Tech-Talks BREGENZ - Ken T. Shimizu, Research & Development Director, Lumileds

QDs have been a hot topic in lighting for a while already, but up until now they haven’t been adopted on a large scale in lighting. The adoption began in display devices because some of the technical issues were of less concern in this application. With continuing development, QDs are now also becoming interesting for general lighting applications. Ken Shimizu, Director of Novel Technologies and Devices, Research and Development at Lumileds, attended the LpS in Bregenz and made a presentation about the company’s QD technology. In this interview he gives some background information about the QD program and future steps.

LED professional: Thank you for coming to our TTB here at the LpS 2017!

Ken T. Shimizu: My pleasure.

LED professional: Like any top LED manufacturer, Lumileds is continuously improving their products. What is striking for me is that meanwhile most LED manufacturers tend not to primarily push efficacy but rather push performance in light quality. That not only means high CRI but they even attempt to come close to sunlight and whatever that brings with it. But the bottom line is quality and I think that quantum dots, which are a fascinating subject for me, could be a way to push light quality because you have more specific opportunities to shape the spectrum. So could you just give us a short explanation of what’s so special about quantum dots for Lumileds?

Ken T. Shimizu: Sure. I think in the phosphor converted LED space one of the key limitations that’s been highlighted, is the absence of narrow red converter material at different wavelengths. We identified colloidal quantum dots for potential use in LEDs almost twenty years ago. Quantum dots can provide you with custom wavelength emission offering a full width at half maximum (FWHM) that’s even as narrow as 30 nm or less. They are solution processed, so in terms of integrating into LED the colloidal quantum dots can give you quite a bit of flexibility, including use of existing manufacturing methods. We identified the most promising material systems and then we went and evaluated the landscape. We’ve done a lot of work with partners as well as internal research, looking at the technology readiness.

You mentioned color quality versus efficacy. But in our viewpoint, it’s not either or. We think that quantum dots can give you both performance improvement and a higher quality of light. We believe that this is a first step of many to come where we think that you’d have different colors of quantum dots available - more suppliers and vendors and even more mature systems that you can access.

To understand our aims and approach it is also relevant to understand that in the lighting business, which is different to displays, I think the form factor has to be more efficient. Meaning that it’s a space budget- it’s a cost budget, which is more important because of how competitive, the market place is. There are so many different customers with so many different needs that you want to have a simplified and universal product as opposed to having a very confined product.

There have been examples of remote phosphor type integration with quantum dots in the past, but we think that is really not the way to go. We think that for quantum dots to make a big impact in performance and energy efficiency we want to have an on-chip configuration. And that’s how we ended up where we are.

LED professional: Before going further, I’d like to come back to the quantum dots in general as most people don’t really know what quantum dots means and how they work. Could you please give a short explanation?

Ken T. Shimizu: Yes, of course. QDs are semiconductor particles with a diameter in the range from 3 to 10 nanometers.

So they are very small particles. Colloidal quantum dots can be made from II-VI or III-V compound semiconductor material. There is usually a higher band gap shell that’s grown to help with the quantum confinement inside the inner core and also provide a passivation layer. An organic surfactant that surrounds the quantum dot surface makes it solution processable. So you can put it into a solution, into polymers and into silicones. Compared to the size scale of phosphors, they are very small. Today most phosphors range from 2 microns to about 20 microns in size. Quantum dots are typically under 10 nanometer in size. So they are different in terms of their handling and their scattering property as well.

LED professional: So you can compare the quantum dot in its function with phosphor but they are smaller and it’s a semiconductor material, and you can use them in a similar way as conventional phosphors. Is that correct?

Ken T. Shimizu: Yes - in our geometry of the LED we’ve chosen the Luxeon 3535L HE Plus mid power LEDs. This is a standard footprint device using blue LED chips that are attached by a silicone bond material and therefore giving a cup around the die for filling the phosphor slurry. So yes, we do indeed have the quantum dots integrated into the silicone matrix along with the various phosphor mixtures.

LED professional: So these quantum dots convert light or do they also themselves emit light?

Ken T. Shimizu: In this case the QDs serve as a down converter from the blue pump of the LED. There are electrically injected quantum dots that can emit light, referred to as QLEDs. These are similar to OLEDs that utilize direct emission from electrically injected organic molecules. The QLED technology is in an earlier stage of development.

LED professional: And is it also possible to pump quantum dots like with the phosphors, in that you have different injection colors like blue or purple to convert to another wavelength or is it limited to one narrow blue range?

