as much. At Everlight, we approach it from a high voltage DC perspective so you still need a bridge rectifier to convert AC to DC but from there you can go directly to a string.

This saves a lot on the converter in the driver. For about 120 V you might need forty 3 V LEDs but we have chips with packages for 30 V or 48 V so all you need is three or four LEDs.

LED professional: Are single dies in series within the package or is it the monolithic chip approach?

Ewing Liu: Actually, both concepts exist. We use monolithic Epistar chips for our 30 V or 48 V HV LEDs, but we have also LEDs with slightly higher voltage compared to standard LEDs. These are 6 V, 9 V or 12 V packages consisting of multiple single chips which we connect in series inside the package.

Christopher Keusch: For example, for a high voltage bulb consisting

of 30 V LEDs, basically the benefit is you can save drastically on driver cost using linear driver technology instead of the old driver concept with components that wear out a lot faster. For instance, capacitors tend to dry out. This doesn’t happen with linear driver technology. In fact, we have high-end customers, even in Germany, who developed linear driving technology simply following the concept of using a lot of LEDs in series or using high voltage LEDs in order to connect them to main voltage. Some customers have eliminated ripples by these kinds of driving technologies.

LED professional: Is 48 Volts the maximum?

Ewing Liu: It could go higher but the price scheme would be a lot higher. Epistar has 50 V, 70 V and even a 110 V chip.

Christopher Keusch: It should be mentioned that there is a low voltage directive of 50 V so a lot of manufacturers have to consider that they may exceed this directive. But more customers now have the competencies to do proper isolation in order to allow using higher voltages. The low voltage directive is a hurdle but also an opportunity to build up competency.

Ewing Liu: Every direction we have talked about so far has been for cost-down, smaller packages, multiple chips and higher lumens per dollar or high voltage LEDs to reduce costs on total lamp cost through the driver. All have been cost driven types of designs. In the next 2 to 3 years there will be an overhaul of lighting manufacturers. Some might go out of business or naturally pull out because the margin is so low.

LED professional: Could you tell us more about tunable white COB technology?

Ewing Liu: This is also in the category of higher ASP (Average Selling Price) for professional lighting markets. In retail applications, you will often see a mixing of warm and cool white lamps. Or they might turn different lamps on at different times of the day. Using this type of COB technology, all you need is one lamp you can create any type of color temperature you want. Other manufacturers make similar products. Ours is circular because the final application in usually a spotlight using a round reflector. Sharp, for example, uses a silicone dam in- between each color.

We don’t have anything in-between. We have a patented way of putting the phosphors right next to each other and keeping it separate so that everything can be shrunken even further.

LED professional: Many major players in this market are now looking at added value in the electronics provided. Right now the products have a very high quality and standard. Lifetime, reliability, color aspects, etc., are very important in the European market. One of these trends is Human Centric Lighting with controls, sensors, drivers, and so on. What are your comments about this trend?

Ewing Liu: This is true because the European market has to justify a higher price compared to Asian competition and they have to find their way in this very competitive business. However, since we are a components manufacturer we would like to serve these luminaire manufacturers within Europe and we would like to provide them with concepts and solutions to stay competitive so that they can provide this added value. Our core competency is packaging and our job is to do it as well as possible and meet requirements in terms of efficiency and competitive prices.

LED professional: Thank you very much.