Thermal Simulation Tool for LED Design Requirements

Light-emitting diodes (LEDs) are used and accepted in many areas of lighting technology today. But without the right thermal design, LED lamps would not be viable. Chris Aldham, Development Manager at 6SigmaET explains why keeping key components within narrow temperature limits is often critical, why this makes thermal simulation important to LED device designers, and how to select the right thermal management simulation tool for this task.

Once seen as the ‘light source of the future’, LEDs are rapidly becoming the norm. The design of LED products is a complex multidisciplinary problem, and thermal design, in particular, is critical to a device’s performance and lifetime. With the right thermal simulation tools, development teams are better able to deliver products that match reliability, form factor, and performance goals.

Design Challenges

LEDs are highly efficient – more so than most “traditional” lighting technologies – thanks to the direct conversion of electrical current to optical radiation in the semiconductor. However, despite being significantly more efficient than incandescent or fluorescent lighting, a high amount of electrical power in LEDs is still converted to heat rather than light - and the higher the current, the more heat is created.

This excess heat must be conducted away from the LEDs: this is because the semiconductor material is limited to a maximum temperature, and its characteristic properties - such as forward voltage, wavelength and lifetime - may vary with temperature.

As temperature increases, the light output of LEDs can decrease by as much as 10%. Similarly, maintaining the desired light color is temperature-dependent.

The expected operating life of LED lamps - usually somewhere between 25,000 and 50,000 hours – is also closely linked to the temperatures experienced within a lighting fixture.

Ultimately, only adequate thermal management can facilitate the full exploitation of LED performance and efficiency during operation. Proper cooling - of both the LED itself and the aluminum electrolytic capacitors employed in driver circuits - is central to the design process.

These fundamental challenges have been further exacerbated by the continuing market demand for ever-more compact fixtures and lamps.

Smaller lighting fixtures are needed in portable applications, such as entertainment lighting, so that they can be transported and handled more easily, and are less obtrusive in use. In retrofit applications - everything from street lamps to domestic downlights - designers need to keep sizes and shapes within the limits defined by existing fixtures. This normally includes squeezing the electronic driver circuit inside the fixture, and - in the case of directional lighting - the LED emitter module and lenses as well. This means that the heat must be dissipated from an ever-decreasing amount of space.

The end application must also be taken into account at the design stage. LEDs are deployed in a wide variety of environments; in automotive applications, for example, devices may need to operate at ambient temperatures up to 85ºC. This means that manufacturers must build their devices to meet customer requirements for output, color and operating life with the operating temperature in mind, and allow for any temperature-induced performance shift.

Managing Heat Transfer

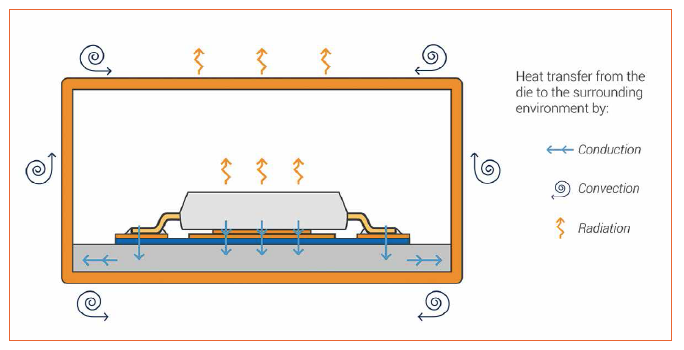

For designers, the aim of thermal management is to transfer the heat generated by the device into the ambient air to prevent components overheating. The scope and complexity of thermal management depends on the amount of heat, the size of the source, and the anticipated ambient conditions. Dealing with these factors requires a clearly defined heat transfer path.

Typically, the system heat transfer path begins at the heat source (semiconductor junction layer), and travels via the PCB, heat sink, and housing before finally reaching the ambient air (Figure 1). The challenge lies in managing this heat transfer within the constraints of the power class and application of a device.

