Technology Challenges in Professional Tunnel Lighting Applications

The guide for tunnel lighting CIE 088:2004 is the most established international standard for the illumination of road tunnels. However, Switzerland’s ASTRA (Bundesamt für Strassen) and the ASFINAG in Austria both provide guidelines that go well beyond these requirements. Maximilian Herzig, Product and Key Account Manager Lighting at SWAREFLEX GmbH shows solutions to satisfy these requirements and explains why the commonly used value of "lumen per watt" is not a perfect method of evaluating system performance and efficiency.

The main purpose of general tunnel lighting is to prevent accidents and enhance safety and comfort for the drivers that drive through or enter a tunnel, by providing maximum visibility of any objects on the road surface.

The CIE 88 - Guide for the Lighting of Road Tunnels

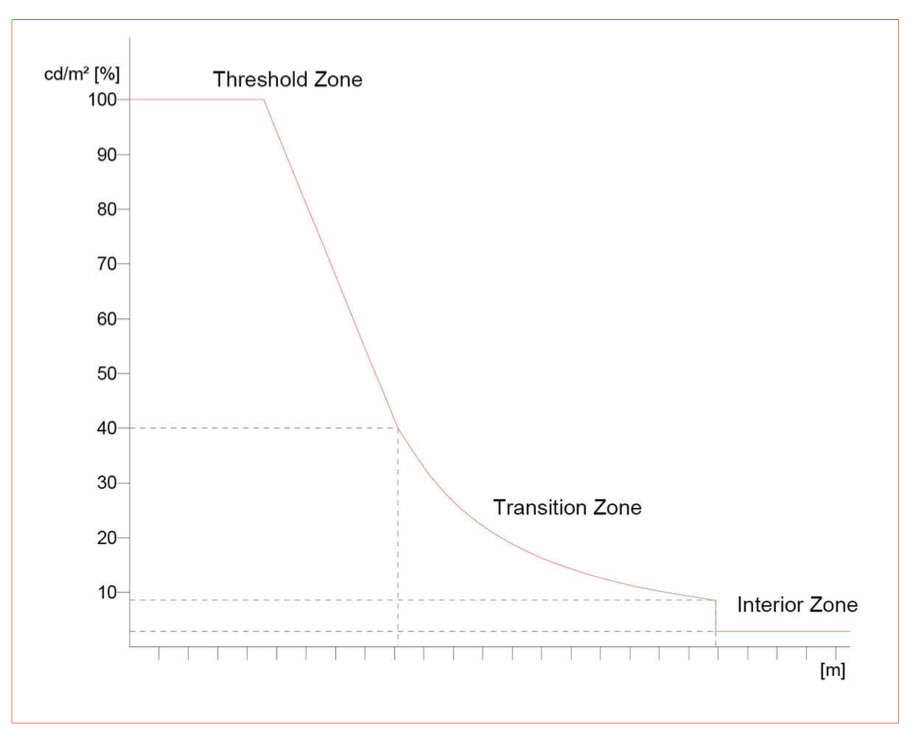

and Underpasses provides a guideline for tunnel lighting that serves as a basis for many national regulations. It divides the tunnel into different zones according to the specific requirements in each one of them. The threshold zone requires very high luminance values in order to facilitate the adaptation of the driver’s eye to the darker lighting conditions in the tunnel compared to the higher outside lighting level. The length of the threshold zone is defined by the speed limit at the tunnel portal, as higher speed limits require a longer threshold zone. In the following transition zone, the luminance on the road surface is slowly reduced until it reaches the lighting level of the tunnel interior zone, offering a smooth adaptation from the entrance levels to the lower interior levels. Typical values, considering a maintenance factor of 0.67, in the first half of the threshold zone are around 150-300 cd/m2, while the interior zone usually is limited to 2-6 cd/m2.

Currently acknowledged parameters for the quality of lighting in road tunnels include total and longitudinal uniformity of the lighting on the road surface (ideally no flickering light / dark transitions), the lighting of the tunnel walls, avoidance of glare as well as color temperature and color rendering. As in recent years, semiconductor technology reached a state in which the LED became a more

than feasible alternative to conventional tunnel luminaires with sodium vapor lamps. Many national standards shaped the requirements on the mentioned parameters into new forms.

