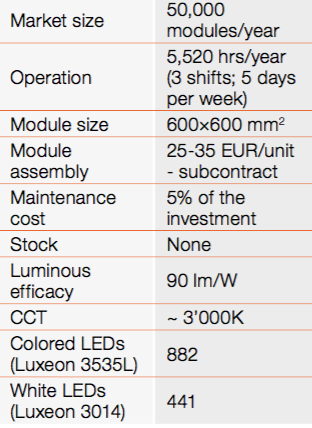

Ultrathin Direct-Lit LED Module with Beam Shaping Thin-Film Optics

Thin, high quality, LED light panels are still a challenge. LED professional’s scientific partner, CSEM, investigated and developed a new approach with its partners, GAIKER-IK4 and BASF-SE. The authors, Oscar Fernández and Rolando Ferrini, from CSEM, Leire Barruetabeña, from GAIKER-IK4, and Sorin Ivanovici from BASF SE, present a solution that uses low-cost and spectrally poor, ultra-cool white LEDs in conjunction with optical color conversion foils, to transform the output to a high-quality light. They also describe a combination with added lime and red LEDs for a color tunable solution.

A direct-lit LED-based lighting module is described that features an ultra-thin form factor and high-quality light both photometrical and spectrally.

Thanks to a smart integration of optical foils for efficient light management, a high luminance uniformity results for a total module thickness well below the LED pitch. In addition, such light management solution produces a directional glare- free photometric light pattern.

Using an appropriately engineered organic-based color conversion foil, CCF,

and the characteristic broad emission of the organic phosphors inside, warm white light with excellent color rendering properties could be achieved from low-cost and spectrally poor ultra-cool white LEDs.

The flexibility of the light management foils and

the CCF foils make their manufacturing compatible with cost-competitive roll-to-roll processes.

On the other hand, the incorporation of independently addressed colored LEDs into the module allows on-Planckian white point tuning, albeit with certain impact on the color rendering properties. Our light management solution performs acceptably in a wide range of color points thanks to its good color mixing capabilities. Suggestions are made to improve on both aspects.

The cost structure of the module, analyzed using life cycle cost analysis revealed that the addition of colored LEDs is, by and large, the main factor for the cost of the module.

LED Panels for High- Quality Lighting

Ultrathin Direct-Lit LED Module with Beam Shaping Thin-Film Optics

Thin high quality are light panels are still a design challenge with LEDs. LED professional’s scientific partner CSEM has investigated and developed a new approach with its Partners GAIKER-IK4 and BASF SE. The authors Oscar Fernández and Rolando Ferrini from CSEM, Leire Barruetabeña from GAILER-IK4, and Sorin Ivanovici from BASF SE present a solution that uses low-cost and spectrally poor ultra-cool white LEDs in conjunction optical color conversion foils to transform the output to a high- quality light. They furthermore describe a combination with added lime and red LEDs for a color tunable solution.

A direct-lit LED-based lighting module is described that features an ultra-thin form factor and high- quality light both photometrical and spectrally.

Thanks to a smart integration of optical foils for efficient light management, a high luminance uniformity results for a total module thickness well below the LED pitch. In addition, such light management solution produces a directional glare-free photometric light pattern.

Using an appropriately engineered organic-based color conversion foil, CCF, and the characteristic broad emission of the organic phosphors inside, warm white light with excellent color rendering properties could be achieved from low-cost and spectrally poor ultra-cool white LEDs.

The flexibility of the light management foils and the CCF foils make their manufacturing compatible with cost- competitive roll-to-roll processes.

On the other hand, the incorporation of independently addressed colored LEDs into the module allows on-Planckian white point tuning, albeit with certain impact on the color rendering properties. Our light management solution performs acceptably in a wide range of color points thanks to its good color mixing capabilities. Suggestions are made to improve on both aspects.

The cost structure of the module, analyzed using life cycle cost analysis revealed that the addition of colored LEDs is, by and large, the main factor for the cost of the module.

LED Panels for High- Quality Lighting

LEDs today can produce extremely high luminance levels (of several 10’000s cd/m2). However, due to their small size (≤ 1 mm2), the total flux is typically not higher than a few tens of lumens, too low for most lighting applications that require two orders of magnitude larger values. Consequently, high flux LED-based lighting devices use LED arrays.