Figure 1: Heat transfer in an LED system

Figure 1: Heat transfer in an LED system

As a rule, the thermal management of an LED system can be broken down into three system levels: the LED itself, the submount/PCB, and the cooling unit. The heat path for system heat transfer can be described in the same terms. The heat generated in the LED barrier layer is transmitted through the LED housing (package) via the soldered joint and on to the carrier (PCB). At PCB level, the heat can be transported to the heat sink by various design measures (horizontal and vertical thermal conductivity). From the cooling unit (e.g. heat sink, system housing), the heat is finally transferred to the ambient environment through natural convection and thermal radiation.

At each stage, designers are faced with a number of crucial decisions in order to optimize heat transfer.

At the LED level, the type of housing has a significant impact on thermal management. To take a couple of examples, lead-frame-based LED housings and ceramic-based LED housings offer different approaches to heat transfer for designers.

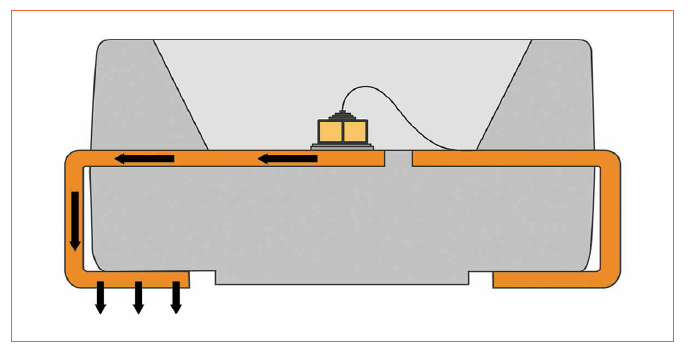

In the case of a lead-frame-based housing (Figure 2), the semiconductor chip is mounted on a lead frame that, in most cases, consists of a plated copper alloy. The connection can be glued or soldered. Starting from the barrier layer, the heat is primarily dissipated from the package via the chip and lead frame. The amount of heat transfer that takes place via the bond wire is insignificant.

Figure 2: Heat conduction via lead(s)

Figure 2: Heat conduction via lead(s)

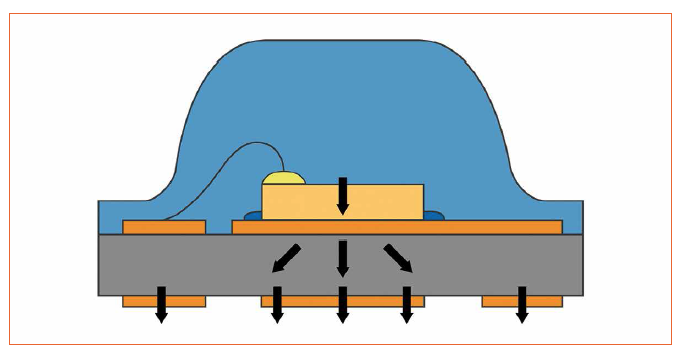

In the case of LED packages based on ceramic substrates (Figure 3), the semiconductor chip is attached to the metallization layer of the ceramic. The good thermal conductivity of the ceramics enables heat spreading in conjunction with the metallization layer. The heat produced in the semiconductor is distributed via the metallization layer and ceramic base material, and transmitted to the PCB via the solder pad.

Figure 3: Heat conduction via ceramic substrate

Figure 3: Heat conduction via ceramic substrate

Knowledge of the heat conduction path in the LED housing is important, as it enables the correct choice of subsequent system components (PCB, solder pads, etc.).

