Transparent Material Considerations for UV Optics in Horticultural Lighting Applications

Advancements in UV LED technology have begun changing the horticultural lighting landscape. Research is still ongoing to discover the extent of benefits and best practices of using UV light in horticulture. Using optics in tandem with UV LED light systems can help reach performance goals and optimize growing. Although there are several UV- transmitting materials available, not all are equivalent or able to meet the requirements for UV applications. Justine Galbraith, glass engineer, and Sharayah Follett, market development manager at Kopp Glass, Inc. discuss the performance considerations of various UV-transmitting materials and how application challenges are addressed by integrating optical elements.

The advancements of LEDs enable simultaneous light intensity and spectrum control, resulting in a more efficient and productive method of providing light for plant growth than traditional sources. This is further realized by improvements made in UV LEDs, allowing growers to integrate specific doses of targeted UV wavelengths at the right time of a harvest cycle to increase the quality of plant growth in a more cost-effective manner.

Though the technology is continually progressing, commercially available UV LEDs still have limitations in achieving performance goals in horticultural applications. Using UV LED array design and corresponding beam angles alone, it can be difficult to maintain or extend working distances, maximize light intensity, and ensure uniform light coverage on the plant canopy.

Traditionally, optics have been used to address these limitations and control the light output of the fixture. However, designing an optic to enhance the performance of UV LEDs, especially at lower UV-B wavelengths, brings an entirely new set of challenges for those experienced in traditional technologies. Not all materials transmit the required UV wavelengths, and not all UV-transmitting materials perform equivalently in application.

Benefits of LEDs in Horticultural Applications

LEDs have many benefits over the legacy technologies of incandescent, fluorescent, high-intensity discharge (HID) or high-pressure sodium vapor (HPS) lights that have historically been used in indoor farming operations.

One major benefit of using LEDs in horticultural settings is temperature control. HPS bulbs produce a broadband spectrum that includes near-infrared light, which accounts for much of the heat generation. For LEDs, most of the energy input is converted to light. Some energy is lost to heat, but it is managed through heat sinks, water-cooling, and other techniques. LEDs allow growers to better manage the environmental temperatures needed for specific plants.

LEDs are generally more energy efficient. For the same amount of light output, LEDs typically use much less energy than legacy bulbs. LEDs also have much longer lifespans, sometimes reaching over ten years. This all translates to lowered costs of ownership for growers [1].

Finally, LEDs offer targeted wavelength emission ranges. With tunable spectrums, the user chooses the optimal wavelengths depending on the application or needs of the species being cultivated. Most commercially available LED lighting fixtures have combinations of red, green, blue, and/or white LEDs that can be tailored based on the desired effect, such as flowering or vegetative plant growth. However, UV light has been shown to bring additional benefits for horticultural applications.

Benefits of UV Radiation on Plant Growth

Research into the effect of UV radiation on crops has been ongoing since the 1960s. With the advancement of UV LEDs, researchers now have low-heat light sources with narrow emission bands in the UV region. This has enabled the evaluation of targeted wavelength ranges; for example, recent testing found that UV-B (280-315 nm) radiation "increases photosynthetic rate, provides photoprotection to young seedlings prior to being transferred to the field, and improves pigmentation, aroma, and resistance to fungal diseases and insects" [2].

UV light targets plant photoreceptors and regulates secondary growth processes throughout plant life. This has been shown to enhance flavor, texture, and appearance of plants. In one study, NUV-B exposure caused both lettuce leaf thickness and poinsettia branching to increase [3].UV light can also improve disease resistance as well as increase shelf life. It has been shown to reduce mold and mildew. For example, cucumber lesions have been shown to decrease with UV-B exposure [3].

It is important to keep in mind that the UV light dosage and required wavelengths are crop dependent. Timing and placement of the UV light into the grow cycle should be chosen carefully per species and desired results, with an understanding that excessive power and exposure to UV rays can be detrimental.

Considerations for Integrating UV LEDs into Horticulture

A key challenge when implementing this technology is determining how to integrate UV light fixtures into existing grow operations or infrastructure.

