UV LED Technology for Emerging Applications in Agriculture

The Ultraviolet (UV) LED market has expanded five-fold in the past decade and is projected to grow to over $1 billion by 2025. A key trend expected to influence the market is the ability to expand into new applications, including agriculture. UV light, at proper frequency and dose, can increase the production of active substances in medicinal and traditional plants and it can also help maintain a healthy growing environment. But to fully take advantage of UV LEDs, some major re-design considerations are required. Terrance Berland, CEO of the Violet Defense Group, the parent company of Violet Gro, will explain which considerations these are; for instance, why it is crucial to incorporate the appropriate lens material.

With the explosion occurring in indoor and urban farming, not only are the energy savings of LEDs appealing, but the advancements made in UV LEDs are making it possible to bring the additional benefits of ultraviolet light, particularly UV-A and UV-B, to indoor agriculture. UV light has been shown to drive increases in the plant production of active substances in medicinal plants, including antioxidant benefits of numerous plants or THC levels in cannabis. UV light can also help maintain a healthy growing environment by reducing mold, mildew, and certain plant pests - all of which need alternatives to chemicals due to increasing fungicidal resistance. While many of the leading fixtures used in indoor agriculture produce some level of UV spectrum (however small), their outer lens materials block most, if not all, of that UV light from actually reaching the plants. As the price of UV LEDs continues to decline, the ability to cost effectively incorporate targeted UV into the growing process with the right wavelengths, the right dosage, and at the right time in the life cycle of specific plant species will improve. However, UV LEDs will still need to be combined with the appropriate lens that enables transmission of the UV light without risking degradation or destruction of the lens and/or the LED itself.

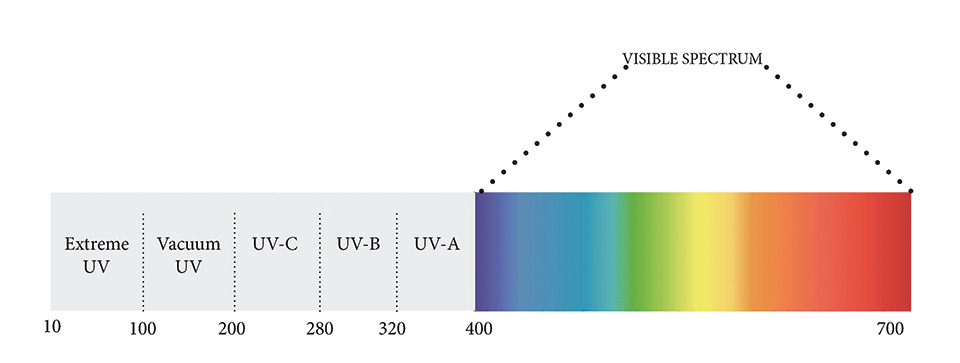

Figure 1: UV and visible light spectrum with UV classifications

Figure 1: UV and visible light spectrum with UV classifications

Introduction

History & wavelengths

Ultraviolet (UV) light is a key part of the electromagnetic spectrum with wavelengths ranging from 10 nm to 400 nm. This portion of the spectrum lies outside of the visible range for the human eye, though some portions of UV light are perceivable by insects and birds [1]. Much of the UV spectrum, including all the Extreme Ultraviolet (10-100 nm) and most of the spectrum below 280 nm is absorbed by the atmosphere. However, it’s still important to understand the benefits of each part of the UV spectrum given our ability to artificially produce these wavelengths.

UV spectra classifications, their use and benefits:

• UV-C (200-280 nm): Almost completely absorbed by Earth’s atmosphere,

UV-C is commonly used for its germicidal effects

• UV-B (280-320 nm): Approximately 95% of UV-B is absorbed by the

Earth’s atmosphere and is frequently known for its association with

increased risk of skin cancer, however, it has also been shown to have

antimicrobial effects including dealing with agricultural infections and pests,

such as powdery mildew or spider mites; as well as triggering plant

responses that increase flavonoids and cannabinoids

• UV-A (320-400 nm): Often referred to as “black light,” UV-A light has the

longest wavelength in the UV spectrum and is considered the least

harmful; it is most known for applications in UV curing, counterfeit

detection, and forensics, but also has applications for agriculture given its

ability to trigger desired plant responses as well

Recent advancements

Much of the UV lighting industry has been dominated by sources other than LEDs, particularly mercury bulbs. However, UV LEDs have made significant progress in recent years, not only due to advances in the manufacturing of solid state UV devices, but also as a result of increased pressure to find more environmentally-friendly and energyfriendly options of producing UV light.

