Tech-Talks BREGENZ - Norman Bardsley, President of Bardsley Consulting

Professor of Physics, Dr. J. Norman Bardsley, has become an internationally recognized expert in SSL through his activities as an advisor for DoE and ISA. Dr. Bardsley has a profoundly deep knowledge and understanding of OLED technology, which includes the manufacturing thereof, cost structures and research activities. LED professional talked with him about the different aspects of OLED lighting technology and asked for his thoughts on future perspectives.

LED professional: Thank you very much for coming here to this interview. We’d like to start with questions about OLED if you don’t mind.

Norman Bardsley: My pleasure. Go ahead!

LED professional: There was a time when all we heard about were OLEDs and how they were going to be the next light source. But it doesn’t seem to have happened. In fact, a lot of big companies have sold their OLED businesses and the EU have stopped some incentive programs and reduced money for other programs. Given this environment, what is your general opinion of the OLED business?

Norman Bardsley: I think there’s still a potential for OLED and other technologies that extend the form factors of Solid State Lighting beyond what’s available now. I’m very disappointed with the way that LEDs have been commercialized in the sense that most of the product developments and sales has been a light switch that looks and operates a lot like the original incandescent or discharge lamps. They are not in a form that takes full advantage of the Solid State technology. So, for example, for the last seven or eight years I’ve been very interested in the completion between OLEDs and edge lit light guides which are illuminated by LEDs. In my opinion both technologies have not progressed as rapidly as one had hoped. Although edge lit LED fixtures are now fairly common, especially in the U.S. They are still very thick and very heavy. You don’t have the thin, lightweight flexible light source that we hoped would appear. So I think there is still an opportunity on the market for OLED.

LED professional: Can you identify some reasons why OLEDs did not evolve faster?

Norman Bardsley: There have been several problems. The major one is cost. And perhaps the most effective way to reduce costs is to manufacture in quantity and design new products, which build on the ones that are selling well and making profits - and that just hasn’t happened.

While the EU put a lot of money into basic research in organic, plastic and printed electronics, the big companies haven’t followed through in designing products and developing manufacturing techniques that use these technologies. As a result, a lot of effective and fascinating research done ten years ago is still widely untapped.

In the past 15 or 20 years, the first real breakthrough for printed or organic or flexible electronics is in OLED with OLED displays. This broad range of interesting technologies is coming to market. But the Asians have brought it to market. I think that is because the Asian companies and the Asian governments have a different approach to supporting industry and research. They are prepared to go all the way to support them to knock others out.

So I think that the promise of OLEDs is still there but there has been very little progress for OLED lighting in getting the task done right. Since so much money is being spent, and so much development work is going into OLED displays, and now almost half of it goes into flexible OLED displays, the big hope is that this technology development might also be a chance for lighting.

OLED displays, including the flexible AMOLED displays for mobile devices are already competitive for high-end products. Alternatives like micro LEDs or nano LEDs don’t seem to be realistic alternatives yet even though there are rumors that they’ll be used in Apple’s next generation mobile phone displays

OLED displays, including the flexible AMOLED displays for mobile devices are already competitive for high-end products. Alternatives like micro LEDs or nano LEDs don’t seem to be realistic alternatives yet even though there are rumors that they’ll be used in Apple’s next generation mobile phone displays

LED professional: Why is the OLED display market so interesting nowadays that companies put more effort into them? I would think that you would only have one or two or maybe three screens in a household but you would have many more luminaires.

Norman Bardsley: Right. But there’s a very big difference in the cost structure. OLED displays succeeded because Samsung found a product where the value of the end product was large enough to pay for a relatively expensive display. The display that goes into a cell phone in terms of dollars per square inch is maybe between ten and a hundred times more expensive than you can afford to pay for any lighting. And it is still not clear whether all that will be successful in other display applications where the cost constraints are more severe. And you’ll see this particularly in TV. The cost constraints in TV are almost as severe as in lighting. So one of my big hopes is that if OLED TV can compete in the mass market, not just the very high-end, then already the cost will have come down enough that it is much easier for companies selling OLED lighting.