Figure 1: Adaptation curve of the luminance in tunnels

Figure 1: Adaptation curve of the luminance in tunnels

New LED Tailored Standards

Besides regulations of, for example, Switzerland’s ASTRA (Bundesamt für Straßen), the planning manual (PLaPB 800.562) of Austria’s ASFINAG from 2016 is one of the first standards that is specifically tailored to the potential offered by LED tunnel lighting systems. While it introduced a clustering into different tunnel lighting classes, specifying not only different lighting requirements per cluster but also defining different distances between luminaires, from up to 18 m (cluster standard) to a continuous luminaire line (cluster premium), it also declared different demands on energy efficiency and lighting color as well as color rendering. Color rendering may not seem the most important topic in tunnel lighting, but given the increasing amount of different markings in signal colors inside road tunnels, it is important to quickly distinguish yellow from red, or blue from green. And still, the advantages of LED systems compared to conventional lighting systems go beyond true color lighting, high luminous efficacy and efficient light distributions via lenses. LED systems can offer analog dimming in the interior and also entrance zone, thereby eliminating problems regarding luminance uniformity on the road surface caused by switching off whole groups of luminaires. Current LED tunnel systems already turned into intelligent solutions that communicate the current state of the luminaire as well as the driver (temperature sensors, input voltage measuring, DALI communication). However, there are still discussions where the supply and control electronics have to be integrated. Some tunnel markets require intelligent drivers inside the luminaire while others demand all electronics to be installed in maintenance rooms inside the tunnels or control buildings at the portals. Both solutions offer advantages with the latter minimizing maintenance works in the tunnel driving space. Basically, the general properties and requirements of tunnel luminaires in D-A-CH countries shifted from orange light with CRI 20 - 30 (provided by sodium vapor lamps) to 4,000-4,500 K with a CRI of 70 or even 80 (with LED) and on top, some current projects require a system efficacy of even above 110 lm / W combined with a system lifetime of > 80,000 h (with less than 10% failures during this period).

Figure 2: Tunnel Lighting Cluster Comfort

Figure 2: Tunnel Lighting Cluster Comfort

Figure 3: Tunnel Lighting Cluster Premium

Figure 3: Tunnel Lighting Cluster Premium

Requirements Beyond the Pure Luminaire Specifications

But some requirements, as they are very important, cannot be fulfilled by the luminaire alone. Due to the fact that, especially early LED luminaires appeared more glaring than conventional luminaires, the avoidance of glare became more and more important. Some regulations already require a

threshold increment of 8% or even only 6%, as a lower value means less glare. The threshold increment is defined by the relation of veiling luminance to the luminance on the road surface, with a lower veiling luminance or a higher road luminance reducing glare. The veiling luminance itself depends on the luminous flux of the luminaire and the light distribution. As it is possible to develop luminaires that maximize the road luminance and also offer a relatively low veiling luminance, there is one key factor that no luminaire manufacturer can control. The luminance coefficient q0 of the pavement which determines the relation between illuminance [lx] and luminance [cd/ m2] on the road surface. Depending on the pavement class, the luminance coefficient usually varies between 0.05 and 0.07. So, the q0 alone can change the luminance value on the road by approx. 30%.

In turn, the luminous flux of the luminaire has to be increased by 30%, leading to a higher veiling luminance and a higher threshold increment.