However, LEDs have only recently been able to meaningfully accommodate all the UV ranges. LEDs transmitting UV light in the upper portion of UV-A (390-420 nm) range have been available since the late 1990s, typically being used for counterfeit detection or validation of driver’s licenses or documents, as well as in forensics [2]. In fact, a large portion of the UV LED market is dominated by industrial and commercial applications for curing, such as inks, coatings or adhesives, typically done by UV-A light in the wavelength of 350-390 nm [3].

As you proceed into the shorter wavelengths of UV-B and UV-C, applications turn to disinfection for food, air, water, and surfaces. These are some of the newest wavelengths to be available in LEDs (the first commercial UV-C LEDbased water disinfection system was introduced in 2012 [4]), although UV light has a long, well-established history of germicidal effects. Not only are the energy savings of LEDs appealing to many industries, such as water purification, but their extremely small sizes make them a very flexible option, including the ability to create portable disinfection systems.

Given these advancements, the UV LED market has expanded five-fold in the past decade and is expected to grow to $1.3 billion by 2025. A key trend expected to influence the market is the ability to further expand into new applications, including solar products, food and beverage industry, and agriculture [5]. However, additional advancements are still needed, particularly as it relates to the lens component of these products, to ensure that the technology can achieve desired outcomes for each industry in a cost-effective manner.

Benefits of UV to Horticulture

With the explosion occurring in indoor and urban farming, there has been an increasing desire to continue to refine the growing process in a cost-effective manner that will still yield positive results for the targeted plants. Much of the existing research on the use of LEDs in agriculture has focused on the wavelengths of visible light and the spectrum that plants need for various processes. During extensive research, “NASA determined that LED lights are the best single source lights for growing plants on Earth as well as in space [6].” In fact, there have been many studies conducted to identify the relationship between various wavelengths and their impact on plant growth. This information will allow for the further development of customized spectrum lighting that produces greater results for the plant at lower energy costs. For example, the red-light spectrum (630-660 nm) has been determined to be essential for stem growth and expansion of leaves. It is also the wavelength that regulates flowering and dormancy periods.

While early LEDs left most plants (and growers) wanting more, the latest state-of-the-art LEDs provide more viable options for indoor growing that will yield substantial cost savings (if paired with the right lens material), especially compared to traditional lighting options such as High Pressure Sodium (HPS).

Now, further advancements in UV LEDs are making it possible to bring the additional benefits of ultraviolet light, particularly UV-A and UV-B, to the indoor grow process in a very targeted way. Researchers found that in the absence of UV light, certain plant breeds may “develop callus-like intumescence growth on leaves and shoot tissues [7].” Ordinary glass, for example, blocks over 90% of UV-B radiation [8], therefore, plants grown in greenhouses or other similar environments, without supplemental lighting may experience adverse effects.

UV light has also been shown to drive increases in the plant production of active substances in medicinal plants, including antioxidant benefits of numerous plants or THC levels in cannabis. Plants have chemical processes which enable them to identify the different wavelengths of light that trigger certain responses, including reactions to UV light that can alter plant shape and change chemical make-up [9]. This area of photonics, however, still needs a lot more research focus to truly understand all of the impacts, including the best methods for deployment.

Figure 2: UV light can enhance the amount of active substances in medicinal plants, such as antioxidant benefits of rosemary or THC

Figure 2: UV light can enhance the amount of active substances in medicinal plants, such as antioxidant benefits of rosemary or THC

One of the most common ways plants respond to UV light is the synthesis and accumulation of UV absorbing compounds. These compounds, including phenolic substances, act like a form of sunscreen for the plants to prevent damage that excessive exposure to UV light can cause. However, the benefits of phenolic compounds not only help protect the plants but have been shown to have significant human health benefits too, including antioxidant benefits and prevention of various chronic diseases, including certain cancers and cardiovascular diseases. Resveratrol, found in grapes and red wine, has been studied for its health effects on the heart, immune system, and even brain functions [10]. A study of rosemary demonstrated that its total phenolics approximately doubled when grown using UV-B radiation. Similar results were found for increased production of essential oils for Mentha spicata (spearmint) [11].