Very often, the light emitted by LEDs must be redistributed to meet the illumination specifications due to their (typically) Lambertian demission pattern. For example, unless fitted with appropriate secondary (and often tertiary) optics, LED arrays illuminate nearby targets non-uniformly and cause multi-shadows.

Lambertian light sources, such as LEDs, are suitable to illuminate flat (i.e. not susceptible to multi-shadow effects) surfaces in very close proximity, like in LCD displays and task lighting, but are nonetheless not useful for large distances unless appropriate optical solutions for beam shaping. [1/p.79]

On the other hand, the average human eye can see in a brightness range of ~9 orders of magnitude from 1/1,000 to 100,000 lux [2/p.102]. Several processes including changes in pupil size achieve such a large dynamic range. [3/p.40.3] The continuous adaptation required when exposed to very different light levels often results in eye fatigue. [4]

In addition, the highly (spatially) concentrated light emission and the concomitantly high (Lambertian) luminance levels produce glare and ultimately loss of visibility, discomfort and irritation. [5/p.553] This issue deserves particular attention in the Professional Lighting segment where highly specular surfaces such as computer screens are commonly found. Furthermore, when brightly illuminated, the perceived characteristics of displays suffer from degradation of the visible grey-level, from reduction of the visible contrast and from reduced peak perceived color gamut [6,7].

The development and implementation of efficient beam shaping solutions will, in addition, contribute to reduce the amount of wasted light (30% in outdoor lighting has been estimated [8]) hence reducing energy consumption and minimizing the potential negative impact on our health [5/p.553, 9].

A common way to alleviate these disadvantages is to use LED panels where the light emitted by a relatively numerous collection of LEDs is uniformly distributed into a large area (typically ~600×600mm2).

In the so-called direct-lit configuration a collection of LEDs are distributed more or less regularly on the surface of a planar substrate. The LEDs illuminate a diffuser plate located at a certain distance, d, above them. In order to achieve a uniform luminance over the entire diffuser, it needs to be separated from the LEDs by a distance comparatively higher than that between adjacent LEDs, the so-called LED pitch, t. The ratio of these two quantities is often referred to as the distance-to-height ratio, DHR=t/d.

The advantages of direct-lit configuration compared to the alternative edge-lit approach have summarized elsewhere. [10]

The main building blocks of the LASSIE-FP7 module [I] are the LED foil with integrated heat management structures, the light management foils, the CCF foil and the intelligence system. Here we report on the light management and CCF components. Insights into the LED foil and the intelligence system technology can be found in [11] and [12] respectively.

Optical Solutions for Ultrathin LED-Based Panels

Slim panels (DHR >> 1) are advantageous not only from an aesthetic perspective but also because of the space/weight savings they offer for recessed/ pendant installations. Both aspects are, in addition, advantageous for stock keeping, handling and transport.

From an aesthetic perspective, uniform luminance distribution across the complete (emitting) area of the module is highly desired for it places the focus on the light itself rather than on the light sources. The well-known fact that human vision is drawn to gradient rather than to absolute luminance levels [13,14/p.24] poses a real challenge for direct-lit panels with DHR >> 1.

The DHR can be reduced by shaping the Lambertian into a batwing emission pattern using lenses, although at the expense of a substantial cost increase. Alternatively, micro structured pixels have also been proposed based on optical simulations [7]. Unfortunately, the experimental demonstration has, so far, proven elusive due to manufacturing constraints of the simulated optical microstructures.

In the LASSIE-FP7 project we have developed a solution based on the vertical stacking of optical thin films which produces highly uniform luminance levels (luminance uniformity ~86%) across the complete emitting whilst keeping a large DHR value of ~1.67 and an optical efficiency of ~70%. Remarkably, the principle of operation of this solution does not relay on the alignment of the foils with respect to the LEDs or with one another, which facilitates their integration into the module. See Spectral tuning with individually addressed colored LEDs section for the proposed solution of very good color mixing capabilities.