Ken T. Shimizu: No, the absorption band of the quantum dots is fairly broad. This allows for a reasonable flexibility in terms of which color to use such as a violet or blue LED but of course there are technical details in achieving the desired final color and LED efficacy. But there’s no difficulty of absorption of blue or violet light for the quantum dots.

LED professional: For a conventional phosphor converted white LED, you have a volume emitter for blue light and a surface emitter for yellow light. And sometimes this is problematic, because you may see color effects depending on the direction of where you look into the LED. Is this the same with QD converted LEDs?

Ken T. Shimizu: Well I think it’s actually very similar to a phosphor package LED, in terms of the emitting surface, the main surface as a package is the same. For mid-power LEDs a lot of design work has been done to correct for color over angle to meet the requirements of our customers. We employ optimized designs and processes to minimize the color over angle variation for both phosphor and QD based LEDs.

LED professional: So you still have the variation?

Ken T. Shimizu: Well, although PC LEDs have a limited color over angle variation and a color over source variation; the current LEDs have been engineered to correct for the color over angle to meet the market needs. Again, the same design rules apply for both phosphors and quantum dots.

LED professional: If we look at the converter - the phosphors - it’s not that we don’t have red converters, but we only have red converters with poor efficiency. So is the conversion efficiency for quantum dots in the red area better than for the phosphor?

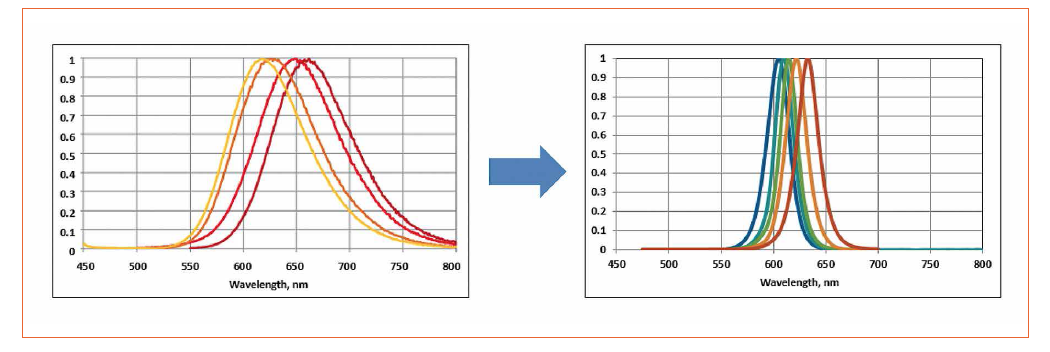

Ken T. Shimizu: Well, modern conventional nitride based red phosphors can have very good quantum efficiency performance. Unfortunately, they also have a fairly broad emission. When these red phosphors are chosen to emit the required light at 620 or 630 nm this also results in a significant percentage of light emitted between 650 to 700 nm. With quantum dots, you can tune the emission to be exactly at the target wavelength, for example at 620 nm, with almost no emission beyond 650 nm. So you’ll not have this excess emission beyond the sensitivity of the eye.

In comparison to QDs (right), conventional phosphors (left), have a much broader FWH emission spectrum. This sometimes has advantages, but in the case of the red spectrum, the disadvantage is that a good portion of the emission lies in a spectral range that is useless in respect to color rendering

In comparison to QDs (right), conventional phosphors (left), have a much broader FWH emission spectrum. This sometimes has advantages, but in the case of the red spectrum, the disadvantage is that a good portion of the emission lies in a spectral range that is useless in respect to color rendering

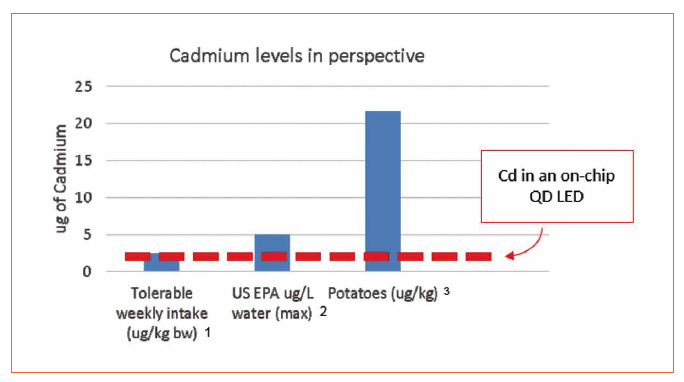

While cadmium-free QDs currently don't provide the required performance, the used QDs contain a small amount of Cd. The graph shows how the amount in one mid power LED compares to some legal limits or measured concentrations in popular foods

While cadmium-free QDs currently don't provide the required performance, the used QDs contain a small amount of Cd. The graph shows how the amount in one mid power LED compares to some legal limits or measured concentrations in popular foods

In terms of the quantum efficiency comparison between quantum dots and phosphor; this is fairly close but the phosphors are more efficient today, especially at higher temperature and drive currents. However, with narrower full width at half maximum, the lumen equivalence is much higher for QDs compared to the red phosphor. This can lead to a dramatically improved QD based LED performance over nitride red phosphor based LED performance even if your quantum dots have a little bit lower efficiency. The narrower FWHM and the precise wavelength of the emission is very important - the tuneability means that you can get the CRI and R9 value that you want for the color quality and maximize the efficiency.