LED professional: The next generation of iPhones is supposed to have a micro LED display with flexible substrates, and so on. There are new opportunities for using inorganic LEDs for these displays using some ideas that could be cheaper than OLED for flexible area illumination or something similar. Do you see a risk that this type of technology or approach will succeed before the OLED is really mature from a perspective of cost, technology and efficiency?

Norman Bardsley: Well, as I’ve already mentioned, I see no technical reason why edge-lit light guides may not provide a solution for very thin, light weight flexible displays. However, the LED industry hasn’t been working very hard on solving the many problems that exist there. And micro-LEDs, at the moment, are like quantum LEDs: It’s something that competitors are throwing out there just to show that they have a different idea. But I think that if you analyze them carefully - for example, Samsung have not yet committed themselves to OLED TV and they keep saying that they’ll go instead with Q-LEDs (quantum LEDs). However, as Barry Young has pointed out, quantum LEDs are probably at least a decade away from giving the performance that you need. Micro-LEDs are also very far from achieving what is dreamt for them.

It’s extremely costly. Setting up the circuit is very expensive and it’s very difficult to do. The other extreme is people at Apple argue that you use micro-LEDs on a much, much lower size scale in hand-held devices. But again – you’re going over from currently having 20 or 30 or even a hundred LEDs in an Apple smart phone to something like 10 million micro-LEDs! And it seems to me that it isn’t anything more than a dream.

LED professional: So, you’re saying that it is much too early for things like quantum LEDs and micro-LEDs. Isn’t that really the same thing that happened when the OLED was announced at the beginning of the new century?

Norman Bardsley: Yes, but we see that OLEDs have made a lot of progress since they were announced. I will admit, though, that the progress is nowhere near as fast as I would like to see it, especially in terms of developing products. But as you pointed out, there are less investments being made in basic research. It’s an interesting question as to which will come to market first, but I think in respect to micro-LEDs and Q-LEDs, OLED is still way ahead. Of course for lighting, it’s a different matter.

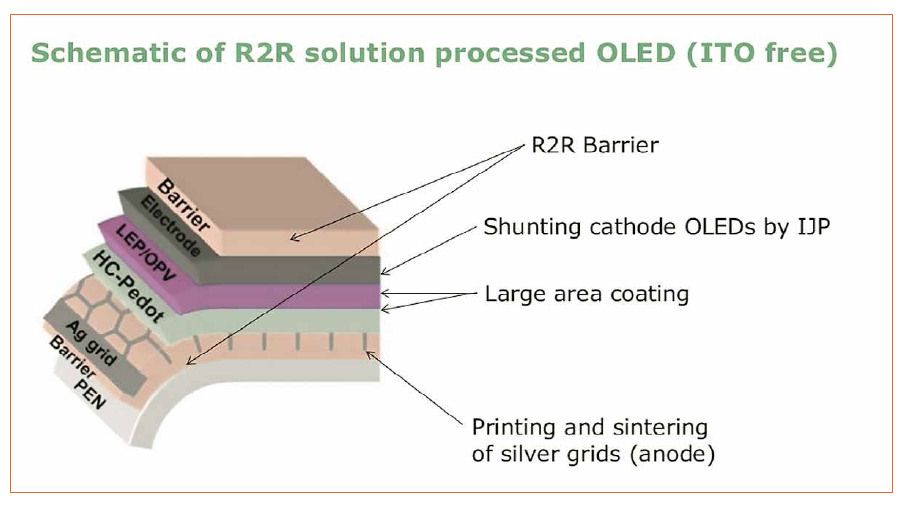

The role-to-role manufacturing process is a key technology for the mass production of flexible OLEDs

The role-to-role manufacturing process is a key technology for the mass production of flexible OLEDs

LED professional: About 10 years ago there was a very simple rule for OLEDs: 100 candela per square meter and about 1,000 hours lifetime or 1,000 candela per square meter and 100 hours lifetime. It has changed in the meantime, but we’re still not where we want to be. What do you think are the chances for progress in both brightness and lifetime?