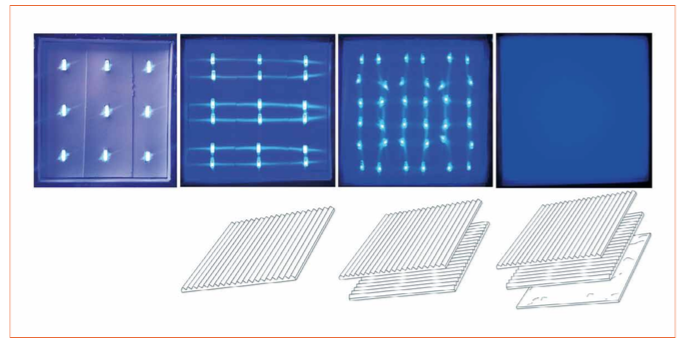

In addition to a thin-film diffuser, the optical stack contains two (similar) prismatic foils perpendicularly oriented with respect to each other in order to exploit the recursion mode [15/p.79] and doubling capabilities characteristics micro prisms [16] (Figure 1).

Figure 1: Top view of a 50×50 mm2, 3×3 LED array with the foil combinations shown below. A highly reflecting substrate (98% reflectance) was used. All foils are less than 200 microns thick

Figure 1: Top view of a 50×50 mm2, 3×3 LED array with the foil combinations shown below. A highly reflecting substrate (98% reflectance) was used. All foils are less than 200 microns thick

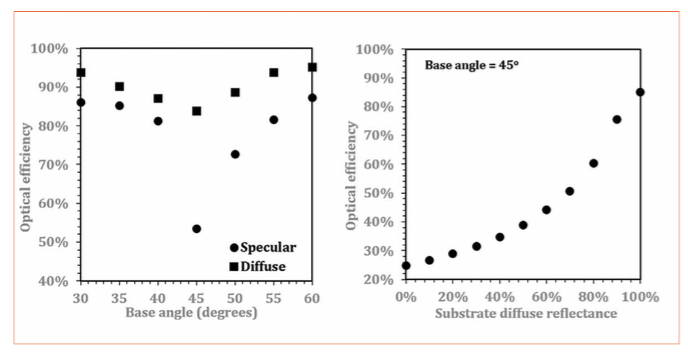

The optimum base angle of the micro prisms was investigated using ZEMAX Ray-Tracing optical simulation software. Figure 2 left shows the predicted efficiency of an LED array with two prismatic foils as a function of the prims base angle. Perfectly reflecting (specular and diffusive) LED substrate is assumed. The observed efficiency dip indicates the angle (45 degrees) where the recursion mode, i.e. light mixing, is at a maximum. Diffusive reflectors convert recursion into emission modes upon reflection on the substrate, thus achieving high efficiency and optimum light mixing.

Figure 2: Simulated optical efficiency of an LED array and two crossed prismatic foils as a function of the prism angle (left). Two cases are considered, 100% diffuse and 100% specular reflectance. The foils are located at 10 mm from the source. Simulated optical efficiency of the same module in the case of a 45 degree prism angle as a function of the module (diffuse) reflectance (right)

Figure 2: Simulated optical efficiency of an LED array and two crossed prismatic foils as a function of the prism angle (left). Two cases are considered, 100% diffuse and 100% specular reflectance. The foils are located at 10 mm from the source. Simulated optical efficiency of the same module in the case of a 45 degree prism angle as a function of the module (diffuse) reflectance (right)

Since light mixing is achieved mainly through light recycling of the recursion mode, highly reflective substrates are mandatory for acceptably low optical losses (Figure 2; right). We selected a white reflecting foil with 98% measured diffuse reflectance across the visible under normal incidence.

Figure 3: Top view of the (20x20 cm2) LASSIE- FP7 module with (left) and without (right) a multilayer light management solution. The multilayer stack transforms the non- homogeneous light pattern produced by the point-like LED sources into a spatially uniform emitting surface

Figure 3: Top view of the (20x20 cm2) LASSIE- FP7 module with (left) and without (right) a multilayer light management solution. The multilayer stack transforms the non- homogeneous light pattern produced by the point-like LED sources into a spatially uniform emitting surface

The capability of the developed solutions in homogenizing the LED light is shown in Figure 3. It is worth mentioning that, contrary to standard micro prismatic foils (such as, e.g., 3M brightness enhancement foils, BEF) those used in LASSIE-FP7 produce a nice diffusive and achromatic off-state appearance even under bright ambient light (not shown).