Efficacy Requirements and How to Achieve Them

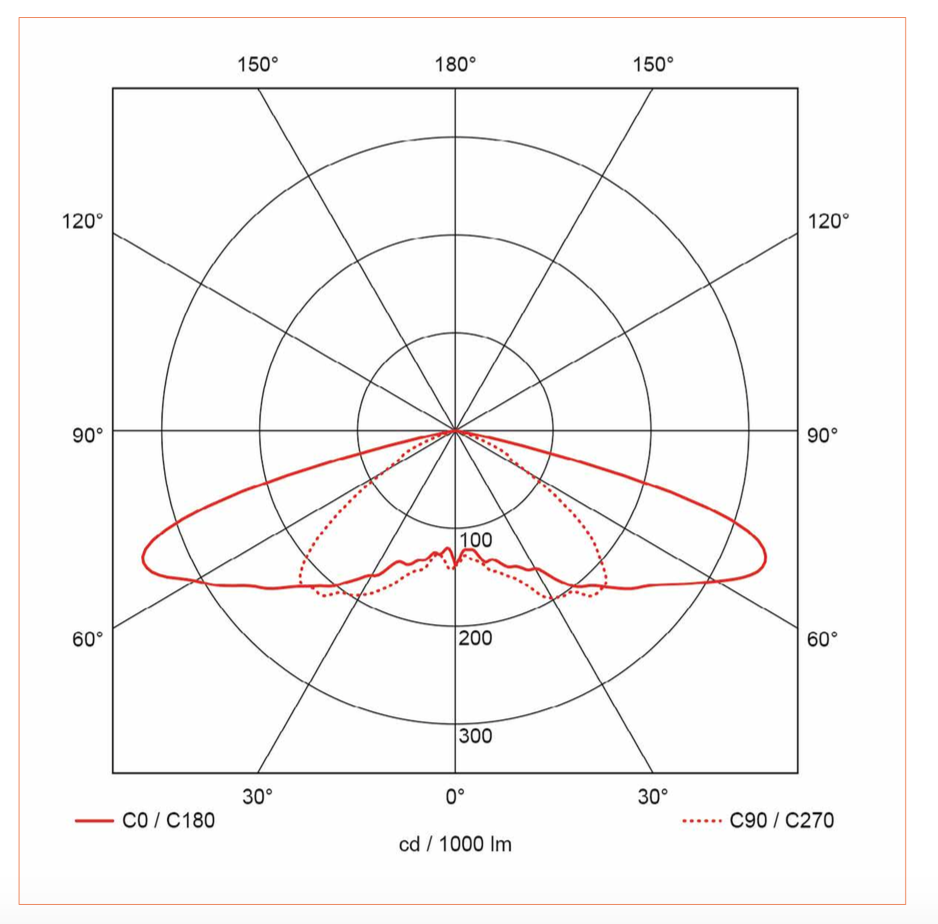

A requirement that makes sense but may not always lead to the intended results is the luminous efficacy, that is lm/W. This value perfectly describes the efficiency of a LED, with higher lm/W guaranteeing more energy efficiency. The same is mostly true for all tunnel luminaires with a symmetrical light distribution, which are almost exclusively used in the interior zone. As the transmission values of the different optics on the market are very comparable and almost always near 90% and the light distributions also provide similar road luminance values, luminous efficacy is here the right and easiest choice for determining the energy efficiency of the whole luminaire. But what about luminaires for the threshold and transition zone?