Norman Bardsley: I think that there has been a great amount of progress during the last few years, for example, in the adoption of multiple stacked OLEDs. These are appearing in displays now but they started out in lighting where people started to have two layers, and then three layers – and then Philips came out with a bright product that has six layers. This means that if you have six layers, the current density is six times less. So the lifetime is maybe 10 times more.

You can do things with this: You can either keep the brightness the same and have a longer lifetime or you can raise the brightness. Roughly, if you double the brightness the lifetime decreases by a factor of three or if you triple it, it decreases by a factor of five. So you still have a trade-off.

There are a lot more serious problems, though. If you have an individual light, you don’t notice a decrease by 20% but if you have two lights side by side, you do. Especially in displays with a question of persistence of image - then 3% or 5% is all they tolerate. So that’s another area where there are benefits coming from displays and materials are being developed where lifetime is critical. The reason I brought this up is that at the moment, the amount of light that is put out by a single panel is still fairly small. So very often you have luminaires with multiple panels and then you have two panels next to each another. If there are two next to each other and you have a difference of 10% you’ll notice it. So luminaire manufacturers may demand something better than L-70. I don’t think that what we have now is good enough.

LED professional: Another issue is the possible size of OLEDs today. I believe the maximum size of a standard OLED today is 32x32 cm and that is by far, not big enough for the ideas that some luminaire manufacturers or designers have. When do you think the technology will have evolved enough to get really large OLEDs?

Norman Bardsley: There are two aspects of this that interest me: One is that the most serious problem is the manufacturing one. If you’re going to build really large panels, you either have to build them on a role – role to role – or you need a very big substrate. Either way requires tremendous capital. And that’s not available yet. Both Konica Minolta and LG Display have said for many years that they’re going to build a new plant. LG Display may come online next year. Konica Minolta built one last year but it hasn’t produced anything of commercial value yet. A big problem has been to scale up the size of the manufacturing facility.

Another related problem with manufacturing is yield. If you try to build one very large panel and you have a certain number of defects per square meter, that’s much more difficult than making the same size panel out of relatively large number of small ones stitched together. So until the yield gets up to certainly more than 80% and first handled panels, it’s just not feasible.

LED professional: What about from a designing point of view?

Norman Bardsley: I think designers have been moving away from having whole homogeneous ceilings and walls. A panel can be very dull - unless you want to make it into a display. So, I would say there is less pull for large homogeneous than there used to be. But it would still be nice to have a variety of panel sizes. And another thing that’s disappointing in terms of size is almost all of the panels that are made now are the circular or rectangular ones. Even the octagonal that Osram made have disappeared. Philips used to show lots of prototypes of flowers and Konica Minolta had the prototype of a tulip but they haven’t appeared in commercial production, which is a shame.

LED professional: OLED is one thing but you need to have electronics to drive the OLED and you need to have something like a luminaire to put the OLED in. Today electronics have form factors, normally a square cross-section and very long. This is not the right form factor for OLED. You should have very thin driving electronics. Could you comment on that?

Norman Bardsley: Like you, I’m really frustrated at the size of drivers and the lack of availability of efficient drivers to meet any required luminaire design. But this is true on the LED side as well as the OLED side. My interest is really in getting thin, lightweight, flexible lighting and whether this is OLED or LED, I want a thin film electronic driver for it. I wish the Europeans and Americans would spend more time and effort in developing innovative drivers – and not just leave it to the Asians. It’s a critical need but the problem is that there were small companies starting to develop the drivers ten years ago but there just isn’t a market there to encourage them to put in the development work. I hope that this is something that will be recognized by the LED industry as a problem so we will get more progress towards more appropriate drivers and connectors.