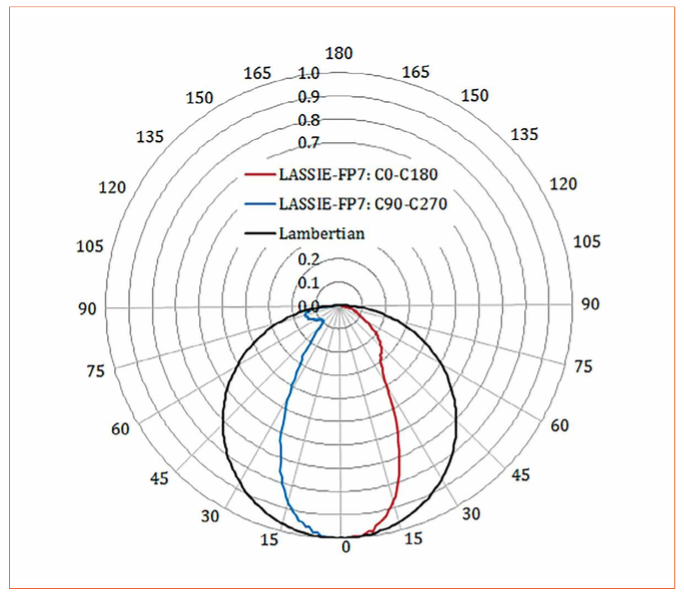

In addition to the light mixing and source doubling, the micro prismatic structures enhance on-axis emission at the expense of that emitted at high angles (Figures 4 and 5). The high directionality of the resulting beam is non-glaring and better suited to illumination of distant targets.

Figure 4: Fully covered module observed off-axis. A small area has

Figure 4: Fully covered module observed off-axis. A small area has

been purposely left uncovered to show the de-glaring properties of our light management solution

Figure 5: Experimentally measured luminance intensity distributions with and without the light management solution

Figure 5: Experimentally measured luminance intensity distributions with and without the light management solution

High-Quality Emission Spectrum

The human eye cannot easily discriminate between two metameric (same white point) visual stimuli. However, we see objects around us by the light they reflect and hence their appearance (particularly color) is determined by the objects’ own nature as well as by the spectral distribution of the light source.

The capability of light to render natural colors, referred as color rendering, is defined in the CIE International Lighting Vocabulary as “the effect of an illuminant on the color appearance of objects by conscious or subconscious comparison with their color appearance under a reference illuminant”. [17]

If a given color (wavelength) is missing or underrepresented in the emission spectrum of the light source, it will not be revealed in the reflected light. [18] Therefore, broadband spectral characteristics with no missing wavelengths render colors better.

High color-rendering LEDs are available commercially from the major LED manufacturers including OSRAM, CREE and Lumileds [19, 20, 21].

However, we know from the Life-cycle analysis (see Cost Analysis section below) that the largest contribution to the cost of the LASSIE-FP7 module corresponds, by far, to the cost of the LEDs themselves. The use of expensive high rendering LEDs will unavoidably result in an unacceptably high cost.

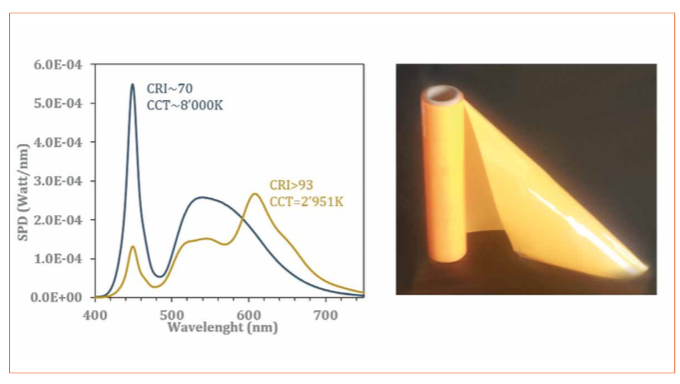

Figure 6: Spectral power distribution, SPD (left), of the cool white (~8’000K) LEDs with (brown curve) and without (blue curve) BASF CCF. The CCT and CRI values are given in the inset. Picture of a BASF CCF roll (right)

Figure 6: Spectral power distribution, SPD (left), of the cool white (~8’000K) LEDs with (brown curve) and without (blue curve) BASF CCF. The CCT and CRI values are given in the inset. Picture of a BASF CCF roll (right)

A proprietary technology, cost-competitive solution for high-quality light spectrum

BASF proprietary color changing foil, CCF, technology offers an excellent cost-competitive alternative to achieve high color rendering light. The flexible CCFs contain efficient organic phosphors embedded inside a thin polymer foil. The CCFs are produced entirely by roll-to-roll processes, which, together with the small phosphors quantities needed to have a substantial down- conversion, make these CCFs a cost-competitive solution.