LED professional: So you have the better control on the spectrum?

Ken T. Shimizu: Yes. We can control the spectrum without having to sacrifice efficiency.

LED professional: If we look at the materials used for the quantum dot technology, often materials are used that the industry tries to eliminate due to health concerns and environmental reasons like, for instance, cadmium. What about the impact of QD LEDs on the environment?

Ken T. Shimizu: Cadmium is a restricted material that is regulated by the directive on ROHS compliance. Our first generation of QD LEDs do contain cadmium. We evaluated both the Cadmium containing and the cadmium-free material landscape and we found that the Cd-free QD material was not yet ready and we also investigated how much Cadmium would be used in a Cd-based QD LED.

The first QD based TV’s also contained cadmium based quantum dots. The technology performance and readiness allowed for the highest color gamut and efficiency over conventional LED based backlight TVs with Cd based QDs. Now the market is slowly transitioning and there are many TV’s using cadmium containing QD’s and a number of TV’s that don’t contain cadmium in their quantum dots. We think that similarly, in the lighting field, the cadmium based quantum dots offer the technology readiness and performance to achieve the required spectral performance, quantum efficiency performance, the process compatibility, and the reliability requirement.

Historically, the initial research in the quantum dot space started using cadmium selenide material. We’ve seen now a lot more work happening in the indium phosphide space as well as other materials that are cadmium free. We see the technology roadmap such that in three to five years we think that the same technology that is cadmium free would be ready for on chip use as well.

As mentioned earlier, there is RoHS compliance directive regulating the use of cadmium in electronic materials. There is also a RoHS exemption for cadmium use as a color converting material.

Lumileds is committed to providing environmentally responsible products. We have demonstrated LED efficiency improvements of 17 percent at the module level where each QD LED contains approximately 1 micro gram of Cadmium encased in an oxide shell and embedded in a silicone matrix. We believe that the net environmental benefits from the efficiency improvements outweigh the limited use of Cd in Cd-based QD LEDs.

LED professional: Do you have a road map that shows how long it will take you to reduce cadmium to a certain value?

Ken T. Shimizu: Yes. We think that there could be reductions in the cadmium amounts used in QD LEDs over the course of next few years of materials improvement. We also think it will be a 3 to 5 year time frame to develop cadmium free QD LEDs. This is an active research effort and in the display space we have seen that conversion from only cadmium based quantum dots to now having a lot of cadmium free quantum dots in display products. Similarly, we think that trend will continue in lighting.

LED professional: What about the stability of quantum dots?