Another plant species known for its increase in production of medicinal compounds under UV radiation is Cannabis sativa. Research has found that higher levels of cannabinoids are found from plants at the lowest equatorial latitudes and higher altitudes (32% greater at 3350 m than 1500 m). The association was made that these areas of the world had higher levels of UV-B. Subsequent studies have shown that exposing plants to UV-B can cause Δ9-tetrahydrocannabinol (Δ9-THC) levels, which have extensive medicinal benefits, to increase by up to 48% in leaf tissues and 32% in flower tissues [12].

UV light can also help maintain a healthy growing environment by reducing mold, mildew, and certain plant pests - all of which need alternatives to chemicals due to increasing fungicidal resistance. The UV-absorbing compounds produced by plants to protect them from receiving too much UV radiation can also aid in defending plants against infection, injury, and certain plant pests. It’s as if these compounds change the “attractiveness” of the plants to these pests.

One major threat to indoor growers is powdery mildew. However, UV light has been demonstrated to significantly reduce mildew in plants ranging from grapes, rose plants, cucumber, rosemary and strawberries. Researchers have successfully reduced the severity of powdery mildew by 90-99% using proper doses of UV-B [13].

UV-B light has also been proven effective at reducing survivorship mites, pests that have been known to destroy entire crops. In a study by Ohtsuka and Osakabe, less than 6% of larvae exposed to UV-B doses survived by the second day, and all larvae died by the 3rd day of their experiment [14].

A third major threat is Botrytis cinerea, a type of gray mold or often called gray rot that can target about 200 different species, typically with fruits or flowers, including strawberries, grapes, and cannabis. This pest is typically brought in from outdoors and then spread into an indoor grow room via air or by shoes and clothing. Therefore, handling this pest may involve whole room air disinfection and/or floor disinfection systems. Studies have shown that Botrytis cinerea spores are most effectively treated by using UV-C irradiation. Mercier et. al (2001) achieved disinfection rates of greater than 90% with UV-C dosages of 440-2200 J/m² [15].

Over the past several decades, the evidence supporting the benefits of UV light for protecting crops from mold, mildew, and other plant pests, along with the ability to enhance medicinal benefits of plants has grown tremendously. However, there are still significant challenges for how to successfully incorporate UV into an indoor grow facility.

Figure 3: Powdery mildew and mites pose a significant threat to many crops but can be substantially reduced with the use of UV light

Figure 3: Powdery mildew and mites pose a significant threat to many crops but can be substantially reduced with the use of UV light

Considerations for Integrating UV into Indoor Agriculture Lighting

When thinking about UV LEDs, you can’t stop at just the LED. A UV LED System must think about the specific LEDs based on UV dose required, wavelength needed for the application, and the layout of the lighting relative to the plant canopy. However, you must then also add in thermal management, optical design, the power supply and driver [16], and most importantly, the lens material.

Determine dosage & wavelength needed for application

With indoor growing, it is critical to identify the spectrum that will best meet the needs of your plants, as the impact of different wavelengths depends on where you are in the grow cycle and on the specific plant species. For example, in the visible spectrum, a small percentage of green light (up to 24% for specific species) can be beneficial to support plant growth, but research has shown that it is species-specific and that more than 50% can have detrimental effects [17]. The same is true when incorporating UV light into agricultural lighting - you must be clear on what you are trying to accomplish for your plants.

Several scenarios may call for integrating UV into the primary lighting source for an indoor grow facility. For instance, Resveratrol, a medicinal substance produced by plants in response to stress, is formed by a chemical reaction that requires UV-A radiation with a wavelength below 360 nm. Growers interested in increasing levels of specific flavonoids or cannabinoids will likely want to target UV-A, UV-B or a combination of both to achieve their target effect.

If a grower is interested in preventing infestation with specific plant pests, such as powdery mildew, spider mites, supplemental lighting designed to deliver specific dosages of UV-B light are critical to helping control these plant pests. To treat Botrytis cinerea, UV light can be integrated in methods designed for whole room air disinfection or as a targeted supplemental lighting that could be used to deliver the right dosage of UV-C light on a regular treatment cycle. Given the varying needs and applications for UV into agriculture, it is important to partner with a lighting company that understands the applications of UV for both enhanced growth as well as disinfection/pest control.

Measuring light output

Whether evaluating a lighting fixture or individual LED components, a common methodology involves comparing the light output measurements advertised by various manufacturers. However, one must use extreme caution to ensure you are actually comparing the same measurement across the various options and be aware that many of the products/ companies out there do not adequately disclose the parameters of their testing, including a critical dimension called distance. Without controlling for differences in these parameters, the comparison of numbers is meaningless.