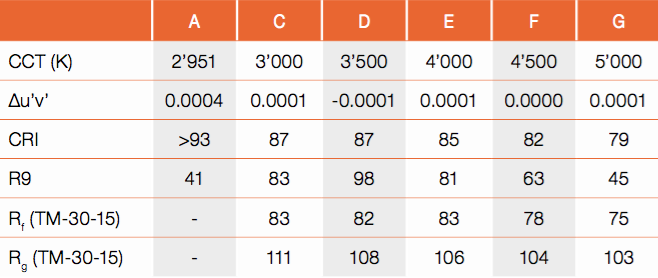

High-quality spectral characteristics (column A in Table 1) have been experimentally recorded (Figure 6) using the CCF in combination with low-cost, LUXEON3014 cool white LEDs (CCT~8’000K) with poor spectral properties (CRI~70).

The luminous efficiency values of 102 and 87 lm/W were recorded with and without the CCF; the moderated optical losses associated to the Stokes-shift (7.7%) and the non-perfect quantum efficiency of the CCF (9%).

Spectral tuning with individually addressed colored LEDs

At the beginning of the century, the so-called Human Centric Lighting, HCL, appeared in the scene of lighting design. Among other features HCL exploits the variable spectra power distributions achievable with LED-based lighting modules that incorporate separately driven LED color channels. [22/p.336]

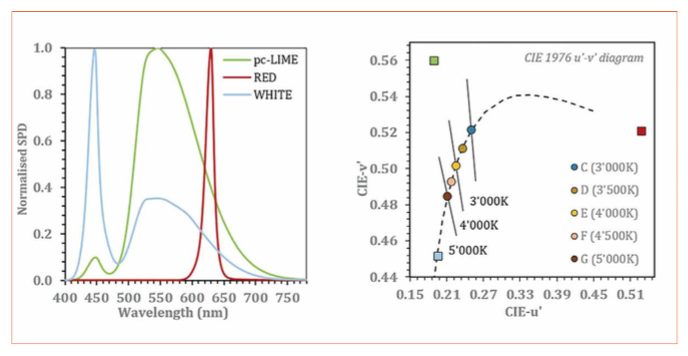

Figure 7: Normalized SPD (left) and color coordinates (right) of the selected LEDs as provided by the suppliers in the datasheets

Figure 7: Normalized SPD (left) and color coordinates (right) of the selected LEDs as provided by the suppliers in the datasheets

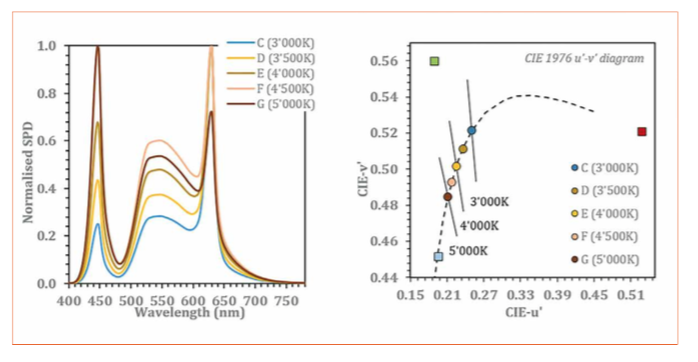

In LASSIE-FP7 we have investigated color tunable LED panels by introducing colored LEDs (LUXEON 3535L pc-lime and red) whose normalized SPDs and CIE-u’v’ color coordinates are given in Figure 7. Since the color gamut defined by the LEDs contains all white points of interest, on-Planckian points in the (3’000-5’000 K) range can be achieved by selecting the adequate driving parameters on each channel (Figure 8).