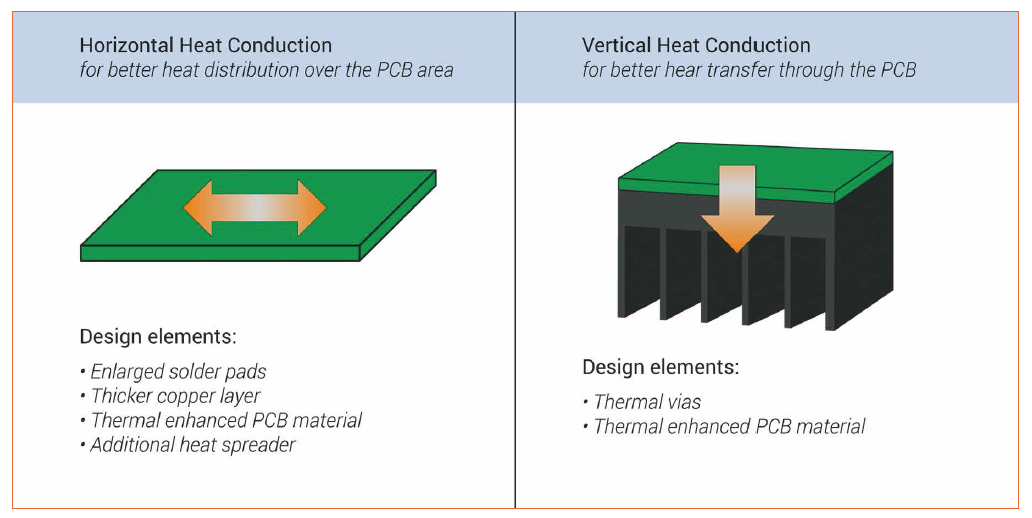

The thermal design of the PCB presents designers with another range of decisions (Figure 4). Heat can be transferred over the PCB (horizontal conduction) or through the PCB (vertical conduction).

Figure 4: Various thermal design elements at PCB level

Figure 4: Various thermal design elements at PCB level

In both cases, conduction paths are impacted by a range of factors: where the LEDs are positioned on the PCB, to what level thermal losses need to be dissipated, and whether there are other potential heat sources in proximity. Moreover, shrinking LED devices adds further complications. Smaller devices have a reduced contact area with the board; previously, older and larger packages meant that more heat spreading could be done on the device itself. Increasingly, these smaller devices are forcing this process to take place on the PCB instead.

These factors then impact material selection, the surface area required, the required thickness of the conducting layers, and the need for thermal vias in the PCB design.

The final system layer is the point of transition to the ambient environment. From this point, heat can only be dissipated effectively via convection or radiation due to the low conductivity of air.

Most LED designs rely on natural convection, rather than forced convection. This means designers require heat sinks that provide maximum surface area - rather than employing active methods like fans, or more sophisticated methods such as Peltier elements, heat pipes or water cooling.