Visible light fixtures are typically more than four feet away from the plant canopy. This working distance provides ample room for plant care and maintenance. This distance is particularly relevant in vegetative and flowering stages for taller plant species, as well as in greenhouse applications where supplemental lighting fixtures can be more than fifteen feet away from the target surface.

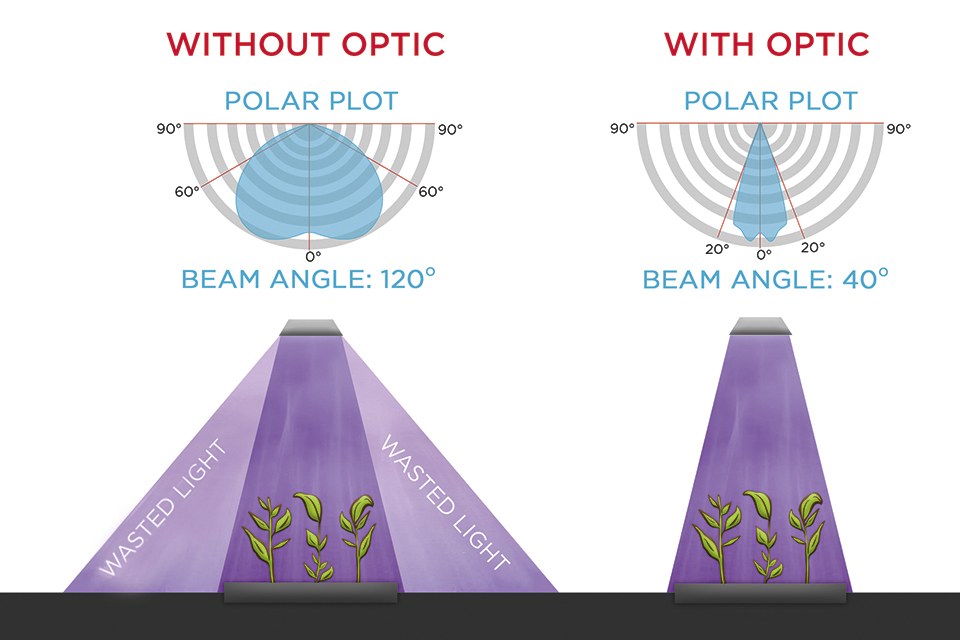

At these working distances, it can be difficult to integrate UV LEDs, especially those emitting in lower wavelengths (UV-B). This is because most commercially available UV LEDs have wide beam angles, typically 120-140 degrees, and lower power outputs compared to visible LEDs. As the working distance is increased, the coverage area from the LEDs also increases and can quickly become larger than standard plant canopies. This results in wasted light limiting both the efficiency of the system as well as the ability to achieve the optimal dosage and photon flux density (PFD) required for plant growth. Figure 1 demonstrates the wide viewing angle of an LED without an optic and the result of wasted light in application.

One method of addressing this challenge is bringing the fixture closer to the plant canopy to ensure that all of the light from the UV LEDs is directed onto the target surface. This may require a significant re-design of infrastructure, which can be cost-prohibitive and interfere with the space necessary for grow operations. Another solution is increasing the number of LEDs to achieve the target PFD. However, this can also be cost-prohibitive and does not address wasted light and optical inefficiencies.

For lighting fixtures using visible LEDs, a common solution is introducing a collimating optic to achieve a specified beam angle. In this way, working distance can be extended while ensuring that energy is not wasted on light missing the intended surface, and that the target power amount is maintained. Figure 2 demonstrates the impact of an optic on viewing angle and the effect in application to direct and capture stray light. By controlling the beam angle of an LED, the design flexibility necessary to overcome extended working distance is made possible.

However, this solution is not as straightforward for lighting fixtures using UV LEDs. This is due to the limited availability of transparent materials suited for UV optics in horticulture. Material requirements include high transmission at critical UV wavelengths, mechanical durability to maintain optical properties in the horticulture operating environment, manufacturability into desired shapes and sizes, and finally corresponding price.

Determining the expected performance and lifetime of different UV-transmitting materials requires the consideration of both critical material properties and operating environment.