Figure 8: Calculated emission spectra (left) expected for 3,000K (C), 3,500K (D), 4,000K (E), 4,500K (F) and 5,000K (G) obtained with 3014L and 3535L red and pc- lime LEDs at different relative radiant flux levels. The CIE u’v’ coordinates (right)

Figure 8: Calculated emission spectra (left) expected for 3,000K (C), 3,500K (D), 4,000K (E), 4,500K (F) and 5,000K (G) obtained with 3014L and 3535L red and pc- lime LEDs at different relative radiant flux levels. The CIE u’v’ coordinates (right)

The main properties of the SPDs are given in columns C-G in Table 1 where it can be seen that color rendering decreases with increasing light “coldness” especially in the TM-30-15 metrics. These results indicate that on-Planckian color tuning and high spectral quality requires additional color channels. Eventually, CCF technology may be used together with colored LEDs to alleviate the observed drop in quality for cool white.

Moreover, the addition of the colored LEDs brings about another interesting advantage, for they can, in combination with the intelligence system, compensate for the color drift of the white LEDs that will likely result following the phosphor degradation.

Figure 9: Emitting surface of the LASSIE-FP7 module tuned to different colors that demonstrates that CSEM light management solution also offers excellent light mixing characteristics

Figure 9: Emitting surface of the LASSIE-FP7 module tuned to different colors that demonstrates that CSEM light management solution also offers excellent light mixing characteristics

Finally, the thin-film light management stack described above demonstrated good color mixing properties (Figures 9 and 10). With color consistency below 3-step MacAdam across all viewing angles when measured at a fixed point of the module.

![CIE-u’ and v’ color coordinates measured over the emitting surface of the LASSIE- FP7 module with the diffuser (left) and with the complete 3-foil solution (right). The MacAdam circles [24] on the right figure correspond to 3, 4, 5 and 6-steps](https://www.led-professional.com/media/resources-1_articles_ultrathin-direct-lit-led-module-with-beam-shaping-thin-film-optics_screen-shot-2017-05-16-at-14-19-15.png/@@images/image-1280-93c8bfd885cbfc68d5f0fa3beb5c282a.png) Figure 10: CIE-u’ and v’ color coordinates measured over the emitting surface of the LASSIE- FP7 module with the diffuser (left) and with the complete 3-foil solution (right). The MacAdam circles [24] on the right figure correspond to 3, 4, 5 and 6-steps

Figure 10: CIE-u’ and v’ color coordinates measured over the emitting surface of the LASSIE- FP7 module with the diffuser (left) and with the complete 3-foil solution (right). The MacAdam circles [24] on the right figure correspond to 3, 4, 5 and 6-steps

The spatial color variation is, to a large extent, a consequence of the LED layout (Figure 3) where LEDs of different colors are separated by a large distance. Arranging the LEDs into arrays of clusters is expected to render color constancy below 3-step MacAdam.

Table 1: Main characteristics of the relevant SPDSs shown in Figures 6 & 7

Table 1: Main characteristics of the relevant SPDSs shown in Figures 6 & 7

Cost Analysis

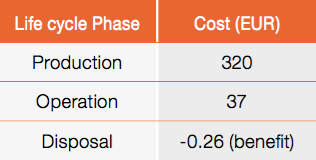

Life cycle cost LCC, is a tool which takes into account all costs directly related to a product over its entire life cycle, from resource extraction over the supply chain to product operation and disposal phases. The continuous feedback provided by LCC has greatly supported us in the selection of the most adequate designs, materials and processes towards minimizing costs.

The estimated cost of the LASSIE- FP7 module (Table 2) is higher than that of standard large-area LED- based modules for Professional Lighting. Nonetheless, our module offers features that are not available in standard products and make LASSIE-FP7 module unique for niche applications that prioritize light quality over cost. Color proof islands in clothing retail stores, with an estimated market size of 50,000 units per year, has been identified as the best fit for the LASSIE-FP7 module.

Table 2: Life-cycle cost of the LASSIE-FP7 module for the different phases

Production cost analysis

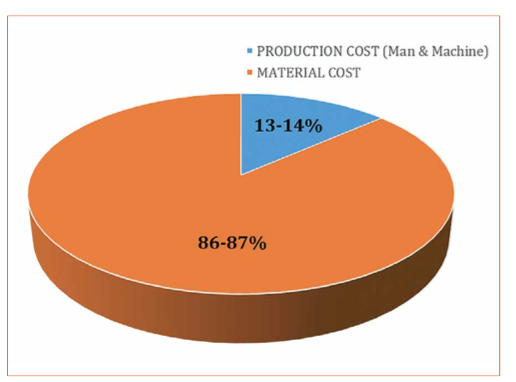

As indicated in Table 2 the production costs account for most of the total cost and hence will be discussed in more detail.