Furthermore, many of the sensors on the market are designed to only measure specific parts of the electromagnetic spectrum and may not properly capture select portions, often including the far-red end of the visible spectrum and the UV end of the non-visible spectrum. For example, when specifically evaluating lighting options using Photosynthetic Photon Flux Density (PPFD), it is important to understand that the sensor will capture any energy in the wavelengths to which the sensor is calibrated. However, not all wavelengths carry the same energy, nor are all wavelengths equally valuable or attractive to the plant, and many of the key wavelengths could be excluded due to limitations on the measurement capabilities of the sensor.

The energy of each photon is inversely proportional to the wavelength of the associated electromagnetic wave. The shorter the wavelength, the more energetic the photon, the longer the wavelength, the less energetic is the photon. Therefore, red light has less energy than yellow or green light, even though red light is more desirable for plants in terms of photosynthesis and other plant chemical processes. In other words, lights producing high amounts of yellow and green light may produce higher PPFD readings but may not be producing the light needed by the plants.

If exclusively evaluating UV lighting options, it is noteworthy to mention that while there are a wide range of UV radiometers designed to measure UV generated by traditional broadband mercury arc systems that primarily produce UV-C, they will not properly measure the UV output generated by UV-LEDs, particularly if your light design includes multiple UV peaks that don’t specifically line up with the target spectrum of the sensor being used. Many manufacturers of UV-LED chips will measure the UV output of their LEDs in an integrating sphere, also known as Ulbricht sphere [18] which may or may not be a good proxy for what the plant will actually experience.

Even if proper caution is taken using appropriate sensors to measure light output, the plants themselves are ultimately the best judge of the performance of your lights and the ability to achieve your desired outcomes, and you should seriously consider in-environment testing to help validate the claims from the product manufacturers.

The impact of the lens

When selecting LED lighting for plants, it’s critically important to remember that while plants may not be able to get too much light, they most certainly can get too much heat. While LEDs are more efficient than mercury lamps, research suggests that UV LEDs only transfer about 15-25% [19] of received input power into light. The remaining is transferred as heat, so thermal management must be a critical part of the system.

In addition, when lights produce wavelengths in areas of the spectrum not needed by plants, the photons not absorbed by the plant, will ultimately translate to heat in the environment requiring more extensive cooling costs - both in terms of ongoing electrical needs, but also upfront infrastructure costs.

Similar to the coverings on greenhouses, certain types of lenses, such as the outer glass jacket from HPS lighting actually blocks much of the UV light from reaching the plants, translating that light into heat.

Another factor in the use of UV, or even deep blue LEDs is that most lens materials will experience significant degradation over time resulting in decreased efficiency, and it may even cause enough heat to remain trapped to ultimately destroy the LED itself.

However, new advances such as the patented technology from Violet Gro enable the combination of a UV light source with a special class of ultraviolet transmissive lens material, in direct and immediate contact, without producing these detrimental effects. This unique lens, and the associated direct contact with the UV LEDs, allows more of the UV light to be transmitted and projected through the lens to its intended source, thereby further increasing efficiency and decreasing heat output. This is beneficial to both the lifetime of the LEDs, and to substantially reducing the cooling requirements in the indoor grow facility.

Figure 4: Example of an LED destroyed by heat trapped within the lens

Figure 4: Example of an LED destroyed by heat trapped within the lens

What’s Next

As UV LEDs continue to come down in price, the ability to effectively incorporate UV into the growing process with the right wavelengths, the right dosage, and at the right time in the life cycle of specific plant species will dramatically increase. This reality will allow for further research and development of UV solutions, including identifying the optimal combinations of UV wavelengths and dosages to achieve the desired effects for specific plant species.

Regardless of the desired plant growth or pest control outcomes, for effectiveness and longevity of the lights, UV LEDs will still need to be combined with an appropriate ultraviolet transmissive lens that enables transmission of the UV light without risking degradation or destruction of the lens and/or the LED itself.