While this article focuses on UV light, it is important to select a transparent material that can transmit visible and IR wavelengths, allowing for the design and realization of full spectrum lighting products.

Transparent Materials or UV Optics

A common misconception is that quartz is the only transparent material able to withstand prolonged exposure at lower UV wavelengths. However, new material advancements, such as Kopp's development of a specially formulated, UV glass, enables optics to be manufactured that have high transmission across UV, visible and IR wavelengths and can withstand demanding operating environments.

The three main categories of transparent materials that can be used for optics in UV applications are polymers like acrylic and silicone, ceramics and glasses like quartz and fused silica, and specialized UV glass compositions. It is important to note that UV glass is not a standard material offering due to compositional design, development, manufacturing restrictions, and cost considerations.

When selecting a transparent material for UV optics, there is no one-size-fits-all solution. Each material has unique properties that dictate the control of light. It is vital to evaluate each material property with all aspects of the lighting system in mind – from the operating environment to the desired light output performance goals for the application.

For horticultural applications, the criteria to consider include transmission, thermal properties, lifetime of material, optical efficiency and most significantly, flexibility in manufacturing the required optical design. Essential properties are summarized in table 1 and discussed in the following sections to detail the impact in application.

|

Property |

Definition |

Impact in Application |

|

Absorption, Transmission, and Reflection |

Absorption is the reduction of light as it travels through a material. Conversely, transmission is the amount of light that makes it through. Reflection for transparent materials usually occurs at the surface and is a function of wavelength and index of refraction. |

These properties—along with design—help to determine the light output of an optic. |

|

Thermal Resistance |

The operating temperature of optical material needs to match the operating temperature of the UV LED. UV LEDs should be thermally managed to reduce operating temperature to maintain lifetime, efficiency and output.

|

If the material is heated above its maximum operating temperature, this can cause the optic to deform. |

|

UV Stability |

Depending on the composition of the material and the quality of the light, transmission may not be stable at certain UV wavelengths. This property is generally healable once exposure stops. UV radiation can also affect the structural integrity of materials in the form of yellowing or breakage on the surface.

|

Materials that are not stable under UV exposure can either lose transmission, become damaged, or both. This causes the light output to degrade. |

|

Chemical Resistance |

Whether the material is exposed to something as common as water or other harsh chemicals, it is vital to know how the material will perform. Chemical resistance depends on the composition of the material. |

Surface degradation, as a result of exposure to humidity and harsh chemicals, affects transmission. |

|

Refractive Index |

The index of refraction determines how much light is reflected and transmitted at the interface and the angle at which it is refracted. This value is unique per material. |

This property is needed by the optical engineer to optimize the optic design to meet performance goals. |

|

Hardness and Rigidity |

Hardness is the ability of a material to resist being scratched, fractured, or permanently deformed by sharp edges of another material. If the hardness of a material is known, one gets a sense of its resistance to abrasion. Rigidity, also known as stiffness, is the extent to which a material can be bent or forced out of shape. |

Soft materials are at risk of becoming abraded at the surface affecting transmission. Lack of rigidity may mean the part can move, which can negatively affect light output. |

Table 1: Important material properties to consider when selecting a UV-transmitting material for an optic