In the production phase, we used the MMM-cost model that stands for Man-Machine-Material, the three principal production costs, although additional elements such as overheads (15%) and margin (15%) have also been accounted for. Furthermore, our methodology for risk-profitability analysis uses the CAPM (Capital Asset Pricing Model) method.

The cost associated with the production of the LASSIE-FP7 module described in the preceding sections is dictated by the cost of each component and the cost of the assembly process and includes the contribution from labor, material, energy and machine costs under the conditions summarized in Table 3.

Table 3: Conditions used in the LCC analysis related to the production phase

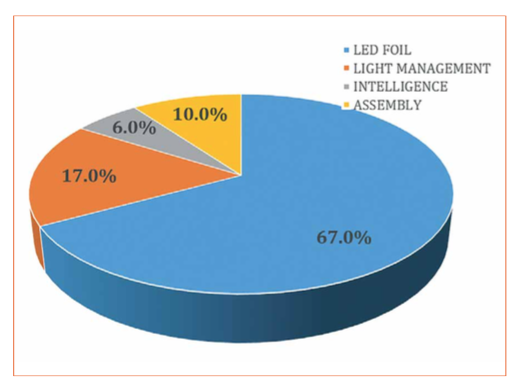

The module components are the LED foil (including heat management structures), the light and color management solutions and the intelligence.

The largest part (86-87%) of the estimated cost of the LASSIE module corresponds to the cost of the materials (Figure 11). In particular, the LED foil represents the largest contribution (67% - Figure 12), being the cost of the LEDs themselves and related processes (substrate, LED and resistor bonding, thermal management structures, etc.). Other components of the foil (substrate, conductive bus lines, and thermal resistors) play a much more minor role.

Figure 11: Relative cost contributions of the materials and production of the LASSIE-FP7 module

Figure 11: Relative cost contributions of the materials and production of the LASSIE-FP7 module

Figure 12: Relative cost contributions of the components and assembly used in the LASSIE-FP7 module

Figure 12: Relative cost contributions of the components and assembly used in the LASSIE-FP7 module

In particular, the LUXEON 3535L colored LEDs is ~6.5 times higher than that of the cool white LUXEON 3014 LEDs (0.13 vs. 0.017 EUR/LED for quantities above 1,000,000 units). This indicates that the color tuning/correction capabilities represent the main contribution to the total cost.

This result is in line with the trend observed in commercially available color tunable LED panels. For example, MEXXOTECH offers two similar modules (Table 4) with and without color tuning; the latter retailing at less than half the price [23].

![Technical specifications of MEXXOTECH LED panels with and without color tuning capabilities [23]](https://www.led-professional.com/media/resources-1_articles_ultrathin-direct-lit-led-module-with-beam-shaping-thin-film-optics_screen-shot-2017-05-16-at-14-19-45.png/@@images/image-1280-93c8bfd885cbfc68d5f0fa3beb5c282a.png) Table 4: Technical specifications of MEXXOTECH LED panels with and without color tuning capabilities [23]

Table 4: Technical specifications of MEXXOTECH LED panels with and without color tuning capabilities [23]

Conclusions

The potential of thin-film optics has been demonstrated to improve photometrical as well as spectral properties of LED-based large-area panels.

The incorporation of the three-foil stack designed by CSEM has demonstrated an increase in luminance uniformity form nearly zero to 86% for a DHR value well above unit.

On the other hand, using the cost-competitive CCF technology from BASF, the low quality light emitted by low-cost bluish LEDs can be down-converted into a warm highly rendering white light.

On-Planckian color tuning using three independently addressed (color) channels is also demonstrated but a price in the rendering ability must be paid when cool white light is pursued. The observed depreciation of the rendering properties in the bluish part of the white zone can likely be solved by combining colored LEDs together with the CCF technology.

The addition to color tuning, colored LEDs permit color correction to counterbalance the degradation of the white LED phosphor and the concomitant white point drift hence maintaining a constant white point across the lifespan of the module.

