White Paper: Shaping LED Diffuser Performance with Polycarbonate Materials

The LED lighting market continues to grow, yet consumers are accustomed to the soft white diffused light from incandescent bulbs. To speed up adoption, manufacturers are utilizing plastic materials containing diffusion additives to offset harsh LED illumination and eliminate hot spots. It’s important to choose the correct diffusion plastic to meet to meet transmission, color and UL requirements. In this paper, we examine how plastic selection, a diffusion package and color help designers achieve the desired look for their application.

White Paper: EXCERPT

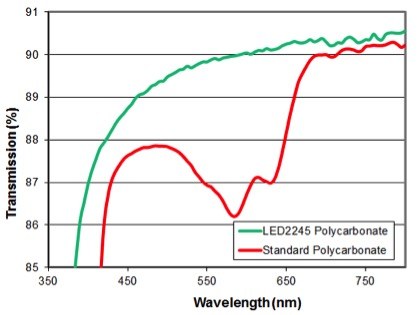

In developing new diffusion polycarbonates, Covestro scientists realized that not only does the diffusion package need to be optimized, but the base resin as well. LED light has emission peaks near 450 nm and 550-650 nm, but standard polycarbonate absorbs at those wavelengths, especially in the 550-650 nm region, resulting in lower LED light transmission (Figure 1). Covestro previously created a line of transparent LED polycarbonate grades to mitigate this effect, and applied the same concept for new diffusion applications in injection molding, sheet and film products.

Figure 1: Transmission curves of polycarbonate

_________________________________________________________

Download the White Paper!

Provided by

_________________________________________________________

Supported by LED professional, Luger Research e.U. - (c) 2017