References:

[1] “UV Light.” Stanford Solar Center, solar-center.stanford.edu/about/uvlight.html

[2] Forte, Vincent C. Understanding Ultraviolet LED Applications and

Precautions. 4 Apr. 2014, 9:47 a.m., www.ecnmag.com/blog/2014/ understanding-ultraviolet-led-applications-and-precautions

[3] Forte, Vincent C. Understanding Ultraviolet LED Applications and

Precautions. 4 Apr. 2014, 9:47 a.m., www.ecnmag.com/blog/2014/ understanding-ultraviolet-led-applications-and-precautions

[4] AquiSense Technologies - UV LED Water, Air, and Surface Disinfection,

www.aquisense.com/water-treatment

[5] ltd, Research and Markets. “UV LED Market to 2025 Global Analysis

and Forecasts by Technology (UV-A LED, UV-B LED, UV-C LED),

Applications (Curing, Medical, Electronic Devices, Water Treatment,

Security and Others).” Research and Markets, Nov. 2017,

www.researchandmarkets.com/research/7khkvm/global_uv_led?w=5.

[6] “NASA Research Determines LEDs Provide the Optimum Light

Wavelengths for Plant Growth.” Advanced LED Lights, 17 Dec. 2016,

advancedledlights.com/blog/technology/nasa-research-optimum-light-wavelengths-plant-growth

[7] “NASA Research Determines LEDs Provide the Optimum Light

Wavelengths for Plant Growth.” Advanced LED Lights, 17 Dec. 2016,

advancedledlights.com/blog/technology/nasa-research-optimum-light-wavelengths-plant-growth

[8] “UVB Light and THC Potency.” California Lightworks, 22 July 2016,

californialightworks.com/uvb-light-and-thc-potency

[9] Gaberscik, Alenka, et al. “All You Wanted to Know about UV Radiation

and Plants.” UV 4 Plants, The International Association for Plant UV

Research, Oct. 2014, www.uv4plants.org/wp-content/uploads/2014/10/UV-web-opt.pdf

[10] Ozcan, T., et al. “Phenolics in Human Health.” International Journal of

Chemical Engineering and Applications, vol. 5, no. 5, Oct. 2014,

pp. 393-396

[11] Zhang, Wen Jing, and Lars Olof Björn. “The Effect of Ultraviolet

Radiation on the Accumulation of Medicinal Compounds in Plants.”

Fitoterapia, vol. 80, no. 4, 2009, pp. 207-218.,

doi:10.1016/j.fitote.2009.02.006

[12] Lydon, John, et al. “UV-B RADIATION EFFECTS ON

PHOTOSYNTHESIS, GROWTH and CANNABINOID PRODUCTION OF

TWO Cannabis Sativa CHEMOTYPES.” Photochemistry and

Photobiology, vol. 46, no. 2, 1987, pp. 201-206.,

doi:10.1111/j.1751-1097.1987.tb04757.x

[13] Suthaparan, A., et al. “Suppression of Powdery Mildews by UV-B:

Application Frequency and Timing, Dose, Reflectance, and Automation.”

Plant Disease, vol. 100, no. 8, 2016, pp. 1643-1650.,

doi:10.1094/pdis-12-15-1440-re

[14] Ohtsuka, Keiko, and Masahiro (Mh.) Osakabe. “Deleterious Effects

of Uv-B Radiation on Herbivorous Spider Mites: They Can Avoid It by

Remaining on Lower Leaf Surfaces.” Environmental Entomology,

vol. 38, no. 3, 2009, pp. 920-929., doi:10.1603/022.038.0346

[15] Kowalski, Wladyslaw J. “UV Light for Mold Control in Indoor Medical

Marijuana Gardens.” Aerobiological Engineering Report 16414, Apr. 2016

[16] Developpement, Yole. “UV LEDs - Technology, Manufacturing and

Application Trends 2016”, LinkedIn SlideShare, 27 July 2016,

www.slideshare.net/Yole_Developpement/uv-leds-technology-manufacturing-and-application-trends-2016-report-by-yole-developpement

[17] Massa, Gioia D, et al. “Plant Productivity in Response to LED Lighting.”

HortScience, vol. 43, no. 7, Dec. 2008, pp. 1951-1956

[18] Heathcote, Jennifer. “UV-LED Overview Part I - Operation and

Measurement.” Radtech Report, 2010, pp. 23-33.,

www.radtech.org/magazinearchives/Publications/RadTechReport/jul-aug-2010/UV-LED%20Basics%20Part%20I-Operation%20and%20Measurement.pdf

[19] Developpement, Yole. “UV LEDs - Technology, Manufacturing and

Application Trends 2016”, LinkedIn SlideShare, 27 July 2016,

www.slideshare.net/Yole_Developpement/uv-leds-technology-manufacturing-and-application-trends-2016-report-by-yole-developpement