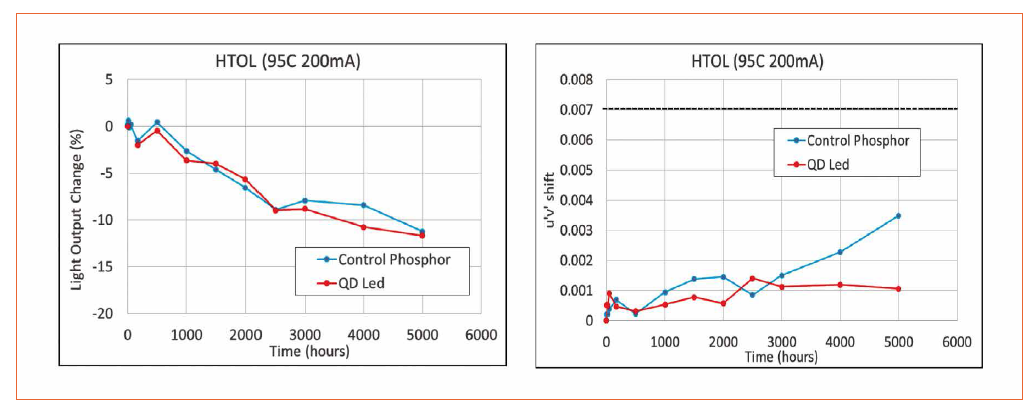

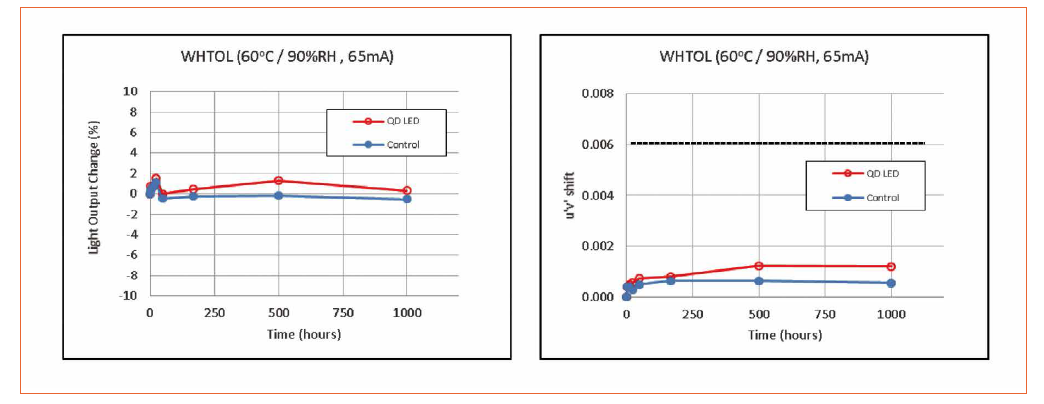

Ken T. Shimizu: QD stability has been a big issue for many years We’ve partnered with a QD vendor who has worked very hard to improve the QD materials and provide reliability on the LED level that is actually matching that of conventional phosphor material. This is proven by 5,000 hours of high temperature operating life data for our QD LEDs. Also, we can pass over a thousand hours of WHTOL testing. So we’ve actually met all of the reliability testing criteria for mid power LEDs.

LED professional: For conventional phosphor material there are some patents and all of the LED manufacturers have access to the same materials. What happens with the quantum dot materials? Does each LED manufacturer have its own materials or are there common materials that they all have access to?

In mid power applications, the new generation of QDs shows similar or even better aging behavior in a HTOL test than a conventional phosphor. Lifetime of mid power QD white LEDs is therefore expected to be suitable for the foreseen applications

In mid power applications, the new generation of QDs shows similar or even better aging behavior in a HTOL test than a conventional phosphor. Lifetime of mid power QD white LEDs is therefore expected to be suitable for the foreseen applications

The 1000 hour WHTOL test shows a similar result and therefore, suggests a similar conclusion to the HTOL test

The 1000 hour WHTOL test shows a similar result and therefore, suggests a similar conclusion to the HTOL test

Ken T. Shimizu: Patents play a significant role in defining the specific designs used by different QD materials companies similar to the role patents play in the LED industry. The QD vendors will develop different types of QD materials that will then be accessible to the LED industry. We do not expect huge barriers to QD LED adoption from an IP perspective.

LED professional: We were talking about QDs and the reduction of cadmium but currently I don’t think there are any products available from Lumileds that use quantum dots. Will they come out in the near future?

Ken T. Shimizu: Yes, the QD LED product has passed all of our technical and manufacturing milestones and it is now released to production. We have also begun engagements with lead customers.

LED professional: And regarding the current packages including the one that you used for the comparison chart; they were all mid-power LEDs?

Ken T. Shimizu: Correct.

LED professional: I think it’s the same issue again - with high power you have high temperatures, and so on and I assume degradation would be too fast. Are you thinking about going into high-power products at a later stage?

Ken T. Shimizu: High power is a bit more challenging. We show that most phosphors suffer from photo-thermal quenching and quantum dots are no different. In fact, the quantum dots have so far shown more photo-thermal quenching at high power LED operating conditions. So our priority is to address the quantum dot material performance at high power LED operating conditions and then the reliability.

LED professional: In high power applications we always have high temperatures. Is the quantum dot material stable in relation to high temperatures?

Ken T. Shimizu: The high power LED applications certainly can have high temperatures. We have performed the reliability and performance studies in mid-power LEDs and see no issues at mid-power LED operating temperatures. Again, work is on-going to improve both the photo-thermal quenching and operational reliability in the QD materials for high power LED applications.

LED professional: If we look at possible products for the future, what kind of applications or markets do you want to approach with this product? Where do you want to go with these products?