The incorporation of color tunability has a substantial impact on the production cost of the module driven by the cost of the colored LEDs. For this reason such module fits niche applications (e.g. color proof islands in retail clothing shops) where the tunability represents a huge added value regardless the cost increase.

Acknowledgments

The authors would like to thank Gerhard Wagenblast at BASF (Ludwigshafen, Germany) for his support with the characterization of the Color Changing Films and Kimmo Keränen at VTT (Oulu, Finland) for the supply of the LED foils.

The research leading to these results has received funding from the European Union Seventh Framework Program [FP7/2007-2013] under grant agreement n°619556, project LASSIE-FP7 (http://lassie-fp7.eu/).

References:

[1] M. N. Khan, Understanding LED Illumination, CRC Press (2014)

[2] R. R. Hainich and O. Bimber, Displays: Fundamental and Applications, CRC Press (2011)

[3] M. Bass (Ed), Handbook of Optics Volume II: Design, Fabrication and Testing; Sources and Detectors; Radiometry and Photometry, McGraw Hill (2010)

[4] G. Stojmenovik, The whole story behind display specifications and human vision. Available online: http://www.siongboon.com/projects/2010-08-22%20electronic%20ballast/The%20whole%20story%20behind%20display%20specifications%20and%20human%20vision.pdf

[5] P. R. Boyce, Human Factors in Lighting, CRC Press (2014)

[6] J. Bauer and M. Kreuzer, Understanding the Requirements for Automotive Displays in Ambient Light Conditions, Information Display 3, p.14 (2016)

[7] R. M. Soneira, Display Color Gamuts: From NTSC to Rec2020, Information Display 4 p. 26 (2016)

[8] T. Gallaway, R. N. Olsen and D. M. Mitchel, The economics of global lighting pollution, Ecologic al Economics 69(3) pp. 658-665 (2010)

[9] R. Chepesiuk, Missing the dark: Health effects of light pollution, Environmental Health Perspectives 117(1) pp. A20-A27 (2009)

[10] O. Fernandez, Ultrathin direct-lit LED module with beam shaping thin-film optics, Proceedings of the LpS2016, Bregenz, 20-22 Sept., Luger Research e.U. pp. 320-328 (2016)

[11] O. Tapaninen, J. Ollila, E. Juntunen, K. Keränen, Thermal management in flexible substrates for LEDs“, Proc. of IMAPS Nordic Conf., Oulu, Finland, June 9-11 (2014)

[12] S. Junger, N. Verwaal, W. Tschekalinskij and N. Weber, Near-infrared cut-off filters based on CMOS nanostructures for ambient light sensors and image sensors, Proc. SPIE 8994, Photonic and Phononic Properties of Engineered Nanostructures IV, 89941K (February 19, 2014)

[13] M. Wood, How bright is bright, Journal of Entertainment Technology Industry pp.13-15 (Summer 2006). Available online: http://www.mikewoodconsulting.com/articles.htm

[14] J. Koshel (Ed.), Illumination Engineering: Design with Nonimaging Optics, Wiley (2013)

[15] S. Kobayashi, S. Mikoshiba and S. Lim (Eds.), LCD Backlights, Wiley (2009)

[16] A. Abileah, LCD Backlight Methodology and Applications Using Optical Enhancement Films, Information display, p.28 (August 2008)

[17] CIE International Lighting Vocabulary, CIE 17.4 (1987)

[18] https://bulbrite.com/wp-content/uploads/2016/10/soraa_quality_of_light_1.pdf

[19] https://ledlight.osram-os.com/2011/04/high-color-rendering-index-cri-led-lights/

[20] http://www.ledsmagazine.com/articles/iif/2013/09/cree-launches-high-cri-led-lamp-that-meets-california-regulatory-spec.html

[21] http://www.lumileds.com/company/blog/design-approaches-for-high-cri-leds

[22] T. Q. Khanh, P. Bodrogi and T. Q. Vinh, Color Quality of Semiconductor and Conventional Light Sources, Wiley-VCH (2017)

[23] http://www.mexxotech.com/english/led-lamps/x-series-ceiling-light

[24] CIE TECHNICAL NOTE TN 001:2014: Chromaticity Difference Specification for Light Sources.

(c) Luger Research e.U. - 2017