While the light spectrum of OLEDs without a blue peak is an advantage for HCL, the lack of an affordable color tuning solution is a significant disadvantage

While the light spectrum of OLEDs without a blue peak is an advantage for HCL, the lack of an affordable color tuning solution is a significant disadvantage

LED professional: Another question is why should it be in the interest of the luminaire manufacturer to make luminaires out of OLEDs? All the value you create, is created by the OLED manufacturer and the electronics manufacturer.

Norman Bardsley: I think you have a good point and I’ve had a long argument with friends and colleagues in the OLED business, one of whom kept arguing that an OLED is a luminaire. I don’t think so. Usually, the end price of a luminaire, even an OLED luminaire, has to be probably four times the cost of the panel. Now, maybe you could come down to two and a half, but it’s got to be a lot more because of all the extra work you have to do or the design you have to make or the warranties you have to give and all the other expenses that luminaire manufacturers have. So I think it’s unrealistic for an OLED panel manufacturer to expect that a luminaire company will come along and just add 10% to the price and sell it. I think it has to be treated like any other lighting component in that an LED in a luminaire is typically 10% to 15% of the cost and the driver is 10% to 15% of the cost. It’s slightly different for an OLED. I think an OLED panel is 25% - but that’s just what I envisage. And the driver might be around 15%. The rest is there for the luminaire manufacturer to do what he has to do to make some profit.

LED professional: Another point is Human Centric Lighting and whatever one understands by that phrase. It is relatively simple to adapt color temperature or color in general with LEDs but not as easy with OLEDs.

Norman Bardsley: Some of the aspects of Human Centric Lighting are more easily met with OLEDs, for example, low temperature – minimizing the blue – and that’s a big advantage. If you want to get a high color rendering, at the moment there’s still a fairly substantial penalty for getting to CRI over 90 in LEDs. It’s easier to do that in OLEDs. So if all you want to do is design a product for a specific application there is a possibility that OLEDs can compete in some markets, like health.

Dynamic control is much more difficult. This is one area where I think that OLEDs have not started to develop. Designing an OLED in which the color can be changed dynamically is something that can be done in the lab – there are ways to do it – but they are expensive. You can do it by having either red, green and blue stripes or pixels just as in a display. You can make them small so that they’re not visible – but this means that you need three separate circuits that have to be connected up – and the smaller you make them, the more expensive the circuit is going to be. Or you can stack them and put in intermediate electrodes and then you connect the electrodes up so you have the potentials across the reds, the greens and the blue are different. But again, that’s a little more expensive to do. The other big problem there is with those intermediate electrodes that give you greater absorption because you usually get 10% or 15% absorption in a transparent conductor.

We know how to do it, but it’s going to make it even more expensive and make the yield even lower in practice.

LED professional: You mentioned that an advantage of the OLED is not having the issues with the blue. But I’m not sure if we are discussing the problem correctly because the blue peak depends on the color temperature you use and on the quality, in general of the LED and the phosphors. A study that Osram did a few years ago showed that the blue peak doesn’t mean that there is more blue than what there is in a fluorescent lamp. How correct are these figures?

Norman Bardsley: I agree with you that there is a lot of fear out there about blue light and I don’t want to make the case that minimizing blue light is incredibly important. It’s just that if a customer wants a light with a CCT of 2700 or 2000 than that makes OLEDs relatively more attractive than if he wants 5000 or 6000. I can’t provide a solution – all I’m saying is that if you have a situation when you’re using this light in the evening, an OLED is more attractive than it is for a luminaire to be used in a school or in an office.

Barrier layers that are also necessary to protect quantum dots on light guides belong to the most critical elements of an OLED

Barrier layers that are also necessary to protect quantum dots on light guides belong to the most critical elements of an OLED

LED professional: We discussed the need for special electronic technologies in reference to OLEDs. Do you think OLED technology will also drive other technologies?