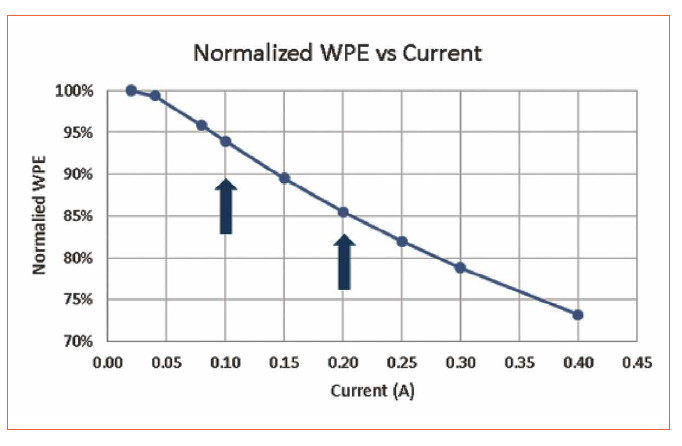

Ken T Shimizu named droop, efficiency reduction at higher currents, to still be one of the most important issues in LED technology that has to be solved. A current way to keep efficiency high is to increase the number of LEDs: Doubling the number LEDs increases efficiency by 10%

Ken T Shimizu named droop, efficiency reduction at higher currents, to still be one of the most important issues in LED technology that has to be solved. A current way to keep efficiency high is to increase the number of LEDs: Doubling the number LEDs increases efficiency by 10%

Ken T. Shimizu: The first QD LED products are 90+ CRI white LEDs in the 3535L HE Plus package. We would like to consider products that can meet the general illumination customer needs for high color quality and high efficiency.

As the QD materials continue their development in terms of optical performance, reliability and lower Cadmium, we hope to see the material become more common as a color converter in LEDs in various applications such as outdoor lighting, horticulture, and specialty lighting. We also believe the on-chip QD LED design allows for greater flexibility for the luminaire or lamp vendors to design in the LED for their applications.

LED professional: You said that you’re doing your research in-house but also with a partner who delivers the quantum dots. So your role is to find the right way to apply the quantum dots and to find the right mixture of the ingredients with silicone, make them stable and make them work properly. Is that the major direction of work on your side?

Ken T. Shimizu: We’ve had a very close collaboration to understand the requirements, to develop and characterize the QD materials, and to develop processes for integration into LEDS. And going forward, yes, we continue with materials and process engineering to optimize the next generation of QD based LEDs.

LED professional: How do you see the future of quantum dots in general lighting?

Ken T. Shimizu: We have always been looking for an ideal phosphor material and quantum dots uniquely fulfill some of those needs. We hope that QDs have a bright future in general lighting as future improvements to both phosphor materials and QD materials continue. Lumileds can trace back a history of over a 100 years of innovation and we hope to continue this effort in both phosphor and quantum dot development.

LED professional: If I understand you correctly, you’re saying that quantum dots are a possible way. There are a lot of problems that we now know can be overcome, but we’re not sure today whether it is really the technology for the future or if another technology will come.

Ken T. Shimizu: Yes, I think that there is no clear winner today, but I think that you need to have the fundamental properties. And quantum dots can claim to have a lot of these fundamental properties, but it remains to be seen whether other materials can claim to have these fundamental properties too. Today, interest is very high in quantum dots and I think excitement is high as well.

My personal viewpoint is that quantum dots are part of a toolbox where we can now think of, if the market moves towards really high quality of light, that would require really fine tuning of phosphors to fit those tailored spectra requirements. And it’s good to have that available.

LED professional: Beyond QDs, in general, what do you think will be most important for solid-state-lighting in the future?

Ken T. Shimizu: At Lumileds, we continue to work on areas such as high luminance light sources and overcoming the challenges with LED droop. There is a trend towards smaller LED chips and high brightness light sources so droop may become even more critical, and we want to continue to maximize the performance of those LEDs.

LED professional: You just mentioned high luminance light sources. Another competing semiconductor technology comes into mind, in that respect: laser lighting. What are your thoughts on that?

Ken T. Shimizu: I think laser lighting will have its role. It can generate a very bright and very directional light. It also allows for designing a very narrow beam angle. We are already seeing laser based lighting in headlights for the high beam as long range light sources. As high power LEDs continue to improve, the question remains if lasers will be the solution or whether LEDs will also be able to fulfill that market need. It’s a question that is still to be explored.

LED professional: Thank you very much for your time and this very interesting conversation.

Ken T. Shimizu: Thank you.

About Ken T. Shimizu

He is Director, Novel Technologies and Devices, Research and Development at Lumileds. His team explores next-generation material systems and novel LED designs to improve overall LED performance and reliability. Ken’s past experience includes a post-doctorate from Stanford University, examining surface plasmon interactions with molecular switches, and as Director of R&D at Stion Corporation, developing novel tandem thin-film solar cells. Ken received his Ph.D. in Chemistry from the Massachusetts Institute of Technology, where he investigated quantum dot optical properties under high excitation flux.

(c) Luger Research e.U. - 2017