Transmission of Transparent Materials

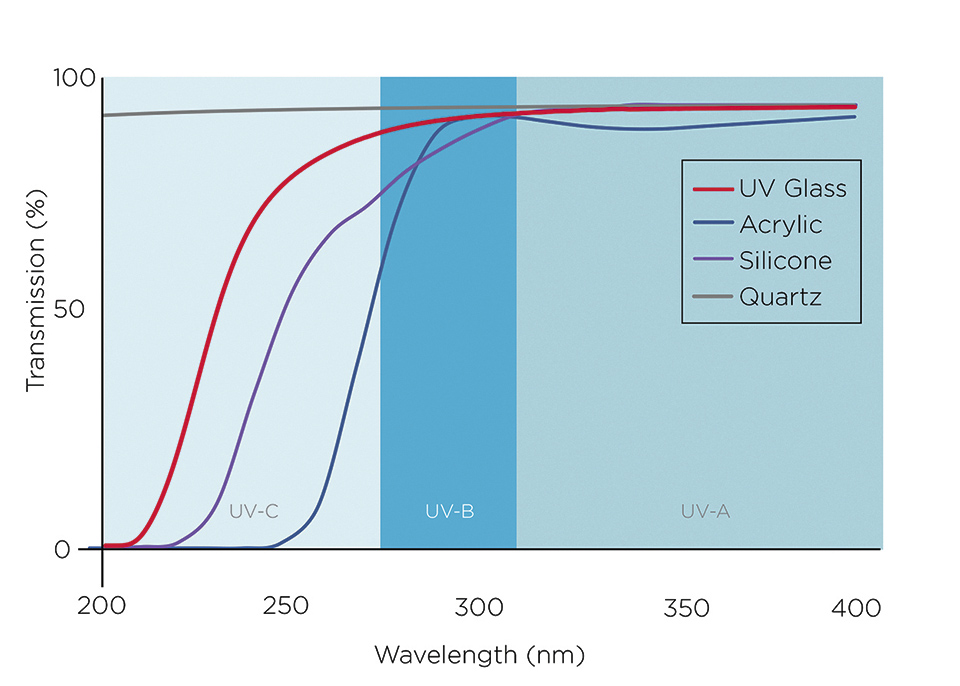

Transmission is the first level of consideration when selecting a UV-transmitting material. It is necessary to identify the wavelength of interest and then determine whether a material will transmit enough light to be an appropriate fit for application. Figure 2 compares the transmission spectra of the above-mentioned materials at UV wavelengths.

Figure 2: Transmission of transparent materials at UV wavelengths

Figure 2: Transmission of transparent materials at UV wavelengths

Optical design is essential

An optimized optical design will direct all possible light onto the target surface and can increase the optical efficiency of a system. In many cases, optics made from materials with lower transmission will result in more light reaching the target plant canopy compared to a flat window with higher transmission but no optical features.

Industries that utilize LEDs have a history of using quartz for windows and simple optics like rods. While quartz has favorable transmission, it has material and manufacturing limitations that make optical designs difficult to manufacture. Unlike quartz, specialized UV glasses that are designed with the end application in mind, can be manufactured into complex and contoured shapes without fabrication. This flexibility allows optical features to be molded into both the incident and exiting surfaces of the optic.

Optical design will be discussed in detail later, but it is important to keep in mind throughout the process of evaluating transparent materials.

Thermal Considerations

As noted above, a key benefit of LEDs in horticultural lighting applications is that they have lower heat outputs and operating temperatures compared to traditional light sources. LEDs do produce some heat; however, the heat is generated due to inefficiencies in the conversion of electrical power to light, rather than by IR radiation.

UV LEDs tend to run hotter than visible LEDs because they have lower wall plug efficiencies. The optical power of UV LEDs accounts for 15-25% of the input electrical power whereas visible LEDs have closer to 40% efficiency in generating light [4] and the higher the power of the LED, the more heat can be produced.

In most cases, LEDs will be thermally managed, usually through air or water-cooling. However, it is necessary to know the operating temperature to select an optical material that will not degrade or deform at that operating temperature.

Effect of Application Environment on Lifetime

It is imperative to keep in mind how the optic will be impacted by exposure to varied operating conditions in the application environment. For example, a material such as UV glass is highly resistant to abrasive conditions, heat cycling and UV radiation exposure, whereas plastics in the same environment will erode and discolor resulting in severe transmission loss. It is important to note that a loss in transmission can significantly affect the performance of a light fixture, especially in applications like horticultural lighting where consistent and uniform light output are required.

Additionally, the influence of application environment on the fixture itself should be considered. UV LEDs, especially in the UV-B region, are still relatively expensive and their performance can be significantly impaired by exposure to water and humidity. Flat windows, cover lenses, and optics are commonly used in visible lighting fixtures to protect internal components against environmental exposure and to achieve industry certifications. These include IP ratings and certification marks such as UL, ETL, CSA, and CE. Similarly, UV-transmitting windows and optics can be used to protect UV LEDs.