Norman Bardsley: Ten years ago I was really hopeful that there would be a lot of synergy between organic photovoltaics and OLED. But it turns out that organic photovoltaics is proceeding almost as slowly as OLED. I can’t point to a specific area where I think that something that we’ve learned in OLEDs will pay off. On the other hand, I’m always surprised when I go to these flexible and printed electronic meetings about how many new applications they have come up with. For example, I’ve been very frustrated with transparent conductors when we were looking for an alternative to ITO. The cost came down tremendously when it was found that the touch-screen people also needed a transparent conductor and then silver nano wires took off and were fairly successful.

LED professional: If we turn that question around – what areas do you see influencing OLED and maybe even other lighting technologies?

Norman Bardsley: My main area of interest has always been the overlap between displays and lighting. Right now, for example, one of the areas where there has been tremendous progress in displays is quantum dots. When quantum dots were tried in lighting five to ten years ago it was found that the life-time was much too short because of the heating. But then in displays you can place them further away from the LEDs. So first of all QD Vision was very successful by putting in a strip of quantum dots on the edge of the display – a little further away from the LEDs – to convert the blue into the green and red or white. Then other companies put quantum dots on the surface of the wave-guide. That puts it even further away from the LEDs so you have less problems with heating but you need more of it. Both of those have been very successful. And now you have people looking back to see if you can use quantum dots as down converters in LEDs inside the package because of what’s been learned about the lifetime. But that’s not a cure. This is still an LED with a quantum dot replacing a phosphor.

Another area where there has been rapid progress is in the area of barrier layers for plastics that are needed for OLEDs. 3M had been working on developing such barrier layers. They have an effective solution but the market wasn’t big enough for them to go into production. But then when the quantum dot people starting putting the quantum dots on the surface of the light guide they needed to be protected – because quantum dots need to be protected against water. And so the market was big enough. That’s another area of what I think would be potential overlap between OLEDs and large area electronics in general. If you have the need for electronics on plastic and you do need a barrier film, there has been a lot of progress and there will be even more progress in the next couple of years. So barrier film technology is an area that is progressing very rapidly right now and the cost is coming down.

LED professional: Just one more question: Do you see any other lighting technologies besides LED and OLED that might start to play an important role in the future?

Norman Bardsley: I’m not aware of any technologies or really of any need for a different technology. Q-LED is an example of something that could come but I’m not convinced that there’s not any kind of lighting application or form factor that you can’t meet with current SSL technology. The LEDs might have to be smaller or thinner or more efficient or they might have to have a longer lifetime but there are so many different ways now that are being developed for deploying LEDs, like chipless packages and COB and just a huge variety.

Furthermore, one of the big problems that OLEDs has had might also be true for other technologies. Luminaire manufacturers very often have said that they are so busy trying to learn how to use LEDs that they just don’t have time for to take on something more difficult! And I think that we’re going to have the situation for at least another decade that luminaire manufacturers are right to be focusing on optimizing and improving the solid-state technology that we have – including LEDs – rather than going off and finding something different.

LED professional: That statement could turn out to be the beginning of a brand new discussion! Thank you very much for your time.

Norman Bardsley: You’re welcome.

Dr. J. Norman Bardsley

He is a member of the Technical Advisory Team for the Solid State Lighting (SSL) Program of the US Department of Energy (DOE). In this role he is a co-author of the DOE’S SSL R&D Plan, helps to set the agenda for the annual R&D Workshop and manages research projects. Norman also acts as Chief Analyst for the International SSL Alliance. Following the award of an M.A. Degree in Mathematics at Cambridge University and a Ph. D in Theoretical Physics from the University of Manchester, Norman served as Professor of Physics at the University of Pittsburgh, Strategic Business Development Manager at Lawrence Livermore National Laboratory, Director of Roadmaps and Standards at the US Display Consortium and Director of Display Technology for DisplaySearch.

(c) Luger Research e.U. - 2017 | All rights reserved