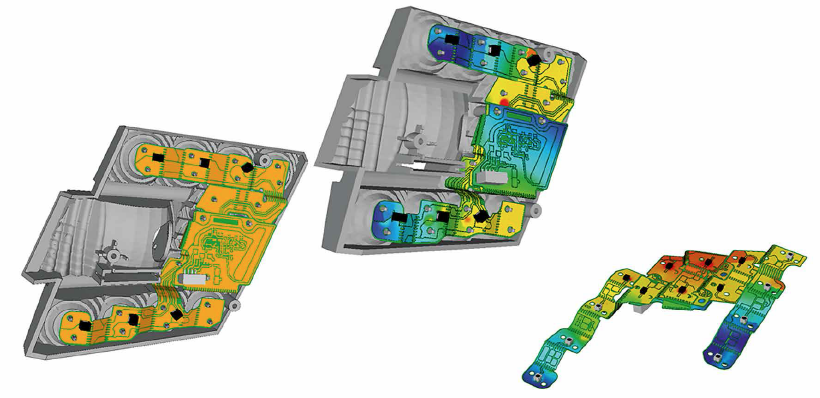

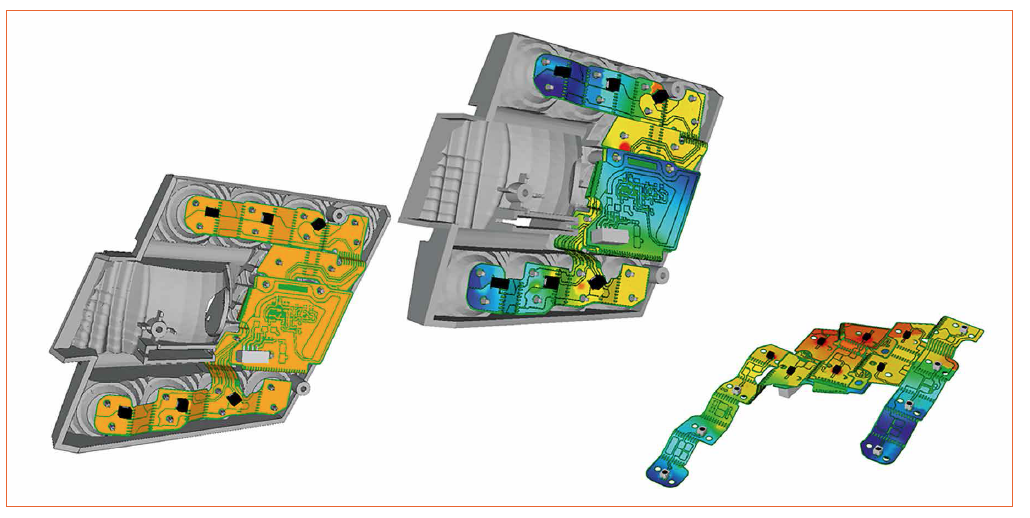

Figure 5: Thermal simulation in automotive LED applications

Figure 5: Thermal simulation in automotive LED applications

The Importance of Simulation in LED Design

The above factors indicate why thermal design is such a significant challenge in the design of LED lighting products. As stated previously, LED lighting designers need to know that their devices will meet specifications, often in very challenging environments. It is unacceptable to provide customers with LEDs that do not provide the desired color or expected lifetime.

6SigmaET’s own research has highlighted that nearly two thirds of engineers [1] tend to ‘over engineer’ their designs, rather than use tools to optimize thermal performance. When it comes to LED lamps, it is not possible to rely on “rules of thumb” due to size constraints and other factors.

There are many variables to consider, and a range of potential design options to choose from. Thermal simulation is the only way to assess different cooling concepts with known marginal conditions and loads. It allows designers to identify thermal issues and to experiment with different LED packages, PCB materials and cooling devices - without the cost of creating prototypes. Using thermal simulation in this way lets LED designers ensure that their designs meet performance requirements. This makes thermal simulation an essential component in the design of LED lighting.

So, what are the key features LED designers should be looking for in thermal simulation tools?

Thermal Simulation Tools in Practice

Increasingly, thermal simulation tools are absolutely essential. They are not just a “nice to have” anymore. One of the key drivers is that the average time to market for a product is now so short. So while using simulation in tandem with physical testing, CFD tools are required to save significant time in the development process. There is simply not the time available to perform extensive physical experiments.

As well as reducing the reliance on physical testing, the use of dedicated thermal simulation software offers other benefits, including a reduction of design risk and a 10-30% improvement in cooling for LED products. Overall, it can be estimated that it saves anything from a few weeks to several months in terms of total time to market for clients.

Figures 6&7: Simulation models of two different LED replacement lamp designs

Key features for any thermal simulation tool are:

- Complex geometry handling:

Most thermal simulation tools can cope easily with square or rectangular shapes - but LED lamps are rarely, if ever, square. As a result, a tool is needed that can easily model and solve for the more rounded or circular shapes expected in LED design - Large model processing:

OTS sees that its design models are becoming larger and increasingly complex. For several of its LED projects, its models have comprised of as many as 5-15 million grid cells. The tool needs to handle these large models without becoming too slow or hard to work with - Fast testing of multiple design variations:

The ability to handle large models is particularly crucial when performing sensitivity studies. To truly optimize a design, quick testing of multiple design variations – placement of components, enclosure materials, environments etc. – is essential to ensure the product will work as required. Choose a tool that is designed to make this process as easy as possible

Conclusion

There is simply no avoiding the fact that without the right thermal design, your LED lamp will fail rapidly. However, optimizing the thermal design of any LED lighting product is a significant challenge, and designers need to have the right tools. If you are struggling with any of factors described above, then it is probably time to re-assess your simulation tools.

Acknowledgements:

The author thanks Osram Opto Semiconductors GmbH and Alpha Numerics GmbH for their support and providing the figures 1-4 and 5 respectively. In particular, the author wants to thank Rainer Huber of Osram Opto Semiconductors GmbH for his help in preparing the article and Norbert Engelberts, founder of OTS for identifying the key features for thermal simulation tools.

References:

[1] http://www.6sigmaet.info/media-centre/whitepapers/the-heat-is-on/

(c) Luger Research e.U. - 2018