To ensure UV LED systems continue to function properly and that the elements are adequately protected, it is essential to use a durable material that will not lose transmission over time or degrade after prolonged use.

Material stability under UV exposure

The optical stability - or the ability for a material to maintain transmission during use - depends on both the light source parameters, like wavelength and optical power, as well as the type of material used. In many instances, prolonged UV exposure can decrease the transmission of a material. This characteristic differs from material to material depending on its chemical composition, design, and processing. Some materials will be much more stable than others. As such, material manufacturers should be consulted regarding UV transmission stability.

It is also important that the structural integrity of the material remain intact after prolonged UV exposure, especially in horticultural lighting applications using UV-B and UV-C wavelengths. When exposed to UV light, quartz and UV glasses are mechanically stable. On the other hand, most polymers, such as acrylic, will degrade and become destroyed at the surface when exposed to UV radiation, even for a short time [5].

Chemical resistance in operating environment

Often, horticultural lighting fixtures are exposed to water, humidity, and other chemicals used in application. Some, such as hydrogen peroxide, can leave a film on the lens that reduces transmission. If the material cannot withstand the environment, its performance will degrade, negatively affecting the growth of plants. Additionally, an easily cleaned and maintained material is ideal.

Quartz and specialized UV glass can both withstand humid environments and are resistant to various chemicals. Polymers are much less resilient to humidity and chemical exposure; they are at a higher risk of degradation, which impairs transmission and efficacy.

Material Selection Impact on Optical Design

As a final step, how the material will be transformed into its final shape as an optic should be considered. Material parameters, such as index of refraction and manufacturability, will determine what optical designs are realistic. The optical design itself and the inherent transmission of the material selection will determine the system's optical efficiency as well as the eventual light output.

Index of refraction

The index of refraction indicates how fast light travels through a material and how it is reflected and refracted at interfaces. This material property is dispersive, so it should be determined for the wavelength of light used in application.

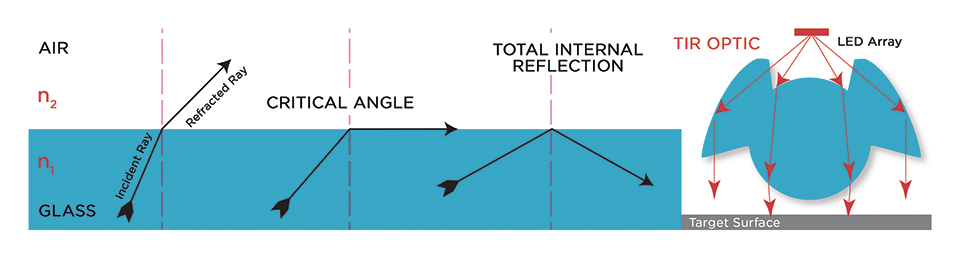

Every material has a critical angle, which is determined by its refractive index. If incident light hits a surface at angles above the critical angle, it will be fully reflected with no transmission. Figure 4 shows an example of total internal reflection (TIR) and how this principle is used in optical design. These angles are fundamental for designing curvatures of optics to achieve design goals. Both material transmission and index of refraction should be known at the onset of the optical design process. Since different materials have different indices of refraction, substituting materials requires redesigning the optic.

Figure 3: Example of total internal reflection (TIR) and how this principle is applied in optical design

Figure 3: Example of total internal reflection (TIR) and how this principle is applied in optical design

Ensuring material manufacturability

To achieve performance goals, the transparent material must be able to take the shape of the optical design. Therefore, manufacturability is a critical characteristic of the transparent material.

Industries that utilize LEDs have a history of using quartz for windows and simple optics like rods. While quartz has favorable transmission, it has material limitations making optical designs difficult to manufacture. It cannot be molded or pressed into complex shapes. Fabrication techniques for this material are also limited. This drives up the cost, making the material impractical.

Polymers are equally as impractical, but for the opposite reason. Polymers can be molded into complex shapes but, due to limitations in processing methods, size is limited. Many compositions lack chemical resistance and will degrade after prolonged UV exposure, negatively impacting performance in horticultural applications. Polymers also lack rigidity, meaning they can bend, whereas glass and quartz are stable. This can allow for an optic to become unaligned from the UV LED array and result in light output variability.