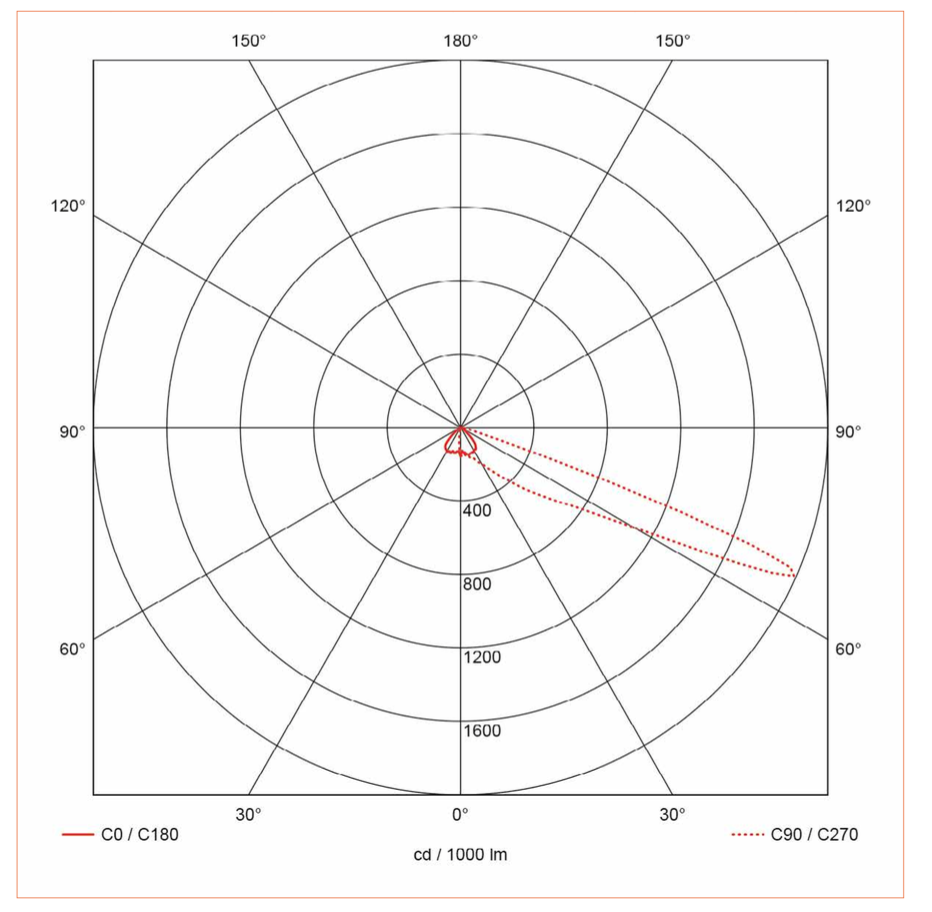

These luminaires are normally equipped with counter beam optics, which distribute the light at a very flat angle to the driver.

Due to their light distribution, counter beam optics provide superior luminance values compared to symmetrical optics. So, counter beam optics are, and also have been in the past, necessary for economic and efficient lighting in the tunnel entrance zones. However, they can only be used in the threshold and transition zone due to the smaller luminaire distance in these areas. Counter beam optics in the interior zone with a typical luminaire distance from 8 - 15 m would create too much glare and the lighting uniformity would not be comparable to the uniformity obtained with symmetrical optics at these luminaire distances. As shown in figure 4, the peak intensities of counter beam optics can be at a vertical angle of above 60° and, more importantly, the light is distributed almost exclusively in one direction. This kind of “light bending” leads to reflective losses and thereby lower transmission values of the optic, which results in less lm/W of the luminaire. What the lm/W value, in the case of threshold and transition luminaires, does not take into account is that - given the same lumen input – counter beam optics with peaks at above 60° will create reasonably higher luminance values on the road surface, than counter beam optics with an intensity peak at, for example, 55°, although the latter might have higher transmission values and therefore a higher luminous efficacy.

Figure 4: Counter beam light distribution

Figure 4: Counter beam light distribution

Figure 5: Symmetrical light distribution

Figure 5: Symmetrical light distribution

Here it is also important to note that the optics with intensity peaks at higher vertical angles do not necessarily produce more glare.

Therefore, a value that would be better suited to describe and require the energy efficiency of tunnel entrance lighting, would be a specific surface power density that takes into account the obtained luminance values, the length of the threshold and transition zone, and the power consumption of all installed entrance (counter beam) luminaires.

Conclusion

Almost all new standards that have been set considering the potential of LED luminaires are headed in the right direction and will lead to a steady increase of lighting quality, which will also result in more perceived and actual safety, higher energy efficiency and more sustainability of current and future tunnel lighting systems. System providers such as Swareflex offer and develop new solutions that fulfill current requirements and push the boundaries even further. Current state-of-the-art luminaires with optics made of top grade technical glass offer a longitudinal uniformity of more than 0.95 at a luminaire distance of 8 - 12 m. That means that the luminance value in the middle of the driving lane does almost not change at all over the course of the tunnel, thereby practically eliminating all flicker effects on the road surface. The latest generation of tube systems offer up to 125 lm/W and completely separate the luminaire in the driving area from the supply and control electronics in the maintenance rooms. But some requirements still have to be challenged as not only technology but also regulations have to be always evolving.

(c) Luger Research e.U. - 2017