Specialized UV glass compositions are designed to achieve performance goals. This includes transmission of critical UV wavelengths, material durability and the opportunity to manufacture complex optical shapes in a cost-effective manner through molding processes. The flexibility in compositional design and manufacturability ensures the optic can meet the needs of an application or operating environment.

Optical design process

The final consideration in material selection is to evaluate how optical design will impact the output of the lighting fixture. When manufactured from the best-suited material, the optic will effectively achieve the performance goals of the end user. For example, an optic can be designed to extend the working distance of the lighting fixture while maintaining light output. It can re-direct UV light to provide uniform light coverage on a plant canopy with a large footprint. It can collimate light to ensure even coverage as the plant grows taller. Or it can achieve all the above as performance goals are varied and driven by the application or end user.

The optical design process typically begins with an optical engineer. They will need to know the parameters of the UV LED (manufacturer, spectral distribution, peak wavelength, beam angle), the optical properties of the material (transmission, refractive index) and the desired performance goals (beam angle, PFD map, irradiance map). The engineer uses this information to determine the type of optic that will optimize the system to achieve optical targets. Figure 4 is an example of a UV glass optic designed to enhance a linear array of ten UV LEDs.

Figure 4: UV glass optic optimized for a linear array of 10 UV LEDs

Figure 4: UV glass optic optimized for a linear array of 10 UV LEDs

To produce an optic that is optimized for both manufacturing and light output, the optical engineer, optic manufacturer and lighting OEM must collaborate early in the design process. Without working together, the optical engineer may design an optic that produces an ideal light distribution within the lighting OEMs fixture constraints that is not aligned with the optic manufacturer's capabilities. As a result, the design could be more costly or even impossible to produce without modifications. Early collaboration reduces time spent in product development, prevents costly re-designs, increases manufacturing yields and accelerates time to market.

Conclusion: Optimize UV LED Performance with UV Glass Optics

Optics benefit and enable the development of differentiated and efficient horticultural lighting fixtures. They allow for design flexibility to overcome application challenges and achieve performance goals. Optics can be paired with both visible and UV LEDs; however, at UV wavelengths, additional consideration needs to be taken to select an appropriate optical material.

When designing an optic for UV LED lighting systems, it is vital to select a material that transmits the appropriate amount of UV light at the critical wavelengths, exhibits durability and maintains output in the horticultural operating environment. The material must also be manufacturable into complex shapes and sizes in a manner that is not cost-prohibitive.

UV glass optics are able to meet the performance and manufacturability requirements of horticultural applications. They improve fixture optical efficiency by effectively directing light to the target surface, providing optimal coverage for the plant canopy, enabling working distance control, and protecting the internal components from the operating environment.

The implementation of UV glass optics allows for growers to realize the benefits of UV LEDs including, enhanced quality of product, increased yield as well as lower energy, operating and maintenance costs, resulting in more productive and profitable grow operations.

References:

[1] Berland, Terrance. "UV LED Technology for Emerging Applications in

Agriculture." LED Professional, Dec. 1, 2018, https://www.led-professional.com/resources-1/articles/uv-led-technology-for-emerging-applications-in-agriculture

[2] Ren-Butcher, Y. "Ultraviolet Supplement for Cannabis Production."

White Paper, Illumitex. Jun. 2018, http://illumitex.com/wp-content/uploads/2018/06/UV-White-Paper.06.2018v2.pdf

[3] Huché-Thélier, L., Crespel, L., Le Gourrierec, J., Morel, P., Sakr, S., Leduc,

N. "Light signaling and plant responses to blue light and UV radiation –

perspectives for applications in horticulture." Environmental and Experimental

Botany, vol. 121, pp. 22–38, Jan. 2016.

[4] "Fact or Fiction –LEDs don't produce heat." LEDs Magazine, 10 May 2005,

https://www.ledsmagazine.com/leds-ssl-design/thermal/article/16696536/fact-or-fiction-leds-dont-produce-heat

[5] Ehrt, Doris. "Deep-UV materials." Advanced Optical Technologies, June 2018.